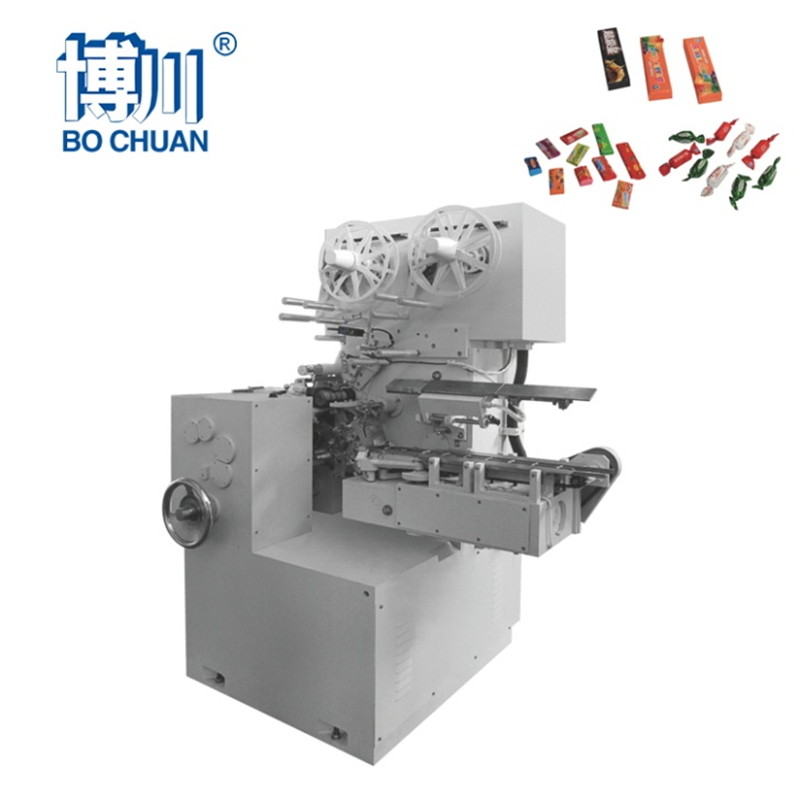

Efficient Horizontal Sealing Machine for Packaging Applications

By:Admin

The Horizontal Sealing Machine is a versatile and advanced piece of equipment that is designed to seal a wide range of packaging materials with precision and accuracy. It is suitable for sealing various types of pouches, including stand-up pouches, flat pouches, and three-sided pouches, making it a versatile and essential tool for our packaging operations.

With its advanced technology and automated features, the Horizontal Sealing Machine is capable of delivering consistent and high-quality seals, ensuring the integrity and freshness of our products. Its adjustable sealing parameters allow us to customize the sealing process according to the specific requirements of each product, ensuring optimal packaging results.

In addition to its sealing capabilities, the Horizontal Sealing Machine is also equipped with a user-friendly interface and intuitive controls, making it easy to operate and maintain. This not only streamlines our production process but also reduces the likelihood of errors and downtime, leading to increased productivity and cost savings.

Furthermore, the Horizontal Sealing Machine is designed with safety in mind, incorporating various safety features and mechanisms to protect our operators and maintain a safe working environment. This commitment to safety aligns with our company’s values and reinforces our dedication to the well-being of our employees.

The addition of the Horizontal Sealing Machine to our production line is a testament to our commitment to investing in advanced technology and equipment to enhance our capabilities and provide our customers with the highest quality products. This new machine reflects our dedication to innovation and continuous improvement, and we are confident that it will have a positive impact on our operations and the overall quality of our products.

As we continue to grow and expand, we remain focused on leveraging the latest technologies and best practices to elevate our production standards and exceed the expectations of our customers. The Horizontal Sealing Machine is a testament to our dedication to staying at the forefront of industry trends and delivering excellence in everything we do.

In conclusion, the Horizontal Sealing Machine represents a significant milestone in our company’s journey towards operational excellence and product quality. Its advanced capabilities, user-friendly interface, and commitment to safety make it a valuable addition to our production line, and we are excited about the positive impact it will have on our operations and the overall quality of our products. We look forward to the opportunities that this new machine will unlock for us and the continued success it will bring to our company.

