Top Automatic Cup Sealer in 2021 - A Complete Guide

By:Admin

The Automatic Cup Sealer is equipped with advanced technology that allows for quick and precise sealing, ensuring a tight and secure seal on each cup. This not only helps to maintain the freshness and quality of the product inside the cup but also enhances the overall presentation, making it more appealing to customers. The machine is capable of sealing a large number of cups in a short amount of time, making it an ideal choice for businesses with high volume production needs.

In addition to its speed and accuracy, the Automatic Cup Sealer is also incredibly user-friendly. It features a simple and intuitive interface that allows operators to easily adjust the settings to accommodate different cup sizes and sealing requirements. This versatility makes it a valuable asset for businesses that offer a variety of products in different sized cups.

One of the key benefits of the Automatic Cup Sealer is its ability to improve efficiency and reduce labor costs. By automating the cup sealing process, businesses can significantly increase their production capacity and minimize the need for manual labor. This not only saves time and money, but also helps to create a more consistent and reliable sealing process.

Furthermore, the Automatic Cup Sealer is designed with durability and reliability in mind. It is built to withstand the rigors of daily use in a commercial setting, ensuring long-term performance and minimal downtime. This makes it a smart investment for businesses looking to enhance their packaging capabilities and improve their overall operations.

As a leading provider of packaging solutions, XYZ Corporation has a strong track record of delivering innovative and high-quality products to the market. The Automatic Cup Sealer is the latest addition to their extensive lineup of packaging equipment, further solidifying their reputation as a trusted partner for businesses in the food and beverage industry.

"We are excited to introduce the Automatic Cup Sealer to the market," said the CEO of XYZ Corporation. "We believe that this machine will revolutionize the way businesses seal their cups, offering a level of efficiency and precision that was previously unmatched. We are confident that the Automatic Cup Sealer will help our customers improve their packaging processes and achieve greater success in their business."

The Automatic Cup Sealer is now available for purchase and XYZ Corporation is offering comprehensive support and training to ensure that businesses can maximize the potential of this innovative machine. With its advanced technology, user-friendly design, and proven reliability, the Automatic Cup Sealer is poised to become an essential tool for businesses looking to take their packaging capabilities to the next level.

Company News & Blog

Automated Filling and Sealing Machines for Unique Shaped Trays

In today's fast-paced world, candy manufacturers are always on the lookout for efficient and effective ways to package their products. One of the best solutions for this is the candy sealer machine. A candy sealer machine is an automated filling and sealing machine specifically designed for the candy-making industry. It is an innovation that saves time, effort, and money in the packaging process.One such machine is the ORICS S-30 13 heart-shaped candy chocolate tray sealing machine. It is the perfect tool for manufacturers who want to create heart-shaped candy for special occasions such as Valentine's Day. The ORICS S-30 13 system is designed to be manually loaded with chocolate-filled, heart-shaped trays, making it easy and efficient to use for manufacturers.The ORICS S-30 13 system is uniquely designed to handle unusual shapes and sizes of trays. The floating head design ensures that a positive seal is achieved around the entire perimeter of the tray. This innovative design makes it possible to seal not only heart-shaped trays but also other shapes and sizes of containers.One of the best features of the ORICS S-30 13 system is the heat sealing technology. The seal heads only apply heat to the container's flange, ensuring that the product inside the trays remains cool and undamaged. This technique saves money as the entire seal head is not heated, only the area directly over the flange.ORICS products, including the ORICS S-30 13 system, are manufactured in the United States at their Farmingdale, NY facility. This ensures that their products meet the highest standards of quality and are made to last.In conclusion, the ORICS S-30 13 heart-shaped candy chocolate tray sealing machine is an excellent choice for candy manufacturers who want to create unique and beautiful heart-shaped candy products. Its innovative design, convenient and efficient use, and heat sealing technology make it an ideal choice for manufacturers who want to improve their candy packaging process. To know more about ORICS S-30 13 or other ORICS products, contact them at 718-461-8613, visit their website at www.orics.com or email them at [email protected]: Candy Sealer Machine, Automated Filling and Sealing Machine, ORICS S-30 13, Heat Sealing Technology, Unique Design, Efficient Use, High-Quality Manufacturing.

