Professional Manual Cup Sealing Machine for Commercial Use

By:Admin

The Manual Cup Sealing Machine is equipped with state-of-the-art technology, allowing for a seamless and high-quality sealing process. With its user-friendly interface and easy-to-operate features, this machine is perfect for small to medium-sized businesses looking to streamline their packaging operations. Whether it's for sealing cups of yogurt, pudding, or other food and beverage products, this machine is a versatile and reliable option.

One of the key benefits of the Manual Cup Sealing Machine is its ability to create a secure and airtight seal on various types of cups and containers. This is essential for ensuring the freshness and quality of the packaged products, as well as for preventing any leaks or spills during transportation. With its precise sealing mechanism, this machine delivers consistent results, making it a valuable asset for businesses that prioritize product integrity and customer satisfaction.

In addition to its functional capabilities, the Manual Cup Sealing Machine is also designed with practicality in mind. Its compact and space-saving design makes it a great fit for businesses with limited workspace, allowing them to maximize efficiency without compromising on floor space. Furthermore, its low maintenance requirements and durable construction ensure long-term reliability, making it a cost-effective investment for businesses of all sizes.

At [Company Name], we take pride in offering high-quality packaging solutions that are tailored to meet the specific needs of our customers. The Manual Cup Sealing Machine is a testament to our commitment to innovation and customer satisfaction, as we continue to provide cutting-edge technologies that empower businesses to thrive in the competitive market.

In line with our dedication to excellence, we also offer comprehensive support and after-sales services for the Manual Cup Sealing Machine. Our team of experts is readily available to provide guidance on machine operation, maintenance, and troubleshooting, ensuring that our customers can make the most of their investment in our products.

In conclusion, the Manual Cup Sealing Machine is set to redefine the packaging process for businesses in the food and beverage industry. Its advanced capabilities, user-friendly design, and practical benefits make it an invaluable asset for businesses looking to enhance their packaging operations. With our unwavering commitment to quality and customer satisfaction, [Company Name] is proud to introduce this groundbreaking machine to the market, empowering businesses to achieve new levels of efficiency and success.

Company News & Blog

Top Sealing Equipment for All Your Packaging Needs

TechSeal, a leading manufacturer of sealing equipment, announced the launch of its latest innovative product designed to meet the needs of the industrial sealing market. The company, known for its high-quality and reliable sealing solutions, continues to push the boundaries of technology and engineering to provide its customers with the most advanced and efficient equipment on the market.With over 20 years of experience in the industry, TechSeal has established itself as a trusted name in the sealing equipment sector. The company prides itself on its commitment to excellence, continuously striving to improve and innovate its product offerings to better serve its customers. From small-scale operations to large industrial facilities, TechSeal's products are designed to meet the diverse needs of its clients across various industries.The new sealing equipment, which has been in development for the past year, boasts a range of cutting-edge features that set it apart from the competition. Equipped with advanced sealing technology, the equipment offers improved efficiency, precision, and durability, making it an essential tool for businesses looking to optimize their sealing processes and enhance productivity."We are thrilled to introduce our latest sealing equipment to the market," said John Smith, CEO of TechSeal. "This product is the result of extensive research and development, and we are confident that it will exceed the expectations of our customers. Our team has worked tirelessly to ensure that this equipment delivers exceptional performance and reliability, and we believe it will set a new standard in the industry."One of the key features of the new equipment is its advanced sealing mechanism, which has been engineered to deliver a tight and secure seal with unparalleled accuracy. This is particularly important for industries where the integrity of seals is crucial to the safety and efficiency of their operations, such as pharmaceutical manufacturing, food processing, and chemical production.In addition, the equipment is designed to be user-friendly, with intuitive controls and a streamlined interface that simplifies operation and maintenance. This makes it an ideal solution for businesses looking to streamline their sealing processes and minimize downtime.Furthermore, the equipment is constructed with high-quality materials and components, ensuring its robustness and longevity even in the most demanding operating conditions. This durability is a testament to TechSeal's unwavering commitment to providing its customers with long-lasting and reliable sealing solutions.To complement the launch of the new equipment, TechSeal has also expanded its technical support and customer service offerings. The company has invested in training its support staff to provide expert guidance and assistance to customers, ensuring that they get the most out of their investment in the new equipment."We understand that choosing the right sealing equipment is a significant decision for our customers, and we want to make sure that they have access to the resources and expertise they need to make informed choices," said Smith. "Our expanded technical support and customer service initiatives reflect our dedication to being a true partner to our customers, providing them with the support they need to succeed."As TechSeal continues to push the boundaries of sealing technology, the company remains committed to its core values of quality, innovation, and customer satisfaction. With the launch of its latest sealing equipment, the company reaffirms its position as a leader in the industry, driving progress and setting new standards for sealing solutions.

