Top Chocolate Making Equipment to Elevate Your Confectionery Game

By:Admin

Introduction:

The confectionery industry has seen a significant shift over the years with the introduction of advanced technology, aimed at enhancing chocolate production processes. One of the latest breakthroughs in this field comes from a leading manufacturer of chocolate making equipment, which has unveiled a cutting-edge solution that promises to revolutionize the way chocolates are produced. This innovative machinery aims to streamline production, improve product quality, and reduce operational costs, thereby meeting the ever-growing demand for high-quality chocolates in an efficient and sustainable manner.

Company Introduction:

{Company Name}, a renowned leader in the confectionery industry, has been at the forefront of developing state-of-the-art chocolate making equipment for over two decades. Its commitment to innovation and excellence has earned it a prominent position in the global market. Known for its dedication to meeting customer needs, {Company Name} has introduced various technological advancements that have transformed the chocolate manufacturing process worldwide.

Industry Insights:

The confectionery industry has witnessed a steady rise in consumer demand for premium, artisanal chocolates. As a result, chocolatiers and manufacturers are constantly seeking efficient and reliable equipment to meet these growing expectations. Traditional chocolate-making methods often involve tedious and time-consuming processes, requiring skilled artisans to work meticulously. This can hinder scalability and increase production costs, making it challenging for manufacturers to meet market demands while maintaining profitability.

Innovation in Chocolate Making Equipment:

{Company Name}'s groundbreaking chocolate making equipment addresses these challenges by integrating cutting-edge technologies and automation into the manufacturing process. With a focus on enhancing productivity and quality, these machines offer significant advantages to chocolatiers, enabling streamlined production and greater control over all aspects of chocolate creation.

Enhanced Process Control:

The latest machinery developed by {Company Name} allows for precise control over various parameters, such as temperature, humidity, and conching time. This technology ensures consistent product quality, flavor, and texture, enabling chocolatiers to create exceptional chocolates with ease. The equipment's intuitive interface and automated controls simplify the production process, reducing the need for manual intervention and minimizing the risk of human errors.

Efficiency and Scalability:

By incorporating advanced engineering principles, {Company Name}'s equipment streamlines production, allowing for increased output while maintaining quality standards. The machinery optimizes various stages of chocolate making, from grinding and refining to tempering and molding. With higher production rates, manufacturers can meet market demands effectively, expand their product lines, and explore new markets, all while reducing operational costs.

Sustainability and Waste Reduction:

In line with the industry's growing focus on sustainability, {Company Name}'s equipment is designed to minimize waste and energy consumption. Through advanced production techniques, the machinery ensures efficient usage of raw materials, reducing waste and enhancing overall sustainability. Moreover, the equipment's energy-saving features contribute to a greener manufacturing process, aligning with the global aim of reducing carbon footprints.

Versatility and Customization:

Understanding the diverse needs of chocolatiers worldwide, {Company Name} has developed its machinery to offer versatility and customization. The equipment can adapt to various chocolate types, accommodating different recipes, flavors, and textures. This flexibility enables chocolatiers to maintain their unique identity within the market, catering to specific customer preferences and offering a personalized chocolate experience.

Conclusion:

With the introduction of {Company Name}'s cutting-edge chocolate making equipment, the confectionery industry is poised to experience a significant transformation. The integration of advanced technologies, enhanced process control, efficiency, sustainability, and versatility offers immense benefits to chocolatiers and manufacturers alike. By revolutionizing the chocolate production process, {Company Name} reinforces its position as an industry leader committed to driving innovation and meeting the evolving needs of the market, while ensuring the delivery of high-quality and enticing chocolates to consumers worldwide.