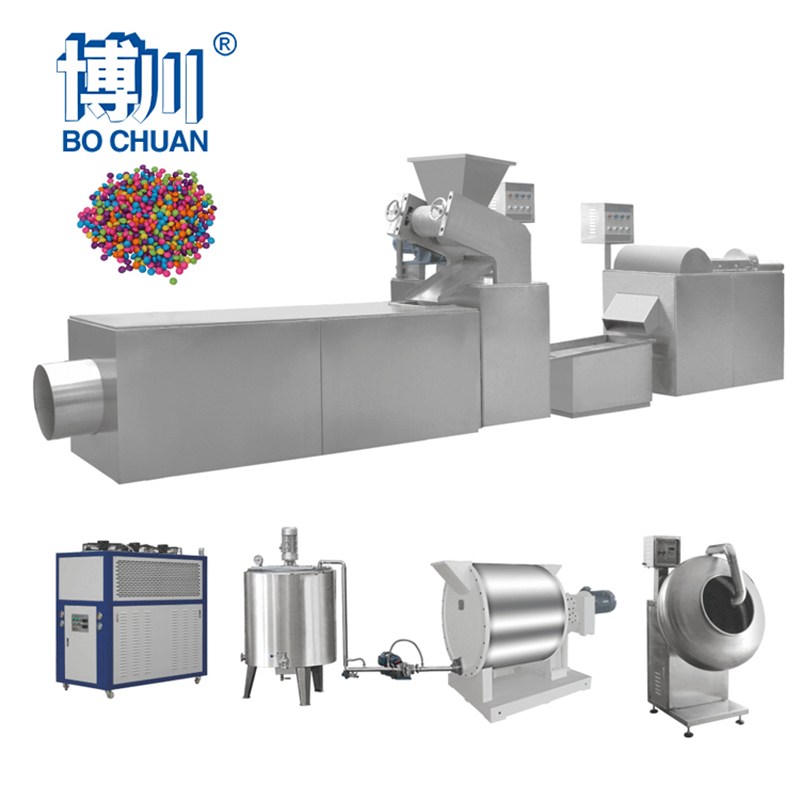

Top Quality Candy Forming Machines with Excellent After Sales Service from China Manufacturers

China Forming Machine Manufacturers Witnessing Increasing DemandChina has been at the forefront of manufacturing various machines and equipment for various industries globally. One such sector that has witnessed immense growth in recent times in China is the candy industry. As the demand for hard candies and various other forms of candies sees an upswing, China has emerged as a leading player in the candy-forming machine manufacturing industry.According to reports, the global candy market is estimated to reach $160 billion by 2023 with a growth rate of 3.7%. This rise in demand for candies, particularly hard candies, has opened up a plethora of opportunities for candy forming machine manufacturers in China.Leading Chinese manufacturers in this field have been at the forefront of supplying superior quality hard candy forming machines to global markets. A hard candy forming machine is primarily used to shape hard candies and other confectionery products into various creative designs. The machine works on a vacuum pump that helps shape the candy mixture into different shapes and sizes according to the mold used.Leading players in this industry offer rotary hard candy forming machines and flat hard candy forming machines. They also custom-make machines according to the specific requirements of their clients.One of the hardest parts of producing hard candies is the forming; it requires a lot of precision, accuracy, and speed. With China's candy-forming machine manufacturers, this tedious task is easier to handle, and with automatic machines, it is further streamlined.The machines' quality is assured, and the companies provide excellent after-sales service to their clients. Their machines are equipped with advanced controls systems that make them user-friendly and easy for operators to navigate.The machines can produce around 200-400 candy pieces per minute, depending on their model's make and the candy's requirement. The machines are designed to handle various hard candy recipes, from both liquid- and powder-based sugar ingredients.China's forming machine manufacturers specialize in producing rotary hard candy forming machines that use a drum for the molding process. The drum rotates during the process, and vacuum pumps shape the hard candy against the molds. The machines have an output capacity of 200-400 pieces per minute.Flat hard candy forming machines are also very popular in the industry. Some manufacturers offer customized machines that can create up to ten different layers, producing candies with multilayered looks.It is interesting to note that most of the hard candy forming machine manufacturers in China also supply to other countries where their products are highly sought after. They have successfully managed to capture a considerable share of world markets and provide unmatched quality to users at competitive pricing.It is no surprise, given the growth potential in the candy market, that China's candy-forming machine manufacturers are experiencing increasing demand from across the globe. Besides, the companies are continually innovating, developing, and improving their products to suit the ever-changing market demands.In conclusion, one can confidently say that the future of hard candy forming machines made in China is bright, and the country is well-positioned to meet diverse requirements and dominate the global candy market.About the company (fill in with company details)We are a leading manufacturer of forming machines for hard candies and other confectionery products in China. Our company has more than ten years of experience in the industry and provides unparalleled quality and service to our customers globally.We specialize in producing rotary hard candy forming machines and flat hard candy forming machines, and custom-made machines according to our customers' specific requirements.Our machines are equipped with advanced controls systems that make them user-friendly and easy for operators to navigate. With an output capacity of 200-400 pieces per minute, our machines deliver high speed and precision for our customers' satisfaction.We are committed to continuous innovation, development, and improvement of our products to meet the ever-changing market demands. With us, you are assured of the highest quality and the best after-sales service.

