Innovative Soft Candy Making Machine for Efficient Production

By:Admin

Innovative technology has always been a driving force behind the evolution of industries, and the confectionery sector is no exception. With the introduction of the revolutionary Soft Candy Making Machine by an industry-leading company in confectionery equipment manufacturing, the production process for soft candies has been completely transformed.

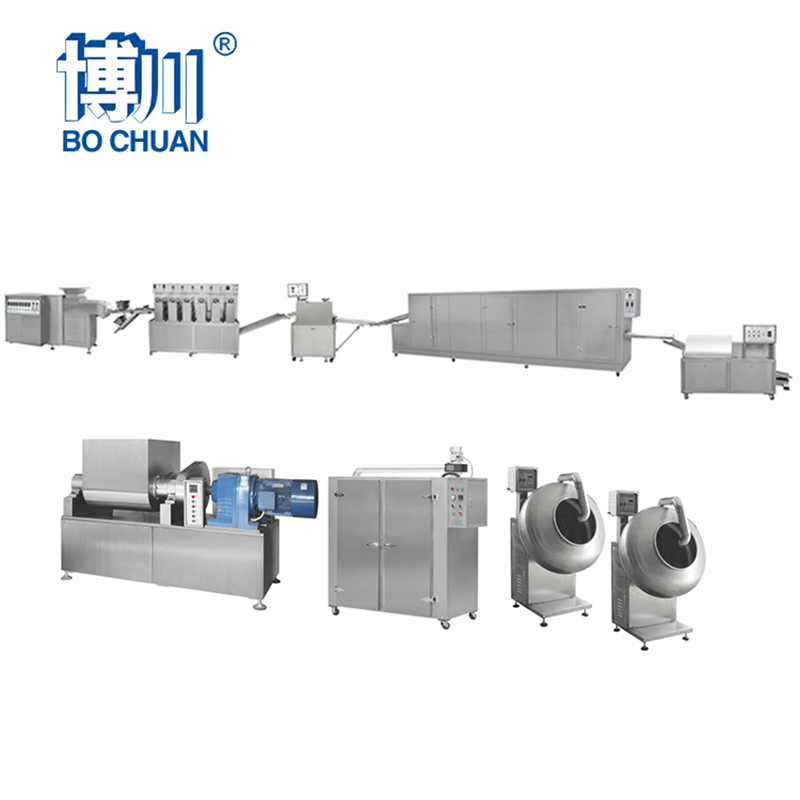

The Soft Candy Making Machine represents a breakthrough in the confectionery industry with its advanced capabilities and cutting-edge features. The machine is designed to streamline the production process, increase efficiency, and enhance the quality of soft candies. It is equipped with state-of-the-art automation technology, allowing for precise control and consistency in the manufacturing process.

The company behind this groundbreaking machine has been a pioneer in the confectionery equipment industry for over two decades. With a strong focus on innovation and continuous improvement, the company has established itself as a trusted and reliable provider of high-quality confectionery equipment.

The Soft Candy Making Machine is a testament to the company's commitment to delivering innovative solutions that meet the evolving needs of the confectionery industry. By leveraging their expertise and technical know-how, the company has succeeded in developing a machine that not only meets industry standards but also sets a new benchmark for soft candy production.

One of the standout features of the Soft Candy Making Machine is its flexibility and versatility. It is capable of producing a wide range of soft candies, including gummies, jellies, and chewy candies, with varying shapes, sizes, and flavors. This flexibility allows confectionery manufacturers to cater to diverse consumer preferences and market demands, giving them a competitive edge in the industry.

Furthermore, the machine is designed for easy operation and maintenance, making it accessible to both small-scale and large-scale confectionery producers. Its user-friendly interface and intuitive controls ensure that operators can quickly adapt to the machine, reducing the learning curve and streamlining production processes.

In addition to its advanced capabilities, the Soft Candy Making Machine also prioritizes food safety and hygiene. It is constructed with food-grade materials and is equipped with sanitary design features to ensure that the production environment remains clean and free from contaminants. This emphasis on food safety reflects the company's dedication to upholding the highest quality standards in confectionery manufacturing.

The introduction of the Soft Candy Making Machine has been met with enthusiasm and praise from industry professionals and confectionery manufacturers worldwide. Its ability to enhance production efficiency, improve product quality, and offer flexibility has positioned it as a game-changer in the confectionery equipment market.

