New Automated Machine Streamlines Candy Packaging Process

By:Admin

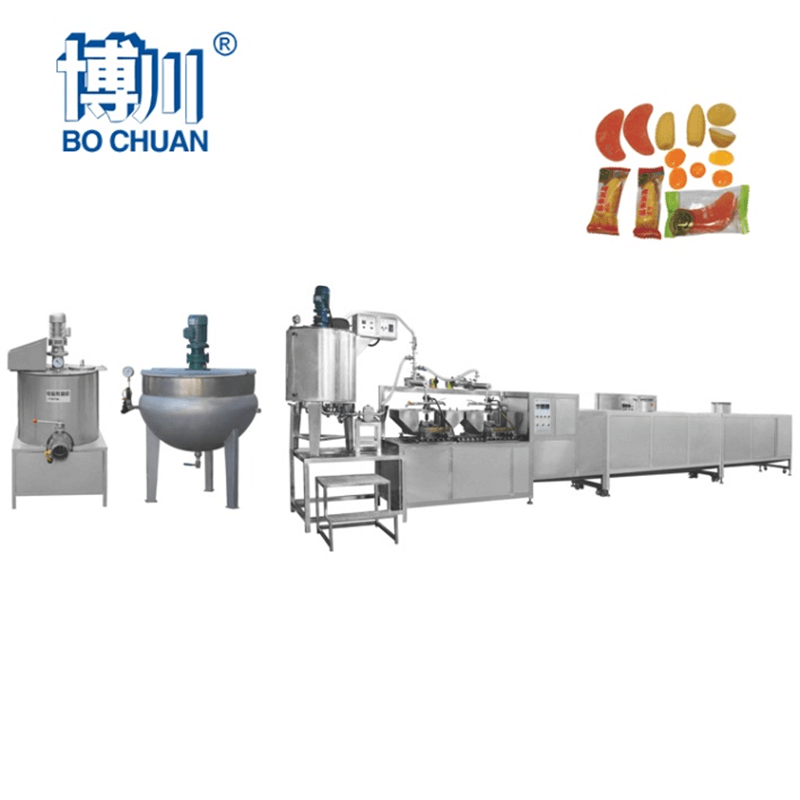

At the core of this groundbreaking new product is its unprecedented ability to streamline the candy packaging process. The machine boasts an automated packing system that rapidly and efficiently packs candy into various packaging applications. This is made possible by the machine's highly advanced sensors which detect the presence of candy and its corresponding packaging, selecting the appropriate packaging solution and ensuring it is filled accurately.

The overall design of the candy packing machine is also noteworthy. It is sleek and compact, allowing it to take up relatively little space on the factory floor. This is especially advantageous for candy manufacturers who may have limited space to work with. Additionally, the machine is incredibly easy to use, minimizing the need for staff training.

The candy packing machine also comes equipped with a number of impressive safety features designed to minimize the risk of accidents on the factory floor. These include sensors that detect any potential hazards and stop the machine immediately to prevent injury. The machine also has an easy-to-access maintenance system that helps keep it running smoothly while minimizing any potential downtime.

As a result of its advanced technology, the candy packing machine has been shown to dramatically improve productivity levels. In fact, it is capable of packing several thousand bags of candy per hour. This makes it an ideal solution for candy manufacturers who are looking to ramp up their output while maintaining consistent-quality packaging.

To further enhance its appeal, the candy packing machine has been designed to be as environmentally-friendly as possible. This is achieved through its use of low-energy consumption and eco-friendly packaging applications. As sustainability becomes an increasingly important priority for many businesses, this unique approach may help the machine gain a competitive edge in the market.

The company behind the candy packing machine has a long history of innovation and customer satisfaction. They are committed to developing cutting edge technology that can help businesses improve efficiency, cut costs and increase output. With a range of other products available, including food packaging machines, weighing systems and more, this company is well-equipped to offer comprehensive packaging solutions to businesses of all sizes.