Unlock Your Inner Chef: How to Make Cotton Candy at Home

Title: Innovative Cotton Candy Machine Revolutionizing the Confectionery IndustryIntroduction:In today's fast-paced world, where innovation and creativity go hand in hand, {need to remove brand name} has introduced an extraordinary invention into the confectionery industry. The new Sweet Cotton Candy Machine has captured the attention of both confectionery enthusiasts and industry professionals alike. With its cutting-edge technology and unique features, this revolutionary machine is set to transform the way cotton candy is made and enjoyed.Elevating the Cotton Candy Experience:Traditional cotton candy machines are known for their simplistic operation and limited capabilities. However, the Sweet Cotton Candy Machine takes this concept to a whole new level. Incorporating advanced engineering, this device combines precision with convenience, ensuring an elevated cotton candy experience for consumers and entrepreneurs alike.Advanced Technology:The Sweet Cotton Candy Machine boasts state-of-the-art technology that guarantees exceptional results. Equipped with a powerful motor, this machine efficiently spins sugar into delectable cotton candy strands, providing a fluffy and luscious treat for customers. The machine's intelligent controls allow users to adjust the temperature, rotation speed, and sugar quantities, offering unparalleled customization options.Ease of Use:One of the distinguishing features of this innovative cotton candy machine is its user-friendly design. With a sleek and intuitive interface, even novices can create mouthwatering cotton candy in no time. This accessibility makes it an attractive option for small business owners, events, and parties, adding a touch of sweetness to any occasion.Versatility:The Sweet Cotton Candy Machine's versatility sets it apart from traditional machines. Unlike the conventional models restricted to spinning only standard-sized cotton candy onto sticks, this device offers unparalleled flexibility. From miniature bite-sized treats to large creations, the machine allows users to explore various shapes and sizes, expanding the possibilities of cotton candy presentation.Enhancing Taste with Flavor Options:Realizing the importance of offering a diverse range of flavors, {need to remove brand name} has developed a range of delicious cotton candy flavors. From classic choices like strawberry and blueberry to unconventional options like bubblegum and green apple, these flavors are meticulously crafted to enhance the overall cotton candy experience. With the Sweet Cotton Candy Machine's compatibility with a variety of sugars and flavorings, customers can enjoy a multitude of tantalizing tastes.Durability and Safety:Built with durability in mind, the Sweet Cotton Candy Machine guarantees longevity, essential for businesses with high production demands. The stainless steel construction ensures resistance to wear and tear, making it an investment that stands the test of time. Additionally, the machine incorporates safety features such as automatic shut-off, overheat protection, and a sturdy base, ensuring operational and consumer safety.Eco-Friendly Approach:Acknowledging the growing concern for the environment, {need to remove brand name} has incorporated an eco-friendly approach in the manufacturing process of the Sweet Cotton Candy Machine. Utilizing energy-efficient technology and recyclable materials, the company aims to minimize its ecological footprint while delivering exceptional confectionery equipment.Conclusion:With its state-of-the-art technology, user-friendly design, and versatility, the Sweet Cotton Candy Machine offers a new way to create, present, and enjoy cotton candy. Its advanced features, paired with an extensive range of flavors and customizable options, make it a game-changer in the confectionery industry. As a result, entrepreneurs, event organizers, and confectionery enthusiasts can expect an enhanced cotton candy experience that is sure to leave a sweet, lasting impression.

