Innovative Candy Production Machine Making Waves in the Market

By:Admin

In the world of confectionery, the production of candy has always been a delicate and intricate process. From the mixing of ingredients to the shaping and packaging of the final product, candy production requires a high level of precision and efficiency. This is where the renowned candy production machine manufacturer comes in.

For over a decade, [Company Name] has been a leader in the design and manufacturing of high-quality candy production machines. The company has gained a strong reputation in the industry for delivering reliable, efficient, and innovative equipment that meets the needs of candy producers worldwide. With a strong focus on research and development, [Company Name] has consistently pushed the boundaries of candy production technology.

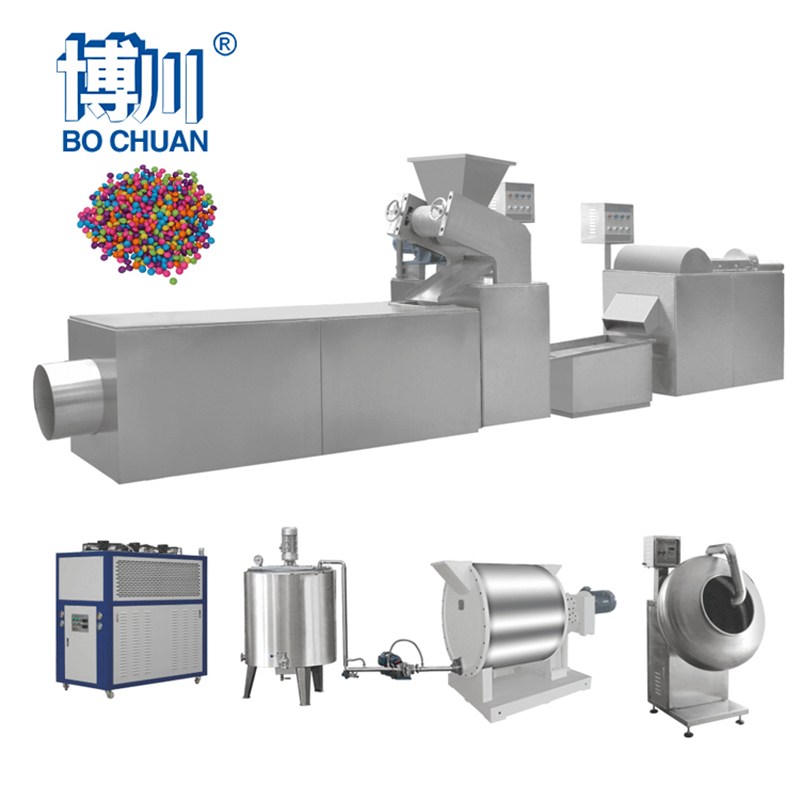

Today, [Company Name] is proud to introduce its latest innovation – a state-of-the-art candy production machine that is set to revolutionize the way candies are manufactured. This new machine boasts cutting-edge technology and features that are designed to streamline the entire candy production process, from start to finish.

One of the key highlights of this new candy production machine is its advanced mixing system. Equipped with precision control and a range of mixing options, this system ensures that the ingredients are perfectly blended to achieve the desired taste and texture of the candies. This level of control and consistency is crucial in producing high-quality candies that satisfy consumers' palates.

In addition to its mixing capabilities, the new candy production machine also features a highly efficient shaping and molding system. This system is designed to produce a wide variety of candy shapes and sizes, giving producers the flexibility to create unique and eye-catching confections. Furthermore, the machine's state-of-the-art packaging system ensures that the finished candies are neatly and securely packed, ready for distribution to retailers and consumers.

To complement its cutting-edge technology, the new candy production machine is also equipped with an intuitive and user-friendly interface. This allows operators to easily monitor and adjust the machine's settings, making it simple to fine-tune the production process and maintain consistent quality standards.

Commenting on the launch of the new candy production machine, [Company Name]’s CEO expressed his excitement and pride in the company's latest achievement. He stated, "We are thrilled to introduce this groundbreaking candy production machine to the market. The technology and features incorporated into this machine represent the culmination of years of hard work and dedication from our team. We believe that this new machine will set a new standard for candy production, offering producers the efficiency and reliability they need to succeed in today's competitive market."