With the Soft Candy Making Machine, the company has once again demonstrated its commitment to driving innovation and shaping the future of confectionery manufacturing. As consumer preferences and industry trends continue to evolve, the company remains at the forefront of the industry, continuously developing solutions that empower confectionery manufacturers to thrive in a competitive market.

In conclusion, the Soft Candy Making Machine represents a significant advancement in confectionery equipment technology, offering a range of benefits for confectionery manufacturers. With its advanced capabilities, user-friendly design, and commitment to food safety, the machine is poised to revolutionize the production process for soft candies. As the industry continues to embrace new technologies, the Soft Candy Making Machine sets a new standard for confectionery equipment, reaffirming the company's position as a leader in the industry.

Company News & Blog

How to Make Lollipop Candy with a Candy Making Machine

Lollipop Candy Making Machine Revolutionizing the Confectionery IndustryIn recent years, the confectionery industry has seen a significant shift towards automation and technological advancements. One company that has been at the forefront of this change is {Company X}, a leading manufacturer of confectionery production equipment. With their innovative approach and cutting-edge technology, {Company X} has been revolutionizing the way lollipop candies are made with their state-of-the-art Lollipop Candy Making Machine.The Lollipop Candy Making Machine is a marvel of engineering and design, capable of producing high-quality lollipop candies with unparalleled efficiency and precision. This advanced machine is equipped with a range of features that make it stand out from traditional candy making equipment. From precision temperature control to automated molding and wrapping, the Lollipop Candy Making Machine streamlines the entire production process, allowing confectionery manufacturers to significantly increase their productivity and output.One of the key features of the Lollipop Candy Making Machine is its versatility. Unlike traditional candy making equipment, which is limited in its capabilities, this innovative machine can produce a wide variety of lollipop shapes, sizes, and flavors, allowing confectionery manufacturers to cater to diverse consumer preferences and market demands. With its adaptable design and customizable settings, the Lollipop Candy Making Machine offers unmatched flexibility and production capabilities.In addition to its technical capabilities, the Lollipop Candy Making Machine is also designed with sustainability in mind. {Company X} is committed to minimizing the environmental impact of their equipment, and the Lollipop Candy Making Machine is no exception. With energy-efficient operation and minimal waste generation, this advanced machine helps confectionery manufacturers reduce their carbon footprint and contribute to a more sustainable future.Furthermore, {Company X} provides comprehensive support and training for the Lollipop Candy Making Machine, ensuring that their clients can maximize the potential of this innovative equipment. From installation and setup to ongoing maintenance and technical assistance, {Company X} is dedicated to helping confectionery manufacturers integrate the Lollipop Candy Making Machine seamlessly into their production processes and achieve the highest levels of efficiency and quality.The impact of the Lollipop Candy Making Machine extends beyond just the confectionery industry. By enabling manufacturers to automate and optimize their production processes, this advanced machine has the potential to create new opportunities for business growth and innovation. With increased production capacity and the ability to deliver a wider range of lollipop candies to the market, confectionery manufacturers can expand their product offerings and reach new consumer segments, driving economic growth and industry advancement.In conclusion, the Lollipop Candy Making Machine from {Company X} represents a significant advancement in confectionery production technology. With its cutting-edge features, versatility, and sustainability, this innovative machine is reshaping the way lollipop candies are made and setting new standards for efficiency and quality in the industry. As {Company X} continues to push the boundaries of confectionery equipment technology, the future looks bright for the confectionery industry, with the prospect of further innovation and growth on the horizon.