Company News & Blog

Efficient and Automated Packing Machines for Mushrooms

[Title]: Advanced Mushroom Packing Machine Revolutionizes Packaging Processes for Mushroom Producers[Subtitle]: The Cutting-Edge Technology Enhances Efficiency and Maximizes Product Quality in the Mushroom Industry[date], [location] - In recent times, the mushroom industry has witnessed a revolutionary transformation in its packaging processes with the introduction of an advanced mushroom packing machine. Developed by an innovative company that specializes in packaging solutions, this state-of-the-art machine focuses on enhancing efficiency and maximizing product quality for mushroom producers worldwide.The mushroom packing machine, which boasts cutting-edge technology and a host of groundbreaking features, has quickly become a game-changer in the industry. Its development stems from the company's commitment to providing innovative packaging solutions that address the unique requirements of mushroom producers.One of the standout features of this mushroom packing machine is its ability to handle a wide variety of mushroom types. The machine is designed to carefully pack different varieties, including white, portobello, shiitake, oyster, and cremini mushrooms, without compromising their quality or appearance. This versatility allows mushroom producers to streamline their packing processes and cater to a more diverse market.Furthermore, the mushroom packing machine incorporates advanced sorting mechanisms to ensure only the highest quality mushrooms make it into the final packaging. By employing cutting-edge technology, including image recognition and artificial intelligence, the machine can identify and sort mushrooms based on size, shape, and color. This feature not only enhances the overall quality of the packed mushrooms but also reduces the need for manual sorting, saving valuable time and resources for mushroom producers.In addition to its exceptional sorting capabilities, the packing machine also employs state-of-the-art packaging materials to extend the shelf life of mushrooms. With the inclusion of moisture-absorbent and breathable packaging, the machine creates an optimal environment for mushrooms, preserving their freshness and flavor for an extended period. This technological advancement plays a crucial role in reducing food waste and ensuring that end consumers receive mushrooms of the highest quality.The mushroom packing machine also emphasizes efficiency and productivity. With automated processes and minimal human intervention, mushroom producers can significantly reduce labor costs and increase production output. The machine's user-friendly interface allows operators to easily modify settings, monitor production progress, and identify any potential issues, ensuring a seamless and hassle-free packing experience.Furthermore, the company behind this groundbreaking technology provides comprehensive after-sales support and maintenance services. This commitment to customer satisfaction ensures that mushroom producers can rely on the machine's consistent performance and receive prompt assistance whenever required.As a result of these innovative features and the company's dedication to excellence, the mushroom packing machine has garnered widespread acclaim within the industry. Mushroom producers worldwide have embraced this advanced technology, enhancing their competitiveness in the market and ensuring that consumers receive mushrooms of exceptional quality.In conclusion, the introduction of the advanced mushroom packing machine has revolutionized the packaging processes within the mushroom industry. With its ability to handle various mushroom varieties, advanced sorting mechanisms, premium packaging materials, and emphasis on efficiency, this machine has raised the bar for mushroom producers worldwide. By integrating cutting-edge technology into their packaging operations, mushroom producers can now meet the increasing demands of the market while ensuring the delivery of fresh and high-quality mushrooms to consumers.

Discover the Debut of Cotton Candy at the St. Louis Fair in "Fairy Floss: The Sweet Story of Cotton Candy" by Ann Ingalls.

Cotton Candy – The Ultimate Sweet TreatCotton candy, also known as fairy floss, is a delicious treat loved by children and adults alike. It is a fluffy cloud of spun sugar that melts in your mouth, leaving behind a sweet taste that you will never forget. The origins of cotton candy can be traced back to the early 1900s, when a dentist in Nashville named William Morrison and a confectioner named John C. Wharton invented a machine that spun sugar threads into a fluffy confection. Today, cotton candy is a carnival staple, loved by millions of people all over the world.The Sweet Story of Cotton CandyCotton candy made its debut at the St. Louis World's Fair in 1904, where it was marketed as Fairy Floss. It was an immediate hit, and soon became a popular carnival food. Over the years, the recipe and machinery used to make cotton candy have evolved, but the basic idea remains the same – to spin sugar into a form that is light and fluffy, and melts in your mouth.The Sugar Candy Floss MachineThe Sugar Candy Floss Machine is the key to making delicious cotton candy at home or at events. It is a simple yet effective machine that spins sugar into a fluffy cloud of deliciousness. The machine consists of a spinning head that heats up and melts the sugar, and a central bowl that catches the spun threads of sugar. The cotton candy is then collected on a stick or cone, ready to be enjoyed.Making Your Own Cotton CandyMaking cotton candy at home is easy with the Sugar Candy Floss Machine. Simply add sugar to the spinning head, and watch as it is transformed into a fluffy cloud of deliciousness. You can add food coloring to the sugar to create colorful cotton candy, or even mix in flavors to create unique tastes. Cotton candy is the perfect treat for parties, events, or just a fun family activity.In conclusion, cotton candy is one of the most beloved sweet treats in the world. Its fluffy texture and sweet taste make it a favorite of both young and old. With the Sugar Candy Floss Machine, you can easily make cotton candy at home or at events, and enjoy the magic of this delightful treat. So go ahead, indulge in some fluffy goodness, and experience the sweet story of cotton candy for yourself.