In line with its commitment to innovation and customer satisfaction, [Company Name] has also made it a priority to provide comprehensive after-sales support for its new candy production machine. The company offers on-site installation and training, as well as ongoing technical assistance and spare parts availability, ensuring that its customers can maximize the performance and lifespan of the equipment.

As the global demand for high-quality candies continues to grow, [Company Name] remains dedicated to driving the advancement of candy production technology. With the introduction of its new state-of-the-art candy production machine, the company is poised to further solidify its position as a leading provider of innovative and reliable equipment for the confectionery industry.

Company News & Blog

Quality Hard Candy Making Equipment for Sale

Hard Candy Making Equipment Reinvents the Confectionery IndustryIn today's fast-paced and ever-evolving confectionery industry, the demand for high-quality hard candy production is on the rise. With consumers becoming more discerning in their tastes, it is crucial for confectionery manufacturers to invest in state-of-the-art equipment to meet the growing market demands. This is where the innovative hard candy making equipment from a leading global supplier comes into play. With a rich history of providing top-notch confectionery manufacturing solutions, this company has become a trusted name in the industry. Their commitment to excellence and continuous innovation has allowed them to stay ahead of the curve, offering cutting-edge equipment that is revolutionizing the way hard candy is made.The hard candy making equipment from this company is designed to streamline the production process, allowing confectionery manufacturers to create high-quality hard candies with maximum efficiency. By leveraging the latest technology and precision engineering, the equipment is able to deliver consistent results, ensuring that every piece of candy meets the highest standards of quality and taste.One of the key features of this hard candy making equipment is its versatility. With the ability to produce a wide range of hard candy shapes, sizes, and flavors, manufacturers have the flexibility to meet the diverse needs of today's market. Whether it's traditional round candies or custom-shaped confections, this equipment can handle it all, giving manufacturers the freedom to bring their creative visions to life.Moreover, the equipment is also designed with ease of use in mind. Intuitive controls and user-friendly interfaces make operation straightforward, allowing manufacturers to focus on the art of candy making without being weighed down by complex machinery. This streamlined approach not only increases productivity but also reduces the need for extensive training, ultimately saving time and resources for confectionery companies.In addition to its cutting-edge capabilities, the hard candy making equipment is also engineered for durability and reliability. Built with robust materials and precision components, the equipment is designed to withstand the rigors of continuous production, ensuring that it operates at peak performance with minimal downtime. This level of dependability is essential for manufacturers looking to meet the demands of a competitive market without compromising on quality.Furthermore, the company stands behind its equipment with a comprehensive support network. From installation and training to ongoing maintenance and technical assistance, manufacturers can rely on the company's expertise every step of the way. This commitment to customer satisfaction underscores the company's dedication to being a true partner in the success of its clients.As the confectionery industry continues to evolve, the demand for high-quality hard candies will only continue to grow. With the innovative hard candy making equipment from this leading global supplier, confectionery manufacturers now have the tools they need to meet this demand head-on. By investing in this state-of-the-art equipment, manufacturers can elevate their production capabilities and stay ahead in a competitive market, ultimately reshaping the confectionery landscape for years to come.