Top Carton Sealing Machine in 2021: A Complete Guide

As the demand for efficient and reliable packaging solutions continues to rise, {Company Name} is proud to introduce its latest innovation, the Carton Sealing Machine. This cutting-edge piece of machinery boasts state-of-the-art technology and is set to revolutionize the packaging industry.{Company Name} has been a leading provider of packaging solutions for over 20 years, specializing in the design and manufacture of high-quality machinery for various industries. With a strong dedication to innovation and customer satisfaction, the company has earned a reputation for delivering top-of-the-line products that meet the evolving needs of its clients.The Carton Sealing Machine is the latest addition to {Company Name}'s extensive product lineup, and it is poised to make a significant impact in the packaging market. Designed to streamline the carton sealing process, this advanced machine offers unparalleled speed, accuracy, and reliability. With its automated operation and user-friendly interface, the Carton Sealing Machine is capable of sealing a high volume of cartons with minimal human intervention, thus optimizing efficiency and reducing labor costs for businesses.One of the key features of the Carton Sealing Machine is its versatility. Equipped with adjustable settings and customizable options, the machine can accommodate a wide range of carton sizes and specifications, making it suitable for diverse packaging operations. Whether it's for a small-scale business or a large industrial facility, the Carton Sealing Machine is adaptable to meet the unique demands of any operation.Furthermore, the Carton Sealing Machine is built to withstand the rigors of continuous use. Constructed with durable materials and precision engineering, this robust machine offers long-term reliability and minimal maintenance requirements, ensuring consistent performance and longevity. This durability translates to cost savings for businesses, as they can count on the Carton Sealing Machine to deliver consistent results over an extended period.In addition to its exceptional performance, the Carton Sealing Machine is designed with safety in mind. Equipped with advanced safety features and emergency stop mechanisms, the machine prioritizes the well-being of its operators and the surrounding environment. This commitment to safety reflects {Company Name}'s dedication to providing not only efficient, but also responsible solutions for its customers.As the global packaging industry continues to evolve, {Company Name} remains at the forefront of innovation, driving progress through its cutting-edge technologies and unwavering commitment to excellence. The introduction of the Carton Sealing Machine is a testament to the company's vision of empowering businesses with advanced and reliable packaging solutions that enhance their productivity and competitiveness in the market.With its track record of delivering superior products and unparalleled customer service, {Company Name} is poised to set new standards with the Carton Sealing Machine, offering a game-changing solution that redefines the way cartons are sealed. As the industry looks toward the future, {Company Name} is dedicated to continuing its legacy of innovation and leadership, positioning itself as a trusted partner for businesses seeking to elevate their packaging capabilities.

Highly Efficient Hot Air Sealing Machine for Industrial Use

Hot Air Sealing Machine Revolutionizes Packaging IndustryIn a rapidly evolving world, the packaging industry is always looking for new and innovative ways to improve efficiency and quality. One company at the forefront of this evolution is {Company Name}, a leading manufacturer of hot air sealing machines. These machines have revolutionized the packaging industry by providing a faster, more efficient, and cost-effective sealing solution for a wide range of products.With a commitment to providing cutting-edge technology and outstanding customer service, {Company Name} has become a trusted partner for businesses across the globe. Their hot air sealing machines are designed to meet the diverse needs of the packaging industry, from small-scale operations to large-scale production facilities.The key to the success of {Company Name}'s hot air sealing machines is their advanced technology and precision engineering. These machines are equipped with state-of-the-art heating elements and temperature control systems, ensuring a consistent and reliable sealing process. Furthermore, their user-friendly interface and customizable settings make them easy to operate and adjust according to specific sealing requirements.One of the key advantages of {Company Name}'s hot air sealing machines is their versatility. These machines can be used to seal a wide variety of materials, including plastic, paper, and fabric. Whether it's sealing bags, pouches, or other types of packaging, {Company Name} has a solution for every application.In addition to their technical capabilities, {Company Name}'s hot air sealing machines are also designed with efficiency in mind. By utilizing hot air technology, these machines can achieve faster sealing speeds and higher throughput compared to traditional sealing methods. This not only saves time but also reduces operating costs, making them a cost-effective choice for businesses.Furthermore, {Company Name} takes pride in providing exceptional customer support. Their team of experts is dedicated to understanding the specific needs of each client and providing personalized solutions to meet those needs. From installation and training to ongoing technical support, {Company Name} is committed to ensuring the success of their customers.The impact of {Company Name}'s hot air sealing machines on the packaging industry has been significant. Businesses that have adopted these machines have seen improvements in productivity, product quality, and overall cost savings. With the ability to seal a wider range of materials at faster speeds, these machines have helped companies stay competitive in a fast-paced market.Looking ahead, {Company Name} continues to push the boundaries of innovation in the packaging industry. They are constantly researching and developing new technologies to further enhance their hot air sealing machines and meet the evolving needs of their customers. With a focus on quality, efficiency, and customer satisfaction, {Company Name} is poised to remain a leader in the packaging industry for years to come.In conclusion, the hot air sealing machines offered by {Company Name} have set a new standard for the packaging industry. With their advanced technology, versatility, and commitment to customer satisfaction, these machines have revolutionized the way products are sealed and packaged. As the industry continues to evolve, {Company Name} is well-positioned to lead the way with their innovative solutions.

