Create Homemade Gummies with a Compact Candy Maker

By:Admin

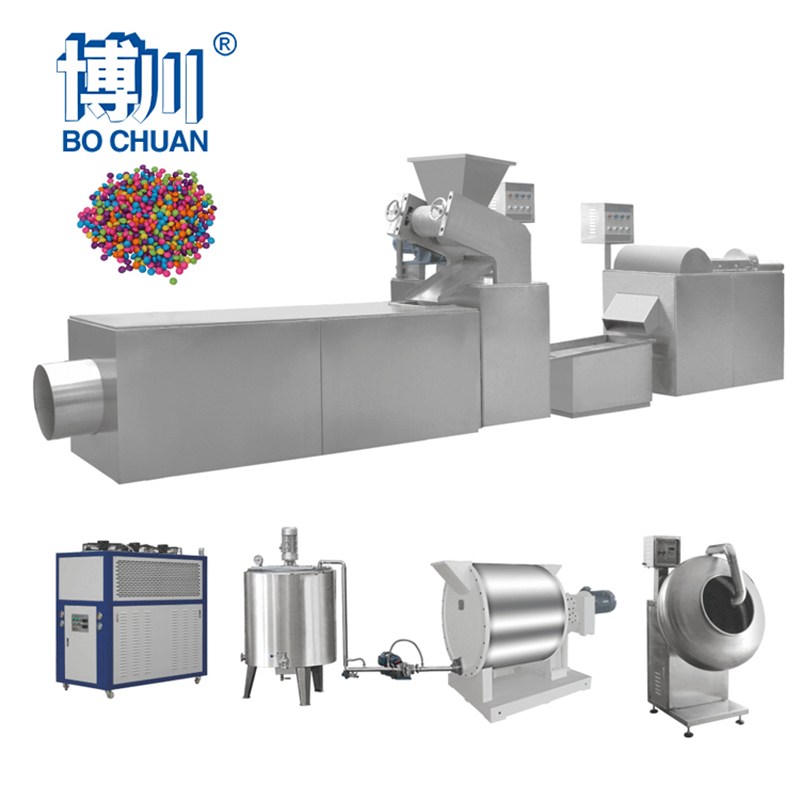

In today's world, consumers crave products that are both tasty and healthy. The confectionary industry has realized this need, and has started producing a range of gummy products that are more nutritious and delicious than ever before. A small gummy making machine known for its quality is transforming the industry, allowing confectionary manufacturers to meet these new demands from consumers in an efficient and cost-effective way.

This remarkable innovation revolutionizes the traditional methods of manufacturing gummies. The traditional manufacturing process required many production steps, both manual and automated, but this remarkable machine is changing the game. With advanced features that include compact design, ease of use, and premium quality output, the small gummy making machine is now the go-to solution for manufacturers.

The small gummy making machine is created by a reputable company that is committed to continuous improvement and customer satisfaction. The company operates on the principle of intensive research and development, the manufacturing of high-quality machines, and world-class customer support. With years of experience in the industry, the company has demonstrated the ability to deliver solutions that guarantee quality and profitability.

The machine operates by a simple process that starts by feeding the ingredients from a confectionary mixture into a hopper. From there, the machine's internal components securly knead and mix the ingredients, before depositing them into trays of the desired shape. The mixture flows through the pipes and nozzles, and then into the trays, before and passes through an advanced cooling system to solidify the gummies. The trays of gummies then move from the cooling system to a conveyor belt, where they undergo packaging and sealing to be ready for sale.

The small gummy making machine is ideal for manufacturers that have limited production space as the compact design of the machine allows it to fit into smaller production areas while still maintaining high production rates. The machine boasts an advanced control system, which allows the manufacturer to adjust the machine's settings easily and precisely. This feature ensures consistent quality production of the gummies, with minimal wastage, and significant cost savings.

The machine is manufactured from robust and durable materials that operate with low maintenance and minimal power requirements. This feature results in reduced manufacturing costs, which translates to a significant increase in the company's bottom-line.

Manufacturing gummy products with the small gummy making machine improves bottom-line profitability, enhances product quality, and increases production efficiency. The machine can optimize production, meet the demand for a high-quality, healthy, and nutritious snack, while minimizing production costs. This machine is the perfect solution for confectionary manufacturers looking to streamline their production processes, efficiently manage their limited production space, and satisfy the insatiable desires of their customers for tasty and healthy gummy products.

