High-Quality Cotton Candy Making Machine for Sale - Complete Guide

By:Admin

The introduction of the Cotton Candy Making Machine by a leading company in the food processing equipment industry is revolutionizing the way cotton candy is made. This state-of-the-art machine is designed to produce high-quality cotton candy quickly and efficiently, making it an ideal choice for businesses looking to meet the demands of a large and diverse customer base.

The Cotton Candy Making Machine is equipped with advanced technology that allows for precise control of the spinning and heating process. This results in cotton candy that is consistently fluffy, flavorful, and visually appealing. In addition, the machine is designed to be easy to operate and maintain, making it a practical choice for businesses of all sizes.

One of the key features of the Cotton Candy Making Machine is its ability to produce a wide variety of cotton candy flavors. This versatility is achieved through the use of specialized sugar blends and flavorings, allowing businesses to offer a diverse range of options to cater to different tastes and preferences. Whether it's classic flavors like strawberry and bubblegum or more unique options like green apple and piña colada, this machine is capable of meeting the demands of even the most discerning cotton candy connoisseurs.

In addition to its innovative technology and versatility, the Cotton Candy Making Machine is also designed with the highest standards of safety and hygiene in mind. The machine is constructed using food-grade materials and is equipped with features that prevent contamination and ensure the cleanliness of the final product. This makes it an ideal choice for businesses that prioritize the health and satisfaction of their customers.

The introduction of the Cotton Candy Making Machine represents a significant advancement in the cotton candy industry. By combining precision engineering, versatility, and safety, this machine is set to become the new standard for businesses looking to produce high-quality cotton candy on a large scale.

Furthermore, the company behind the Cotton Candy Making Machine has a strong reputation for excellence and innovation in the food processing equipment industry. With a track record of providing cutting-edge solutions to businesses around the world, they have established themselves as a leader in the field. Their commitment to quality, reliability, and customer satisfaction makes them the ideal partner for businesses looking to invest in the future of cotton candy production.

In conclusion, the introduction of the Cotton Candy Making Machine by a leading company in the food processing equipment industry represents a significant advancement in the cotton candy industry. With its advanced technology, versatility, and commitment to safety and hygiene, this machine is set to become the new standard for businesses looking to produce high-quality cotton candy on a large scale. As the popularity of cotton candy continues to grow, this innovative machine is poised to play a key role in meeting the demands of a dynamic and evolving market.