Top Candy Bar Making Machines for Your Business

Candy Bar Making Machines: The Latest Innovation in Confectionery ProductionIn the world of confectionery production, the demand for candy bars continues to remain high. With consumers constantly seeking new and innovative flavors and textures, manufacturers are under pressure to keep up with the latest trends. This has led to the development of cutting-edge candy bar making machines, which are revolutionizing the way these popular treats are produced.One company at the forefront of this technological innovation is {company name}, a leading manufacturer of confectionery production equipment. With a history of over 50 years in the industry, {company name} has established itself as a trusted provider of high-quality machinery and solutions for candy production. Their candy bar making machines are designed to streamline the production process, improve efficiency, and ultimately deliver a superior product to consumers.The candy bar making machines developed by {company name} are equipped with state-of-the-art technology that enables manufacturers to create a wide variety of candy bar shapes, sizes, and flavors. Whether it's a traditional chocolate bar, a nougat-filled delight, or a crunchy nut-filled treat, these machines are capable of producing them all with precision and consistency. This level of flexibility allows confectionery producers to meet the diverse preferences of their customer base and stay ahead of the competition.One of the key features of {company name}'s candy bar making machines is their ability to ensure food safety and quality. With strict adherence to industry regulations and standards, these machines are designed to maintain hygienic conditions throughout the production process. This is essential in the confectionery industry, where consumer trust and confidence in the safety of the products are paramount. By investing in {company name}'s candy bar making machines, manufacturers can rest assured that their products meet the highest standards of quality and safety.Furthermore, these machines are built to maximize production efficiency, thus reducing operational costs and increasing overall profitability. With automated processes and precise control systems, {company name}'s candy bar making machines minimize waste and optimize raw material usage. This not only benefits the bottom line of confectionery producers but also contributes to a more sustainable and environmentally friendly approach to production.To complement their cutting-edge technology, {company name} offers comprehensive support and maintenance services for their candy bar making machines. Their team of experts is dedicated to ensuring that their customers can operate their equipment at peak performance at all times. From installation and training to ongoing technical assistance, {company name} is committed to providing a seamless experience for their clients.In addition to their focus on technological innovation and customer support, {company name} places a strong emphasis on research and development. They are constantly exploring new ways to improve their machines and develop new solutions to meet the evolving needs of the confectionery industry. This commitment to innovation has cemented {company name}'s position as a leader in the field of candy bar making machines.As the confectionery industry continues to evolve, the demand for high-quality candy bars remains unabated. Thanks to companies like {company name}, manufacturers now have access to advanced machinery that can streamline production, ensure product quality, and ultimately meet the needs of consumers. With their state-of-the-art candy bar making machines, {company name} is shaping the future of confectionery production and driving the industry towards new heights of success.

Delicious Candy Manufacturing Process Unveiled

article.Candy Production Industry – A Sweet Business!Candies have always been an integral part of our lives. From childhood to adulthood, these sweet treats have never failed to bring a smile to our faces. The candy production industry is one of the oldest and most successful industries across the world, with numerous players offering sweet delights to their customers. Amongst all, one name stands out - {brand name removed} - a company that has been satisfying the sweet cravings of people for over 100 years.{Brand name removed} is a leading candy production company that has come a long way since its inception in 1909. The company has its headquarters in (location) and has always been focused on producing the highest quality sweets for their customers. {Brand name removed} believes in innovation and has continuously experimented with new flavors, colors, and shapes to cater to different tastes and preferences.The candy production industry is highly competitive, and {brand name removed} has always stayed ahead of the game with its unique approach to candy-making. The company produces a wide range of products, including gummies, hard candies, and chocolate bars, among others. Each of these products is made with the finest ingredients and with the utmost care, which is why {brand name removed} has become a household name across the globe.It takes a lot of effort and dedication to produce the perfect candy, and {brand name removed} takes this very seriously. The company's manufacturing process is of the highest standard, and it ensures that all its products are free from artificial colors, allergens, and genetically modified organisms. {Brand name removed} has also invested in state-of-the-art technology that guarantees consistency, flavor, and texture across all its candy products.In addition to producing high-quality sweets, {brand name removed} is also dedicated to sustainable candy production. The company ensures that all its manufacturing processes are sustainable and minimize waste. From using eco-friendly packaging to reducing greenhouse gas emissions, the company is committed to protecting the environment. {Brand name removed} also believes in ethical business practices and follows fair-trade policies to ensure that all its ingredients are sourced responsibly.The candy production industry has faced several challenges in recent times, with the outbreak of the COVID-19 pandemic affecting businesses across the world. However, {brand name removed} has been able to stay afloat and has even managed to boost candy sales during these difficult times. The company has adopted online sales channels and has also focused on innovative marketing strategies to engage with their customers.As lockdowns and travel restrictions have affected many people's ability to go out and socialize, {brand name removed} has introduced virtual tasting sessions, where their customers can experience their products from the comfort of their own homes. The company has also offered special discounts and promotions to keep their sales going during these tough times.In conclusion, the candy production industry is a sweet business, and {brand name removed} has proven to be a leader in this field. With its commitment to high-quality, sustainable, and ethical candy production, the company has set a benchmark for others to follow. Its dedication to innovation and its customer-centric approach have allowed {brand name removed} to stay ahead of the curve, even amidst challenging times. We look forward to seeing what the company has in store for us in the future and what new sweet treats we can expect from them.