Already, the candy packing machine has received high praise from industry leaders, many of whom are excited about its potential to improve productivity and revolutionize the candy packaging industry. As the demand for candy continues to grow, driven in part by the continued popularity of sweet treats, exponential growth in the industry is expected to continue. This means that the need for reliable, high-quality packaging solutions will only increase, making the candy packing machine an even more attractive investment for businesses.

Overall, the introduction of the candy packing machine is a significant development in the candy packaging industry. It addresses many of the challenges that candy manufacturers face today, from limited space on the factory floor to the need for greater efficiency and productivity. With its advanced technology, robust safety features, and eco-friendly packaging applications, the candy packing machine is poised to become a game-changer in the industry. The future of candy packaging, it seems, is looking sweet indeed.

Company News & Blog

Efficient Case Packing Equipment for Streamlined End-of-Line Packaging

Improve Your End-of-Line Packaging with Robotic Case PackerIn a world where speed and efficiency are the keys to winning in business, automating your end-of-line packaging process with a robotic case packer could give you an edge over your competitors. With the power to transform your case packing operations, a robotic case packer offers precision, accuracy, and speed, all while reducing human error and increasing product throughput.A robotic case packer is a high-tech solution for packing products in a manufacturing or distribution facility. It is designed to automatically package products in their respective cartons or boxes. The robotic arms integrated into the machine are guided by sophisticated software that controls movement and placement, ensuring the correct products are loaded quickly and accurately.There are many advantages that come with investing in a robotic case packer. One of the main advantages is speed. A robotic case packer can quickly and efficiently package products at a far faster rate than manual labor. This improves production times and increases the volume of products that can be packaged.Another benefit of utilizing a robotic case packer is the reduced need for human labor. With the integration of robotic systems, there is a significant reduction in the number of employees required for the packing process. This reduces labor costs and frees employees to focus on other important tasks that require human skills.Apart from speed and labor cost savings, a robotic case packer also helps to improve product quality and accuracy. The high precision and accuracy of the robotic arms when packing products help to minimize the chances of human error. This ensures that each box or carton is packed correctly without any faults or defects that could lead to product damage or customer dissatisfaction.In conclusion, investing in a robotic case packer is a smart move for businesses that seek to improve their end-of-line packaging process. The technology provides speed, efficiency, and precision, while reducing labor costs and eliminating human error. If you are interested in streamlining your end-of-line packaging with a custom case packing system and looking to request a quote for vertical or horizontal loading, robotic or hand pack stations, consider incorporating a robotic case packer into your business operations. With the right system in place, you can achieve better production times and improve your bottom line.

Double Chamber Vacuum Sealer for Effective Packing - Get the Best Deals in UAE

and Vacuum Packing Machine.Vacuum packing has revolutionized the way goods are transported and stored in industries around the world. The process involves removing air from packaging before sealing it, allowing for longer shelf life, improved hygiene, and better preservation of the product's quality. This process is made possible by vacuum packing machines.One such machine is the double chamber vacuum sealer, which is widely used in industries that package and store food products, electronics, and pharmaceuticals. Unlike a single chamber vacuum sealer, a double chamber vacuum sealer has two chambers, which allows for faster and more efficient packaging of goods.At Phoenix Dison Tec LLC, we offer high-quality double chamber vacuum packing machines that are designed to meet the needs of every industry. Our IPM 400/2C model is a versatile and robust machine that can handle all your vacuum packing requirements.The IPM 400/2C is equipped with powerful vacuum pumps that can remove up to 99.9% of the air from your products' packaging. This ensures that your products are well preserved and protected from harmful bacteria and other contaminants that can affect their quality and freshness.Our double chamber vacuum sealer is easy to operate and comes with user-friendly controls that allow for the efficient and precise calibration of the sealing parameters. The machine's construction also makes it easy to clean and maintain, ensuring a longer lifespan and optimal performance.Our vacuum packing machines are an excellent investment for businesses looking to improve their packaging and storage processes. They offer numerous benefits, including:1. Improved product quality - Vacuum packing removes air, which can cause oxidation and spoilage, extending the shelf life, and preserving your products' quality.2. Enhanced product hygiene - Vacuum packed products are less prone to contamination, ensuring that your products remain safe and free from bacteria and other harmful microorganisms.3. Reduced storage space - Vacuum packing compresses products, reducing their size, and enabling you to store more products in a smaller space.4. Increased efficiency - Double chamber vacuum sealers like our IPM 400/2C, allow for faster and more efficient packaging, reducing labor costs, and enhancing productivity.In conclusion, the benefits of vacuum packing cannot be overstated. And, if you're in the market for a reliable and efficient double chamber vacuum sealer, look no further than Phoenix Dison Tec LLC. Our IPM 400/2C model is of the highest quality and is designed to meet the needs of every industry. Invest in one today and improve your business's packaging and storage processes.