and Flexible Packaging.In the world of packaging, there have been many advancements over the years that have revolutionized the industry. One of the most significant changes in recent years has been the shift towards flexible packaging. Flexible packaging is a type of packaging that is made from materials that are more pliable than traditional rigid materials, such as glass or metal. Instead, flexible packaging is made from materials such as plastic, paper, and foil.One of the key benefits of flexible packaging is the decreased carbon footprint. Because flexible packaging is lighter and more compact than rigid packaging, it requires less energy to transport and store. This means that less fuel is needed to transport products, resulting in a lower carbon footprint for the company using flexible packaging.Another benefit of flexible packaging is the savings on shipping and storage. Because flexible packaging is lighter and more compact, it takes up less space in warehouses and on trucks. This means that companies can store more products in a smaller space, reducing the need for additional storage facilities or trucks.Flexible packaging also offers a more prominent shelf-presence. Because it can be easily molded and shaped, it can be designed to stand out on store shelves. This makes it easier for consumers to find the products they are looking for and can increase sales for the company.Finally, flexible packaging offers a larger canvas for automatic packing machine. Because it can be easily printed on, it can be used to showcase the brand’s message or to provide additional information about the product. This can help to differentiate the product from its competitors and can create a stronger brand identity in the minds of consumers.Overall, the benefits of using flexible packaging are clear. Whether you are in the food industry, the cosmetics industry, or any other industry that requires packaging, flexible packaging can help you to reduce your carbon footprint, save money on shipping and storage, increase sales, and create a stronger brand identity. So if you haven’t already, consider making the switch to flexible packaging for your automatic packing machine needs.

Idli and Dosa Gain Popularity in UAE During Pandemic Due to Indian CEO's Efforts

Idli and dosa are two of the most popular dishes in Indian cuisine. They are not just popular in India, but also among millions of Indians all around the world. And when it comes to Idli and Dosa, one name that surely comes to mind is P.C Musthafa, the CEO and co-founder of a popular Indian food brand.Musthafa has been instrumental in introducing the traditional Indian idli and dosa to the UAE market, and his food brand has seen a huge growth opportunity in this region. During the pandemic, the consumption of idli and dosa has surged in UAE homes, and this has presented a great opportunity for Musthafa to expand his business.One of the things that sets Musthafa's food brand apart from others is the fact they offer ready-made idli and dosa batter packing covers. These ready-made batter covers have become very popular among people who don't have the time or expertise to prepare the batter from scratch.This has allowed people to enjoy authentic Indian idli and dosa in the comfort of their own home, without the need for any special skills or equipment. The batter packing covers are made with high-quality ingredients, and they are easy to use, making it a hit among busy professionals and families alike.Apart from the batter packing covers, Musthafa's food brand offers a wide range of Indian food products that are made using traditional recipes and ingredients. The company has taken great care to ensure that their products are of the highest quality, and they have built a strong reputation for offering authentic Indian food products in the UAE.Musthafa's vision of promoting Indian cuisine in the UAE has been successful, and his food brand has become a trusted name in the region. As the demand for Indian food products continues to grow, Musthafa is all set to expand his business even further, and the future looks very promising.In conclusion, the popularity of idli and dosa in UAE homes is a testament to the growing demand for Indian cuisine in the region. With his high-quality food products and innovative ideas like ready-made batter covers, P.C Musthafa is sure to continue taking his food brand to new heights of success and popularity. So, if you're a fan of Indian food, be sure to check out Musthafa's food brand and enjoy the authentic taste of India.