High-quality Air Tight Packing Machine for Efficient Packaging

Air Tight Packing Machine Revolutionizes Food PackagingIn today's fast-paced world, consumers are increasingly drawn towards convenience. As a result, food packaging needs to keep up with the demand for products that are not only convenient but also fresh and long-lasting. This is where the Air Tight Packing Machine, developed by a leading packaging solution company, comes into play.The Air Tight Packing Machine is revolutionizing the way food is packaged, ensuring that it stays fresh for longer periods of time. This innovative machine utilizes state-of-the-art technology to create an airtight seal around food products, preserving their quality and extending their shelf life.{Company Name} is dedicated to providing cutting-edge packaging solutions for a wide range of industries. With a focus on innovation and quality, the company has established itself as a leader in the packaging industry. The Air Tight Packing Machine is just one example of {Company Name}'s commitment to developing advanced packaging technology that meets the evolving needs of consumers and businesses alike.The Air Tight Packing Machine is designed to cater to the specific packaging requirements of food products, ensuring that they remain fresh and free from contaminants. The machine utilizes a combination of vacuum and gas flushing technology to create a hermetic seal, preventing oxygen and moisture from compromising the quality of the packaged food items. This not only extends the shelf life of the products but also reduces the need for preservatives, making it an ideal solution for health-conscious consumers.One of the key benefits of the Air Tight Packing Machine is its ability to package a wide variety of food products, including fresh produce, meats, dairy products, and pre-made meals. This versatility makes it an invaluable asset for food manufacturers and retailers looking to extend the shelf life of their products without compromising on quality.Additionally, the Air Tight Packing Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and programmable settings allow for precise control over the packaging process, ensuring consistent and reliable results with every use. This not only streamlines the packaging process but also minimizes the risk of human error, further enhancing the quality and safety of the packaged food products.In addition to its practical benefits, the Air Tight Packing Machine offers environmental advantages as well. By extending the shelf life of food products, it helps to reduce food waste and minimize the environmental impact of food packaging. This aligns with {Company Name}'s commitment to sustainability and responsible business practices, further cementing its position as a leader in the packaging industry.The introduction of the Air Tight Packing Machine marks a significant advancement in food packaging technology, offering a solution that meets the demands of modern consumers and businesses. As the market for convenient, long-lasting food products continues to grow, the need for advanced packaging solutions like the Air Tight Packing Machine will only become more pronounced.With its innovative design, user-friendly features, and environmental benefits, the Air Tight Packing Machine is set to revolutionize the way food is packaged and preserved. {Company Name} continues to lead the way in developing packaging solutions that prioritize quality, efficiency, and sustainability, setting a new standard for the industry as a whole.

How to Make Jelly Chocolate with a Chocolate Making Machine?