Company News & Blog

High-Quality Hard Candy Making Machine for Sale - Find Out More!

Hard Candy Maker Machine Revolutionizes Confectionery ProductionIn the world of confectionery production, innovation is the key to staying ahead of the competition. One company that has been leading the way in this regard is [Company Name], a renowned manufacturer of confectionery machinery. With a strong focus on research and development, the company has recently unveiled its latest offering – a state-of-the-art Hard Candy Maker Machine that promises to revolutionize the way hard candies are produced.The Hard Candy Maker Machine is the result of years of dedicated research and development by [Company Name]'s team of engineers and confectionery experts. Designed to streamline the candy making process and optimize production efficiency, this machine is set to significantly impact the confectionery industry.One of the key features of the Hard Candy Maker Machine is its advanced automation capabilities. By incorporating cutting-edge technology, the machine is able to perform complex production tasks with a high degree of precision and consistency. This not only ensures that each batch of candies is of the highest quality, but also minimizes the margin of error, leading to cost savings for confectionery manufacturers.Furthermore, the machine is equipped with a user-friendly interface that allows for easy operation and monitoring. This intuitive design not only simplifies the production process but also reduces the need for extensive training, making it accessible to a wide range of confectionery manufacturers.Another standout feature of the Hard Candy Maker Machine is its versatility. With the ability to produce a wide variety of hard candies in different shapes, sizes, and flavors, this machine offers confectionery companies the flexibility to meet the ever-changing demands of the market. Whether it's traditional fruit-flavored candies or innovative novelty shapes, the machine can cater to a diverse range of products.In addition to its advanced capabilities, the Hard Candy Maker Machine also prioritizes hygiene and safety. Constructed with food-grade materials and designed for easy cleaning and maintenance, the machine complies with the strictest health and safety standards, ensuring that the candies produced are not only delicious but also safe for consumption.[Company Name]'s commitment to sustainability is also reflected in the design of the Hard Candy Maker Machine. By incorporating energy-efficient components and optimizing resource usage, the machine minimizes its environmental impact, aligning with the growing consumer demand for eco-conscious products.As a leader in the confectionery machinery industry, [Company Name] has a track record of providing top-quality products and unparalleled customer support. With a global presence and a strong network of distributors and service centers, the company offers reliable assistance to its clients, ensuring that their production processes run smoothly and efficiently.The introduction of the Hard Candy Maker Machine is poised to elevate [Company Name]'s position as an industry frontrunner and set a new standard for confectionery production. With its advanced technology, user-friendly interface, versatility, and commitment to sustainability, the machine is set to make a significant impact on the confectionery industry.As the demand for high-quality confectionery continues to grow, [Company Name]'s Hard Candy Maker Machine presents an exciting opportunity for confectionery manufacturers to enhance their production capabilities and meet the evolving needs of consumers. In an ever-changing market, innovation is the key to success, and [Company Name] has once again demonstrated its dedication to driving progress in the confectionery industry.