Packaging Equipment Market Witnessing Growth and Innovation: Key Insights into Modern Solutions

Packaging Equipment Provider Delivers Unmatched Quality and EfficiencyFor businesses of all sizes, the right packaging equipment can be a game-changer. With the right tools, companies can streamline their packaging processes and quickly scale their operations. Enter Packaging Equipment Provider, a leading provider of high-quality packaging equipment for businesses of all sizes.With a range of packaging equipment solutions, including sealing machines, strapping machines, and carton sealing machines, the Packaging Equipment Provider has been delivering unmatched quality and efficiency to a wide range of clients. From small businesses to large corporations, their machines are designed to streamline packaging processes, reduce downtime, and improve overall efficiency.But what makes the Packaging Equipment Provider stand out from the crowd?First and foremost, the company is committed to delivering the highest quality equipment to their clients. All of their machines are built with premium materials and are designed to last, ensuring that your packaging process never misses a beat.Furthermore, the Packaging Equipment Provider understands that every business has unique packing needs. As such, they offer customized solutions for clients, tailoring their machines to fit each client's specific needs. With an experienced team of engineers and technicians, the company can create packaging equipment solutions that perfectly meet their clients' requirements.But the company goes beyond just delivering excellent products. Superior customer service and support are hallmarks of the Packaging Equipment Provider. From the first inquiry to post-installation support, their team is committed to providing the best possible experience for their clients.One of the Packaging Equipment Provider's satisfied clients is a large food manufacturer in the United States. The company sought to streamline its packaging process by implementing an automated carton sealing solution. With the help of the Packaging Equipment Provider, the company implemented an innovative solution with a carton sealing machine that could handle different sized boxes quickly and efficiently.According to the company's spokesperson, "the machine has transformed our packaging process, greatly reducing our downtime and labor costs. The Packaging Equipment Provider team worked closely with us to understand our unique needs and delivered a customized solution that perfectly met our requirements."Whether it's sealing machines, strapping machines, or carton sealing machines, the Packaging Equipment Provider delivers best-in-class solutions for businesses. Their commitment to quality, customization, and excellent customer service sets them apart from the competition.The company's spokesperson added, "We are passionate about delivering the best possible packaging equipment solutions to our clients. Our goal is to help businesses of all sizes streamline their packaging process, reduce downtime, and improve overall efficiency."With the Packaging Equipment Provider on your side, you can be sure that your packaging process is in good hands. The company's commitment to quality, customization, and customer service ensures that you get the best possible solutions for your business's packaging needs. So, whether you're a small business just starting or a large corporation looking to scale, the Packaging Equipment Provider has got you covered.

High-Quality Cardboard Packaging for Sandwiches Extends Shelf Life

Sandwich packing is a crucial aspect of any sandwich making operation. Whether you run a small sandwich shop or a large-scale food manufacturing unit, you need to ensure that your product remains fresh and appetizing for as long as possible. This requires the use of high-quality sandwich packaging materials and sealing machines that can provide the perfect seal, thus prolonging the shelf life of your sandwiches.One such sealing machine that stands out in the market today is the Enterpack sandwich sealing machine. This unique and innovative machine has been designed to provide the perfect seal for your sandwiches, thereby prolonging their shelf life by up to three days. The Enterpack sandwich packaging system is compatible with a wide range of cardboard sandwich packaging, making it an ideal choice for sandwich makers who place a high value on quality.Unlike plastic containers that are commonly used in sandwich packaging, cardboard sandwich packs are much higher in quality. They offer superior insulation, which protects the sandwiches from moisture, heat, and UV light, all of which contribute to food spoilage. Cardboard sandwich packaging is also much more environmentally friendly, as it can be easily disposed of and recycled.Using the Enterpack sandwich sealing machine, you can seal any type of sandwich, from cold and hot sandwiches, wraps, paninis, baguettes, and more. The machine comes with adjustable sealing and cutting functions to accommodate different sandwich sizes and shapes. This makes it an ideal machine for businesses with a diverse sandwich production line.In addition to ensuring the freshness and quality of your sandwiches, cardboard sandwich packaging provided by Enterpack also serve as an excellent marketing tool. They can be customized with your brand colors, logo, and tagline, thus promoting your brand to potential customers. This can be particularly useful for businesses that rely on takeout and delivery services, where customers are more likely to judge the quality of the food by its packaging.Overall, the Enterpack sandwich sealing machine is a must-have for any sandwich maker who values quality, freshness, and sustainability. It offers a cost-effective and efficient way of prolonging the shelf life of your sandwiches, while also providing an excellent marketing opportunity. So whether you are running a small sandwich shop or a large-scale food manufacturing unit, be sure to invest in the Enterpack sandwich sealing machine for all your sandwich packaging needs.Keywords: Sandwich Sealer Machine, Enterpack sandwich packaging system, cardboard sandwich packs, plastic containers, sandwich making operation, sandwich packaging materials, food spoilage, environmentally friendly, adjustable sealing and cutting functions, sandwich production line.