Unlock Your Inner Chef: How to Make Cotton Candy at Home

Title: Innovative Cotton Candy Machine Revolutionizing the Confectionery IndustryIntroduction:In today's fast-paced world, where innovation and creativity go hand in hand, {need to remove brand name} has introduced an extraordinary invention into the confectionery industry. The new Sweet Cotton Candy Machine has captured the attention of both confectionery enthusiasts and industry professionals alike. With its cutting-edge technology and unique features, this revolutionary machine is set to transform the way cotton candy is made and enjoyed.Elevating the Cotton Candy Experience:Traditional cotton candy machines are known for their simplistic operation and limited capabilities. However, the Sweet Cotton Candy Machine takes this concept to a whole new level. Incorporating advanced engineering, this device combines precision with convenience, ensuring an elevated cotton candy experience for consumers and entrepreneurs alike.Advanced Technology:The Sweet Cotton Candy Machine boasts state-of-the-art technology that guarantees exceptional results. Equipped with a powerful motor, this machine efficiently spins sugar into delectable cotton candy strands, providing a fluffy and luscious treat for customers. The machine's intelligent controls allow users to adjust the temperature, rotation speed, and sugar quantities, offering unparalleled customization options.Ease of Use:One of the distinguishing features of this innovative cotton candy machine is its user-friendly design. With a sleek and intuitive interface, even novices can create mouthwatering cotton candy in no time. This accessibility makes it an attractive option for small business owners, events, and parties, adding a touch of sweetness to any occasion.Versatility:The Sweet Cotton Candy Machine's versatility sets it apart from traditional machines. Unlike the conventional models restricted to spinning only standard-sized cotton candy onto sticks, this device offers unparalleled flexibility. From miniature bite-sized treats to large creations, the machine allows users to explore various shapes and sizes, expanding the possibilities of cotton candy presentation.Enhancing Taste with Flavor Options:Realizing the importance of offering a diverse range of flavors, {need to remove brand name} has developed a range of delicious cotton candy flavors. From classic choices like strawberry and blueberry to unconventional options like bubblegum and green apple, these flavors are meticulously crafted to enhance the overall cotton candy experience. With the Sweet Cotton Candy Machine's compatibility with a variety of sugars and flavorings, customers can enjoy a multitude of tantalizing tastes.Durability and Safety:Built with durability in mind, the Sweet Cotton Candy Machine guarantees longevity, essential for businesses with high production demands. The stainless steel construction ensures resistance to wear and tear, making it an investment that stands the test of time. Additionally, the machine incorporates safety features such as automatic shut-off, overheat protection, and a sturdy base, ensuring operational and consumer safety.Eco-Friendly Approach:Acknowledging the growing concern for the environment, {need to remove brand name} has incorporated an eco-friendly approach in the manufacturing process of the Sweet Cotton Candy Machine. Utilizing energy-efficient technology and recyclable materials, the company aims to minimize its ecological footprint while delivering exceptional confectionery equipment.Conclusion:With its state-of-the-art technology, user-friendly design, and versatility, the Sweet Cotton Candy Machine offers a new way to create, present, and enjoy cotton candy. Its advanced features, paired with an extensive range of flavors and customizable options, make it a game-changer in the confectionery industry. As a result, entrepreneurs, event organizers, and confectionery enthusiasts can expect an enhanced cotton candy experience that is sure to leave a sweet, lasting impression.