How to Make Lollipop Candy with a Candy Making Machine

Lollipop Candy Making Machine Revolutionizing the Confectionery IndustryIn recent years, the confectionery industry has seen a significant shift towards automation and technological advancements. One company that has been at the forefront of this change is {Company X}, a leading manufacturer of confectionery production equipment. With their innovative approach and cutting-edge technology, {Company X} has been revolutionizing the way lollipop candies are made with their state-of-the-art Lollipop Candy Making Machine.The Lollipop Candy Making Machine is a marvel of engineering and design, capable of producing high-quality lollipop candies with unparalleled efficiency and precision. This advanced machine is equipped with a range of features that make it stand out from traditional candy making equipment. From precision temperature control to automated molding and wrapping, the Lollipop Candy Making Machine streamlines the entire production process, allowing confectionery manufacturers to significantly increase their productivity and output.One of the key features of the Lollipop Candy Making Machine is its versatility. Unlike traditional candy making equipment, which is limited in its capabilities, this innovative machine can produce a wide variety of lollipop shapes, sizes, and flavors, allowing confectionery manufacturers to cater to diverse consumer preferences and market demands. With its adaptable design and customizable settings, the Lollipop Candy Making Machine offers unmatched flexibility and production capabilities.In addition to its technical capabilities, the Lollipop Candy Making Machine is also designed with sustainability in mind. {Company X} is committed to minimizing the environmental impact of their equipment, and the Lollipop Candy Making Machine is no exception. With energy-efficient operation and minimal waste generation, this advanced machine helps confectionery manufacturers reduce their carbon footprint and contribute to a more sustainable future.Furthermore, {Company X} provides comprehensive support and training for the Lollipop Candy Making Machine, ensuring that their clients can maximize the potential of this innovative equipment. From installation and setup to ongoing maintenance and technical assistance, {Company X} is dedicated to helping confectionery manufacturers integrate the Lollipop Candy Making Machine seamlessly into their production processes and achieve the highest levels of efficiency and quality.The impact of the Lollipop Candy Making Machine extends beyond just the confectionery industry. By enabling manufacturers to automate and optimize their production processes, this advanced machine has the potential to create new opportunities for business growth and innovation. With increased production capacity and the ability to deliver a wider range of lollipop candies to the market, confectionery manufacturers can expand their product offerings and reach new consumer segments, driving economic growth and industry advancement.In conclusion, the Lollipop Candy Making Machine from {Company X} represents a significant advancement in confectionery production technology. With its cutting-edge features, versatility, and sustainability, this innovative machine is reshaping the way lollipop candies are made and setting new standards for efficiency and quality in the industry. As {Company X} continues to push the boundaries of confectionery equipment technology, the future looks bright for the confectionery industry, with the prospect of further innovation and growth on the horizon.

Innovative Gummy Bear Making Machine Revolutionizes Candy Manufacturing Industry

Gummy Bear Making Machine revolutionizing the confectionery industryAs the demand for gummy candies continues to rise, companies are constantly seeking new and innovative ways to meet the needs of consumers. In response to this growing demand, a leading confectionery equipment manufacturer has recently announced the launch of a cutting-edge Gummy Bear Making Machine that is set to revolutionize the production process for gummy candies.This state-of-the-art Gummy Bear Making Machine is a game changer for confectionery producers, as it is capable of producing high-quality gummy candies with unmatched precision and efficiency. Equipped with advanced technology and cutting-edge features, this machine is designed to streamline the entire gummy bear manufacturing process, from mixing the ingredients to shaping and packaging the final product.The Gummy Bear Making Machine boasts a range of innovative capabilities that set it apart from traditional candy-making equipment. Its automated mixing and pouring system ensures that the gummy candy mixture is consistently distributed into the molds, resulting in uniform and perfectly-shaped gummy bears. Additionally, the machine's precise temperature control system guarantees that the gummy candies are cooked to perfection, achieving the ideal texture and flavor that consumers love.Furthermore, this revolutionary Gummy Bear Making Machine is equipped with a high-speed packaging system that enables confectionery producers to efficiently pack the gummy bears into individual bags, ensuring product freshness and quality. This feature not only enhances the overall production efficiency but also minimizes the risk of product contamination, meeting the highest standards of food safety and hygiene.In addition to its cutting-edge capabilities, the Gummy Bear Making Machine is designed with user-friendly controls and intuitive interfaces, making it easy for confectionery manufacturers to operate and maintain. With its ability to produce a wide variety of gummy bear shapes, sizes, and flavors, this machine offers unparalleled flexibility and versatility to meet the diverse demands of the market.The introduction of this innovative Gummy Bear Making Machine marks a significant milestone for the confectionery industry, as it not only elevates the production standards for gummy candies but also drives the overall growth and advancement of the sector. With its potential to enhance product quality, consistency, and efficiency, this machine is expected to set a new benchmark for gummy bear production and pave the way for the future of confectionery manufacturing.In line with the company's commitment to excellence and innovation, the development of the Gummy Bear Making Machine is a testament to its dedication to delivering cutting-edge solutions that meet the evolving needs of its customers. With a track record of excellence in confectionery equipment manufacturing, the company has established itself as a trusted partner for confectionery producers worldwide, providing them with the tools and technologies needed to stay ahead in a competitive market.The launch of the Gummy Bear Making Machine showcases the company's relentless pursuit of innovation, as it continues to push the boundaries of confectionery manufacturing and set new industry standards. With its unrivaled expertise and passion for excellence, the company is poised to make a lasting impact on the confectionery industry with this groundbreaking machine, empowering producers to take their gummy candy production to the next level.In conclusion, the introduction of the Gummy Bear Making Machine is a significant development that is poised to revolutionize the confectionery industry. With its advanced capabilities, unmatched precision, and unparalleled efficiency, this machine is set to redefine the production process for gummy candies, setting a new benchmark for quality, consistency, and innovation. As the company continues to lead the way in confectionery equipment manufacturing, the launch of this groundbreaking machine underscores its commitment to driving the future of the industry and empowering producers to thrive in a dynamic market.