Company News & Blog

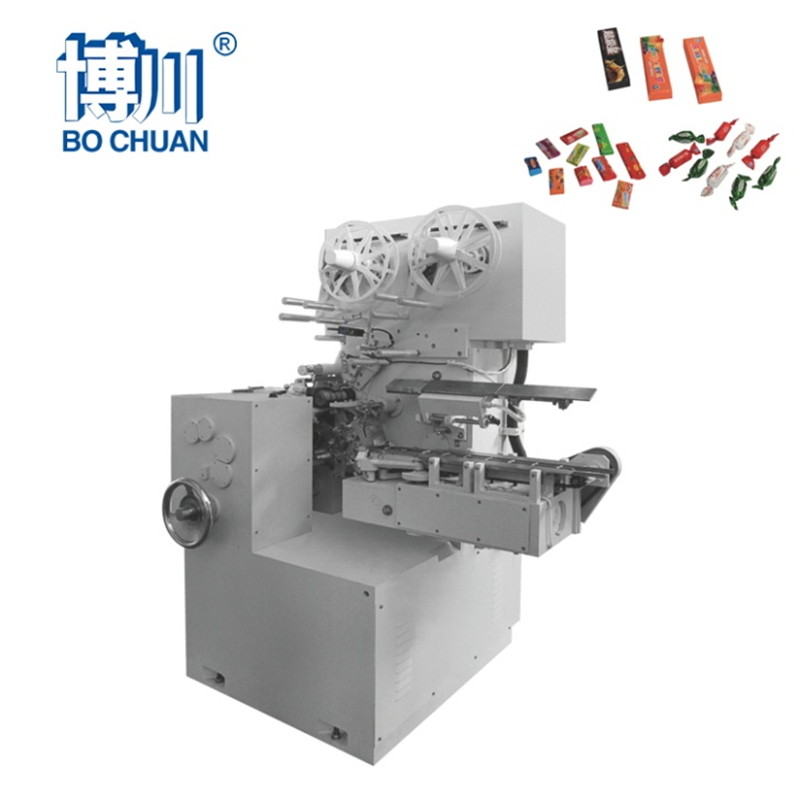

Innovative Candy Packaging Machine Revolutionizes Sweet Treat Production

Candy Packaging Machine: Streamlining Candy ProductionIn the world of confectionery, the demand for innovative and efficient candy packaging solutions is on the rise. To meet this demand, {Company Name}, a leading manufacturer of packaging machinery, has developed a state-of-the-art Candy Packaging Machine that is revolutionizing the way candies are packaged and distributed.With over 20 years of experience in the industry, {Company Name} has earned a reputation for producing high-quality packaging machines that are tailored to the specific needs of their clients. Their Candy Packaging Machine is no exception, as it boasts a range of advanced features that streamline the packaging process and improve overall efficiency.One of the key highlights of the Candy Packaging Machine is its versatility. Designed to accommodate a wide variety of candy shapes and sizes, the machine can handle everything from small, individually-wrapped confections to larger, bulk packaging. This flexibility allows candy manufacturers to package different products on the same machine, reducing the need for multiple packaging lines and increasing overall productivity.In addition to its versatility, the Candy Packaging Machine is also equipped with cutting-edge technology that ensures precise and consistent packaging. Advanced sensors and controls enable the machine to accurately weigh and portion candies, ensuring that each package contains the correct amount of product. This level of precision not only enhances the overall quality of the packaged candies but also minimizes product giveaway, ultimately saving manufacturers money in the long run.Furthermore, the Candy Packaging Machine is designed with user-friendly features that make it easy to operate and maintain. An intuitive touchscreen interface allows operators to adjust settings and monitor the machine's performance with ease. Additionally, the machine is constructed from high-quality materials and components, making it durable and reliable for continuous use in a production environment.With the global demand for candies on the rise, the Candy Packaging Machine is set to become a game-changer for candy manufacturers around the world. By investing in this cutting-edge packaging solution, companies can significantly improve their production efficiency, reduce operating costs, and ultimately gain a competitive edge in the market.{Company Name} is committed to providing exceptional customer service and support, offering comprehensive training and technical assistance to ensure that their clients get the most out of their Candy Packaging Machine. With a global network of sales and service representatives, the company is able to provide prompt and reliable support to their clients, no matter where they are located.In conclusion, the Candy Packaging Machine from {Company Name} represents the next generation of packaging technology for the confectionery industry. With its versatility, precision, and user-friendly design, this innovative machine is poised to revolutionize the way candies are packaged, setting a new standard for efficiency and quality in candy production. As the demand for confectionery continues to grow, the Candy Packaging Machine offers candy manufacturers a competitive advantage, enabling them to meet the needs of the market with ease and confidence.