Automated Cotton Candy Machines: Making Sweet Treats Faster and Easier Than Ever Before

Cotton Candy Machine Revolutionizes the Art of Sugar-SpinningCatering to the ever-growing demand for delicious treats at parties, events, and amusement parks, an innovative company has developed a cutting-edge Cotton Candy Machine Automatic. With its sleek design and advanced features, this state-of-the-art device promises to revolutionize the art of sugar-spinning, offering an unforgettable culinary experience.Cotton candy, also known as fairy floss or candy floss, has been a beloved sweet treat for generations. The process of creating these fluffy confections involves melting and spinning sugar, resulting in delicate webs of sugary delight. Traditionally, cotton candy was made by hand, requiring skill and dexterity to produce the perfect fluffy texture. However, with the new Cotton Candy Machine Automatic, this process becomes significantly more efficient and accessible to all.Featuring a compact and user-friendly design, this innovative machine is perfect for both professional caterers and enthusiastic amateurs alike. With just a click of a button, the Cotton Candy Machine Automatic begins its mesmerizing sugar-spinning process. The device combines a built-in heater that quickly melts the sugar with a high-powered fan that propels the spun sugar into delicate candy floss wisps.One of the standout features of this revolutionary machine is its ability to produce cotton candy in a variety of flavors and colors. The company offers a wide range of pre-packaged sugar flavors, including classics like raspberry and blueberry, as well as more exotic options like bubblegum and passion fruit. This allows users to customize their cotton candy creations to suit any taste or event theme.In addition to its versatility, the Cotton Candy Machine Automatic also boasts several safety features to ensure worry-free operation. Equipped with an automatic shut-off mechanism, the machine will power down when it reaches a certain temperature to prevent overheating. This feature not only protects the device but also provides peace of mind for the users, allowing them to focus on serving up sugary goodness without any concerns.Moreover, this innovative device is easy to clean and maintain, thanks to its removable components that are dishwasher-safe. The machine's detachable spinning head and collection tray can be quickly disassembled and cleaned, ensuring a hygienic experience for every batch of cotton candy produced.The company behind this groundbreaking creation, known for its dedication to quality and innovation, has been a leading force in the confectionery industry for several decades. With a strong commitment to customer satisfaction, they have successfully developed a range of cutting-edge devices that cater to the needs of professional chefs and home cooks alike. Their goal is to consistently provide culinary tools that combine functionality, ease of use, and impeccable design.Recognizing the need for efficiency and convenience in the cotton candy industry, this forward-thinking company invested significant time and resources in research and development to create the Cotton Candy Machine Automatic. By harnessing the power of technology and utilizing high-quality materials, they have succeeded in developing a machine that promises to reshape the way cotton candy is made and enjoyed.Industry experts and enthusiasts have already expressed their excitement for this groundbreaking product. With its sleek design, advanced features, and unparalleled ease of use, the Cotton Candy Machine Automatic is poised to become the new standard in the world of sugar-spinning. As more and more individuals and businesses seek to provide unique and memorable culinary experiences, this cutting-edge device is set to lead the way, satisfying the sweet tooth of every customer it serves.