Pressure Seal Forms and Equipment: A Low-Cost and Efficient Alternative to Traditional Mailing

article about Pressure Seal forms and equipment and their benefits.In today's fast-paced business world, time is money. Any time-saving strategy that can be implemented is well worth considering. One such strategy that has been gaining popularity is the use of pressure seal forms and equipment.Pressure seal forms and equipment provide a low-cost, high-efficiency alternative to the traditional mailing of forms and documents. Pressure seal mailers eliminate the need for envelopes by combining the document and mailer into one. After being printed, the mailer is loaded into the pressure seal machine where it is folded and sealed with pressure. The pressure seal forms can then be mailed or delivered to their respective recipients.The use of pressure seal forms and equipment provides several advantages to businesses. One of the most significant benefits is the cost savings that come with eliminating envelopes. Without the need to purchase and stuff envelopes, businesses can save on both material and labor costs associated with traditional mailings. This can translate into significant cost savings for companies that produce large volumes of forms and documents.Another benefit of pressure seal forms is their speed and efficiency. With pressure seal equipment, the process of printing, folding, and sealing documents is automated. This means that businesses can process large volumes of documents quickly, reducing processing time and increasing efficiency. This increased speed can also have a positive impact on customer service. With faster document processing, businesses can respond more quickly to customer requests, inquiries, and orders.One of the most significant advantages of pressure seal forms and equipment is their versatility. Pressure seal forms can be used for a wide range of applications, including invoices, statements, checks, and even marketing materials. This versatility makes it possible for businesses to consolidate their document printing and mailing processes, reducing the need for multiple forms and processes.Pressure seal forms and equipment are also secure. Since the documents are sealed with pressure, they are tamper-proof. This eliminates concerns associated with traditional mailing, such as lost or stolen mail, or documents being intercepted and altered.Finally, pressure seal forms can be customized to meet the specific needs of businesses. Companies can customize their forms with branding, logos, and other relevant information. This customization helps businesses to reinforce their brand, increase visibility, and drive customer engagement.In conclusion, pressure seal forms and equipment provide a low-cost, high-efficiency alternative to traditional mailing processes. Their cost-saving benefits, speed, versatility, security, and customization options make them an excellent choice for businesses looking to streamline their document processing and improve customer service. As businesses continue to search for ways to maximize efficiency and reduce costs, the use of pressure seal forms and equipment will undoubtedly continue to grow in popularity.