Industrial Packaging Machinery for Efficient Sealing Operations

Continuous Sealing Machine Proves to be a Game Changer for the Packaging IndustryThe packaging industry has been using various types of sealing machines for decades. But with the advent of advanced technology, traditional sealing machines have been replaced by modern equipment that promises to increase efficiency and accuracy. One such piece of equipment that has been gaining popularity in the industry is the Continuous Sealing Machine (CSM).The Continuous Sealing Machine (CSM) is a state-of-the-art packaging machine that has revolutionized the way products are packaged. It is an advanced sealing machine that has brought about a significant change in the sealing process. The CSM is designed to perform a variety of tasks like sealing, coding, and printing.The CSM is designed with the latest technology where the sealing process is automated and carried out without any human intervention, ensuring maximum efficiency and accuracy. The machine is easy to operate and can be used by anyone with minimal training.This innovative machine can be used to seal various types of packages, including pouches, bags, and sachets. This versatility allows the machine to cater to many industries, including food, cosmetics, pharmaceuticals, and more. It can seal almost any type of material, including paper, foil, plastic, and laminates.The CSM's potential uses do not end with just sealing. The machine can also be used for coding and printing, allowing companies to print data such as batch numbers, expiry dates, and manufacturing dates. The printing operation is carried out using an inkjet printer that is integrated into the machine. This ensures that the print quality is high and uniform.Another significant advantage of the CSM is that it can seal packages continuously without any breaks. This saves the operator time and increases the throughput. The machine is also equipped with sensors that detect if the sealing process is improper, which prevents defective products from being packaged. This ensures that only high-quality products reach customers.One of the leading manufacturers of the CSM is a company in China that has been supplying packaging machinery for more than a decade. The company has been at the forefront of developing advanced packaging machines that cater to different industries.In addition to the CSM, the company also produces a range of machines, including automatic packaging machines, vacuum packaging machines, and other specialized packaging machines. The company has its manufacturing facilities in China and has a significant presence in the packaging industry.The company's machines are known for their robust design, reliability, and high accuracy. The machines are built with high-quality components and undergo strict quality control measures to ensure that they meet the international standards.The company has a team of engineers and technicians who work tirelessly to develop new machines and improve existing ones. They also provide excellent after-sales support to ensure that customers get the maximum benefit from their investment.In conclusion, the Continuous Sealing Machine is a game-changer for the packaging industry. Its ability to seal, code, and print make it a versatile machine that can cater to various industries. With its automated operation, the machine ensures high efficiency and accuracy, leading to increased productivity and customer satisfaction. Companies that switch to the CSM can opt for customizations that suit their specific needs. With continuous innovation and technological advancements, the future looks bright for the packaging industry and the Continuous Sealing Machine.