Innovative Dry Fruit Packing Machine: Streamline Your Packaging Process

ABC Company is proud to announce the launch of their latest innovation, the Dry Fruit Packing Machine. This state-of-the-art machine is designed to revolutionize the way in which dry fruits are packed and processed, offering a range of benefits for both manufacturers and consumers.The Dry Fruit Packing Machine is equipped with the latest technology and features advanced automation capabilities, ensuring a high level of precision and efficiency in the packing process. With its ability to handle a wide range of dry fruits, including almonds, cashews, and pistachios, the machine is versatile and adaptable to the needs of different manufacturers.One of the key features of the Dry Fruit Packing Machine is its ability to maintain the freshness and quality of the dry fruits throughout the packing process. This is achieved through the use of advanced sealing and packaging techniques, which help to preserve the flavor, texture, and nutritional value of the fruits. As a result, consumers can enjoy the convenience of pre-packed dry fruits without compromising on quality.In addition to its packing capabilities, the Dry Fruit Packing Machine is also designed with efficiency in mind. Its high-speed operation and seamless integration with other production line equipment ensure that manufacturers can meet the demands of a fast-paced industry. This not only improves productivity but also reduces the overall cost of production.Furthermore, the machine is designed with user-friendly controls and interfaces, making it easy for operators to set up, monitor, and adjust the packing process as needed. This reduces the need for extensive training and streamlines the overall operation of the machine.ABC Company has a long-standing reputation for delivering high-quality and reliable packaging solutions to the food industry. With over 20 years of experience in the field, the company has built a strong foundation of expertise and innovation, continually striving to meet the evolving needs of their clients.Their commitment to excellence is evident in the design and development of the Dry Fruit Packing Machine. The company's team of engineers and technicians have dedicated themselves to creating a machine that not only meets industry standards but also sets new benchmarks for quality, reliability, and efficiency.ABC Company's dedication to sustainable practices is also reflected in the design of the Dry Fruit Packing Machine. The machine is built with energy-efficient components and materials, aiming to minimize its environmental impact while maximizing its performance. This aligns with the company's mission to contribute to a more sustainable and responsible food industry.As the global demand for packaged dry fruits continues to grow, the launch of the Dry Fruit Packing Machine comes at a critical time. With its innovative features and advanced technology, the machine is well-positioned to meet the needs of manufacturers seeking to streamline their production processes and deliver high-quality products to consumers.ABC Company is excited to introduce the Dry Fruit Packing Machine to the market and looks forward to the positive impact it will have on the industry. With its combination of precision, efficiency, and sustainability, the machine is set to become a game-changer in the world of dry fruit packaging.

Blister Packing Machines: Emerging Trends and Advancements in Research and Clinical Applications by 2031

Blister packing machines are an essential piece of equipment used in the pharmaceutical industry. They are used to package drugs and medical devices in a manner that is sterile, secure, and easy to handle. In recent years, the global blister packing machine market has grown significantly, and it is expected to continue to grow in the coming years. One of the primary factors driving the growth of the blister packing machine market is the increasing demand for innovative packaging solutions. As the pharmaceutical industry continues to evolve, there is a need for new packaging technologies that can provide better protection for drugs and medical devices. Blister packing machines are known for their ability to create a secure and tamper-evident packaging solution that is also easy to open.Another factor contributing to the growth of the blister packing machine market is the increasing demand for personalized medicine. As more and more drugs are customized to meet the needs of individual patients, the packaging requirements for these drugs also become more complex. Blister packing machines are capable of producing customized packaging solutions that meet the unique needs of each patient.The blister packing machine market is also benefiting from advances in technology. Many blister packing machines now feature advanced automation and control systems that enable them to operate more efficiently and produce higher quality packaging. Additionally, the development of new materials and coatings has improved the durability and shelf life of blister packaging.Some of the key players in the blister packing machine market include SaintyCo, Bosch Packaging Technology, Sonoco Products Company, Marchesini Group S.p.A., Uhlmann Pac-Systeme GmbH & Co. KG, and CAM Packaging Solutions. These companies are investing heavily in research and development to create new and innovative blister packing machines that can meet the evolving needs of the pharmaceutical industry.Looking ahead, it is clear that the blister packing machine market will continue to grow and evolve in the coming years. As new drugs and medical devices are developed, there will be an increasing need for customized packaging solutions that can provide the necessary protection and security. Blister packing machines will remain a key technology in the pharmaceutical industry, and the companies that innovate and adapt will be well-positioned to succeed in this growing market.In conclusion, Bqs blister packing machines are an essential component in the pharmaceutical industry. The market for blister packing machines is expected to continue to grow due to the increasing demand for innovative packaging solutions, personalized medicine, advances in technology, and the need for better protection and security for drugs and medical devices. With the investments made by key players like SaintyCo, Bosch Packaging Technology, and Sonoco Products Company, the future of blister packing machines looks bright.