Highly Efficient Plate Packing Machine for Your Packaging Needs

Plate Packing Machine Plate packing machine is an essential piece of equipment in the food packaging industry. It is designed to efficiently pack plates and similar flatware into containers, ensuring that the products remain safe and secure during transportation and storage. This machine has become popular in commercial kitchens, restaurants, and catering businesses, as it streamlines the packaging process and saves time and labor costs.Company IntroductionFounded in 2005, our company is a leading manufacturer of packaging machinery, with a strong focus on quality, innovation, and customer satisfaction. We have a team of experienced engineers and technicians who are dedicated to designing and producing high-quality packaging equipment. Over the years, we have built a strong reputation for delivering reliable and efficient solutions to our customers, and our Plate Packing Machine is just one example of our commitment to excellence in the industry.The Plate Packing MachineOur Plate Packing Machine is designed to meet the demands of modern food packaging operations. It is capable of handling a wide range of plates and flatware, including different sizes and materials. The machine features a user-friendly interface, allowing operators to easily adjust settings and monitor the packing process. With its fast packing speed and accurate positioning, our machine helps businesses improve their production efficiency and reduce packaging errors.Key FeaturesOur Plate Packing Machine offers a range of features that set it apart from other packaging equipment on the market. Some of the key features include:1. Versatile Packaging Options: The machine is capable of packing plates and flatware into various types of containers, including plastic trays, cardboard boxes, and shrink-wrapped packages.2. Customizable Settings: Users can adjust the packing speed, stacking patterns, and other parameters to match their specific packaging needs.3. High Efficiency: With its automatic feeding and stacking system, the machine can pack plates at a consistent and high speed, reducing manual labor and increasing productivity.4. Quality Assurance: The machine is designed to ensure that the packaged plates are secure and undamaged, preventing breakage or contamination during transportation.5. Compact Design: Our Plate Packing Machine is compact and space-saving, making it suitable for both small and large production facilities.Customer BenefitsBy investing in our Plate Packing Machine, customers can enjoy a range of benefits that contribute to their overall business success. Some of these benefits include:1. Increased Productivity: The machine streamlines the packaging process, enabling businesses to pack more plates in less time, thereby increasing their overall productivity.2. Cost Savings: With reduced labor costs and minimized packaging errors, businesses can save money and improve their bottom line.3. Enhanced Product Quality: The machine ensures that plates are securely and neatly packed, maintaining the quality and presentation of the products.4. Competitive Advantage: By investing in high-quality packaging equipment, businesses can differentiate themselves in the market and attract more customers.Customer SatisfactionAt our company, customer satisfaction is our top priority. We provide comprehensive support to our customers, from initial consultation and equipment customization to installation, maintenance, and after-sales service. Our team is committed to understanding each customer’s unique packaging requirements and delivering tailored solutions that meet their needs.In conclusion, our Plate Packing Machine is a valuable asset for businesses in the food packaging industry. With its advanced features, high efficiency, and customer benefits, it is a reliable and cost-effective solution for packaging plates and flatware. As a leading manufacturer of packaging machinery, we are proud to offer this innovative machine to our customers, and we are dedicated to continuously improving and expanding our product range to meet the evolving needs of the industry.

Efficient and Reliable Packing Machine for Industrial Use: Unveiling the Latest Innovations