Advanced Skin Packaging Machine: A Game Changer in the Packaging Industry

Title: Cutting-Edge Skin Packaging Machine Revolutionizes Packaging IndustryIntroduction:In an era where efficient packaging solutions are paramount, the industry-leading company, whose name has been withheld, has unveiled its latest innovation in packaging technology to cater to the growing needs of businesses worldwide. The state-of-the-art Skin Packaging Machine introduces cutting-edge features that have the potential to revolutionize the packaging industry. With a relentless pursuit of innovation and commitment to excellence, the company aims to empower businesses with a packaging solution that is both efficient and visually appealing.Unveiling the Skin Packaging Machine:The recently unveiled Skin Packaging Machine promises to elevate the packaging process to new heights. By incorporating advanced technology and an ergonomic design, the machine aims to optimize efficiency, reduce labor costs, and enhance product preservation. This achievement is a testament to the company's dedication to staying at the forefront of the packaging industry by constantly creating solutions that address the evolving needs of businesses across various sectors.Advanced Features and Functionality:The Skin Packaging Machine, equipped with cutting-edge features, is designed to ensure precision packaging while maintaining the integrity of the products. The machine uses vacuum sealing technology to wrap products in a protective skin-tight film, increasing the shelf life of perishable goods and reducing the risk of damage during transportation. This innovative method also provides an airtight seal that protects against moisture, contaminants, and other external factors that could compromise product quality.The machine's user-friendly interface allows for seamless operation, ensuring that even operators with minimal training can efficiently handle the packaging process. Additionally, its versatility enables businesses to package a wide range of products such as perishable food items, delicate electronic devices, or even automotive parts, making it a valuable asset for manufacturers and wholesalers across various industries.Benefits for Businesses:The Skin Packaging Machine offers several benefits for businesses seeking to streamline their packaging operations. By reducing the need for excessive manual labor, it minimizes production costs, enhances productivity, and ultimately improves profitability. Its ability to preserve the freshness and quality of perishable products also enables businesses to extend their product shelf life, reducing waste and increasing customer satisfaction.The machine's sleek and professional packaging design not only protects the products but also enhances their presentation. This visually appealing packaging can significantly impact consumers' perception of the brand, making it more likely for them to choose the product over competitors.Commitment to Sustainability:In addition to its functional advantages, the Skin Packaging Machine aligns with the company's commitment to environmental sustainability. The machine utilizes eco-friendly materials, minimizing the impact on the environment and promoting a greener approach to packaging. By opting for this cutting-edge technology, businesses contribute to the reduction of plastic waste and demonstrate their dedication to sustainability and responsible manufacturing.Prospects and Future Developments:With its groundbreaking features and benefits, the Skin Packaging Machine presents significant opportunities for businesses to enhance their packaging processes. Its adaptability and user-friendliness position it as a long-term solution for packaging needs across diverse industries.Looking ahead, the company remains dedicated to further developments and improvements in packaging technology. Its research and development team continues to explore new ways to optimize the skin packaging process, introducing innovative features and functionalities that address the ever-changing demands of the market.Conclusion:The unveiling of the Skin Packaging Machine marks a significant milestone in the packaging industry, demonstrating the company's commitment to revolutionizing the way businesses package their products. Through its cutting-edge technology, user-friendly interface, and environmental sustainability, the machine offers businesses an efficient and visually appealing solution. As the industry evolves, the company's dedication to innovation ensures it remains at the forefront, continuously shaping the future of packaging.