Top Heat Sealers for Food Packaging to Keep Your Products Fresh

Introducing Innovative Heat Sealers for Food PackagingIn the food packaging industry, the need for effective and efficient packaging solutions is always at the forefront. With the increasing demand for convenience and sustainability, companies are continuously seeking new methods to ensure that their products are packaged securely and attractively. This has led to the development of advanced heat sealing technology, which has revolutionized the way food products are packaged and sealed.One company that has been at the forefront of this innovation is {}. With a long history of providing high-quality packaging solutions, the company has recently introduced a new line of heat sealers that are designed to meet the diverse needs of the food packaging industry. These heat sealers are engineered to provide a secure and airtight seal, keeping food products fresh and safe for extended periods of time.The company's heat sealers are equipped with advanced features that make them ideal for a wide range of food packaging applications. Whether it's for packaging fresh produce, frozen foods, or dry goods, these heat sealers are versatile enough to handle the task with precision and reliability. This versatility is crucial for companies looking to streamline their packaging processes and ensure that their products are delivered to consumers in the best possible condition.One of the key advantages of {}'s heat sealers is their user-friendly design. With intuitive controls and easy-to-use settings, operators can quickly and efficiently seal packages without any hassle. This not only saves time and labor costs but also ensures consistent and reliable sealing results. Additionally, the heat sealers are equipped with safety features to protect operators from potential hazards, making them an ideal choice for busy packaging facilities.In addition to their functionality, {}'s heat sealers are also designed with sustainability in mind. The company is committed to reducing the environmental impact of packaging processes, and their heat sealers are engineered to minimize waste and energy consumption. This is achieved through innovative sealing techniques that optimize material usage and reduce the overall carbon footprint of the packaging process.With the growing emphasis on sustainable packaging solutions, {}'s heat sealers are well-positioned to meet the evolving needs of the food packaging industry. By providing a combination of reliability, efficiency, and sustainability, these heat sealers offer a compelling solution for companies looking to improve their packaging processes and reduce their environmental impact.Furthermore, {}'s heat sealers are backed by the company's extensive support network. From installation and training to ongoing maintenance and technical support, customers can rely on {} to provide the assistance they need to maximize the performance of their heat sealers. This level of support is essential for companies looking to invest in new packaging equipment and ensures that they can maintain peak operational efficiency.As the food packaging industry continues to evolve, the demand for innovative and reliable packaging solutions will only continue to grow. With {}'s heat sealers, companies can stay ahead of the curve by implementing cutting-edge technology that delivers superior sealing performance while also addressing sustainability concerns. By investing in {}'s heat sealers, companies can enhance their packaging processes, reduce their environmental impact, and ultimately deliver better products to consumers.

Durable and Efficient Nylon Sealing Machine for Industrial Use

Nylon Sealing Machine Revolutionizes Packaging IndustryIn today’s fast-paced world, convenience and efficiency are paramount. This is especially true in the packaging industry, where the need for quick and reliable sealing solutions is vital. Recognizing this demand, {{Company Name}} has introduced a cutting-edge Nylon Sealing Machine that is set to revolutionize the industry.The {{Company Name}} Nylon Sealing Machine is a versatile and user-friendly device that is designed to streamline the packaging process. With its state-of-the-art technology and innovative features, this machine is set to become an essential tool for businesses looking to enhance their packaging operations.One of the key features of the {{Company Name}} Nylon Sealing Machine is its ability to seal a wide range of materials, including nylon, polyethylene, and polypropylene. This flexibility makes it an ideal solution for businesses working with various types of packaging materials, allowing them to achieve consistent and reliable seals regardless of the material being used.In addition to its versatile sealing capabilities, the {{Company Name}} Nylon Sealing Machine also boasts a number of user-friendly features that enhance its efficiency and convenience. These include a digital temperature control system, an adjustable sealing time, and a durable sealing blade that ensures precise and secure seals every time.Furthermore, the {{Company Name}} Nylon Sealing Machine is designed with the user in mind, featuring a compact and ergonomic design that makes it easy to operate and maintain. Its robust construction and high-quality components also ensure that it can withstand the rigors of continuous use, making it a reliable and durable investment for businesses of all sizes.With its advanced technology, user-friendly features, and versatile sealing capabilities, the {{Company Name}} Nylon Sealing Machine is set to make a significant impact on the packaging industry. By providing businesses with a reliable and efficient solution for their sealing needs, this innovative machine is poised to improve productivity and enhance the overall packaging process.In addition to its revolutionary Nylon Sealing Machine, {{Company Name}} is a leading provider of a wide range of packaging solutions, including sealing machines, shrink wrap machines, and vacuum sealers. With a commitment to quality and innovation, the company has established itself as a trusted partner for businesses seeking to optimize their packaging operations.With a strong focus on customer satisfaction and continuous improvement, {{Company Name}} is dedicated to providing cutting-edge solutions that meet the evolving needs of the packaging industry. By staying ahead of the curve and embracing the latest technological advancements, the company is well-positioned to drive positive change and innovation within the industry.In conclusion, the {{Company Name}} Nylon Sealing Machine is a game-changing product that is set to redefine the way businesses approach their packaging needs. With its versatile capabilities, user-friendly features, and commitment to quality, this innovative machine is poised to become an essential tool for businesses looking to streamline their packaging operations and achieve greater efficiency and reliability. As {{Company Name}} continues to lead the way in the packaging industry, it is clear that the future of packaging is in good hands.