Stand Up Plastic Bags for Powders and Ready-to-Drink Beverages: Facts and Usage

Doypack Packaging: A Convenient and Versatile SolutionIn today's fast-paced world, packaging is an essential element in the successful promotion and sales of products. With numerous packaging options available, manufacturers need to choose a solution that can maintain the product's quality while being convenient for consumers. Doypack packaging is a popular and widely used solution that offers notable benefits for packaging powders or ready-to-drink beverages.Doypack packaging, also known as stand-up pouches, came into existence in the 1960s. It was created as a convenient and practical solution to address the needs of customers who require packaging that is easy to use, store and dispose of. Today, Doypack packaging is widely used for various products, including food, beverages, and non-food items.One of the significant advantages of Doypack packaging is its design, which enables it to stand up and display product information and branding. This feature provides an excellent opportunity for brand promotion and advertising, which can help increase sales and market presence. Additionally, Doypack packaging is lightweight and easy to carry, making it an ideal packaging solution for people on the go.Doypack packaging is also reusable, which is an essential characteristic of sustainable packaging. Its flexible material can be cleaned and reused multiple times, thus reducing environmental waste and promoting eco-friendliness. The resealable feature of Doypack packaging also provides added convenience and helps ensure that the product stays fresh for longer.Another notable advantage of Doypack packaging is its flexibility in design and customization. With advances in packaging technology, Doypack packaging can be customized to meet specific product requirements. For instance, it can be designed to be aseptically filled to ensure product safety and extend shelf life. Moreover, Doypack packaging can be designed to be tamper-evident, which assures customers of the product's integrity and enhances brand trust.In conclusion, Doypack packaging is a versatile, practical, and sustainable option that offers several benefits for packaging powders or ready-to-drink beverages. Its distinctive stand-up design, reusability, and flexibility in design and customization make it an ideal packaging solution for modern customers. As the demand for convenience, sustainability, and efficiency continues to grow, Doypack packaging is poised to remain a popular option in the packaging industry.

Innovative Spices Packing Machine Revolutionizes Packaging Process

The demand for spices packing machines has been on the rise in recent years due to the increasing popularity of packaged spices in the market. Spices packing machines are used to efficiently pack various spices such as turmeric, coriander, cumin, and chili powder, among others, into pouches or containers, thereby increasing the production capacity and reducing manual labor.With the growing demand for spices packing machines, {Company Name} has emerged as a leading manufacturer and supplier of high-quality packaging machines for the spice industry. Established in {year}, {Company Name} has garnered a strong reputation for delivering reliable and efficient packaging solutions to its customers worldwide.The {Company Name} spices packing machine is designed to meet the specific requirements of the spice industry. It is equipped with advanced technology that ensures accurate weighing, filling, and sealing of spice pouches at a high speed. The machine is capable of handling a wide variety of spices and can be customized to accommodate different packaging sizes and formats.One of the key features of the {Company Name} spices packing machine is its user-friendly interface, which allows operators to easily control and monitor the packaging process. The machine also incorporates safety measures to ensure the protection of workers and the integrity of the packaged spices.In addition to its advanced technology, {Company Name} is committed to providing exceptional customer service and support. The company offers comprehensive training and technical assistance to its clients to ensure the smooth operation and maintenance of the spices packing machine. Furthermore, {Company Name} has a dedicated team of experts who are readily available to address any inquiries or issues related to the packaging equipment.Furthermore, {Company Name} takes pride in its environmentally friendly approach to manufacturing packaging machines. The company emphasizes the use of sustainable and energy-efficient practices in its production processes, thereby contributing to a greener and healthier environment."Customer satisfaction and product quality are our top priorities," says {Spokesperson}, the CEO of {Company Name}. "We are constantly innovating and improving our packaging solutions to meet the evolving needs of the spice industry. Our spices packing machine is a testament to our commitment to delivering superior performance and reliability."The {Company Name} spices packing machine has received accolades from customers for its efficiency, durability, and cost-effectiveness. Its ability to streamline the packaging process and improve productivity has made it a sought-after choice among spice manufacturers and suppliers.As the demand for packaged spices continues to grow, {Company Name} remains at the forefront of providing cutting-edge packaging solutions to meet the industry's requirements. With its unwavering dedication to excellence, {Company Name} is poised to continue its success in delivering top-notch spices packing machines to customers around the globe.