Final Thoughts

The small gummy making machine is a revolutionary innovation in confectionary production, delivering quality, efficient, and cost-effective gummy production. Its development has strengthened the confectionary industry's commitment to delivering high-quality, healthy, and nutritious products. As the industry continues to evolve, it's essential to adopt modern technology such as this, improve production efficiency, reduce costs, and remain competitive in the market. Choosing this small gummy making machine from a reputable company will transform your confectionary production game, enhancing your chances of success and profitability in today’s demanding world.

Company News & Blog

New System for Sealing Packaging Safely and Efficiently

Title: New Packaging Solution Enhances Efficiency and ProductivityIntroduction:As technology continues to advance at an exponential rate, companies across various industries are constantly on the lookout for innovative solutions that can streamline their operations and boost productivity. In recent news, a leading packaging equipment manufacturer has unveiled its latest addition to the market, the advanced Web Sealer Machine. This cutting-edge technology is set to revolutionize the packaging process, offering businesses a highly efficient and automated solution. With its range of features and capabilities, the Web Sealer Machine is poised to become a game-changer in the packaging industry.Streamlined Packaging Process:The Web Sealer Machine eliminates the need for manual packaging, reducing human labor and enhancing overall operational efficiency. With its automated sealing and wrapping capabilities, this advanced machinery significantly reduces packaging time, allowing businesses to meet increasing demand without compromising on quality. Equipped with advanced control systems, the Web Sealer Machine ensures consistent and precise packaging, eliminating the inconsistencies often associated with manual labor.Advanced Technology:1. Precision Sealing: The Web Sealer Machine employs state-of-the-art technology to achieve precise and secure seals on various packaging materials, including shrink wrap and polyethylene. This ensures that products are fully protected during transportation and storage, minimizing the risk of damage or spoilage.2. Variable Speed Control: With the ability to adjust the machine's speed according to the specific packaging requirements, businesses can customize the packaging process to suit different product dimensions and sizes. This flexibility allows for seamless integration into existing packaging lines, improving overall efficiency and productivity.3. User-Friendly Interface: The intuitive and user-friendly interface of the Web Sealer Machine allows operators of all skill levels to easily navigate and control the machine. Its digital display and simple controls make it easy to monitor and adjust settings, reducing the need for extensive training and minimizing the likelihood of errors.Increased Productivity:1. High-Speed Performance: The Web Sealer Machine boasts an impressive packaging speed, making it ideal for industries with large production volumes. Capable of sealing hundreds of products per minute, this advanced packaging solution allows businesses to meet tight deadlines and fulfill customer orders promptly.2. End-to-End Automation: Designed to minimize human intervention, the Web Sealer Machine automates the entire packaging process, from sealing to shrink-wrapping. By reducing the reliance on manual labor, businesses can expect a significant increase in productivity and output, without compromising on quality.Environmental Benefits:In addition to its numerous operational advantages, the Web Sealer Machine also contributes to environmental sustainability. The reduced need for excess packaging materials and energy-efficient sealing technology help minimize waste and promote eco-friendly practices. By utilizing this advanced packaging solution, businesses can align their operations with sustainable practices, catering to the growing consumer demand for environmentally responsible manufacturing.Conclusion:The introduction of the Web Sealer Machine marks a significant milestone in the packaging industry. With its advanced technology, streamlined packaging process, and increased productivity, businesses can benefit from improved operational efficiency and reduced costs. The user-friendly interface and automated features ensure ease of use while maintaining consistent and precise packaging results. Furthermore, its environmental benefits align with the global push towards sustainability. As the market continues to evolve, adopting innovative packaging solutions like the Web Sealer Machine is crucial for companies to remain competitive in the ever-changing business landscape.