Efficient and Reliable Packaging Machine for Box Processing

Box Packaging Machine Revolutionizing the Packaging IndustryIn today's fast-paced and highly competitive market, efficient packaging plays a crucial role in ensuring the success and competitiveness of a company. Recognizing this need, [Company Name] has recently introduced an innovative box packaging machine that is revolutionizing the packaging industry. By automating and streamlining the packaging process, this cutting-edge machine is improving productivity, reducing costs, and enhancing overall customer satisfaction.The box packaging machine developed by [Company Name] incorporates state-of-the-art technology and advanced automation features. This machine has the ability to package a wide variety of products, including food items, electronics, pharmaceuticals, and consumer goods, with precision and efficiency. Regardless of the size or shape of the product, this machine can adapt to accommodate various packaging requirements.One of the key advantages of this box packaging machine is its high speed and reliability. With a capacity to package hundreds of boxes per minute, it significantly reduces manual labor and increases productivity. By eliminating human errors and inconsistencies, this machine ensures that each product is packaged accurately and securely, minimizing the risk of damage during transportation.Additionally, this packaging machine stands out due to its versatility and flexibility. It can be easily programmed to handle different box sizes, sealing methods, and labeling options, making it suitable for a wide range of packaging needs. This adaptability greatly benefits businesses that deal with multiple product lines or frequently change their packaging designs.Furthermore, the box packaging machine by [Company Name] prioritizes product safety and hygiene. It includes advanced measures to prevent contamination, such as a sterilization feature and a dust-free packaging environment. This ensures that the packaged products meet the highest quality standards and comply with industry regulations, giving customers peace of mind.Another noteworthy feature of this packaging machine is its user-friendly interface. The machine is equipped with an intuitive control panel that allows operators to easily adjust settings, monitor production, and diagnose any potential issues. Proper training and technical support are offered by [Company Name] to ensure that users obtain optimal performance and fully leverage the capabilities of the machine.Moreover, this box packaging machine incorporates sustainable practices that align with eco-conscious initiatives. It minimizes material waste by optimizing box dimensions and using recyclable packaging materials. By reducing the environmental impact of packaging, [Company Name] demonstrates its commitment to sustainability and corporate social responsibility.The introduction of this innovative box packaging machine has garnered significant attention and appreciation from industry experts. Many leading companies have already adopted this technology, reaping its benefits and experiencing a positive impact on their bottom line. With the increasing demand for efficient packaging solutions, there is no doubt that this machine will continue to disrupt the packaging industry, enabling businesses to achieve higher levels of efficiency, cost savings, and customer satisfaction.In conclusion, [Company Name] has introduced a game-changing box packaging machine that is transforming the packaging industry. Through its advanced technology, high speed, versatility, and sustainable practices, this machine revolutionizes the packaging process for businesses across various sectors. With its positive impact on productivity, cost reduction, and product safety, this packaging machine proves to be an essential tool for companies aiming to stay competitive in today's dynamic market.