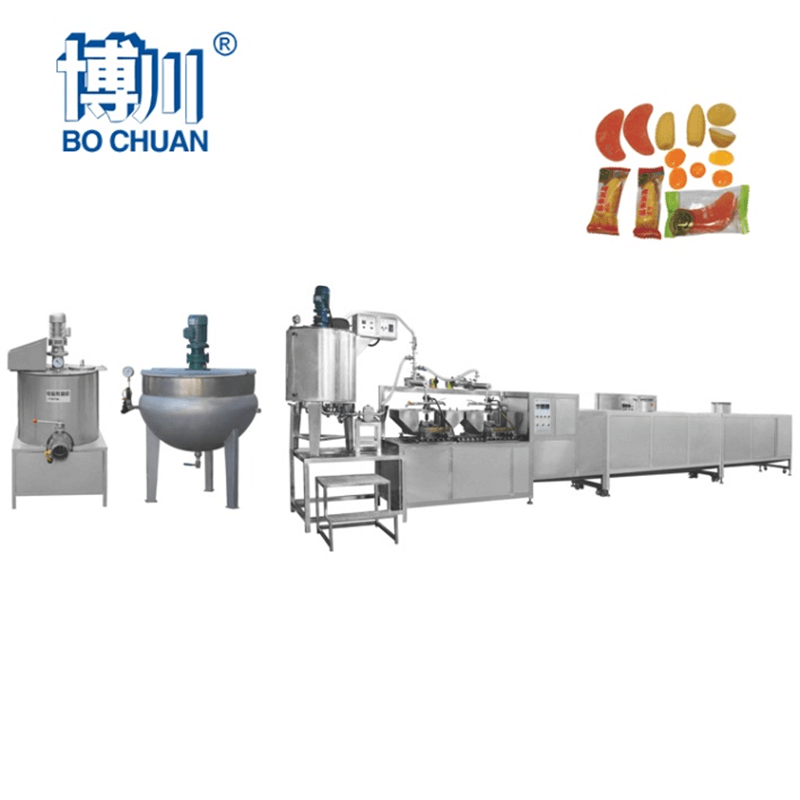

Delicious Candy Manufacturing Process Unveiled

article.Candy Production Industry – A Sweet Business!Candies have always been an integral part of our lives. From childhood to adulthood, these sweet treats have never failed to bring a smile to our faces. The candy production industry is one of the oldest and most successful industries across the world, with numerous players offering sweet delights to their customers. Amongst all, one name stands out - {brand name removed} - a company that has been satisfying the sweet cravings of people for over 100 years.{Brand name removed} is a leading candy production company that has come a long way since its inception in 1909. The company has its headquarters in (location) and has always been focused on producing the highest quality sweets for their customers. {Brand name removed} believes in innovation and has continuously experimented with new flavors, colors, and shapes to cater to different tastes and preferences.The candy production industry is highly competitive, and {brand name removed} has always stayed ahead of the game with its unique approach to candy-making. The company produces a wide range of products, including gummies, hard candies, and chocolate bars, among others. Each of these products is made with the finest ingredients and with the utmost care, which is why {brand name removed} has become a household name across the globe.It takes a lot of effort and dedication to produce the perfect candy, and {brand name removed} takes this very seriously. The company's manufacturing process is of the highest standard, and it ensures that all its products are free from artificial colors, allergens, and genetically modified organisms. {Brand name removed} has also invested in state-of-the-art technology that guarantees consistency, flavor, and texture across all its candy products.In addition to producing high-quality sweets, {brand name removed} is also dedicated to sustainable candy production. The company ensures that all its manufacturing processes are sustainable and minimize waste. From using eco-friendly packaging to reducing greenhouse gas emissions, the company is committed to protecting the environment. {Brand name removed} also believes in ethical business practices and follows fair-trade policies to ensure that all its ingredients are sourced responsibly.The candy production industry has faced several challenges in recent times, with the outbreak of the COVID-19 pandemic affecting businesses across the world. However, {brand name removed} has been able to stay afloat and has even managed to boost candy sales during these difficult times. The company has adopted online sales channels and has also focused on innovative marketing strategies to engage with their customers.As lockdowns and travel restrictions have affected many people's ability to go out and socialize, {brand name removed} has introduced virtual tasting sessions, where their customers can experience their products from the comfort of their own homes. The company has also offered special discounts and promotions to keep their sales going during these tough times.In conclusion, the candy production industry is a sweet business, and {brand name removed} has proven to be a leader in this field. With its commitment to high-quality, sustainable, and ethical candy production, the company has set a benchmark for others to follow. Its dedication to innovation and its customer-centric approach have allowed {brand name removed} to stay ahead of the curve, even amidst challenging times. We look forward to seeing what the company has in store for us in the future and what new sweet treats we can expect from them.

Top 5 Efficient Packing Machines to Improve Your Workflow

Packing Machine Unveils Cutting-Edge Technology to Boost Food Preservation and PackagingTechnology has been shaping the packaging industry, making innovative solutions available for businesses to operate with more convenience and efficiency. Packing Machine, a renowned packaging machinery manufacturer, has unveiled its cutting-edge technology to improve food preservation and packaging.The company has commercialized a series of specialized machinery that enables food to be packed in a way that retains its freshness, color, and quality for an extended period. The technology developed by Packing Machine's team of experts has taken the food packaging industry to another level, and it's bound to revolutionize food preservation.The packing machinery has been designed to provide customers with complete solutions tailored to their specific packaging needs. The machines are top-notch, with different features that are ideal for different food preservation requirements, delivering customized packaging solutions for all food packaging businesses.Packing Machine stands out for offering easy-to-use and automated packing equipment. In addition, their packaging machines offer high-level performance, ensuring that businesses achieve superior results when packaging and preserving different types of food. The machines are user-friendly, and with a few clicks and steps, all the food packaging needs are met.Moreover, the machines contribute significantly to reducing food waste. The equipment's technology is mainly focused on preserving food and maintaining its quality for as long as possible, from the moment it is packed up to the point it reaches the customers' shelves. The technology employed by Packing Machine helps food last longer, thus reducing the amount of food wasted in the packaging process.Furthermore, the machinery is adaptable to various industry standards, including meat, dairy, seafood, confectionery, bakery products, and many more. The company's team of engineers continues to test, develop, and introduce new features and innovations to make their machines even more efficient, functional and suited to the food packaging industry's ever-changing trends.Packing Machine's years of experience and vast knowledge have bolstered their reputation in the food packaging industry. The company has developed an extensive network of clients across the globe, with a strong presence in China, Italy, Spain, Russia, and the United States. Such a global presence speaks volumes about the quality of Packing Machine's products and their commitment to serving their customers better.The company's dedication to high-quality manufacturing is evident in its manufacturing process. The packing machines undergo rigorous quality control procedures before they are shipped to clients globally, to ensure that they meet industry standards. This ensures that customers get top-of-the-line equipment that will not compromise or damage their products.Packing Machine CEO, John Zhou, expressed his excitement about the launching of their new range of advanced equipment, saying, "the outlook of the food packaging industry is transforming, and we are excited to be at the forefront of these changes. Our machines are designed with the aim of meeting the packaging needs of our clients, improving their packaging efficiency, and helping the environment by reducing food waste. We prioritize quality control in our manufacturing process, putting the customer's satisfaction first. We are constantly evolving, and with the ever-changing packaging industry, we aim to provide innovative packaging solutions to our customers."In conclusion, Packing Machine has undoubtedly demonstrated a commitment to innovation, quality, and efficiency in the manufacturing of their packaging machinery. With their extensive experience in the food packaging industry, they have continually provided customized solutions for their clients' specific needs. Their focus on reducing food waste through preservation technology is a significant advantage to food security and sustainability. As demand for high-quality packaging machinery in the industry increases, Packing Machine's cutting-edge technology will undoubtedly continue to stand out.