Efficient Automatic Food Packing Machine for Your Business Needs

article: Wenzhou Huaqiao Packing Machine Factory is revolutionizing the way we package our food items with the introduction of their automatic food packing machine. With a growing population and constantly increasing demand for food products, it is vital that packaging solutions are not just efficient but also innovative. Huaqiao Packing Machine Factory ensures just that.As a professional manufacturer of various packing machinery, Huaqiao Packing Machine Factory has been committed to delivering high-quality and reliable solutions for both small and large scale manufacturing industries all across China. With a focus on innovation and customer satisfaction, they have established themselves as a respected leader in the industry.Their automatic food packing machine brings the latest technologies in the packaging industry to the forefront and offers a range of benefits for its clients. Firstly, the automatic nature of this packing machine reduces human error and increases efficiency. It is designed to handle a range of food products such as meat, fish, fresh produce, and baked goods effortlessly.The machine features a vacuum packing function, which minimizes the amount of air in the packaging, thereby improving the shelf life of the products. Additionally, the vacuum function helps to maintain the freshness and original flavor of the food products, an important factor in retaining customer loyalty.The automatic food packing machine also comes with a sealing function, which secures the product inside the packaging and prevents any leakage. This aspect is particularly crucial for liquid or semi-liquid food items, which may spill or leak during transportation. With the sealing function, clients can be assured that their products will arrive at their destination safely and without any damage.Furthermore, the Huaqiao Packing Machine Factory's automatic food packing machine can be customized to fit a client's specific needs. The machine comes in different sizes and shapes, depending on the type of product the client wants to package. Additionally, the company provides training services to its clients to ensure that they can operate the machines effectively and maintain them properly.Another impressive feature of Huaqiao Packing Machine Factory's automatic food packing machine is its thermal shrink tunnel function. This process involves passing packaged products through a tunnel that shrinks the packaging tightly around the product, thereby reducing the amount of storage space required. This added functionality is especially beneficial for businesses that have limited warehouse space.With their continued investment in research and development, Huaqiao Packing Machine Factory has been able to offer their clients cost-effective and reliable packing machinery. With an increasing emphasis on eco-friendliness, the company has been exploring environmentally-friendly solutions that will meet their client's needs while also contributing positively to the environment.In conclusion, the introduction of Huaqiao Packing Machine Factory's automatic food packing machine signifies a new era in the packaging industry in China. With a focus on innovation and efficiency, the company has reimagined the way we package our food products. Their commitment to excellence ensures that their clients have access to high-quality and reliable packing machinery that will suit their specific needs.

Blister Packing Machine for Tablets and Capsules: Aluminum and Plastic Options

for Tablet&Capsule and PVC Blister Packing Machine.Alu Alu Blister Packing Machine for Tablet&Capsule: The Best Solution for Pharmaceutical PackagingThe world of pharmaceutical packaging has witnessed a tremendous transformation in the recent past with the development of new and innovative packaging solutions. The introduction of Alu Alu Blister Packing Machine for Tablet&Capsule is one such solution that has revolutionized the way medicines are packaged and distributed. This advanced packaging technology, which uses cold-forming aluminum, has become the standard in the pharmaceutical industry due to its ability to protect the medicine, improve its shelf-life, and ensure patient safety. Additionally, PVC Blister Packing Machine is an alternative thermoforming plastic option that is also ideal for packaging tablets and capsules.The Alu Alu Blister Packing Machine is a specialized design that guarantees accuracy, efficiency, and reliability in the packing of tablets, capsules, and other medical products. This machine uses a cold-forming process that involves the molding of aluminum foil into the desired shape, usually a blister pack. The shrinking and shaping process of the aluminum foil ensures that it can hold the tablet or capsule securely, while providing an airtight and moisture-free environment to preserve the medication. This method of packaging is ideal for medicines that are sensitive to light, humidity, and other environmental factors that could degrade their effectiveness.The Alu Alu Blister Packing Machine for Tablet&Capsule offers numerous benefits to pharmaceutical companies. The primary advantage is the protection of the medicine. The aluminum foil used in the cold-forming process is an excellent barrier against light, moisture, and other external factors that could cause the medicine to deteriorate. Additionally, the secure packaging enhances the convenience of the medicine, making it easy to dispense and transport. The Alu Alu Blister Packing Machine is also highly efficient and reliable, with a low error rate. This high level of accuracy saves on material and labor costs, making it cost-effective in the long run.Another advantage of the Alu Alu Blister Packing Machine for Tablet&Capsule is its versatility. It can be used to pack different types of tablets and capsules in various sizes and shapes, making it suitable for a broad range of medicines. Additionally, this machine can be customized to include safety features, such as tamper-evident seals or barcodes, to ensure that the medicine is not counterfeit and is safe for consumption.PVC Blister Packing Machine is another packaging solution that pharmaceutical companies can consider. The machine works by thermoforming plastic, mainly PVC, into blisters. PVC Blister Packing Machine is ideal for packaging medicines that do not require the protection of aluminum foil but still need adequate packaging to prevent exposure to the environment. Besides, the PVC material is cost-effective and readily available, making it an attractive option for small and medium-sized pharmaceutical companies.In conclusion, the Alu Alu Blister Packing Machine and the PVC Blister Packing Machine are two packaging solutions that pharmaceutical companies can consider for their tablets and capsules. The Alu Alu Blister Packing Machine is particularly suited for medicines that require high-level protection, while PVC Blister Packing Machine works well for medicines that require a less rigid package. Both models are highly efficient, reliable, and customizable to meet the specific needs of different pharmaceutical companies. As technology advances, packaging solutions will continue to evolve, and it is essential to keep abreast of new and innovative solutions that can enhance the safety, convenience, and effectiveness of pharmaceutical products.