Title: Enhanced Confectionery Production: Innovative Jelly Chocolate Making Machine Revolutionizes Treat ManufacturingIntroduction:In a groundbreaking endeavor to enhance the confectionery manufacturing process, a leading company in the food processing industry has developed an innovative Jelly Chocolate Making Machine. The technologically advanced equipment is set to revolutionize the production of jelly chocolates, offering a convenient solution for manufacturers to meet increasing consumer demand for their favorite treats.Company Overview:The company behind the development of the Jelly Chocolate Making Machine is a recognized leader in the food processing industry. With a strong commitment to innovation and a dedication to deliver state-of-the-art solutions, the company has consistently introduced cutting-edge technologies to streamline and optimize various food production processes. With a focus on enhancing efficiency, quality, and sustainability, they have successfully revolutionized the way confectionery manufacturers operate globally.The Jelly Chocolate Making Machine:The Jelly Chocolate Making Machine represents the latest addition to the company's impressive portfolio of food processing equipment. Tailored specifically for the production of jelly chocolates, this revolutionary machine boasts exceptional features and functionalities that ensure efficiency, precision, and superior-quality end products.1. Increased Production Capacity:One of the standout features of this cutting-edge machine is its ability to significantly increase the production capacity of jelly chocolates. It utilizes advanced automation technology, offering an unbeatable speed and throughput. With its streamlined processes, manufacturers can now fulfill larger orders without compromising on quality and taste.2. Enhanced Customization Options:The Jelly Chocolate Making Machine offers manufacturers the flexibility to create a wide range of customized jelly chocolates. With adjustable molds, sizes, shapes, and flavors, confectioners can cater to evolving consumer preferences and offer a diverse selection of mouthwatering treats.3. Precise Ingredient Dosage Control:Accurate dosage of ingredients plays a crucial role in ensuring consistent taste and quality. The Jelly Chocolate Making Machine excels in this aspect, employing state-of-the-art sensors and controllers that precisely measure and control the dosage of ingredients. This eliminates any variations in taste and texture, resulting in a uniform product experience for consumers.4. Rapid Production Processes:With the Jelly Chocolate Making Machine, manufacturers can now produce jelly chocolates at an unprecedented pace. The advanced machinery's quick cooling and setting processes significantly reduce production time, enabling confectioners to meet strict deadlines and efficiently respond to high demand.5. Easy Maintenance and Automation:The machine's user-friendly interface and automation capabilities simplify operation and maintenance processes, ensuring even novice operators can efficiently control the production line. Intuitive software controls streamline operations and allow for remote monitoring, further enhancing convenience and productivity.Implications for the Confectionery Industry:The introduction of the Jelly Chocolate Making Machine carries several implications for the confectionery industry:1. Market Competitiveness:Manufacturers equipped with this advanced technology gain a competitive edge by boosting production capacity, fulfilling orders promptly, and staying ahead of the competition.2. Profitability and Cost Efficiency:Enhanced production efficiency and reduced labor requirements contribute to overall cost savings for manufacturers. This increased profitability can be reinvested into further research and development, expansion, and employee welfare.3. Improved Product Quality:The precise ingredient dosage control and streamlined processes ensure consistent taste, texture, and quality, enhancing customer satisfaction and loyalty.4. Meeting Consumer Demand:As the demand for jelly chocolates continues to surge, the Jelly Chocolate Making Machine enables manufacturers to efficiently cater to consumer preferences, diversify their product offerings, and expand their market share.Conclusion:The Jelly Chocolate Making Machine represents a significant leap forward in confectionery manufacturing technology. Its exceptional features and benefits empower manufacturers to meet consumer demand more efficiently, increase profitability, and maintain a competitive edge in the ever-evolving confectionery industry. With this innovation, the company continues to spearhead advancements that revolutionize the way food production processes are approached and executed globally.

Automated Filling and Sealing Machines for Unique Shaped Trays

In today's fast-paced world, candy manufacturers are always on the lookout for efficient and effective ways to package their products. One of the best solutions for this is the candy sealer machine. A candy sealer machine is an automated filling and sealing machine specifically designed for the candy-making industry. It is an innovation that saves time, effort, and money in the packaging process.One such machine is the ORICS S-30 13 heart-shaped candy chocolate tray sealing machine. It is the perfect tool for manufacturers who want to create heart-shaped candy for special occasions such as Valentine's Day. The ORICS S-30 13 system is designed to be manually loaded with chocolate-filled, heart-shaped trays, making it easy and efficient to use for manufacturers.The ORICS S-30 13 system is uniquely designed to handle unusual shapes and sizes of trays. The floating head design ensures that a positive seal is achieved around the entire perimeter of the tray. This innovative design makes it possible to seal not only heart-shaped trays but also other shapes and sizes of containers.One of the best features of the ORICS S-30 13 system is the heat sealing technology. The seal heads only apply heat to the container's flange, ensuring that the product inside the trays remains cool and undamaged. This technique saves money as the entire seal head is not heated, only the area directly over the flange.ORICS products, including the ORICS S-30 13 system, are manufactured in the United States at their Farmingdale, NY facility. This ensures that their products meet the highest standards of quality and are made to last.In conclusion, the ORICS S-30 13 heart-shaped candy chocolate tray sealing machine is an excellent choice for candy manufacturers who want to create unique and beautiful heart-shaped candy products. Its innovative design, convenient and efficient use, and heat sealing technology make it an ideal choice for manufacturers who want to improve their candy packaging process. To know more about ORICS S-30 13 or other ORICS products, contact them at 718-461-8613, visit their website at www.orics.com or email them at [email protected]: Candy Sealer Machine, Automated Filling and Sealing Machine, ORICS S-30 13, Heat Sealing Technology, Unique Design, Efficient Use, High-Quality Manufacturing.