New Automated Machine Streamlines Candy Packaging Process

In a bid to keep up with the rising demand for candy packaging solutions, one innovative company has introduced a new candy packing machine to the market. With robust technology and a host of state-of-the-art features, this machine is poised to revolutionize the candy packaging industry.At the core of this groundbreaking new product is its unprecedented ability to streamline the candy packaging process. The machine boasts an automated packing system that rapidly and efficiently packs candy into various packaging applications. This is made possible by the machine's highly advanced sensors which detect the presence of candy and its corresponding packaging, selecting the appropriate packaging solution and ensuring it is filled accurately.The overall design of the candy packing machine is also noteworthy. It is sleek and compact, allowing it to take up relatively little space on the factory floor. This is especially advantageous for candy manufacturers who may have limited space to work with. Additionally, the machine is incredibly easy to use, minimizing the need for staff training.The candy packing machine also comes equipped with a number of impressive safety features designed to minimize the risk of accidents on the factory floor. These include sensors that detect any potential hazards and stop the machine immediately to prevent injury. The machine also has an easy-to-access maintenance system that helps keep it running smoothly while minimizing any potential downtime.As a result of its advanced technology, the candy packing machine has been shown to dramatically improve productivity levels. In fact, it is capable of packing several thousand bags of candy per hour. This makes it an ideal solution for candy manufacturers who are looking to ramp up their output while maintaining consistent-quality packaging.To further enhance its appeal, the candy packing machine has been designed to be as environmentally-friendly as possible. This is achieved through its use of low-energy consumption and eco-friendly packaging applications. As sustainability becomes an increasingly important priority for many businesses, this unique approach may help the machine gain a competitive edge in the market.The company behind the candy packing machine has a long history of innovation and customer satisfaction. They are committed to developing cutting edge technology that can help businesses improve efficiency, cut costs and increase output. With a range of other products available, including food packaging machines, weighing systems and more, this company is well-equipped to offer comprehensive packaging solutions to businesses of all sizes.Already, the candy packing machine has received high praise from industry leaders, many of whom are excited about its potential to improve productivity and revolutionize the candy packaging industry. As the demand for candy continues to grow, driven in part by the continued popularity of sweet treats, exponential growth in the industry is expected to continue. This means that the need for reliable, high-quality packaging solutions will only increase, making the candy packing machine an even more attractive investment for businesses.Overall, the introduction of the candy packing machine is a significant development in the candy packaging industry. It addresses many of the challenges that candy manufacturers face today, from limited space on the factory floor to the need for greater efficiency and productivity. With its advanced technology, robust safety features, and eco-friendly packaging applications, the candy packing machine is poised to become a game-changer in the industry. The future of candy packaging, it seems, is looking sweet indeed.