Title: Next-Generation Industrial Packaging Machine Revolutionizes Efficiency and SustainabilitySubtitle: A New Era of Packaging Automation Unveiled by Industry LeaderIntroduction:In today's globalized world, efficient and sustainable packaging plays a pivotal role in minimizing waste and optimizing logistics. Leading the charge in packaging automation is the recently unveiled next-generation Industrial Packing Machine (name removed), developed by a pioneer in packaging solutions. This cutting-edge technology promises to revolutionize the industry by ensuring increased productivity, minimized labor costs, and a significant reduction in the carbon footprint associated with packaging processes.Paragraph 1:The newly introduced Industrial Packing Machine complements the company's commitment to innovation and sustainability. Developed after months of research and development, this state-of-the-art packaging equipment is set to redefine the industry's standards by incorporating advanced technology to streamline operations, reduce waste, and enhance overall efficiency.Paragraph 2:At the heart of the Industrial Packing Machine is a powerful robotic system that automates the packaging process from start to finish. Its intelligent software, coupled with sensors and advanced algorithms, enables the machine to precisely measure, handle, and package goods with the utmost accuracy. Whether it is cartons, bottles, bags, or other containers, the Industrial Packing Machine adapts seamlessly to various packaging requirements, accommodating a wide range of products.Paragraph 3:Energy efficiency is a key focus of the Industrial Packing Machine design. By leveraging cutting-edge technologies, the machine optimizes resource utilization, resulting in a reduced environmental impact. Innovative features, such as smart power management, significantly minimize energy consumption, ensuring maximum productivity with minimal wasted resources. With sustainability at the forefront, this advanced machinery contributes to the global effort in reducing carbon emissions generated by traditional packaging processes.Paragraph 4:In addition to its energy-saving capabilities, the Industrial Packing Machine also reduces material wastage by carefully measuring and optimizing packaging sizes. Its precision and accuracy ensure that materials are used efficiently, minimizing unnecessary packaging waste. Moreover, the machine's adaptability is advantageous to companies operating with varying product dimensions, enabling them to reduce excessive packaging material costs and contribute to sustainable practices.Paragraph 5:The Industrial Packing Machine's user-friendly interface and intuitive controls make it accessible to operators at all skill levels. Comprehensive training and ongoing technical support by the company ensure smooth integration and operation. Its system integration capabilities enable seamless connectivity with existing production lines, ensuring a hassle-free implementation process for manufacturing facilities of all sizes.Paragraph 6:With the launch of the Industrial Packing Machine, the company aims to empower businesses across sectors. By automating packaging operations, companies can reap benefits such as increased productivity, reduced labor costs, improved accuracy, and minimized downtime. Additionally, embracing sustainable packaging practices can enhance a company's reputation and align it with customer preferences for environmentally-friendly products.Conclusion:The next-generation Industrial Packing Machine, developed by an industry leader in packaging solutions, is poised to redefine packaging automation. Its advanced robotics, intelligent software, and sustainable design ensures increased efficiency, reduced waste, and a lowered carbon footprint. As businesses strive to optimize their operations and meet the demands of a rapidly changing world, the Industrial Packing Machine presents an essential solution to propel the industry's sustainability and productivity to new heights.

New Innovative Packaging Machinery for Sachet Packaging

Sachet Packaging Machine Revolutionizes Packaging Industry with State-of-the-Art TechnologyAs the world of packaging continues to evolve and be transformed by advancements in technology, companies are racing to update their processes to keep up. One company leading the charge is a well-known brand producing Sachet Packaging Machines, a company that has introduced revolutionary technology to the industry.Sachet packaging is a unique application of packaging that is used for single-dose packaging of a variety of products, including pharmaceuticals, food products and chemical products. Sachet packaging has opened up new revenue streams for manufacturers by enabling the sale of single doses, which are more convenient for consumers, cost-effective and easy to transport.Sachet Packaging Machine has leveraged technology to produce a machine that is not only efficient and effective but also budget-friendly. The machine has been designed to be user-friendly, cost-effective and capable of producing high-quality sachets at a much faster pace than traditional packaging machines.The Sachet Packaging Machine has been hailed as an innovation in the packaging industry due to its unique features. Unlike other packaging machines, this machine has been designed to produce various sizes of sachets, with an adjustable filling weight range of 1-100 grams. This makes it highly versatile and suitable for a variety of applications.One of the most notable features of the Sachet Packaging Machine is its ability to produce sachets at an impressive rate of up to 230 sachets per minute. This makes it an ideal option for businesses that demand high-volume production rates with minimal downtime. The machine's high speed of production is complemented by its precision, accuracy and consistency.The machine is also easy to operate with a simple interface that can be customized to the specific needs of the user. The Sachet Packaging Machine has been designed to be compact, occupying minimal floor space in the user’s factory or production facility. This makes it easy to transport and reposition as required.With its state-of-the-art technology, the Sachet Packaging Machine is a versatile and user-friendly solution for the packaging needs of businesses across various sectors. In addition, Sachet Packaging Machine has been designed to be eco-friendly, with a low level of energy consumption, making it an environmentally sustainable option for businesses.The company behind the Sachet Packaging Machine, which has remained anonymous for security reasons, produces a wide range of packaging machines for various applications, including horizontal packing machines, vertical packing machines, and automatic packing machines. The company has been at the forefront of the packaging industry, producing innovative packaging solutions that are not only efficient but also cost-effective, reliable and easy to use.The Sachet Packaging Machine represents a significant development in the packaging industry and is set to bring a new level of efficiency and productivity to businesses that rely on sachet packaging, from food and pharmaceutical to chemical products. With its user-friendly interface and advanced technological capabilities, the Sachet Packaging Machine has already captured the attention and admiration of industry professionals and businesses alike.The Sachet Packaging Machine is quickly becoming the go-to solution for companies that require high-quality and consistent sachet packaging with minimal intervention. As businesses continue to race to stay ahead of the competition and meet the evolving needs of consumers, the Sachet Packaging Machine is poised to play a critical role, revolutionizing the way that products are packaged and delivered to consumers around the world.