Efficient and Automated Sandwich Packaging Machine Revolutionizes Industry

Title: Cutting-edge Sandwich Packaging Machine Revolutionizes Food Packaging IndustryIntroduction:Innovative packaging solutions have been a cornerstone of the rapidly evolving food industry. As consumers demand convenience without compromising on quality, sandwich packaging machines have emerged as a vital component in streamlining food packaging processes. {} is at the forefront of this revolution, introducing a state-of-the-art sandwich packaging machine that will transform the way sandwiches are packaged and produced.The Revolutionary Sandwich Packaging Machine:{} unveils its latest cutting-edge sandwich packaging machine, which promises to optimize the packaging process for sandwich manufacturers. This innovative machine incorporates the latest technological advancements, ensuring unmatched efficiency, speed, and quality.Compared to traditional packaging methods, this machine employs intelligent automation, enhancing accuracy and reducing human error. Its fully automated process starts with precise ingredient placement, followed by proper sealing of the sandwich. It then individually packs each sandwich offering full tamper-proof protection. This eliminates the need for manual labor-intensive processes and significantly increases production capacity.Key Features and Advancements:This sandwich packaging machine is equipped with several groundbreaking features that set it apart from its predecessors:1. Advanced Ingredient Placement System:The machine utilizes a highly efficient ingredient placement system, ensuring that the desired quantities of different ingredients are uniformly spread across the sandwich. This system guarantees consistency in every sandwich, providing customers with a superior taste experience while minimizing ingredient wastage.2. Versatile Sealing Mechanism:The packaging machine employs a versatile sealing mechanism that adapts to various types of bread, ensuring effective sealing regardless of shape or size. This flexibility allows for the packaging of a wide range of sandwich varieties, catering to diverse customer preferences.3. Smart Tamper-Proof Packaging:{}'s sandwich packaging machine incorporates intelligent tamper-proof packaging, assuring customers of the sandwich's authenticity and the manufacturer's commitment to food safety. This feature provides an added layer of security, boosting consumer confidence in the brand.4. Enhanced Efficiency and Speed:With automated processes, this machine significantly reduces the time required for sandwich packaging. It boosts production capacity, meeting the growing demand in the market, and allowing manufacturers to deliver their products to consumers in a timely manner.5. Minimal Maintenance and Downtime:The sandwich packaging machine is designed with durability and reliability in mind. Its robust construction ensures minimal maintenance requirements, with routine checks and servicing efficiently carried out. This reduces downtime, allowing manufacturers to focus on uninterrupted production.Impact on Sandwich Manufacturers and Consumers:The introduction of {}'s sandwich packaging machine has the potential to bring substantial benefits to both sandwich manufacturers and consumers:1. Streamlined Operations and Increased Profitability:By automating the packaging process, sandwich manufacturers can optimize their operations, reducing production costs and labor requirements. This enables them to allocate resources more efficiently, ultimately increasing profitability.2. Consistent Quality and Enhanced Shelf Life:The advanced ingredient placement system ensures consistent quality across sandwiches, improving overall customer satisfaction. Additionally, the tamper-proof packaging extends the sandwich's shelf life, maintaining freshness and reducing waste.3. Improved Food Safety Measures:The intelligent tamper-proof packaging offers an additional layer of protection against contamination. It reassures consumers about the uncompromised safety standards followed by the manufacturer, fostering trust and loyalty.Conclusion:{}'s groundbreaking sandwich packaging machine signifies a significant development in the food packaging industry. The incorporation of innovative features, automation, and intelligent systems not only revolutionize the sandwich manufacturing process but also enhance the overall experience for both manufacturers and consumers. As the demand for convenient and high-quality food products continues to rise, this cutting-edge sandwich packaging machine is poised to set new industry standards and pave the way for future advancements.