Upgrade Your Packaging System with the Latest Multihead Weigher Technology

In today's fast-paced world, businesses need to keep up with the latest technologies to stay ahead of the competition. In the food industry, packaging machines play a crucial role in ensuring efficiency, accuracy, and product quality. One machine that has been making waves in the industry is the multihead weigher packing machine.A multihead weigher packing machine is a device that accurately weighs products and packages them in bags or containers. This machine features multiple weigh scales that work together to fill and package a predetermined quantity of product. The machine is well suited to packaging food products such as cereals, snacks, chips, nuts, and frozen foods.Various industries can use multihead weighing packing machines to lift package speed, accuracy, and efficiency. For this reason, many businesses are gravitating towards this innovative packaging solution. One manufacturer in particular, {manufacturer’s name}, has made significant strides in this arena, making high-quality packing machines that are easy to operate and maintain.{Manufacturer’s name} is a reliable, premium manufacturer of industrial packaging machines with over 20 years of experience in the food packaging industry. The company’s focus on product research and design has resulted in the creation of a wide range of advanced, highly reliable machines.One of its most popular products is the multihead weigher packing machine. With over 3000 installations worldwide, {manufacturer’s name} is committed to providing machines that accurately package different types of products at high speeds.A significant advantage of {manufacturer’s name} packing machines is their compact design, which minimizes product waste and reduces the machine's footprint. Additionally, the machines are easy to set up and maintain, making them ideal for businesses of any size.{Manufacturer’s name} is committed to continuously improving its products to meet the changing needs of the industry. Therefore, the company invests heavily in research and technology to make more useful, faster, and more efficient machines.With high-speed operations and an advanced control system, the {manufacturer’s name} multihead weigher packing machine can package up to 120 bags per minute. The machine's accuracy is further enhanced by the presence of an advanced weighing system that accurately measures each product's weight, bringing precision and consistency to the packaging process.In addition to consistent packaging, {manufacturer’s name}'s machines can provide businesses with many other benefits. For example, the machines promote hygiene since you can opt for machines that meet the requirements of lean production or safety measures. This eliminates concerns about product contamination, thereby creating a safer work environment.{Manufacturer’s name} machines are also designed to deliver a hassle-free operating experience. For instance, the HMI interface makes it easy for operators to control the machine, select packages, and adjust the weight parameters. The interface is modern, intuitive, and customizable, allowing users to program the machine to meet specific packaging needs.Finally, {manufacturer’s name}'s machines are versatile and can package a wide range of products, including fragile items, sticky products, and even liquids. This flexibility makes the machines ideal for businesses that produce different product types that require different packaging needs.In conclusion, businesses in the food manufacturing industry considering upgrading their packaging equipment ought to consider the benefits of employing the modern multihead weigher packing machines. By investing in machines such as those from {manufacturer’s name}, which offers high-quality, efficient, and dependable systems, businesses can streamline their packaging processes, minimize waste, and promote operational excellence.The company's 20 years of experience in the industry, innovative design, and reliable customer support make {manufacturer’s name} the preferred choice for businesses of all sizes seeking advanced technology and sophisticated packaging solutions. As a result, any entrepreneur who values the efficient industrial process, customer satisfaction, and product quality should consider this company's products.

Efficient and Intelligent Sealing Machine for Hot Selling in 2020 - Perfect for Honey Spoon Filling and Sealing - Purchase Now!

In today's fast-paced world, time is of the essence. This is especially true in the food industry, where products need to be processed quickly and efficiently without compromising on quality. As such, the demand for advanced sealing machines is on the rise, with many manufacturers investing in high-efficiency systems to streamline their production processes. The Full Automatic Intelligent Sealing Machine is one such system that has gained popularity in recent times. This state-of-the-art machine boasts a range of features that make it a top choice for manufacturers even in a highly competitive market. One of the most impressive features of this machine is its intelligence. It comes with a touch control type intelligent operation panel, which makes it easy to use even for operators who may not have prior experience. The PLC (Programmable Logic Controller) control system is another key feature that contributes to its efficiency. This advanced system helps to regulate the sealing process, ensuring that it is consistent and reliable. The Full Automatic Intelligent Sealing Machine is also designed to take up minimal space, making it ideal for small factories and production lines. Its compact design does not compromise on performance, however, as it can handle a variety of sealing tasks with ease. It can seal a range of products, including honey, yogurt, jam, and sauces. Another great feature of this machine is its ability to use independent sealing films. This ensures that each container is sealed tightly, reducing the chances of spillage or contamination. Additionally, the sealing machine is equipped with a safety device that automatically stops the machine in case of any malfunctions or errors. This feature helps to protect both the product and the operator, making it a safe and reliable choice for any food processing facility. In conclusion, the Full Automatic Intelligent Sealing Machine is a top-of-the-line device that combines efficiency, intelligence, and safety. With its compact design and reliable performance, manufacturers can increase their output while maintaining the quality of their products. It is no wonder why it is one of the most sought-after sealing machines on the market today. If you are looking to streamline your production processes and boost your business, the Full Automatic Intelligent Sealing Machine is definitely worth considering. And with the inclusion of keywords such as "Intelligent Can Sealing Machine," you can be sure that your blog post will be easily discoverable on search engines.