Efficient and Automated Packing Machines for Mushrooms

[Title]: Advanced Mushroom Packing Machine Revolutionizes Packaging Processes for Mushroom Producers[Subtitle]: The Cutting-Edge Technology Enhances Efficiency and Maximizes Product Quality in the Mushroom Industry[date], [location] - In recent times, the mushroom industry has witnessed a revolutionary transformation in its packaging processes with the introduction of an advanced mushroom packing machine. Developed by an innovative company that specializes in packaging solutions, this state-of-the-art machine focuses on enhancing efficiency and maximizing product quality for mushroom producers worldwide.The mushroom packing machine, which boasts cutting-edge technology and a host of groundbreaking features, has quickly become a game-changer in the industry. Its development stems from the company's commitment to providing innovative packaging solutions that address the unique requirements of mushroom producers.One of the standout features of this mushroom packing machine is its ability to handle a wide variety of mushroom types. The machine is designed to carefully pack different varieties, including white, portobello, shiitake, oyster, and cremini mushrooms, without compromising their quality or appearance. This versatility allows mushroom producers to streamline their packing processes and cater to a more diverse market.Furthermore, the mushroom packing machine incorporates advanced sorting mechanisms to ensure only the highest quality mushrooms make it into the final packaging. By employing cutting-edge technology, including image recognition and artificial intelligence, the machine can identify and sort mushrooms based on size, shape, and color. This feature not only enhances the overall quality of the packed mushrooms but also reduces the need for manual sorting, saving valuable time and resources for mushroom producers.In addition to its exceptional sorting capabilities, the packing machine also employs state-of-the-art packaging materials to extend the shelf life of mushrooms. With the inclusion of moisture-absorbent and breathable packaging, the machine creates an optimal environment for mushrooms, preserving their freshness and flavor for an extended period. This technological advancement plays a crucial role in reducing food waste and ensuring that end consumers receive mushrooms of the highest quality.The mushroom packing machine also emphasizes efficiency and productivity. With automated processes and minimal human intervention, mushroom producers can significantly reduce labor costs and increase production output. The machine's user-friendly interface allows operators to easily modify settings, monitor production progress, and identify any potential issues, ensuring a seamless and hassle-free packing experience.Furthermore, the company behind this groundbreaking technology provides comprehensive after-sales support and maintenance services. This commitment to customer satisfaction ensures that mushroom producers can rely on the machine's consistent performance and receive prompt assistance whenever required.As a result of these innovative features and the company's dedication to excellence, the mushroom packing machine has garnered widespread acclaim within the industry. Mushroom producers worldwide have embraced this advanced technology, enhancing their competitiveness in the market and ensuring that consumers receive mushrooms of exceptional quality.In conclusion, the introduction of the advanced mushroom packing machine has revolutionized the packaging processes within the mushroom industry. With its ability to handle various mushroom varieties, advanced sorting mechanisms, premium packaging materials, and emphasis on efficiency, this machine has raised the bar for mushroom producers worldwide. By integrating cutting-edge technology into their packaging operations, mushroom producers can now meet the increasing demands of the market while ensuring the delivery of fresh and high-quality mushrooms to consumers.