Efficient Pedal Sealing Machine for Large Bags

Sealing Machine - Top Maple Sealing Pedal Sealing PedalThe sealing machine industry is one that is continually evolving and advancing with the rise of e-commerce businesses around the world. With the increase of online orders, more companies are investing in sealing machines to improve their operations and the delivery of their products. Top Maple Sealing Pedal Sealing Pedal is a sealing machine that has become popular with businesses due to its top-quality features and affordable price.Top Maple Sealing Pedal Sealing Pedal is an essential tool for different businesses that deal with packaging products. This machine provides an efficient and reliable way to seal bags, pouches, and other packaging materials with ease. The machine makes use of a pedal that allows the operator to seal the bags with both hands, making the process faster and more accurate.One of the outstanding features of the Top Maple Sealing Pedal Sealing Pedal is its speed. The machine is capable of sealing bags at rates of up to eight meters per minute, making it ideal for businesses with high output requirements. The pedal sealer is also very durable and can work for long hours without overheating or developing any mechanical problems.Furthermore, the Top Maple Sealing Pedal Sealing Pedal provides businesses with a cost-effective way to seal their bags and pouches. The machine's design is such that it is easy to maintain and does not require significant maintenance costs. This affordability makes it ideal for businesses operating on a tight budget.In addition to sealing bags and pouches, the machine can be used for other applications, such as sealing big bags. The Big Bag Sealing feature of this product is one that businesses have found increasingly useful in recent years. It allows for the easy sealing of larger bags and packaging materials that would otherwise be difficult to deal with.Top Maple Sealing Pedal Sealing Pedal is a product of a renowned and reputable company in the industry. The company has long been committed to providing quality sealing solutions to businesses worldwide. With years of experience and expertise in the industry, the company has established itself as a leader in the sealing machine market.One of the critical aspects of the company's operations is its commitment to innovation. Over the years, the company has continued to develop new and innovative sealing solutions that meet the ever-changing needs of businesses worldwide. This approach has been instrumental in pushing the sealing machine industry forward and has helped businesses improve their operational efficiency.The company also places a strong emphasis on customer service. It understands that businesses operate in a fast-paced environment where every minute counts. To this end, the company provides timely and effective customer support to ensure that its customers can achieve their goals and objectives.In conclusion, Top Maple Sealing Pedal Sealing Pedal is a high-quality and reliable sealing machine that is ideal for different types of businesses. Its affordable cost, efficient speed, and durability have made it a popular choice among businesses worldwide. Moreover, the product is a testament to the company's commitment to innovation and customer satisfaction. With this product, businesses can improve their operations and meet the ever-changing needs of their customers.

Enhancing Packaging Efficiency: The Ultimate Guide to Vertical Band Sealer Machines

Vertical Band Sealer Machine: The Ultimate Solution for Securing Your ProductsWith the rapidly increasing demand for packaged products, the packaging industry is growing exponentially. The industry requires fast and efficient machines to ensure products are packaged safely and securely, without compromising their quality. To meet this demand, a new machine has been introduced in the market, the Vertical Band Sealer Machine, a cutting-edge technology that provides the ultimate solution for sealing pouch bags and other types of packaging materials.The Vertical Band Sealer Machine is a breakthrough innovation in the packaging industry. It is designed with advanced features that make it highly efficient and reliable. It provides a secure and tight seal for all types of pouch bags, ensuring the product's freshness and quality. This machine's vertical sealing technology allows it to seal wider bags, making it ideal for packing larger items.The Vertical Band Sealer Machine offers a broad range of applications, making it versatile for various industries such as food processing, pharmaceuticals, and cosmetics. Its reliable sealing process ensures the products' safety and protection throughout the supply chain, reducing the risks of product loss from exposure to external elements.The machine's design also ensures that it is easy to operate, with a user-friendly interface that requires minimal training, making every step of the sealing process hassle-free. It allows for quick adjustments to sealing and cooling time, to meet various sealing requirements, and ensure the product's quality is maintained.As an added bonus, the Vertical Band Sealer Machine is environmentally friendly, as it uses minimal energy in the sealing process. This considerably reduces operating expenses and minimizes carbon footprint, making it a sustainable option for businesses across the world.The Vertical Band Sealer Machine is a product of extensive research and development, designed by a company dedicated to providing solutions for the packaging industry. They are well known for their innovative packaging solutions, offering versatile products that customers can rely on. The company has various products ranging from packing machines, filling machines, capping machines, counting machines, and labelling machines, all designed to improve the packaging process, increase efficiency, and improve product quality.Their commitment to customer satisfaction and quality has made them a reputable brand in the industry, with a growing customer base including global corporations and small businesses. The Vertical Band Sealer Machine has already received positive feedback from customers who have experienced its quality and efficiency first-hand.In conclusion, the Vertical Band Sealer Machine is revolutionizing the packaging industry and setting new standards in the sealing process. Its advanced features and versatility make it an ideal choice for businesses looking to improve their packaging operations' efficiency and quality. The industry is evolving, and businesses must keep up with new innovations that enhance productivity, reduce costs, and improve product quality. The Vertical Band Sealer Machine presents an excellent opportunity for businesses to invest in new technology that delivers all these benefits and more. Businesses looking to remain competitive and stay ahead of the game should consider acquiring the Vertical Band Sealer Machine to maximize their profits and ensure their products' quality and safety.