Highly Efficient Manual Packing Machine for Your Production Needs

The demand for efficient and practical packaging solutions has been on the rise in recent years, especially in industries such as food, pharmaceuticals, and consumer goods. To meet this demand, companies are turning to innovative solutions such as the Manual Packing Machine from [Company Name Omitted].The Manual Packing Machine is a versatile and reliable packaging solution that is designed to streamline the packing process for a variety of products. With its user-friendly design and customizable features, it is well-suited for businesses of all sizes, from small startups to large-scale manufacturing facilities.[Company Name Omitted] is a leading provider of packaging solutions, with a strong emphasis on innovation and customer satisfaction. With a proven track record of delivering high-quality products and exceptional service, [Company Name Omitted] has built a strong reputation in the industry.The Manual Packing Machine is the latest addition to [Company Name Omitted]’s extensive line of packaging solutions. It is designed to offer businesses a cost-effective and efficient way to pack their products, helping them to increase productivity and reduce the risk of damage during the shipping process.One of the key features of the Manual Packing Machine is its flexibility. It can accommodate a wide range of products, from small items such as candies and nuts to larger items such as electronic components and hardware. This makes it an ideal solution for businesses that need a versatile packaging machine that can handle different types of products.In addition, the Manual Packing Machine is designed with ease of use in mind. Its user-friendly interface and intuitive controls make it easy for operators to set up and use, reducing the need for extensive training and minimizing the risk of errors during the packing process.Another important feature of the Manual Packing Machine is its durability. Constructed from high-quality materials and precision-engineered components, it is built to withstand the rigors of daily use in a demanding production environment. This ensures that businesses can rely on the Manual Packing Machine to deliver consistent performance and reliability day in and day out.The Manual Packing Machine is also highly customizable, allowing businesses to tailor its features to meet their specific packaging needs. Whether it’s adjusting the packing speed, incorporating specialized labeling options, or integrating with existing production lines, the Manual Packing Machine can be adapted to suit a wide range of requirements.At [Company Name Omitted], customer satisfaction is a top priority. The company provides comprehensive support and technical assistance to help businesses get the most out of their Manual Packing Machine. From initial installation and training to ongoing maintenance and troubleshooting, [Company Name Omitted] is committed to ensuring that its customers have the support they need to maximize the benefits of their packaging solution.With the introduction of the Manual Packing Machine, [Company Name Omitted] is once again demonstrating its commitment to providing innovative and practical solutions to the packaging industry. By combining advanced technology with a focus on user-friendly design and durability, the Manual Packing Machine is set to make a significant impact on businesses looking to improve their packing processes.For businesses seeking a reliable and efficient solution for their packaging needs, the Manual Packing Machine from [Company Name Omitted] offers a compelling option that delivers on both performance and versatility. With its extensive range of features and strong focus on customer satisfaction, it is a clear choice for businesses looking to take their packaging operations to the next level.