Horizontal Wrapping Machine for Stretch Wrapping Long Products and Special-Shaped Objects

article.In the world of packaging, stretch wrapping has become an essential part of the process. It offers numerous advantages over other methods, including protection, containment, and unitization of products. And when you add automation to the equation, the benefits multiply exponentially. That's where the Fhope series of horizontal orbital stretch wrapping machines come in.The Fhope series of horizontal wrapping machines are designed to handle long, straight objects like profile, board, aluminum, and doors. But they're not limited to just those shapes. They've also achieved success in wrapping special-shaped products, tubes, and plates.One of the standout features of the Fhope machines is their build quality. They're constructed to high standards and specifications, and those standards have only improved with time. This dedication to quality is reflected in the satisfaction of customers who have used the machines.But the Fhope machines are more than just well-built stretch wrappers. They also come equipped with a range of features that make them highly automated and customizable. For example, there's an automatic cutting system that ensures precise and consistent cuts, as well as a timber feeding device that can handle a wide range of materials.But perhaps the most important feature of the Fhope machines is their soft press down device. This device ensures a tight and secure wrap of the product, while also protecting it from damage. This is especially important when wrapping delicate or fragile items, as it can prevent them from being crushed or dented during the wrapping process.All of these features combine to make the Fhope series of horizontal orbital stretch wrapping machines an indispensable tool for any packaging operation. They offer unparalleled protection and unitization of products, while also saving time and reducing labor costs. And with their flexibility and automation, they can be customized to meet the specific needs of any industry or product.So if you're in the market for a stretch wrapping machine, look no further than Fhope. Their commitment to quality and innovation is evident in every machine they produce, and their customer satisfaction is a testament to their success. With Fhope, you can be confident that your products will be wrapped securely and efficiently, every time.

The Art of Crafting Handmade Vegan Chocolate Truffles in Norfolk

Booja-Booja is a UK-based company that specializes in creating exquisite vegan chocolate truffles. The company was founded in 1999 by Colin Mace and Sue Paine, who were passionate about creating high-quality, organic treats that were both delicious and sustainable.Over the years, Booja-Booja has become known for its devotion to excellence in chocolate-making, with a commitment to using only the finest, organic ingredients. Their vegan chocolate truffles are handmade in Norfolk, England, and have gained a worldwide following for their rich, decadent flavor and beautiful, artisanal appearance.One of the things that sets Booja-Booja apart from other chocolate makers is their dedication to ethical and sustainable practices. The company is certified by the Soil Association and is committed to using organic, fair trade ingredients whenever possible. Their packaging uses recycled materials and is designed to be as environmentally friendly as possible.When it comes to creating their vegan chocolate truffles, Booja-Booja takes great care in every step of the process. The company's team of talented chocolatiers works tirelessly to ensure that each truffle is crafted to perfection, from selecting the finest ingredients to molding each delicate piece by hand.One of the secrets to Booja-Booja's success is their dedication to using only the purest, most natural ingredients. Their vegan chocolate truffles are made with a base of organic coconut oil and organic cocoa powder, which gives them their rich, silky texture. They are then flavored with organic fruits, nuts, and spices, which come together to create a complex, indulgent taste.One of the most remarkable things about Booja-Booja's vegan chocolate truffles is their versatility. Despite being vegan and dairy-free, they are beloved by chocolate-lovers of all types, from strict vegans to those who simply appreciate delicious, high-quality chocolate. Their range of flavors is extensive, with options like Fine de Champagne, Hazelnut Crunch, and Almond Salted Caramel.But it's not just the taste of Booja-Booja's vegan chocolate truffles that sets them apart. Their beautiful, artistic appearance is just as much a part of the experience as the flavor. Each truffle is carefully molded and decorated by hand, with stunning designs that bring a touch of luxury to any occasion.Overall, Booja-Booja has proven that vegan chocolate can be every bit as delicious and indulgent as traditional chocolate. Their commitment to excellence in every aspect of chocolate-making sets them apart as a truly unique and exceptional brand. Whether you're a lifelong vegan or just looking to indulge in a guilt-free treat, Booja-Booja's vegan chocolate truffles are sure to delight your tastebuds and leave you wanting more.