Shop a Vast Range of Vacuum Sealer Bags for Your Needs

Vacuum Sealer Bags - The Ideal Solution for Successful Food PackagingIf you are in the food industry, whether it is a restaurant, grocery store, or manufacturing business, you know how important it is to preserve the freshness of your food products. With a vacuum sealer packaging machine, you can seal your food products and prevent spoilage. However, to ensure that the sealing process is successful, you need to use the right type of vacuum sealer bags.Correct Products is a supplier of vacuum sealer bags that cater to different types of food packaging requirements. Their selection includes Poly Nylon Vacuum Seal Bags and Channel Vacuum Bags, among others. Let us look at the advantages of using vacuum sealer bags for your food products:Extends Shelf LifeOne of the greatest benefits of vacuum sealer bags is that they extend the shelf life of your food products. When you remove air from the bag, it reduces the possibility of bacterial growth, which helps in preserving the freshness of the food. This extended shelf life means that your food products can have a longer storage time, which helps you to save on wastage costs.Enhances FreshnessWhen you use vacuum sealer bags for your food packaging, the food products remain fresh for a longer duration. The reason being, vacuum sealer bags prevent the exchange of gases between the package and the atmosphere. This helps to retain the flavor, texture, and aroma of your food products, making them taste as good as the day they were prepared.Cost-EffectiveVacuum sealer bags offer a cost-effective solution to food packaging. Their extended shelf life means that you can buy your food products in bulk and package them for an extended period, which reduces the need to purchase products more frequently. Also, vacuum sealer bags are durable and easy to store, which makes them an ideal choice for businesses with limited storage space.CustomizableAnother great feature of vacuum sealer bags is that they can be customized to meet your specific requirements. Whether you need them in different sizes or with a specific design, vacuum sealer bags can be manufactured to suit your needs. This means that you can package your food products in a manner that best represents your brand.Easy to UseVacuum sealer bags are easy to use. You simply load your food product into the bag, and then place it in the vacuum sealer packaging machine. The machine then removes the air from the bag and seals it to create an airtight environment for your food products. This process is easy to execute, and it helps to save on time and labor costs.In conclusion, vacuum sealer bags are an ideal solution for successful food packaging. They help to extend the shelf life of your food products, enhance their freshness, and offer a cost-effective solution to food storage. Additionally, vacuum sealer bags can be customized to meet your specific requirements, making them a great addition to businesses in the food industry. For all your vacuum sealer bag needs, contact Correct Products today.