High Quality Automatic Packing Machines for Food and Other Products

In today's fast-paced world, the demand for cutting-edge technology is increasing rapidly. People are always looking for ways to make their lives more convenient, and this includes the way they buy and consume food. Packaging plays a critical role in this, and it is more important than ever before to have efficient and reliable food packaging machines.Wenzhou Huaqiao Packing Machine Factory is one such manufacturer that has made a name for itself in the food packaging industry. As a professional manufacturer of vacuum packers, automatic food packing machines, sealing machines for bags, carton sealers, cup sealers, thermal shrink tunnel machines, and date printers, the company has been providing top of the line packaging products since its inception.With years of experience and a team of highly skilled professionals, Wenzhou Huaqiao Packing Machine Factory has refined its manufacturing process to deliver machines that are highly efficient, reliable, and user-friendly. Their machines have become a staple in many businesses, including food processing plants, supermarkets, and cafes.The automatic food packing machine is one of the many products that Wenzhou Huaqiao offers. It is designed to pack food automatically, taking the hassle out of the process and saving valuable time and labor costs. The machine can handle a wide range of food products, from fresh fruits and vegetables to meats, dairy products, and more.The automatic food packing machine works by feeding the food product into the machine, where it is sealed in a bag and then vacuum packed. The machine is equipped with state-of-the-art sensors that ensure the packaging process is accurate, efficient, and consistent. This ensures that the food is packed with precision and is safe for consumption.Another product that Wenzhou Huaqiao offers is the vacuum packer. It is designed to extend the shelf life of food products by removing all the air from the packaging. This not only keeps the food fresh but also prevents the growth of bacteria, which can cause the food to spoil.The vacuum packer is a versatile machine that can handle a variety of food products, including dry goods, meats, and even liquids. The machine is easy to operate and comes with a user-friendly interface that is designed to minimize downtime.In addition to the vacuum packer and automatic food packing machine, Wenzhou Huaqiao also provides a range of sealing machines for bags, carton sealers, cup sealers, thermal shrink tunnel machines, and date printers. These machines are designed to meet the unique needs of different businesses and provide an all-in-one solution for packaging requirements.Wenzhou Huaqiao has built a reputation for itself as a company that provides high-quality packaging machines at competitive prices. Their commitment to quality, innovation, and customer satisfaction is what sets them apart from the competition. Their machines not only meet but exceed industry standards, ensuring that their clients get the best value for their money.In conclusion, the demand for efficient and reliable food packaging machines is increasing worldwide. Wenzhou Huaqiao Packaing Machine Factory has been providing top quality packaging products for years. Their machines are user-friendly, efficient, and innovative, making them an ideal choice for businesses in the food industry. With a team of experienced professionals, the company ensures that they meet and exceed their clients' expectations in every way possible.