Automated Heat Packing Machine for Efficient Product Packaging

A Leading Manufacturing Company Introduces New Heat Packing Machine for Efficient Packaging SolutionsIn the ever-evolving world of manufacturing and packaging, companies are constantly seeking innovative solutions to optimize their production processes and deliver high-quality products to their customers. In line with this vision, a leading manufacturing company has recently introduced a state-of-the-art Heat Packing Machine, a cutting-edge technology designed to revolutionize the packaging industry.With a rich history of over 30 years in the manufacturing sector, the company has garnered a strong reputation for delivering top-of-the-line machinery and equipment to a wide range of industries, including food and beverage, pharmaceuticals, cosmetics, and more. Their commitment to excellence and relentless pursuit of innovation has allowed them to stay at the forefront of the industry, continually providing their clients with the latest advancements in technology to meet their evolving needs.The new Heat Packing Machine is the latest addition to the company's extensive product lineup, and it promises to be a game-changer for businesses looking to streamline their packaging processes and improve overall efficiency. Equipped with cutting-edge features and advanced automation capabilities, the machine is designed to handle a variety of packaging materials, including plastic, paper, and aluminum foils, making it a versatile solution for a wide range of applications.One of the key highlights of the Heat Packing Machine is its ability to deliver precise and consistent heat sealing, ensuring that products are securely packaged and protected from external elements. This level of reliability is crucial for industries where product integrity is of the utmost importance, such as the pharmaceutical and food sectors. Additionally, the machine's high-speed operation and customizable settings allow for efficient production, enabling businesses to meet tight deadlines and maintain a competitive edge in the market.Furthermore, the machine is designed with user-friendly features and intuitive controls, making it easy for operators to set up and operate, minimizing the risk of human error and ensuring smooth and seamless production. Its compact and space-saving design also makes it ideal for businesses with limited floor space, allowing for maximum productivity without compromising on production area.In addition to its advanced capabilities, the Heat Packing Machine is also built with durability and reliability in mind, ensuring minimal downtime and maximum longevity. This is a testament to the company's commitment to delivering quality products that not only meet industry standards but also exceed the expectations of their customers.With the introduction of the new Heat Packing Machine, the company aims to provide businesses with a reliable and efficient packaging solution that can adapt to the dynamic demands of the industry. By leveraging their expertise and technical prowess, they are poised to set a new standard for packaging technology, offering their clients a competitive edge in an increasingly competitive market.As a customer-centric company, the manufacturing company is dedicated to providing comprehensive support and after-sales service to ensure that their clients can fully maximize the potential of the Heat Packing Machine. From installation and training to maintenance and troubleshooting, their team of experts is committed to delivering unparalleled assistance every step of the way.Overall, the introduction of the Heat Packing Machine underscores the company's unwavering dedication to innovation and customer satisfaction, solidifying their position as a trusted partner for businesses seeking top-of-the-line packaging solutions. With their proven track record of excellence and a commitment to pushing boundaries, the company is set to make a significant impact on the packaging industry with the launch of this ground-breaking technology.