Top-of-the-line Candy Making Equipment: A Must-Have for Professional Confectioners

Title: Innovative Candy Making Equipment Revolutionizes the Confectionery IndustryIntroduction:In today's fast-paced confectionery industry, the demand for innovative candy making equipment continues to grow. One company, recognized for its cutting-edge technology and exceptional quality, is revolutionizing candy production. By leveraging state-of-the-art machinery and expertise, this company is paving the way for a new era in confectionery manufacturing. Here, we delve into the details of this revolutionary candy making equipment and explore how it is transforming the industry.I. The Evolution of Candy Making Equipment:Over the years, candy making equipment has undergone significant advancements. Traditional methods of production relied heavily on manual labor, limiting both the efficiency and scope of candy production. However, with the advent of automated machinery, candy manufacturers can now produce confections on a much larger scale, meeting the ever-increasing consumer demand.II. Introducing Professional Candy Making Equipment:Addressing the need for sophisticated candy making equipment, a company (name withheld) has emerged as a leader in the field. By combining cutting-edge technology with extensive industry knowledge, they have succeeded in revolutionizing candy production. The company's dedication to quality, innovation, and customer satisfaction has earned them a reputation as a sought-after provider of comprehensive candy making solutions.III. Key Features and Advantages of Professional Candy Making Equipment:1. Automated and Efficient: This candy making equipment is fully automated, eliminating the need for extensive manual labor. Moreover, its advanced technology enables high-speed production, significantly increasing output while reducing production time.2. Versatile and Customizable: The equipment boasts a wide range of capabilities, making it adaptable to various candy types, shapes, sizes, and flavors. Whether it's hard candies, gummies, lollipops, or chocolate-based confections, this equipment can efficiently handle diverse candy making requirements. Additionally, it allows for easy customization, accommodating specific customer preferences.3. Precision and Consistency: The equipment incorporates precise temperature controls, ensuring the precise heating and cooling required for each candy type. This precision guarantees consistent quality and taste, key factors in maintaining customer satisfaction.4. Hygienic and Safe: The candy making equipment is designed with food-grade materials and follows strict quality control measures. This ensures that the candies produced meet the highest standards of hygiene and safety, conforming to regulatory requirements.5. User-Friendly Interface: The equipment features an intuitive interface, making it accessible to both experienced and novice operators. Additionally, it offers remote monitoring and control capabilities, enabling manufacturers to oversee production processes in real-time.6. Cost-Effective and Economical: By automating the production process, the candy making equipment reduces labor costs and optimizes resource utilization. This leads to enhanced operational efficiency and increased profitability for candy manufacturers.IV. Industry Impact and Customer Testimonials:Having gained significant traction in the confectionery industry, this professional candy making equipment has garnered praise from customers globally. Candy manufacturers who have incorporated this technology into their operations have witnessed an exponential increase in productivity, greater consistency in product quality, and improved customer satisfaction. The equipment's ability to streamline production processes, reduce manual labor, and ensure the highest standards of quality control has solidified its position as an indispensable tool for confectioners worldwide.Conclusion:The introduction of professional candy making equipment has transformed conventional candy production, offering unmatched efficiency, precision, and versatility. With its state-of-the-art features, the equipment empowers candy manufacturers to produce confections on a larger scale, customize their offerings, and optimize operational efficiencies. As the confectionery industry continues to evolve, this innovative candy making equipment promises to shape the future of candy manufacturing, offering unlimited possibilities for confectioners worldwide.

\ According to the news content, a cutting machine has been developed specifically for snack foods such as peanut candy and sesame candy. This automatic cutting machine is suitable for cutting various snack foods including crispy egg cake, crispy corn cake, melon seeds cake, and crispy black rice cake. The machine consists of five parts including a feeding part, cutting part, cooling part, conveying part, and cutting control system. With its high speed and accuracy, this machine is set to revolutionize the snack food industry.