Efficient and Reliable Packing Machine for Industrial Use: Unveiling the Latest Innovations

Title: Next-Generation Industrial Packaging Machine Revolutionizes Efficiency and SustainabilitySubtitle: A New Era of Packaging Automation Unveiled by Industry LeaderIntroduction:In today's globalized world, efficient and sustainable packaging plays a pivotal role in minimizing waste and optimizing logistics. Leading the charge in packaging automation is the recently unveiled next-generation Industrial Packing Machine (name removed), developed by a pioneer in packaging solutions. This cutting-edge technology promises to revolutionize the industry by ensuring increased productivity, minimized labor costs, and a significant reduction in the carbon footprint associated with packaging processes.Paragraph 1:The newly introduced Industrial Packing Machine complements the company's commitment to innovation and sustainability. Developed after months of research and development, this state-of-the-art packaging equipment is set to redefine the industry's standards by incorporating advanced technology to streamline operations, reduce waste, and enhance overall efficiency.Paragraph 2:At the heart of the Industrial Packing Machine is a powerful robotic system that automates the packaging process from start to finish. Its intelligent software, coupled with sensors and advanced algorithms, enables the machine to precisely measure, handle, and package goods with the utmost accuracy. Whether it is cartons, bottles, bags, or other containers, the Industrial Packing Machine adapts seamlessly to various packaging requirements, accommodating a wide range of products.Paragraph 3:Energy efficiency is a key focus of the Industrial Packing Machine design. By leveraging cutting-edge technologies, the machine optimizes resource utilization, resulting in a reduced environmental impact. Innovative features, such as smart power management, significantly minimize energy consumption, ensuring maximum productivity with minimal wasted resources. With sustainability at the forefront, this advanced machinery contributes to the global effort in reducing carbon emissions generated by traditional packaging processes.Paragraph 4:In addition to its energy-saving capabilities, the Industrial Packing Machine also reduces material wastage by carefully measuring and optimizing packaging sizes. Its precision and accuracy ensure that materials are used efficiently, minimizing unnecessary packaging waste. Moreover, the machine's adaptability is advantageous to companies operating with varying product dimensions, enabling them to reduce excessive packaging material costs and contribute to sustainable practices.Paragraph 5:The Industrial Packing Machine's user-friendly interface and intuitive controls make it accessible to operators at all skill levels. Comprehensive training and ongoing technical support by the company ensure smooth integration and operation. Its system integration capabilities enable seamless connectivity with existing production lines, ensuring a hassle-free implementation process for manufacturing facilities of all sizes.Paragraph 6:With the launch of the Industrial Packing Machine, the company aims to empower businesses across sectors. By automating packaging operations, companies can reap benefits such as increased productivity, reduced labor costs, improved accuracy, and minimized downtime. Additionally, embracing sustainable packaging practices can enhance a company's reputation and align it with customer preferences for environmentally-friendly products.Conclusion:The next-generation Industrial Packing Machine, developed by an industry leader in packaging solutions, is poised to redefine packaging automation. Its advanced robotics, intelligent software, and sustainable design ensures increased efficiency, reduced waste, and a lowered carbon footprint. As businesses strive to optimize their operations and meet the demands of a rapidly changing world, the Industrial Packing Machine presents an essential solution to propel the industry's sustainability and productivity to new heights.