Top Chocolate Making Equipment to Elevate Your Confectionery Game

Title: Innovation in Chocolate Making Equipment Revolutionizes the Confectionery IndustryIntroduction:The confectionery industry has seen a significant shift over the years with the introduction of advanced technology, aimed at enhancing chocolate production processes. One of the latest breakthroughs in this field comes from a leading manufacturer of chocolate making equipment, which has unveiled a cutting-edge solution that promises to revolutionize the way chocolates are produced. This innovative machinery aims to streamline production, improve product quality, and reduce operational costs, thereby meeting the ever-growing demand for high-quality chocolates in an efficient and sustainable manner.Company Introduction:{Company Name}, a renowned leader in the confectionery industry, has been at the forefront of developing state-of-the-art chocolate making equipment for over two decades. Its commitment to innovation and excellence has earned it a prominent position in the global market. Known for its dedication to meeting customer needs, {Company Name} has introduced various technological advancements that have transformed the chocolate manufacturing process worldwide. Industry Insights:The confectionery industry has witnessed a steady rise in consumer demand for premium, artisanal chocolates. As a result, chocolatiers and manufacturers are constantly seeking efficient and reliable equipment to meet these growing expectations. Traditional chocolate-making methods often involve tedious and time-consuming processes, requiring skilled artisans to work meticulously. This can hinder scalability and increase production costs, making it challenging for manufacturers to meet market demands while maintaining profitability.Innovation in Chocolate Making Equipment:{Company Name}'s groundbreaking chocolate making equipment addresses these challenges by integrating cutting-edge technologies and automation into the manufacturing process. With a focus on enhancing productivity and quality, these machines offer significant advantages to chocolatiers, enabling streamlined production and greater control over all aspects of chocolate creation.Enhanced Process Control:The latest machinery developed by {Company Name} allows for precise control over various parameters, such as temperature, humidity, and conching time. This technology ensures consistent product quality, flavor, and texture, enabling chocolatiers to create exceptional chocolates with ease. The equipment's intuitive interface and automated controls simplify the production process, reducing the need for manual intervention and minimizing the risk of human errors.Efficiency and Scalability:By incorporating advanced engineering principles, {Company Name}'s equipment streamlines production, allowing for increased output while maintaining quality standards. The machinery optimizes various stages of chocolate making, from grinding and refining to tempering and molding. With higher production rates, manufacturers can meet market demands effectively, expand their product lines, and explore new markets, all while reducing operational costs.Sustainability and Waste Reduction:In line with the industry's growing focus on sustainability, {Company Name}'s equipment is designed to minimize waste and energy consumption. Through advanced production techniques, the machinery ensures efficient usage of raw materials, reducing waste and enhancing overall sustainability. Moreover, the equipment's energy-saving features contribute to a greener manufacturing process, aligning with the global aim of reducing carbon footprints.Versatility and Customization:Understanding the diverse needs of chocolatiers worldwide, {Company Name} has developed its machinery to offer versatility and customization. The equipment can adapt to various chocolate types, accommodating different recipes, flavors, and textures. This flexibility enables chocolatiers to maintain their unique identity within the market, catering to specific customer preferences and offering a personalized chocolate experience.Conclusion:With the introduction of {Company Name}'s cutting-edge chocolate making equipment, the confectionery industry is poised to experience a significant transformation. The integration of advanced technologies, enhanced process control, efficiency, sustainability, and versatility offers immense benefits to chocolatiers and manufacturers alike. By revolutionizing the chocolate production process, {Company Name} reinforces its position as an industry leader committed to driving innovation and meeting the evolving needs of the market, while ensuring the delivery of high-quality and enticing chocolates to consumers worldwide.

Efficient and Reliable Packaging Machine for Box Processing

Box Packaging Machine Revolutionizing the Packaging IndustryIn today's fast-paced and highly competitive market, efficient packaging plays a crucial role in ensuring the success and competitiveness of a company. Recognizing this need, [Company Name] has recently introduced an innovative box packaging machine that is revolutionizing the packaging industry. By automating and streamlining the packaging process, this cutting-edge machine is improving productivity, reducing costs, and enhancing overall customer satisfaction.The box packaging machine developed by [Company Name] incorporates state-of-the-art technology and advanced automation features. This machine has the ability to package a wide variety of products, including food items, electronics, pharmaceuticals, and consumer goods, with precision and efficiency. Regardless of the size or shape of the product, this machine can adapt to accommodate various packaging requirements.One of the key advantages of this box packaging machine is its high speed and reliability. With a capacity to package hundreds of boxes per minute, it significantly reduces manual labor and increases productivity. By eliminating human errors and inconsistencies, this machine ensures that each product is packaged accurately and securely, minimizing the risk of damage during transportation.Additionally, this packaging machine stands out due to its versatility and flexibility. It can be easily programmed to handle different box sizes, sealing methods, and labeling options, making it suitable for a wide range of packaging needs. This adaptability greatly benefits businesses that deal with multiple product lines or frequently change their packaging designs.Furthermore, the box packaging machine by [Company Name] prioritizes product safety and hygiene. It includes advanced measures to prevent contamination, such as a sterilization feature and a dust-free packaging environment. This ensures that the packaged products meet the highest quality standards and comply with industry regulations, giving customers peace of mind.Another noteworthy feature of this packaging machine is its user-friendly interface. The machine is equipped with an intuitive control panel that allows operators to easily adjust settings, monitor production, and diagnose any potential issues. Proper training and technical support are offered by [Company Name] to ensure that users obtain optimal performance and fully leverage the capabilities of the machine.Moreover, this box packaging machine incorporates sustainable practices that align with eco-conscious initiatives. It minimizes material waste by optimizing box dimensions and using recyclable packaging materials. By reducing the environmental impact of packaging, [Company Name] demonstrates its commitment to sustainability and corporate social responsibility.The introduction of this innovative box packaging machine has garnered significant attention and appreciation from industry experts. Many leading companies have already adopted this technology, reaping its benefits and experiencing a positive impact on their bottom line. With the increasing demand for efficient packaging solutions, there is no doubt that this machine will continue to disrupt the packaging industry, enabling businesses to achieve higher levels of efficiency, cost savings, and customer satisfaction.In conclusion, [Company Name] has introduced a game-changing box packaging machine that is transforming the packaging industry. Through its advanced technology, high speed, versatility, and sustainable practices, this machine revolutionizes the packaging process for businesses across various sectors. With its positive impact on productivity, cost reduction, and product safety, this packaging machine proves to be an essential tool for companies aiming to stay competitive in today's dynamic market.