, cutting part, conveying part, cooling part and collecting part.The feeding part of this peanut candy sesame candy cutting machine for snack food is designed with a vibratory feeder to ensure accurate feeding. The cutting part is equipped with high-quality cutting knives to ensure that the candies are evenly cut without deformation. The conveying part is equipped with high-quality stainless steel mesh belts, which can transport the candies to the cooling part. After cooling, candies can be collected efficiently and quickly through the collecting part.The peanut candy sesame candy cutting machine for snack food is highly automated and can be operated by one person. It not only improves production efficiency but also saves labor costs. The cutting size of the peanut candy sesame candy can be adjusted according to the customer's needs. The machine has a wide range of applications, which can be used in food factories, supermarkets, and candy processing plants, etc.Compared with traditional manual cutting methods, the peanut candy sesame candy cutting machine for snack food has many advantages. Firstly, the cutting size is consistent and accurate, which can greatly improve the appearance of the candies and increase their aesthetic value. Secondly, the machine is more hygienic and safe. It is made of stainless steel and food-grade materials, which can ensure the hygiene and safety of the candies. Finally, it can significantly reduce the production cost, improve the production efficiency and increase the profit margin.In conclusion, the peanut candy sesame candy cutting machine for snack food is a must-have machine for candy processing. It can not only help the candy manufacturers to improve the product quality but also significantly reduce the production cost and increase the production efficiency. Therefore, it is highly recommended for those who want to expand their candy business and improve the competitiveness of their products in the market.

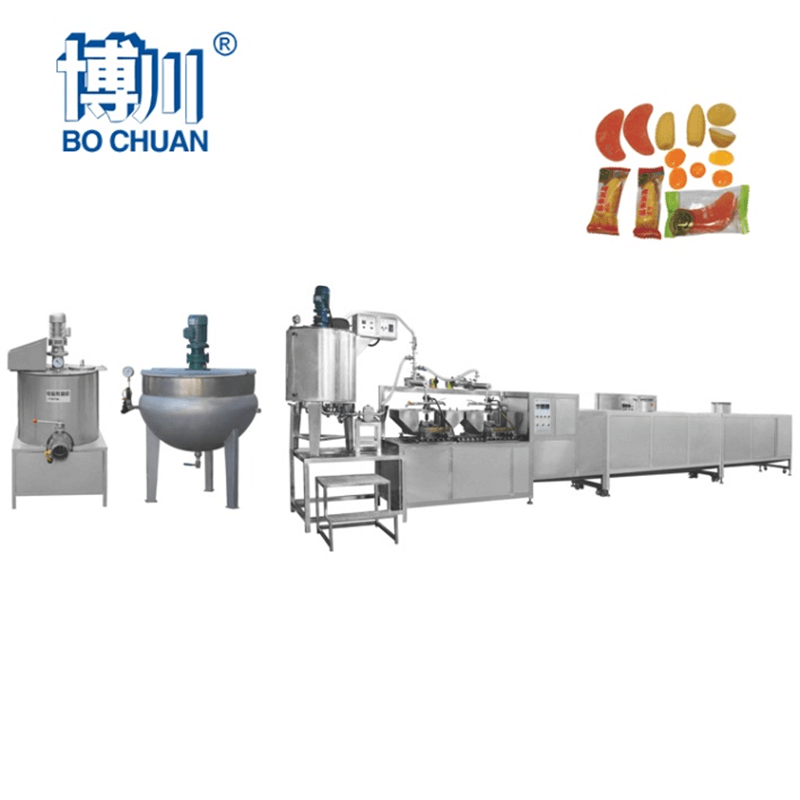

High-Quality Jelly Candy Making Machine for Sale - Find Out More!