Top Candy Bar Making Machines for Your Business

Candy Bar Making Machines: The Latest Innovation in Confectionery ProductionIn the world of confectionery production, the demand for candy bars continues to remain high. With consumers constantly seeking new and innovative flavors and textures, manufacturers are under pressure to keep up with the latest trends. This has led to the development of cutting-edge candy bar making machines, which are revolutionizing the way these popular treats are produced.One company at the forefront of this technological innovation is {company name}, a leading manufacturer of confectionery production equipment. With a history of over 50 years in the industry, {company name} has established itself as a trusted provider of high-quality machinery and solutions for candy production. Their candy bar making machines are designed to streamline the production process, improve efficiency, and ultimately deliver a superior product to consumers.The candy bar making machines developed by {company name} are equipped with state-of-the-art technology that enables manufacturers to create a wide variety of candy bar shapes, sizes, and flavors. Whether it's a traditional chocolate bar, a nougat-filled delight, or a crunchy nut-filled treat, these machines are capable of producing them all with precision and consistency. This level of flexibility allows confectionery producers to meet the diverse preferences of their customer base and stay ahead of the competition.One of the key features of {company name}'s candy bar making machines is their ability to ensure food safety and quality. With strict adherence to industry regulations and standards, these machines are designed to maintain hygienic conditions throughout the production process. This is essential in the confectionery industry, where consumer trust and confidence in the safety of the products are paramount. By investing in {company name}'s candy bar making machines, manufacturers can rest assured that their products meet the highest standards of quality and safety.Furthermore, these machines are built to maximize production efficiency, thus reducing operational costs and increasing overall profitability. With automated processes and precise control systems, {company name}'s candy bar making machines minimize waste and optimize raw material usage. This not only benefits the bottom line of confectionery producers but also contributes to a more sustainable and environmentally friendly approach to production.To complement their cutting-edge technology, {company name} offers comprehensive support and maintenance services for their candy bar making machines. Their team of experts is dedicated to ensuring that their customers can operate their equipment at peak performance at all times. From installation and training to ongoing technical assistance, {company name} is committed to providing a seamless experience for their clients.In addition to their focus on technological innovation and customer support, {company name} places a strong emphasis on research and development. They are constantly exploring new ways to improve their machines and develop new solutions to meet the evolving needs of the confectionery industry. This commitment to innovation has cemented {company name}'s position as a leader in the field of candy bar making machines.As the confectionery industry continues to evolve, the demand for high-quality candy bars remains unabated. Thanks to companies like {company name}, manufacturers now have access to advanced machinery that can streamline production, ensure product quality, and ultimately meet the needs of consumers. With their state-of-the-art candy bar making machines, {company name} is shaping the future of confectionery production and driving the industry towards new heights of success.

Highly Efficient Industrial Vacuum Packaging Machine for Food and Product Preservation

Industrial Vacuum Packaging Machine has revolutionized the food packaging industry with its innovative technology and efficient packaging solutions. The company, with a strong focus on research and development, has been a pioneer in the development of vacuum packaging machines that cater to the specific needs of the food industry. The company's commitment to quality and customer satisfaction has made it a trusted name in the packaging industry.The Industrial Vacuum Packaging Machine is designed to provide a reliable and efficient packaging solution for a wide range of food products. The machine is equipped with advanced technology that ensures the preservation of food products by removing air from the packaging, thereby extending their shelf life. This not only minimizes food waste but also helps in maintaining the quality and freshness of the products.The machine is also designed to cater to the specific requirements of the food industry, including packaging of liquid and semi-liquid products. Its efficient sealing technology ensures that the products are securely packaged, preventing any leakage or spoilage. This is particularly beneficial for businesses involved in the production and packaging of sauces, marinades, and other liquid food products.The Industrial Vacuum Packaging Machine is also known for its user-friendly interface and easy operation. With intuitive controls and clear instructions, the machine can be operated with minimal training, making it an ideal choice for businesses of all sizes. Additionally, the machine is designed for easy maintenance and cleaning, ensuring smooth and uninterrupted operation.The company takes pride in its commitment to environmental sustainability, and the Industrial Vacuum Packaging Machine reflects this ethos. The machine is designed to minimize packaging material waste and is also energy-efficient, reducing the overall carbon footprint. This makes it an environmentally responsible choice for businesses looking to reduce their environmental impact.Furthermore, the company provides comprehensive customer support, including installation, training, and technical assistance. This ensures that businesses can seamlessly integrate the Industrial Vacuum Packaging Machine into their operations and maximize its benefits. The company's dedication to customer satisfaction has earned it a strong reputation in the industry, with a loyal customer base that values its reliability and professionalism.In addition to its focus on the food industry, the Industrial Vacuum Packaging Machine has also found applications in other sectors, including pharmaceuticals, electronics, and aerospace. Its versatility and adaptability have made it a popular choice for businesses looking for reliable and efficient packaging solutions.With a track record of innovation and excellence, the company behind the Industrial Vacuum Packaging Machine continues to lead the way in the packaging industry. Its commitment to quality, reliability, and customer satisfaction sets it apart as a trusted partner for businesses looking to enhance their packaging capabilities.In conclusion, the Industrial Vacuum Packaging Machine has redefined the standards of packaging technology in the food industry, offering efficient, reliable, and environmentally responsible solutions. With a strong focus on innovation and customer satisfaction, the company behind this groundbreaking machine continues to set the bar high for the packaging industry. Businesses that choose the Industrial Vacuum Packaging Machine can be confident in its ability to meet their packaging needs and contribute to their success.