Get the Best Hot Air Sealing Machine for Efficient Packaging

Title: Advanced Hot Air Sealing Machine Revolutionizes Packaging IndustryIntroduction:In today's rapidly growing packaging industry, innovative technologies are at the forefront of driving efficiency, speed, and reliability. One such groundbreaking invention is the advanced Hot Air Sealing Machine, an industry-leading solution that promises to revolutionize packaging operations. This cutting-edge equipment, developed by a renowned manufacturing company, is poised to transform the way products are sealed, delivering superior results and unparalleled convenience.The Hot Air Sealing Machine, designed and manufactured by [the company], represents a remarkable engineering feat. Equipped with state-of-the-art features and cutting-edge automation, this innovation sets new standards for packaging precision, speed, and reliability. Built to cater to a wide range of industrial sectors, including food and beverage, electronics, pharmaceuticals, and textiles, this machine boasts exceptional versatility.With a focus on providing thermal sealing solutions, the Hot Air Sealing Machine offers significant advantages over traditional sealing methods. Its advanced technology ensures better airtightness, greater resistance to environmental factors, and higher seal strength. By utilizing precise temperature and pressure controls, this equipment guarantees a consistent, foolproof sealing process, eliminating potential leaks and enhancing product protection.The Hot Air Sealing Machine delivers unparalleled flexibility to accommodate a variety of packaging materials, including composites, laminates, and films. Its adjustable settings allow operators to easily customize the sealing process based on specific product requirements, ensuring compatibility with a plethora of packaging types. Therefore, manufacturers can seamlessly adapt to changing market needs without compromising on quality or productivity.Moreover, the machine's cutting-edge automation capabilities significantly improve packaging efficiency and reduce labor costs. With a user-friendly interface, operators can effortlessly program their desired settings, leading to streamlined operations and increased productivity. Furthermore, this equipment's high-speed sealing process enables superior output in a shorter timeframe, enhancing overall production capacity.The Hot Air Sealing Machine also exhibits exceptional safety features, making it an ideal choice for manufacturers prioritizing employee well-being. The integration of advanced sensors and safety measures ensures optimal performance while safeguarding operators from any potential accidents. This emphasis on safety not only protects workers but also mitigates production delays and minimizes maintenance requirements.One of the standout features of this machine is its compatibility with Industry 4.0 standards. The integration of Internet of Things (IoT) capabilities allows seamless connectivity with other production equipment, creating a smart and interconnected production line. By accessing real-time data and analytics, manufacturers can proactively address any deviations, optimize production processes, and make informed decisions to drive efficiency and cost-effectiveness.As the packaging industry continues to evolve, the innovative Hot Air Sealing Machine presents an unparalleled opportunity for manufacturers to elevate their operations. With its state-of-the-art features, this equipment ensures superior product protection, streamlined processes, and increased overall efficiency. By embracing this technology, companies can stay ahead of the competition, deliver exceptional packaging solutions, and meet the ever-growing demands of the market.In conclusion, the Hot Air Sealing Machine, developed by [the company], is a remarkable addition to the packaging industry. With its advanced features, superior flexibility, and exceptional efficiency, this innovation promises to revolutionize the way products are sealed. Manufacturers across various sectors can now leverage this technology to enhance their operations, ensuring optimal product protection, reducing labor costs, and driving long-term success in a competitive market.

Packaging Machinery Company For Sugar Powder Sachet Filling And Sealing - Vertical Equipment Available. Contact For Pricing.