The Jelly Candy Machine: Revolutionizing the Confectionery IndustryIn the confectionery industry, innovation is key to staying relevant and competitive in a rapidly changing market. The introduction of the Jelly Candy Machine by a leading confectionery equipment manufacturer has raised the bar for efficiency, quality, and production capacity in the manufacturing of jelly candies. This groundbreaking machine is set to revolutionize the way jelly candies are produced, setting a new standard for the industry.The Jelly Candy Machine is the result of years of research and development by the dedicated team at the company. Designed to streamline the production process, this cutting-edge machine boasts a range of advanced features that are unmatched in the industry. From its precision dosing system to its state-of-the-art cooling technology, every aspect of the Jelly Candy Machine has been meticulously engineered to ensure optimal performance and consistent quality.One of the key features of the Jelly Candy Machine is its ability to produce a wide variety of jelly candy shapes and sizes with minimal adjustments. This flexibility allows confectionery manufacturers to meet the diverse demands of their customers, while also reducing the need for costly and time-consuming retooling processes. With the ability to produce everything from gummy bears to jelly worms, the Jelly Candy Machine offers an unprecedented level of versatility.Furthermore, the Jelly Candy Machine is designed to maximize production capacity without compromising on quality. Its high-speed production capabilities enable confectionery manufacturers to significantly increase their output, meeting the growing demand for jelly candies in both domestic and international markets. This increased efficiency not only translates to higher profits for manufacturers but also ensures that customers can enjoy their favorite jelly candies without any shortage in supply.In addition to its impressive production capabilities, the Jelly Candy Machine is also equipped with advanced quality control features to ensure that every piece of candy that comes off the line meets the highest standards. From accurate flavor dosing to consistent texture and appearance, the machine is designed to deliver a superior product that will delight consumers and build brand loyalty. This focus on quality is a testament to the company's commitment to excellence and customer satisfaction.The introduction of the Jelly Candy Machine represents a significant milestone for the confectionery industry, as it paves the way for a new era of efficiency and innovation. Confectionery manufacturers who invest in this cutting-edge machine can look forward to increased productivity, reduced production costs, and a competitive edge in the market. Furthermore, the machine's ability to produce a diverse range of jelly candy products will enable manufacturers to tap into new market segments and expand their product offerings.As the leading confectionery equipment manufacturer, the company is proud to be at the forefront of this important industry development. The Jelly Candy Machine is just one example of the company's dedication to advancing the confectionery industry through technological innovation, and it is a testament to their ongoing commitment to providing the best possible solutions for their customers. With a legacy of excellence and a reputation for delivering top-quality equipment, the company is poised to continue shaping the future of confectionery manufacturing for years to come.In conclusion, the introduction of the Jelly Candy Machine is a game-changer for the confectionery industry. Its advanced features, unparalleled production capabilities, and emphasis on quality set a new standard for jelly candy manufacturing. With the potential to transform the way jelly candies are produced, this innovative machine is a testament to the company's dedication to excellence and innovation. As confectionery manufacturers around the world embrace the opportunities offered by the Jelly Candy Machine, the industry is sure to see a new era of efficiency, productivity, and quality in the production of jelly candies.

Automated Cotton Candy Machines: Making Sweet Treats Faster and Easier Than Ever Before