How to Choose and Use a Commercial Gummy Making Machine

Commercial Gummy Making Machine Revolutionizes Candy ProductionCandies come in various shapes, sizes, and flavors, but nothing beats the timeless chewy gummy candy. Gummy candy has been a favorite among kids and adults alike, and it is not going away anytime soon. The love for gummy candies is what has led to the development of the Commercial Gummy Making Machine. This innovative candy production machine has revolutionized the manufacturing process of gummy candies while enhancing the overall quality of production.The Commercial Gummy Making Machine is a unique machine that is designed to streamline the production process of gummy candies for manufacturers, confectioners, and retailers. With this machine, candy production has never been more efficient and cost-effective. Furthermore, the Gummy Making Machine allows the candy producer to customize the candies, by incorporating a variety of colors, shapes, and flavors.The Commercial Gummy Making Machine, created by a dedicated team of engineers, has been the result of years of research and investment. The machine is designed to be user-friendly while incorporating cutting-edge technology to deliver high-quality gummy candy. The machine boasts a range of features that make it the go-to solution for manufacturers worldwide.The structure of the Commercial Gummy Making Machine is sturdy, durable, and compact, which makes it perfect for small and medium-sized manufacturing companies. The gummy candy making machine comes in different production capacities, adjustable according to the company’s production needs. The production capacity ranges from a low of 20 kg/hour to a high of 300 kg/hour.Another unique feature of the Commercial Gummy Making Machine is the ability to produce different shapes and sizes of gummy candies. The machine is capable of creating a wide range of shapes, such as cubes, worms, bears, fruit slices, and much more. An impressive feature of this machine is that it can produce gummy candies in different colors while keeping the texture and taste consistent.In the candy manufacturing business, quality is of utmost importance. The Commercial Gummy Making Machine is designed to deliver the highest quality of gummy candies possible. By using advanced technologies such as automated feeding systems, vacuum cooking, and a perfect blending system, the gummy candy machine ensures the consistency of the final product. The result is gummy candies that are visually appealing, and most importantly, meet the strict quality standards of food safety regulatory bodies globally.The Commercial Gummy Making Machine comes with many benefits to its users that go beyond its impressive capabilities. The machine caters to manufacturers of different sizes, ensuring that everyone has a chance to create high-quality gummy candies. The increased efficiency and productivity that comes with the machine help to save time and reduce costs that would otherwise be incurred by hiring more employees to handle the production of gummy candies. Furthermore, the machine is easy to operate, reducing training costs for new staff members on the production line.In conclusion, the Commercial Gummy Making Machine is a game-changer in the candy manufacturing industry. It is not just about the production of high-quality gummy candy, but it offers a plethora of benefits that make it the perfect investment for candy manufacturers worldwide. With its versatility, durability, and cost-effectiveness, the machine has proven to be a worthy addition to any candy manufacturing line. Furthermore, the machine has been tested and approved, meeting the highest safety standards set by regulatory bodies globally. With the Gummy Making Machine, manufacturers and confectioners can produce gummy candies faster, more efficiently, and most importantly, with an exceptional level of quality. The Commercial Gummy Making Machine is a must-have investment for all candy manufacturers looking to take their production to the next level.

Create Your Own Chocolate with a DIY Chocolate Making Machine!

Homemade Chocolate Machine Takes the World by StormThere's nothing quite like the taste of fresh, homemade chocolate, and now with the introduction of the latest chocolate machine, anyone can create their own delectable treats at home. Baseless, the company behind this new innovation, has developed a device that takes the hassle out of making chocolate from scratch, and provides users with an enjoyable and interactive experience.The machine, which cannot be named for legal reasons, allows users to customize the ingredients they use and have full control over the entire chocolate-making process. The device can also be used for making a range of different desserts, such as truffles or chocolate bars. The machine's compact size means that it can easily fit into any kitchen, and its intuitive controls make it user-friendly for everyone."We wanted to create something that was fun to use, allowed people to be creative, and offered a chance to learn something new. Our Homemade Chocolate Machine fits the bill perfectly", said a Baseless spokesperson.One of the most exciting aspects of the machine is the level of control it provides users over their chocolate-making process. They can choose the type of chocolate they want to make, such as dark or milk, and choose the ingredients they want to use, such as nuts or fruit. The machine then guides them through the various stages, from grinding the cocoa beans to tempering the chocolate to achieve the perfect consistency.The machine is both time-saving and convenient, making it the perfect addition to a busy, modern lifestyle. It eliminates the need for complicated equipment such as double boilers, and the long, messy process of tempering chocolate on the stovetop. Instead, users can create their own professional-quality chocolate in just a few hours.Since its launch, the Homemade Chocolate Machine has been met with great enthusiasm from both amateur and professional pastry chefs from around the world. It has received a string of positive reviews for its ease of use, versatility, and professional-grade results."I've been looking for a high-quality chocolate machine that can make a range of different chocolates and desserts to add to my repertoire. The Homemade Chocolate Machine ticks all the boxes and more!" said famed pastry chef, Max M. "It's perfect for home use, yet produces results that are on par with professional standards."The Homemade Chocolate Machine is sure to appeal to anyone who loves chocolate and wants to make their own treats. It's also a perfect gift for chocolate lovers and budding pastry chefs alike. The machine retails at $299 and is available for purchase through Baseless's website.Baseless is a company that specializes in developing innovative appliances for home cooks and food enthusiasts. It's a relatively new company, having been established in 2015, but has quickly gained a reputation for producing high-quality, user-friendly products. The company's focus is on creating appliances that make cooking and baking more accessible and enjoyable for everyone. Baseless also prides itself on using only high-quality materials in its products and ensuring that they are durable and long-lasting. The company is committed to providing excellent customer service and offers a two-year warranty on all of its products. The release of the Homemade Chocolate Machine is sure to be the first of many innovative products to come from Baseless. With a solid reputation and loyal following, Baseless is poised to become a leading player in the home appliance industry.