Innovative Multihead Weigher Packing Machine for Efficient Packaging

In the world of modern manufacturing and packaging, the Multihead Weigher Packing Machine has become an indispensable tool for companies looking to efficiently and accurately pack their products. These innovative machines utilize advanced technology to precisely measure and dispense products into packaging, increasing productivity and reducing waste. One company that has been at the forefront of this technology is {company name}, a leader in the development and manufacturing of packaging machinery.{Company name} was founded in 2005 and has since established itself as a trusted and reliable provider of packaging solutions for various industries. The company's mission is to deliver high-quality, innovative, and cost-effective packaging machinery that meets the needs of their customers. With a focus on research and development, {company name} has continuously worked to improve their products and stay ahead of the ever-evolving market demands.One of {company name}'s standout products is their Multihead Weigher Packing Machine, which has garnered attention for its superior performance and advanced features. This cutting-edge machine is designed to accurately weigh and dispense a wide range of products, including snacks, nuts, frozen food, and more. The Multihead Weigher Packing Machine is equipped with multiple weigh heads, allowing for simultaneous measurement and dispensing, resulting in increased efficiency and throughput.One of the key features of {company name}'s Multihead Weigher Packing Machine is its precision and accuracy. The machine utilizes advanced technology to ensure that each product is weighed and dispensed with exact measurements, reducing product giveaway and minimizing waste. This level of accuracy is crucial for companies looking to maintain consistency and quality in their packaged products.Additionally, the Multihead Weigher Packing Machine is designed for ease of use and maintenance, incorporating user-friendly controls and easy-to-clean components. This allows companies to maximize their production efficiency while minimizing downtime for cleaning and maintenance.In addition to the Multihead Weigher Packing Machine, {company name} offers a comprehensive range of packaging machinery, including filling machines, sealing machines, and labeling machines. This diverse portfolio allows {company name} to cater to the unique needs of different industries and provide complete packaging solutions for their customers.As a forward-thinking company, {company name} is committed to sustainability and environmental responsibility. Their packaging machinery is designed to minimize material waste and energy consumption, contributing to overall cost savings and reducing their environmental footprint. This aligns with the growing trend of companies seeking eco-friendly packaging solutions to meet the demands of today's conscientious consumer market.In conclusion, {company name} has solidified its position as a frontrunner in the packaging machinery industry, with their Multihead Weigher Packing Machine standing out as a testament to their commitment to innovation and quality. With a focus on precision, efficiency, and sustainability, {company name} continues to pave the way for the future of packaging technology, providing companies with the tools they need to thrive in a competitive market.

Packing Machine Updates: Stay Informed with the Latest News!

Title: Revolutionary Packaging Solution Unveiled: Intelligent Machinery Aims to Transform Packaging IndustryIntroduction:In a bid to revolutionize the packaging industry, a progressive machinery engineering company has launched an innovative packaging solution that promises to streamline and enhance the packing process across various sectors. The newly introduced intelligent machinery, now known as the R-Pack System, aims to redefine the industry's efficiency and productivity, providing businesses with a state-of-the-art solution for their packaging needs.I. The Evolution of Packaging Machinery: A Brief OverviewPackaging machinery has come a long way since its inception in the early 19th century. From manual labor to semi-automated processes, the industry has witnessed significant advancements over the years. These advancements have consistently strived to improve speed, accuracy, and safety while reducing downtime and minimizing waste.II. The Birth of the R-Pack System: Intelligent Packaging at Its FinestThe R-Pack System, developed by a leading machinery engineering company, represents a landmark milestone in the packaging industry. By harnessing the latest advancements in artificial intelligence, robotics, and automation, this cutting-edge solution aims to optimize and simplify packaging operations across various industries.III. Streamlined Efficiency: Redefining Packaging ProcessesOne of the core goals of the R-Pack System is to enhance efficiency by automating and streamlining the packaging process. The advanced software incorporated within the system ensures optimal packaging precision while significantly reducing the time required for packing a product. By eliminating manual errors and achieving unparalleled precision, this intelligent machinery empowers businesses to meet high production demands while maintaining consistency in their packaging.IV. Increased Productivity: Meeting Market DemandThe R-Pack System is designed to cater to the ever-increasing demand for fast-paced and accurate packaging solutions. With its rapid output capabilities, this state-of-the-art machinery ensures that businesses can efficiently fulfill customer orders without compromising on quality. Through its intelligent systems, the R-Pack System promotes higher productivity, providing companies with a competitive edge in the market.V. Versatility: Adapting to Diverse Product Packaging NeedsA unique advantage of the R-Pack System lies in its adaptability to varying packaging requirements. Whether it be the food industry, pharmaceuticals, or consumer goods, this intelligent machinery can accommodate diverse products of varying size, shape, and weight. The system's flexible configuration allows it to be easily customized to cater to the specific needs of different industries, making it a suitable choice for businesses seeking a versatile packaging solution.VI. Safety and Sustainability: Prioritizing the EnvironmentIn line with modern consumer demands, the R-Pack System prioritizes safety and sustainability in packaging processes. The intelligent software continually monitors the packing process to avoid potential hazards and minimize accidents, ensuring the well-being of workers. Additionally, the system is designed to promote eco-friendly packaging practices, optimizing material usage and reducing waste, contributing to a greener supply chain.VII. Ease of Integration: Seamless Transition Into Existing ProcessesEnsuring a seamless transition for businesses, the R-Pack System can easily integrate into existing packaging processes. Its compatibility with various production lines allows for efficient adoption without the need for extensive modifications or time-consuming training. This plug-and-play compatibility ensures that businesses can embrace the intelligent machinery with minimal disruption to their operations.Conclusion:With the introduction of the R-Pack System, the packaging industry stands poised to witness a significant transformation. This intelligent packaging machinery promises to revolutionize processes, enhance efficiency, and increase productivity across diverse sectors. Businesses can now harness the power of technology to overcome traditional packaging limitations while meeting rising market demands. The adoption of this intelligent solution positions companies at the forefront of innovation and provides a competitive edge in an ever-evolving marketplace.