Innovative Automatic Chocolate Making Machine Unveiled: Revolutionizing Chocolate Production Industry

[Company Name], a leading manufacturer of industrial food processing equipment, has recently launched an innovative Automatic Chocolate Making Machine that is set to revolutionize the chocolate manufacturing industry. This state-of-the-art machine is designed to streamline the chocolate making process, significantly reducing production time and increasing efficiency.The Automatic Chocolate Making Machine is equipped with advanced technology and a user-friendly interface, making it easy to operate and maintain. It is capable of producing a wide range of chocolate products, including bars, truffles, and filled chocolates, with precision and consistency. This machine is designed to meet the high demands of the chocolate industry, providing manufacturers with a reliable solution for their production needs.With a focus on quality and performance, [Company Name] takes pride in delivering cutting-edge solutions to the food processing industry. The Automatic Chocolate Making Machine is a testament to the company's commitment to innovation and excellence. With a strong emphasis on research and development, [Company Name] ensures that its equipment is at the forefront of technological advancement, offering its customers the latest and most efficient solutions for their manufacturing processes.In addition to its technological advancements, the Automatic Chocolate Making Machine is also designed with sustainability in mind. It is equipped with energy-efficient features that minimize power consumption, making it a more environmentally friendly option for chocolate manufacturers. This aligns with [Company Name]'s dedication to reducing its environmental impact and promoting sustainable practices within the food processing industry.Furthermore, the Automatic Chocolate Making Machine is built to meet the highest standards of hygiene and safety. It is constructed with food-grade materials and is designed for easy cleaning and maintenance, ensuring that the chocolate products produced are of the highest quality and meet regulatory standards. This emphasis on food safety is a testament to [Company Name]'s commitment to providing equipment that prioritizes the well-being of consumers.The launch of the Automatic Chocolate Making Machine comes at a time when the demand for high-quality chocolate products is on the rise. With consumers increasingly seeking premium and innovative chocolate offerings, manufacturers are facing the challenge of meeting this demand while maintaining efficiency and quality. The new machine from [Company Name] is poised to address these challenges, offering a solution that enhances production capabilities and delivers superior chocolate products to the market.Through the introduction of the Automatic Chocolate Making Machine, [Company Name] aims to empower chocolate manufacturers with a reliable and efficient tool that can elevate their production processes. By leveraging state-of-the-art technology and a commitment to sustainability and food safety, [Company Name] is poised to make a significant impact on the chocolate manufacturing industry, positioning itself as a leader in providing innovative solutions to meet the evolving needs of its customers.As the Automatic Chocolate Making Machine enters the market, [Company Name] is confident that it will set a new standard for chocolate production, serving as a testament to the company's dedication to advancing the food processing industry. With its focus on quality, efficiency, and sustainability, the new machine is set to make a lasting impression on the chocolate manufacturing landscape, offering a solution that empowers manufacturers to meet the growing demand for high-quality chocolate products.