In today's fast-paced world, packaging is an increasingly important aspect of many industries. The need for properly sealing and packaging products has never been more crucial, especially for food-related items. This is where packaging equipment comes into play, such as the Sugar Powder Pouch Sachet Stick Filling And Packing Machine-Shuntian China Sugar Powder Pouch Sachet Packaging Machinery Company.Shuntian China Sugar Powder Pouch Sachet Packaging Machinery Company (name removed) has been a leading provider of vertical sugar filling and sealing equipment for years. Their state-of-the-art technology and quality products have made them a reliable partner in the packaging industry, with customers all over the world.The Sugar Powder Pouch Sachet Stick Filling And Packing Machine is an ideal solution for packaging sugar powder and other similar products. The machine is equipped with all the latest technology needed to accurately measure and fill pouches or sachets with the product. The machine is also designed to ensure that the product remains fresh, free from contaminants, and with an extended shelf life.The machine has an easy-to-use interface that allows for stress-free set-up and adjustment. Additionally, it is constructed using a modular design, meaning that maintenance and repairs can be done without having to dismantle the entire machine. This feature is extremely beneficial as it minimizes downtime, ensuring production continues smoothly, thereby increasing profits for the company.The machine is highly customizable, with the ability to package various sizes of the pouches and sachets, depending on the volume required by the end-user. This flexibility has made it a versatile machine, allowing it to cater to different customer needs. Moreover, the machine is designed to operate at high speeds, thereby increasing the production time and reducing labor costs. This is particularly crucial for companies that require large volumes of sugar powder packaging in a short amount of time.The vertical sugar filling and sealing equipment combines a filling machine, a sealing machine, and a conveyor into one unit. This means fewer pieces of equipment are required, saving valuable floor space, which could be utilized more efficiently. The conveyor is adjustable to different speeds, enabling the production team to package the product at the desired rate.In addition to the machine itself, Shuntian China Sugar Powder Pouch Sachet Packaging Machinery Company's customer service is second to none. They have a dedicated team of professionals who are always willing to provide advice and support to their customers. Any issues that arise are dealt with in a timely manner, ensuring that the production process is not affected. This has made them a favorite among customers, especially those who highly value excellent customer service.In conclusion, the Sugar Powder Pouch Sachet Stick Filling And Packing Machine-Shuntian China Sugar Powder Pouch Sachet Packaging Machinery Company is a high-quality product that has been designed to meet the needs of modern-day packaging. It is a reliable, efficient, and cost-effective solution that has gained popularity in the packaging industry. With a combination of cutting-edge technology, fast production time, and excellent customer service, it's no wonder that Shuntian China Sugar Powder Pouch Sachet Packaging Machinery Company is a force to be reckoned with.

High Quality Automatic Packing Machines for Food and Other Products

In today's fast-paced world, the demand for cutting-edge technology is increasing rapidly. People are always looking for ways to make their lives more convenient, and this includes the way they buy and consume food. Packaging plays a critical role in this, and it is more important than ever before to have efficient and reliable food packaging machines.Wenzhou Huaqiao Packing Machine Factory is one such manufacturer that has made a name for itself in the food packaging industry. As a professional manufacturer of vacuum packers, automatic food packing machines, sealing machines for bags, carton sealers, cup sealers, thermal shrink tunnel machines, and date printers, the company has been providing top of the line packaging products since its inception.With years of experience and a team of highly skilled professionals, Wenzhou Huaqiao Packing Machine Factory has refined its manufacturing process to deliver machines that are highly efficient, reliable, and user-friendly. Their machines have become a staple in many businesses, including food processing plants, supermarkets, and cafes.The automatic food packing machine is one of the many products that Wenzhou Huaqiao offers. It is designed to pack food automatically, taking the hassle out of the process and saving valuable time and labor costs. The machine can handle a wide range of food products, from fresh fruits and vegetables to meats, dairy products, and more.The automatic food packing machine works by feeding the food product into the machine, where it is sealed in a bag and then vacuum packed. The machine is equipped with state-of-the-art sensors that ensure the packaging process is accurate, efficient, and consistent. This ensures that the food is packed with precision and is safe for consumption.Another product that Wenzhou Huaqiao offers is the vacuum packer. It is designed to extend the shelf life of food products by removing all the air from the packaging. This not only keeps the food fresh but also prevents the growth of bacteria, which can cause the food to spoil.The vacuum packer is a versatile machine that can handle a variety of food products, including dry goods, meats, and even liquids. The machine is easy to operate and comes with a user-friendly interface that is designed to minimize downtime.In addition to the vacuum packer and automatic food packing machine, Wenzhou Huaqiao also provides a range of sealing machines for bags, carton sealers, cup sealers, thermal shrink tunnel machines, and date printers. These machines are designed to meet the unique needs of different businesses and provide an all-in-one solution for packaging requirements.Wenzhou Huaqiao has built a reputation for itself as a company that provides high-quality packaging machines at competitive prices. Their commitment to quality, innovation, and customer satisfaction is what sets them apart from the competition. Their machines not only meet but exceed industry standards, ensuring that their clients get the best value for their money.In conclusion, the demand for efficient and reliable food packaging machines is increasing worldwide. Wenzhou Huaqiao Packaing Machine Factory has been providing top quality packaging products for years. Their machines are user-friendly, efficient, and innovative, making them an ideal choice for businesses in the food industry. With a team of experienced professionals, the company ensures that they meet and exceed their clients' expectations in every way possible.