Stick Packing Machine for Individual Candy Packaging with Automatic Controls

Stick packing machine is an innovative solution for packaging individual formed toffees, milky candies, and hard candies in stick fin seal packs. The machine is designed to offer fast and efficient packaging of candies, making it a highly sought-after solution in the confectionary industry. The machine is equipped with advanced features that make it easy to operate, maintain and clean.One of the main features of the stick packing machine is its PLC control and touch screen HMI, which allows for integrated control, making it easy to operate with minimal human supervision. The paper feeding and positioned packing are driven by a servo motor, eliminating the need for complicated mechanical systems. This makes the machine highly reliable and efficient, ensuring maximum uptime and minimal downtime.The stick packing machine is also designed to be highly versatile, allowing it to be used for a wide range of candy types and sizes. With its modularity design, the machine is easy to disassemble, making it easy to clean and maintain. This makes it an ideal solution for companies looking for a low-maintenance machine that can deliver consistent and reliable results.Another key feature of the stick packing machine is its automatic stop function. The machine is designed to stop automatically when there is no candy present, or when there is a jam or when the paper runs out. This ensures the safety of the operators and minimizes the risk of machine damage.When it comes to technical specifications, the stick packing machine is capable of packing candies with a maximum size of (need remove brand name) length and (need remove brand name) width. It has a maximum packing speed of (need remove brand name) per minute and a maximum packaging film width of (need remove brand name).Overall, the stick packing machine is a highly efficient and versatile solution for companies looking to streamline their candy packaging process. Its advanced features, fast packing speeds, and ease of maintenance make it an ideal solution for companies of all sizes. Whether you are a small startup or a large corporation, the stick packing machine is a highly reliable and efficient solution that can help you improve your operations while reducing costs. If you are looking for a stick packing machine, be sure to consider the Apexmeco Stick Packing Machine.

High-Quality Vacuum Machine for Food Packaging: A Must-Have for Home Cooks and Professionals