Automated Chocolate Packing Machine for Homemade Treats

Homemade Chocolate Packing Machine revolutionizes packaging processIn the world of homemade chocolate production, efficiency and precision are key factors in delivering high-quality products to customers. The introduction of the innovative Homemade Chocolate Packing Machine is set to revolutionize the packaging process for small-scale chocolate producers, offering a fast, reliable and efficient solution for packaging their delicious creations.The {Company Name} is a leading manufacturer of packaging machinery, specializing in the design and production of customized packaging solutions for a wide range of industries. With a focus on innovation and customer satisfaction, the company has gained a reputation for delivering high-quality, user-friendly equipment that meets the specific needs of its clients.The Homemade Chocolate Packing Machine is the latest addition to {Company Name}'s product lineup, and it has already generated significant interest within the homemade chocolate industry. Designed to streamline the packaging process for small-scale chocolate producers, this machine offers a range of features and capabilities that make it an ideal solution for businesses looking to improve their packaging operations.One of the key features of the Homemade Chocolate Packing Machine is its versatility. The machine is designed to accommodate a variety of packaging materials and sizes, allowing producers to package their chocolate products in a way that best suits their brand and product offerings. This level of flexibility is essential for small-scale producers who often have limited resources and need to adapt to changing market demands.In addition to its versatility, the Homemade Chocolate Packing Machine is also designed with efficiency in mind. The machine is capable of high-speed packaging, ensuring that producers can meet the demands of their customers without sacrificing quality. This level of efficiency can have a significant impact on a producer's bottom line, allowing them to increase their output and streamline their production process.Furthermore, the Homemade Chocolate Packing Machine also offers precision and consistency in packaging, ensuring that each product is packaged with the same high standard. This level of accuracy is essential for maintaining the quality and presentation of the products, and it can help producers build a strong reputation for their brand in the market.The introduction of the Homemade Chocolate Packing Machine comes at a time when the homemade chocolate industry is experiencing significant growth. As consumers become more conscious of where their food comes from and are seeking out unique, artisanal products, small-scale chocolate producers are finding themselves in high demand. However, in order to meet the needs of the market, these producers must invest in equipment that can help them scale their operations while maintaining the quality and integrity of their products.The {Company Name} is committed to supporting the growth and success of small-scale chocolate producers, and the introduction of the Homemade Chocolate Packing Machine is a testament to that commitment. With its innovative design, versatile capabilities, and focus on efficiency and precision, this machine is set to become an essential tool for chocolate producers looking to elevate their packaging process.In conclusion, the introduction of the Homemade Chocolate Packing Machine by {Company Name} is a game-changer for small-scale chocolate producers. With its innovative design, versatile capabilities, and focus on efficiency and precision, this machine offers a reliable and efficient solution for packaging homemade chocolate products. As the homemade chocolate industry continues to grow, equipment like the Homemade Chocolate Packing Machine will be essential for producers looking to meet the demands of the market while maintaining the quality of their products.