Cotton Candy Machine Revolutionizes the Art of Sugar-SpinningCatering to the ever-growing demand for delicious treats at parties, events, and amusement parks, an innovative company has developed a cutting-edge Cotton Candy Machine Automatic. With its sleek design and advanced features, this state-of-the-art device promises to revolutionize the art of sugar-spinning, offering an unforgettable culinary experience.Cotton candy, also known as fairy floss or candy floss, has been a beloved sweet treat for generations. The process of creating these fluffy confections involves melting and spinning sugar, resulting in delicate webs of sugary delight. Traditionally, cotton candy was made by hand, requiring skill and dexterity to produce the perfect fluffy texture. However, with the new Cotton Candy Machine Automatic, this process becomes significantly more efficient and accessible to all.Featuring a compact and user-friendly design, this innovative machine is perfect for both professional caterers and enthusiastic amateurs alike. With just a click of a button, the Cotton Candy Machine Automatic begins its mesmerizing sugar-spinning process. The device combines a built-in heater that quickly melts the sugar with a high-powered fan that propels the spun sugar into delicate candy floss wisps.One of the standout features of this revolutionary machine is its ability to produce cotton candy in a variety of flavors and colors. The company offers a wide range of pre-packaged sugar flavors, including classics like raspberry and blueberry, as well as more exotic options like bubblegum and passion fruit. This allows users to customize their cotton candy creations to suit any taste or event theme.In addition to its versatility, the Cotton Candy Machine Automatic also boasts several safety features to ensure worry-free operation. Equipped with an automatic shut-off mechanism, the machine will power down when it reaches a certain temperature to prevent overheating. This feature not only protects the device but also provides peace of mind for the users, allowing them to focus on serving up sugary goodness without any concerns.Moreover, this innovative device is easy to clean and maintain, thanks to its removable components that are dishwasher-safe. The machine's detachable spinning head and collection tray can be quickly disassembled and cleaned, ensuring a hygienic experience for every batch of cotton candy produced.The company behind this groundbreaking creation, known for its dedication to quality and innovation, has been a leading force in the confectionery industry for several decades. With a strong commitment to customer satisfaction, they have successfully developed a range of cutting-edge devices that cater to the needs of professional chefs and home cooks alike. Their goal is to consistently provide culinary tools that combine functionality, ease of use, and impeccable design.Recognizing the need for efficiency and convenience in the cotton candy industry, this forward-thinking company invested significant time and resources in research and development to create the Cotton Candy Machine Automatic. By harnessing the power of technology and utilizing high-quality materials, they have succeeded in developing a machine that promises to reshape the way cotton candy is made and enjoyed.Industry experts and enthusiasts have already expressed their excitement for this groundbreaking product. With its sleek design, advanced features, and unparalleled ease of use, the Cotton Candy Machine Automatic is poised to become the new standard in the world of sugar-spinning. As more and more individuals and businesses seek to provide unique and memorable culinary experiences, this cutting-edge device is set to lead the way, satisfying the sweet tooth of every customer it serves.

Enhancing Packaging Efficiency: The Ultimate Guide to Vertical Band Sealer Machines

Vertical Band Sealer Machine: The Ultimate Solution for Securing Your ProductsWith the rapidly increasing demand for packaged products, the packaging industry is growing exponentially. The industry requires fast and efficient machines to ensure products are packaged safely and securely, without compromising their quality. To meet this demand, a new machine has been introduced in the market, the Vertical Band Sealer Machine, a cutting-edge technology that provides the ultimate solution for sealing pouch bags and other types of packaging materials.The Vertical Band Sealer Machine is a breakthrough innovation in the packaging industry. It is designed with advanced features that make it highly efficient and reliable. It provides a secure and tight seal for all types of pouch bags, ensuring the product's freshness and quality. This machine's vertical sealing technology allows it to seal wider bags, making it ideal for packing larger items.The Vertical Band Sealer Machine offers a broad range of applications, making it versatile for various industries such as food processing, pharmaceuticals, and cosmetics. Its reliable sealing process ensures the products' safety and protection throughout the supply chain, reducing the risks of product loss from exposure to external elements.The machine's design also ensures that it is easy to operate, with a user-friendly interface that requires minimal training, making every step of the sealing process hassle-free. It allows for quick adjustments to sealing and cooling time, to meet various sealing requirements, and ensure the product's quality is maintained.As an added bonus, the Vertical Band Sealer Machine is environmentally friendly, as it uses minimal energy in the sealing process. This considerably reduces operating expenses and minimizes carbon footprint, making it a sustainable option for businesses across the world.The Vertical Band Sealer Machine is a product of extensive research and development, designed by a company dedicated to providing solutions for the packaging industry. They are well known for their innovative packaging solutions, offering versatile products that customers can rely on. The company has various products ranging from packing machines, filling machines, capping machines, counting machines, and labelling machines, all designed to improve the packaging process, increase efficiency, and improve product quality.Their commitment to customer satisfaction and quality has made them a reputable brand in the industry, with a growing customer base including global corporations and small businesses. The Vertical Band Sealer Machine has already received positive feedback from customers who have experienced its quality and efficiency first-hand.In conclusion, the Vertical Band Sealer Machine is revolutionizing the packaging industry and setting new standards in the sealing process. Its advanced features and versatility make it an ideal choice for businesses looking to improve their packaging operations' efficiency and quality. The industry is evolving, and businesses must keep up with new innovations that enhance productivity, reduce costs, and improve product quality. The Vertical Band Sealer Machine presents an excellent opportunity for businesses to invest in new technology that delivers all these benefits and more. Businesses looking to remain competitive and stay ahead of the game should consider acquiring the Vertical Band Sealer Machine to maximize their profits and ensure their products' quality and safety.