Innovative Fruit Jelly Making Machine - A game changer in the food industry

In the fast-paced world of food production, innovation and technology are constantly driving the industry forward. One such innovation that has caught the attention of the food industry is the Jelly Fruit Making Machine developed by an industry leader in food processing equipment. This state-of-the-art machine is revolutionizing the way fruit jelly products are made, offering unparalleled efficiency and quality.The Jelly Fruit Making Machine is a marvel of engineering and design. It is equipped with advanced technology that allows for the precise mixing and cooking of ingredients to create high-quality fruit jelly products. The machine’s automated process ensures consistency and uniformity in the end product, meeting the highest standards of quality and taste.The company behind this groundbreaking machine, with a solid background in the food processing industry, has been at the forefront of innovation and technology. With years of experience in developing and manufacturing food processing equipment, they have earned a reputation for delivering cutting-edge solutions that meet the evolving needs of the food industry. Their commitment to quality, efficiency, and customer satisfaction has made them a trusted name in the industry.The Jelly Fruit Making Machine is the latest example of the company’s dedication to innovation. By leveraging their expertise in food processing technology, they have created a machine that offers unmatched performance and reliability. The machine is designed to meet the demands of large-scale production, making it an ideal solution for food processing companies looking to enhance their production capabilities.One of the key features of the Jelly Fruit Making Machine is its versatility. It is capable of producing a wide range of fruit jelly products, from traditional flavors like strawberry and raspberry to more exotic options like mango and passion fruit. This flexibility allows food producers to cater to diverse consumer preferences, ensuring that they can meet the demands of a dynamic market.Furthermore, the machine’s efficient production process maximizes output while minimizing waste, contributing to a more sustainable and cost-effective production operation. This is in line with the company’s commitment to environmentally friendly and resource-efficient solutions, aligning with the growing emphasis on sustainability in the food industry.The Jelly Fruit Making Machine also prioritizes ease of use and maintenance. Its user-friendly interface and automated operation streamline the production process, reducing the need for manual labor and supervision. Additionally, the machine is designed for easy cleaning and upkeep, minimizing downtime and maximizing productivity.In addition to its technical capabilities, the company provides comprehensive support services to ensure that their customers can make the most of the Jelly Fruit Making Machine. From installation and training to ongoing maintenance and troubleshooting, they are dedicated to providing end-to-end support that enables their customers to achieve optimal performance and results.The introduction of the Jelly Fruit Making Machine is poised to have a significant impact on the food industry. Its advanced technology, efficient production process, and versatility make it a valuable asset for food processing companies seeking to elevate their fruit jelly production. As the industry continues to evolve, this innovative machine exemplifies the power of technology to drive progress and transformation in food production.In conclusion, the Jelly Fruit Making Machine developed by the company is a game-changer for the food processing industry. Its advanced technology, versatility, and efficiency are set to revolutionize the production of fruit jelly products, offering a competitive edge to food processing companies. With a track record of excellence and a commitment to innovation, the company has once again demonstrated its leadership in delivering cutting-edge solutions that meet the evolving needs of the food industry.

Efficient Pedal Sealing Machine for Large Bags

Sealing Machine - Top Maple Sealing Pedal Sealing PedalThe sealing machine industry is one that is continually evolving and advancing with the rise of e-commerce businesses around the world. With the increase of online orders, more companies are investing in sealing machines to improve their operations and the delivery of their products. Top Maple Sealing Pedal Sealing Pedal is a sealing machine that has become popular with businesses due to its top-quality features and affordable price.Top Maple Sealing Pedal Sealing Pedal is an essential tool for different businesses that deal with packaging products. This machine provides an efficient and reliable way to seal bags, pouches, and other packaging materials with ease. The machine makes use of a pedal that allows the operator to seal the bags with both hands, making the process faster and more accurate.One of the outstanding features of the Top Maple Sealing Pedal Sealing Pedal is its speed. The machine is capable of sealing bags at rates of up to eight meters per minute, making it ideal for businesses with high output requirements. The pedal sealer is also very durable and can work for long hours without overheating or developing any mechanical problems.Furthermore, the Top Maple Sealing Pedal Sealing Pedal provides businesses with a cost-effective way to seal their bags and pouches. The machine's design is such that it is easy to maintain and does not require significant maintenance costs. This affordability makes it ideal for businesses operating on a tight budget.In addition to sealing bags and pouches, the machine can be used for other applications, such as sealing big bags. The Big Bag Sealing feature of this product is one that businesses have found increasingly useful in recent years. It allows for the easy sealing of larger bags and packaging materials that would otherwise be difficult to deal with.Top Maple Sealing Pedal Sealing Pedal is a product of a renowned and reputable company in the industry. The company has long been committed to providing quality sealing solutions to businesses worldwide. With years of experience and expertise in the industry, the company has established itself as a leader in the sealing machine market.One of the critical aspects of the company's operations is its commitment to innovation. Over the years, the company has continued to develop new and innovative sealing solutions that meet the ever-changing needs of businesses worldwide. This approach has been instrumental in pushing the sealing machine industry forward and has helped businesses improve their operational efficiency.The company also places a strong emphasis on customer service. It understands that businesses operate in a fast-paced environment where every minute counts. To this end, the company provides timely and effective customer support to ensure that its customers can achieve their goals and objectives.In conclusion, Top Maple Sealing Pedal Sealing Pedal is a high-quality and reliable sealing machine that is ideal for different types of businesses. Its affordable cost, efficient speed, and durability have made it a popular choice among businesses worldwide. Moreover, the product is a testament to the company's commitment to innovation and customer satisfaction. With this product, businesses can improve their operations and meet the ever-changing needs of their customers.