Vacuum Machine For Food Packaging Eliminates Air and Extends Shelf LifeIn the competitive and fast-paced world of food packaging, the need to preserve the quality and freshness of products for longer periods of time is of paramount importance. This is where the Vacuum Machine for Food Packaging from {} comes in to play. This innovative piece of equipment is designed to remove air from food packaging, thereby eliminating the presence of oxygen that can cause food to spoil, ultimately extending shelf life and reducing food waste.{} has been a leading player in the food packaging industry for over two decades, providing cutting-edge solutions to businesses of all sizes. Their commitment to quality, innovation, and customer satisfaction has earned them a reputation as a trusted partner in the industry.The Vacuum Machine for Food Packaging is a testament to {}'s dedication to providing efficient and reliable solutions for their customers. This state-of-the-art machine is equipped with advanced technology that allows for precise vacuum sealing, ensuring that food products are properly preserved. By removing air from the packaging, the growth of bacteria and molds is inhibited, leading to a longer shelf life for a wide range of food items.The benefits of using the Vacuum Machine for Food Packaging are numerous. Not only does it extend the shelf life of food products, but it also helps to maintain the sensory qualities of the food, such as its taste, texture, and appearance. This is especially important for businesses that deal with perishable items, as it allows them to deliver high-quality products to their customers while minimizing food waste.The versatility of the Vacuum Machine for Food Packaging makes it suitable for use in various industries, including but not limited to, fresh produce, meat and poultry, dairy products, and ready-to-eat meals. This adaptability allows businesses to streamline their packaging processes and improve the overall efficiency of their operations.In addition to its functionality, the Vacuum Machine for Food Packaging is also designed with user-friendly features that make it easy to operate and maintain. Its compact and durable construction ensures that it can withstand the rigors of daily use in a commercial setting, while its intuitive controls and interfaces make it accessible to operators of all skill levels.Furthermore, the Vacuum Machine for Food Packaging is equipped with safety features to prevent accidents and ensure the well-being of its users. This commitment to safety and reliability is a testament to {}'s dedication to providing the highest quality equipment for their customers.With the growing demand for sustainable packaging solutions, the Vacuum Machine for Food Packaging is also designed with eco-friendly considerations in mind. By extending the shelf life of food products, businesses can reduce the amount of food that goes to waste, ultimately minimizing their environmental impact. This aligns with {}'s commitment to sustainability and corporate social responsibility, as they continue to innovate and develop products that support a more sustainable future.In conclusion, the Vacuum Machine for Food Packaging from {} is a game-changing solution for businesses looking to extend the shelf life of their food products while reducing food waste. Its advanced technology, user-friendly design, and eco-friendly considerations make it a valuable addition to any food packaging operation. With {}'s reputation for excellence and innovation, customers can trust that they are investing in a reliable and effective solution for their packaging needs.

Efficient and Dependable Case Sealer Machine Makes Packaging a Breeze

In the fast-paced world of manufacturing, every second counts. With so much competition, companies are constantly searching for ways to maximize efficiency and productivity while minimizing costs. For this reason, many businesses have turned to automated solutions such as case sealers to streamline their operations.One of the companies at the forefront of this trend is [Company Name Goes Here]. Founded in [Year Founded], [Company Name] specializes in the design and manufacture of innovative packaging equipment for a variety of industries, including food and beverage, pharmaceuticals, and consumer goods. Their products are known for their reliability, efficiency, and ease of use, making them a top choice for businesses seeking to optimize their packaging processes.One of [Company Name]'s most popular products is their Case Sealer Machine, a versatile and robust system that can handle a wide range of case sizes and packaging materials. Designed with the end user in mind, the Case Sealer Machine is simple to operate and requires minimal maintenance, making it an ideal choice for businesses of all sizes.At the heart of the Case Sealer Machine is a powerful motor that drives the sealing mechanism. The system uses a hot melt adhesive to seal the flaps of the case securely, ensuring that the contents are protected during transport. The adhesive is applied precisely and evenly, minimizing waste and reducing the risk of leaks or damage to the products inside.One of the key advantages of the Case Sealer Machine is its flexibility. The system can handle both uniform and random case sizes, and can be easily adjusted to accommodate changes in packaging requirements. This means that businesses can adapt quickly to evolving market conditions and maintain a competitive edge.Another important feature of the Case Sealer Machine is its compact design. The system has a small footprint, making it easy to integrate into existing packaging lines and minimizing the amount of floor space required. This is especially beneficial for businesses that need to maximize production in a limited area.In addition to its technical capabilities, [Company Name]'s Case Sealer Machine is backed by a team of experienced engineers and technicians who provide comprehensive support and training to customers. This ensures that users are able to operate the system effectively and get the most out of its features and capabilities.Overall, the Case Sealer Machine is an excellent choice for businesses seeking to optimize their packaging processes and minimize costs. With its efficiency, flexibility, and ease of use, it offers a powerful tool for improving productivity and enhancing the bottom line. As competition continues to intensify in the manufacturing industry, companies that invest in automation solutions like the Case Sealer Machine are well positioned to succeed and thrive in the years to come.