Efficient and Automated Sandwich Packaging Machine Revolutionizes Industry

Title: Cutting-edge Sandwich Packaging Machine Revolutionizes Food Packaging IndustryIntroduction:Innovative packaging solutions have been a cornerstone of the rapidly evolving food industry. As consumers demand convenience without compromising on quality, sandwich packaging machines have emerged as a vital component in streamlining food packaging processes. {} is at the forefront of this revolution, introducing a state-of-the-art sandwich packaging machine that will transform the way sandwiches are packaged and produced.The Revolutionary Sandwich Packaging Machine:{} unveils its latest cutting-edge sandwich packaging machine, which promises to optimize the packaging process for sandwich manufacturers. This innovative machine incorporates the latest technological advancements, ensuring unmatched efficiency, speed, and quality.Compared to traditional packaging methods, this machine employs intelligent automation, enhancing accuracy and reducing human error. Its fully automated process starts with precise ingredient placement, followed by proper sealing of the sandwich. It then individually packs each sandwich offering full tamper-proof protection. This eliminates the need for manual labor-intensive processes and significantly increases production capacity.Key Features and Advancements:This sandwich packaging machine is equipped with several groundbreaking features that set it apart from its predecessors:1. Advanced Ingredient Placement System:The machine utilizes a highly efficient ingredient placement system, ensuring that the desired quantities of different ingredients are uniformly spread across the sandwich. This system guarantees consistency in every sandwich, providing customers with a superior taste experience while minimizing ingredient wastage.2. Versatile Sealing Mechanism:The packaging machine employs a versatile sealing mechanism that adapts to various types of bread, ensuring effective sealing regardless of shape or size. This flexibility allows for the packaging of a wide range of sandwich varieties, catering to diverse customer preferences.3. Smart Tamper-Proof Packaging:{}'s sandwich packaging machine incorporates intelligent tamper-proof packaging, assuring customers of the sandwich's authenticity and the manufacturer's commitment to food safety. This feature provides an added layer of security, boosting consumer confidence in the brand.4. Enhanced Efficiency and Speed:With automated processes, this machine significantly reduces the time required for sandwich packaging. It boosts production capacity, meeting the growing demand in the market, and allowing manufacturers to deliver their products to consumers in a timely manner.5. Minimal Maintenance and Downtime:The sandwich packaging machine is designed with durability and reliability in mind. Its robust construction ensures minimal maintenance requirements, with routine checks and servicing efficiently carried out. This reduces downtime, allowing manufacturers to focus on uninterrupted production.Impact on Sandwich Manufacturers and Consumers:The introduction of {}'s sandwich packaging machine has the potential to bring substantial benefits to both sandwich manufacturers and consumers:1. Streamlined Operations and Increased Profitability:By automating the packaging process, sandwich manufacturers can optimize their operations, reducing production costs and labor requirements. This enables them to allocate resources more efficiently, ultimately increasing profitability.2. Consistent Quality and Enhanced Shelf Life:The advanced ingredient placement system ensures consistent quality across sandwiches, improving overall customer satisfaction. Additionally, the tamper-proof packaging extends the sandwich's shelf life, maintaining freshness and reducing waste.3. Improved Food Safety Measures:The intelligent tamper-proof packaging offers an additional layer of protection against contamination. It reassures consumers about the uncompromised safety standards followed by the manufacturer, fostering trust and loyalty.Conclusion:{}'s groundbreaking sandwich packaging machine signifies a significant development in the food packaging industry. The incorporation of innovative features, automation, and intelligent systems not only revolutionize the sandwich manufacturing process but also enhance the overall experience for both manufacturers and consumers. As the demand for convenient and high-quality food products continues to rise, this cutting-edge sandwich packaging machine is poised to set new industry standards and pave the way for future advancements.