Efficient and Reliable Packing Machine for Industrial Use: Unveiling the Latest Innovations

Title: Next-Generation Industrial Packaging Machine Revolutionizes Efficiency and SustainabilitySubtitle: A New Era of Packaging Automation Unveiled by Industry LeaderIntroduction:In today's globalized world, efficient and sustainable packaging plays a pivotal role in minimizing waste and optimizing logistics. Leading the charge in packaging automation is the recently unveiled next-generation Industrial Packing Machine (name removed), developed by a pioneer in packaging solutions. This cutting-edge technology promises to revolutionize the industry by ensuring increased productivity, minimized labor costs, and a significant reduction in the carbon footprint associated with packaging processes.Paragraph 1:The newly introduced Industrial Packing Machine complements the company's commitment to innovation and sustainability. Developed after months of research and development, this state-of-the-art packaging equipment is set to redefine the industry's standards by incorporating advanced technology to streamline operations, reduce waste, and enhance overall efficiency.Paragraph 2:At the heart of the Industrial Packing Machine is a powerful robotic system that automates the packaging process from start to finish. Its intelligent software, coupled with sensors and advanced algorithms, enables the machine to precisely measure, handle, and package goods with the utmost accuracy. Whether it is cartons, bottles, bags, or other containers, the Industrial Packing Machine adapts seamlessly to various packaging requirements, accommodating a wide range of products.Paragraph 3:Energy efficiency is a key focus of the Industrial Packing Machine design. By leveraging cutting-edge technologies, the machine optimizes resource utilization, resulting in a reduced environmental impact. Innovative features, such as smart power management, significantly minimize energy consumption, ensuring maximum productivity with minimal wasted resources. With sustainability at the forefront, this advanced machinery contributes to the global effort in reducing carbon emissions generated by traditional packaging processes.Paragraph 4:In addition to its energy-saving capabilities, the Industrial Packing Machine also reduces material wastage by carefully measuring and optimizing packaging sizes. Its precision and accuracy ensure that materials are used efficiently, minimizing unnecessary packaging waste. Moreover, the machine's adaptability is advantageous to companies operating with varying product dimensions, enabling them to reduce excessive packaging material costs and contribute to sustainable practices.Paragraph 5:The Industrial Packing Machine's user-friendly interface and intuitive controls make it accessible to operators at all skill levels. Comprehensive training and ongoing technical support by the company ensure smooth integration and operation. Its system integration capabilities enable seamless connectivity with existing production lines, ensuring a hassle-free implementation process for manufacturing facilities of all sizes.Paragraph 6:With the launch of the Industrial Packing Machine, the company aims to empower businesses across sectors. By automating packaging operations, companies can reap benefits such as increased productivity, reduced labor costs, improved accuracy, and minimized downtime. Additionally, embracing sustainable packaging practices can enhance a company's reputation and align it with customer preferences for environmentally-friendly products.Conclusion:The next-generation Industrial Packing Machine, developed by an industry leader in packaging solutions, is poised to redefine packaging automation. Its advanced robotics, intelligent software, and sustainable design ensures increased efficiency, reduced waste, and a lowered carbon footprint. As businesses strive to optimize their operations and meet the demands of a rapidly changing world, the Industrial Packing Machine presents an essential solution to propel the industry's sustainability and productivity to new heights.