Efficient and Reliable Oil Packing Machine for Your Packaging Needs

Oil Packing Machine Revolutionizes Packaging IndustryIn the fast-paced world of packaging and manufacturing, the introduction of the Oil Packing Machine has revolutionized the industry. This new innovation has been designed to streamline the packaging process by automating the filling, sealing, and labeling of oil products. With its state-of-the-art technology and advanced features, the Oil Packing Machine has become a game-changer for companies looking to improve efficiency and reduce costs in their packaging operations.The Oil Packing Machine, developed by a leading packaging solutions provider, has been engineered to meet the specific needs of the oil industry. Its innovative design allows for precise filling of oil products, ensuring accurate and consistent packaging every time. In addition, the machine is equipped with advanced sealing and labeling capabilities, ensuring that the final product meets the highest quality standards.One of the key advantages of the Oil Packing Machine is its versatility. It is capable of handling a wide range of oil products, including cooking oil, lubricants, and essential oils, making it an ideal solution for companies with diverse packaging needs. Furthermore, the machine can accommodate various packaging formats, from bottles and cans to pouches and sachets, providing companies with the flexibility to package their products in the most suitable and cost-effective manner.The company behind the Oil Packing Machine is a renowned leader in the packaging industry, with a proven track record of delivering cutting-edge solutions to its customers. With a strong focus on innovation and customer satisfaction, the company has continuously invested in research and development to bring state-of-the-art products to the market. The introduction of the Oil Packing Machine is a testament to the company's commitment to providing its customers with the best-in-class packaging solutions.In addition to its technical capabilities, the company is also known for its exceptional customer support and service. It offers comprehensive training and technical assistance to ensure that its customers can maximize the performance and efficiency of the Oil Packing Machine. Furthermore, the company's team of experts is available to provide guidance and support to its customers, from machine installation and setup to ongoing maintenance and troubleshooting.The impact of the Oil Packing Machine on the packaging industry has been significant. Companies that have adopted this innovative technology have reported substantial improvements in their packaging operations, including increased productivity, reduced labor costs, and enhanced product quality. Moreover, the machine's ability to streamline the packaging process has helped companies to meet growing demand and expand their market reach.Looking ahead, the company is committed to further advancements in packaging technology, with a focus on sustainability and environmental responsibility. It is exploring new ways to reduce packaging waste and minimize the environmental footprint of its machines, in line with the industry's increasing emphasis on sustainability. With its dedication to innovation and customer satisfaction, the company is well-positioned to continue driving positive changes in the packaging industry.The introduction of the Oil Packing Machine has undoubtedly set a new standard for packaging technology in the oil industry. Its advanced features, versatility, and impact on the industry have solidified its position as a game-changer in the packaging landscape. As companies continue to seek efficient and cost-effective packaging solutions, the Oil Packing Machine is poised to play a crucial role in shaping the future of the industry.

High-quality Automated Rice Packing Machine for Efficient Packaging

The rice packing industry is set to receive a significant boost with the introduction of a state-of-the-art rice packing machine by a leading packaging machinery manufacturer. This advanced machine is designed to revolutionize the rice packing process, offering increased efficiency, precision, and versatility.With over 20 years of experience in the packaging industry, the company has established a strong reputation for delivering high-quality and innovative packaging solutions. Their commitment to research and development has led to the creation of the rice packing machine, which promises to streamline the packing process for rice producers and distributors.The new rice packing machine boasts a range of advanced features that set it apart from traditional packing machines. Its high-speed capabilities allow for rapid packing of rice, significantly increasing productivity and reducing downtime. Additionally, the machine is equipped with precision weighing technology, ensuring that each pack of rice is accurately measured and filled to the desired weight.One of the key advantages of the rice packing machine is its versatility. It is capable of handling various types of rice, including long-grain, medium-grain, and short-grain varieties, as well as different packaging materials such as paper bags, plastic bags, and woven polypropylene bags. This flexibility makes it an ideal solution for rice producers with diverse product lines.In addition to its technical capabilities, the rice packing machine is designed with user-friendly features that prioritize ease of operation and maintenance. Its intuitive interface and automated functions minimize the need for manual intervention, while its robust construction ensures durability and reliability even in demanding production environments.Furthermore, the company's dedication to customer satisfaction is evident in its comprehensive customer support services. From installation and training to ongoing technical assistance and spare parts availability, the company is committed to ensuring that rice producers can maximize the benefits of the rice packing machine.The introduction of this cutting-edge rice packing machine is expected to have a significant impact on the rice industry. By improving efficiency and accuracy in the packing process, rice producers can enhance their overall operational efficiency and meet the growing demand for high-quality packaged rice products.Furthermore, the machine's ability to accommodate various types of rice and packaging materials aligns with the diverse needs of the market, offering a flexible and adaptive solution for rice producers and distributors.The company's long-standing reputation for excellence and innovation positions it as a trusted partner for rice producers seeking to optimize their packaging operations. With a track record of delivering reliable and high-performance packaging machinery, the company is well-positioned to support the success of rice producers in today's competitive market.Overall, the introduction of the rice packing machine represents a significant advancement for the rice industry, offering a combination of cutting-edge technology, operational efficiency, and customer-centric support. As rice producers continue to adapt to evolving market demands, this innovative packaging solution is set to play a pivotal role in shaping the future of the rice packing process.