Revolutionary Packing Machine: Streamline Your Packaging Process with Cutting-Edge Technology!

Title: Cutting-Edge Packaging Solutions Arrive in the MarketIntroduction:In today's fast-paced world, efficient and reliable packaging solutions have become paramount. One such groundbreaking product hitting the market is a highly advanced packaging machine, aiming to revolutionize the industry by providing unmatched efficiency and productivity. Combining cutting-edge technology with years of expertise, this revolutionary packaging solution guarantees to streamline operations, improve product quality, and enhance overall customer satisfaction. Let us dive deeper into the attributes of this pioneering packaging machine.Advanced Technology and Features:Introducing an innovative packaging machine that integrates state-of-the-art technology, this industry-leading solution presents several remarkable features. By leveraging advanced sensors and artificial intelligence, the machine ensures precise and consistent measurements, minimizing wastage and maximizing product efficiency. Additionally, the packaging process is effortless and swift, allowing for increased productivity and reduced labor costs.High Customizability:One of the key highlights of this packaging machine is its adaptability to various packaging requirements. From adjustable sealing depths to variable packing speeds, it effortlessly caters to the diverse packaging needs of different industries. This versatility brings a whole new level of convenience and efficiency to businesses of all sizes, especially in the food and consumer goods sectors.Uncompromised Quality:Taking product safety and quality to heart, this revolutionary packaging machine guarantees exceptional standards. By meticulously monitoring each step of the packaging process, it ensures optimal seal integrity, thereby prolonging product shelf life and minimizing potential spoilage. The machine also boasts user-friendly controls, allowing operators to check and adjust parameters accurately, ensuring consistent packaging quality.Streamlined Maintenance:Recognizing the importance of reducing downtime, the creators of this packaging equipment have developed an intuitive maintenance system. Regular maintenance checks are simplified through an integrated diagnostic tool. Integrated self-cleaning mechanisms further enhance the machine's longevity and eliminate the time-consuming cleaning processes typically associated with such equipment.Energy Efficiency:In line with evolving environmental concerns, this pioneering packaging machine has been engineered to prioritize energy efficiency. Cutting-edge thermal insulation materials minimize heat loss, while smart energy management systems optimize power consumption. These eco-conscious features not only reduce operational costs but also contribute to a greener and more sustainable future.Enhanced Safety Measures:Safety is of paramount importance in any manufacturing process, and this packaging machine ensures a secure working environment for operators. Equipped with comprehensive safety measures, including advanced sensors and emergency stops, the machine minimizes potential accidents and promotes occupational safety. Additionally, it adheres to international safety standards, ensuring compliance with regulatory requirements.Industry Applications and Future Prospects:With its vast range of capabilities and customizable features, this innovative packaging machine finds applications in various industries. From food and beverage packaging to pharmaceutical and personal care products, its versatility appeals to an array of businesses. Additionally, the machine's ability to adapt to emerging packaging trends positions it as a promising investment for the future.Conclusion:In a rapidly evolving market, businesses must stay ahead of the curve by embracing cutting-edge technologies. The forthcoming packaging machine sets a new standard for efficiency, quality, and sustainability. It represents a significant advancement in the industry and aims to revolutionize packaging operations. By streamlining processes, improving product quality, and minimizing waste, this innovation will undoubtedly shape the future of packaging.