Celebrate Peanut Brittle Day on January 26th with this Easy Recipe for Nut Brittle!

Title: Celebrate Peanut Brittle Day with an Easy Homemade Recipe and Peanut Brittle Making MachineIntroduction:January 26th is celebrated as Peanut Brittle Day, a perfect occasion to indulge in this delicious, crunchy treat. Whether you prefer the traditional peanut brittle or enjoy experimenting with different nuts, making peanut brittle at home can be a fun activity to do with kids. Additionally, to enhance your peanut brittle-making experience and ensure consistent results, investing in a high-quality Peanut Brittle Making Machine can be a game-changer. Join us as we share an easy peanut brittle recipe while exploring the advantages of using a Peanut Brittle Making Machine.Homemade Peanut Brittle Recipe:Below is a simple recipe for making peanut brittle that can be customized with various types of nuts and toppings. This recipe can be a great way to bond with your kids while celebrating Peanut Brittle Day.Ingredients:- 2 cups granulated sugar- 1 cup light corn syrup- 1/2 cup water- 2 cups raw unsalted peanuts (or any nut of your choice)- 2 tablespoons unsalted butter- 1 teaspoon vanilla extract- 1 teaspoon baking soda- Optional: salt or chocolate for sprinkling or coatingInstructions:1. Prepare a baking sheet by lining it with parchment paper or greasing it with butter.2. In a large saucepan, combine sugar, corn syrup, and water. Stir until the sugar dissolves completely.3. Place the saucepan on medium heat and bring the mixture to a boil. Insert a candy thermometer and cook until the temperature reaches 300°F (150°C), also known as the "hard crack" stage.4. Add the peanuts to the boiling mixture and stir continuously for 5-7 minutes or until the mixture turns amber in color.5. Remove the saucepan from heat and quickly stir in the butter, vanilla extract, and baking soda. The mixture will foam and bubble.6. Pour the hot mixture onto the prepared baking sheet and spread it evenly using a heat-resistant spatula.7. If desired, sprinkle some salt over the hot peanut brittle for a savory twist or melt chocolate and coat the brittle pieces.8. Allow the brittle to cool completely, then break it into desired pieces.9. Store in an airtight container.Advantages of a Peanut Brittle Making Machine:To simplify and enhance the peanut brittle-making process, investing in a Peanut Brittle Making Machine can be highly beneficial. These machines are specifically designed to ensure quick, efficient, and consistent production of peanut brittle, saving both time and effort. Some key advantages of using a Peanut Brittle Making Machine include:1. Automated Production: Peanut Brittle Making Machines offer automated production, eliminating the need for constant manual stirring and monitoring. This allows for greater convenience and increased productivity.2. Precise Temperature Control: These machines come equipped with advanced temperature control systems, guaranteeing accurate and consistent cooking temperatures. This ensures that each batch of peanut brittle is perfectly cooked.3. Versatile Nut Options: Peanut Brittle Making Machines allow for the use of different types of nuts, such as almonds, cashews, or macadamia nuts. This allows you to cater to various taste preferences or create unique combinations.4. Uniform Thickness: Peanut Brittle Making Machines are designed to spread and flatten the mixture evenly, resulting in uniformly thick brittles. This ensures a consistent texture and enhances the overall presentation.5. Improved Safety: The use of a Peanut Brittle Making Machine reduces the risks associated with traditional stovetop cooking, such as burns or accidental spills. This makes it safer, particularly when involving children in the process.Conclusion:As Peanut Brittle Day approaches, celebrate the occasion by making your own homemade peanut brittle. Get creative by using different nuts and exploring various toppings like salt or chocolate. To make the process even more enjoyable and efficient, consider investing in a Peanut Brittle Making Machine. These machines offer automated production, precise temperature control, versatility with nut options, uniform thickness, and improved safety. So gather your ingredients, get ready to make some tasty brittle, and enjoy this delightful treat on Peanut Brittle Day!