Celebrate Peanut Brittle Day on January 26th with this Easy Recipe for Nut Brittle!

Title: Celebrate Peanut Brittle Day with an Easy Homemade Recipe and Peanut Brittle Making MachineIntroduction:January 26th is celebrated as Peanut Brittle Day, a perfect occasion to indulge in this delicious, crunchy treat. Whether you prefer the traditional peanut brittle or enjoy experimenting with different nuts, making peanut brittle at home can be a fun activity to do with kids. Additionally, to enhance your peanut brittle-making experience and ensure consistent results, investing in a high-quality Peanut Brittle Making Machine can be a game-changer. Join us as we share an easy peanut brittle recipe while exploring the advantages of using a Peanut Brittle Making Machine.Homemade Peanut Brittle Recipe:Below is a simple recipe for making peanut brittle that can be customized with various types of nuts and toppings. This recipe can be a great way to bond with your kids while celebrating Peanut Brittle Day.Ingredients:- 2 cups granulated sugar- 1 cup light corn syrup- 1/2 cup water- 2 cups raw unsalted peanuts (or any nut of your choice)- 2 tablespoons unsalted butter- 1 teaspoon vanilla extract- 1 teaspoon baking soda- Optional: salt or chocolate for sprinkling or coatingInstructions:1. Prepare a baking sheet by lining it with parchment paper or greasing it with butter.2. In a large saucepan, combine sugar, corn syrup, and water. Stir until the sugar dissolves completely.3. Place the saucepan on medium heat and bring the mixture to a boil. Insert a candy thermometer and cook until the temperature reaches 300°F (150°C), also known as the "hard crack" stage.4. Add the peanuts to the boiling mixture and stir continuously for 5-7 minutes or until the mixture turns amber in color.5. Remove the saucepan from heat and quickly stir in the butter, vanilla extract, and baking soda. The mixture will foam and bubble.6. Pour the hot mixture onto the prepared baking sheet and spread it evenly using a heat-resistant spatula.7. If desired, sprinkle some salt over the hot peanut brittle for a savory twist or melt chocolate and coat the brittle pieces.8. Allow the brittle to cool completely, then break it into desired pieces.9. Store in an airtight container.Advantages of a Peanut Brittle Making Machine:To simplify and enhance the peanut brittle-making process, investing in a Peanut Brittle Making Machine can be highly beneficial. These machines are specifically designed to ensure quick, efficient, and consistent production of peanut brittle, saving both time and effort. Some key advantages of using a Peanut Brittle Making Machine include:1. Automated Production: Peanut Brittle Making Machines offer automated production, eliminating the need for constant manual stirring and monitoring. This allows for greater convenience and increased productivity.2. Precise Temperature Control: These machines come equipped with advanced temperature control systems, guaranteeing accurate and consistent cooking temperatures. This ensures that each batch of peanut brittle is perfectly cooked.3. Versatile Nut Options: Peanut Brittle Making Machines allow for the use of different types of nuts, such as almonds, cashews, or macadamia nuts. This allows you to cater to various taste preferences or create unique combinations.4. Uniform Thickness: Peanut Brittle Making Machines are designed to spread and flatten the mixture evenly, resulting in uniformly thick brittles. This ensures a consistent texture and enhances the overall presentation.5. Improved Safety: The use of a Peanut Brittle Making Machine reduces the risks associated with traditional stovetop cooking, such as burns or accidental spills. This makes it safer, particularly when involving children in the process.Conclusion:As Peanut Brittle Day approaches, celebrate the occasion by making your own homemade peanut brittle. Get creative by using different nuts and exploring various toppings like salt or chocolate. To make the process even more enjoyable and efficient, consider investing in a Peanut Brittle Making Machine. These machines offer automated production, precise temperature control, versatility with nut options, uniform thickness, and improved safety. So gather your ingredients, get ready to make some tasty brittle, and enjoy this delightful treat on Peanut Brittle Day!