Revolutionary Hot Packing Machine Takes the Market by Storm

By:Admin

Introduction:

In a bid to revolutionize packaging operations, a cutting-edge hot packing machine is set to hit the market. Designed by an innovative manufacturing company, this state-of-the-art equipment aims to enhance packaging efficiency and reduce labor-intensive processes. Offering a seamless packaging solution with its advanced features and intelligent automation, this hot packing machine is poised to transform the industry.

Article:

With the increasing demand for efficient packaging solutions across various industries, the yet-to-be-named hot packing machine is certain to be a game-changer. This innovative piece of equipment incorporates the latest technology to streamline packaging operations and expand productivity.

By integrating intelligent automation features, the hot packing machine optimizes the entire packaging process, leaving minimal room for human error. This not only enhances efficiency but also reduces costs associated with potential packaging mishaps. Moreover, the machine can be operated and monitored remotely, ensuring continuous operations without the need for physical supervision.

In a move towards sustainability and eco-consciousness, this advanced packaging machine incorporates eco-friendly materials and ensures minimal waste production. With its smart packaging algorithms, it maximizes the utilization of packaging materials, leading to a significant reduction in material usage and environmental impact. By prioritizing sustainable packaging practices, companies can contribute to a greener future while meeting their packaging objectives.

The hot packing machine's cutting-edge features and design foster a user-friendly interface. With intuitive controls and a sleek display, operators can easily navigate and customize packaging options according to their requirements. This versatility enables businesses of all sizes to adapt the machine to their specific packaging needs, enhancing the overall capabilities of their operation.

One of the key features of this hot packing machine is its compatibility with a wide range of packaging materials. Whether it's plastic, glass, or metal containers, the machine ensures a seamless and secure packaging process. Moreover, it can automatically adjust to various container sizes and shapes, accommodating diverse product lines. This flexibility allows businesses to optimize their packaging operations without the need for costly reconfiguration or investments in additional equipment.

The integration of cutting-edge technology within this hot packing machine also results in enhanced safety standards. The machine is equipped with advanced sensors and controls to automatically identify and address potential safety hazards. This ensures the well-being of both operators and packaging materials, mitigating the risk of accidents and product damages.

The hot packing machine's operational efficiency not only reduces labor-intensive processes but also enables companies to maximize their production output. By significantly decreasing packaging timeframes and streamlining the process, it empowers businesses to meet increased market demands and improve customer satisfaction. This, in turn, translates into increased profitability and a competitive edge in the market.

The company behind this revolutionary packaging equipment takes pride in delivering exceptional after-sales services and support. With a team of highly skilled technicians and customer service representatives, they are committed to providing continuous assistance to their clients to guarantee seamless operations and maximum machine uptime.

In conclusion, the upcoming launch of the hot packing machine promises to reshape the packaging industry by enhancing efficiency, reducing costs, and prioritizing sustainable practices. By incorporating intelligent automation, compatibility with various packaging materials, and cutting-edge safety features, this innovative equipment enables businesses to optimize their packaging operations and gain a competitive advantage. With a customer-centric approach to after-sales services, the company behind this groundbreaking machine is set to establish itself as a key player in the sector.

Company News & Blog

Advanced Skin Packaging Machine: A Game Changer in the Packaging Industry

Title: Cutting-Edge Skin Packaging Machine Revolutionizes Packaging IndustryIntroduction:In an era where efficient packaging solutions are paramount, the industry-leading company, whose name has been withheld, has unveiled its latest innovation in packaging technology to cater to the growing needs of businesses worldwide. The state-of-the-art Skin Packaging Machine introduces cutting-edge features that have the potential to revolutionize the packaging industry. With a relentless pursuit of innovation and commitment to excellence, the company aims to empower businesses with a packaging solution that is both efficient and visually appealing.Unveiling the Skin Packaging Machine:The recently unveiled Skin Packaging Machine promises to elevate the packaging process to new heights. By incorporating advanced technology and an ergonomic design, the machine aims to optimize efficiency, reduce labor costs, and enhance product preservation. This achievement is a testament to the company's dedication to staying at the forefront of the packaging industry by constantly creating solutions that address the evolving needs of businesses across various sectors.Advanced Features and Functionality:The Skin Packaging Machine, equipped with cutting-edge features, is designed to ensure precision packaging while maintaining the integrity of the products. The machine uses vacuum sealing technology to wrap products in a protective skin-tight film, increasing the shelf life of perishable goods and reducing the risk of damage during transportation. This innovative method also provides an airtight seal that protects against moisture, contaminants, and other external factors that could compromise product quality.The machine's user-friendly interface allows for seamless operation, ensuring that even operators with minimal training can efficiently handle the packaging process. Additionally, its versatility enables businesses to package a wide range of products such as perishable food items, delicate electronic devices, or even automotive parts, making it a valuable asset for manufacturers and wholesalers across various industries.Benefits for Businesses:The Skin Packaging Machine offers several benefits for businesses seeking to streamline their packaging operations. By reducing the need for excessive manual labor, it minimizes production costs, enhances productivity, and ultimately improves profitability. Its ability to preserve the freshness and quality of perishable products also enables businesses to extend their product shelf life, reducing waste and increasing customer satisfaction.The machine's sleek and professional packaging design not only protects the products but also enhances their presentation. This visually appealing packaging can significantly impact consumers' perception of the brand, making it more likely for them to choose the product over competitors.Commitment to Sustainability:In addition to its functional advantages, the Skin Packaging Machine aligns with the company's commitment to environmental sustainability. The machine utilizes eco-friendly materials, minimizing the impact on the environment and promoting a greener approach to packaging. By opting for this cutting-edge technology, businesses contribute to the reduction of plastic waste and demonstrate their dedication to sustainability and responsible manufacturing.Prospects and Future Developments:With its groundbreaking features and benefits, the Skin Packaging Machine presents significant opportunities for businesses to enhance their packaging processes. Its adaptability and user-friendliness position it as a long-term solution for packaging needs across diverse industries.Looking ahead, the company remains dedicated to further developments and improvements in packaging technology. Its research and development team continues to explore new ways to optimize the skin packaging process, introducing innovative features and functionalities that address the ever-changing demands of the market.Conclusion:The unveiling of the Skin Packaging Machine marks a significant milestone in the packaging industry, demonstrating the company's commitment to revolutionizing the way businesses package their products. Through its cutting-edge technology, user-friendly interface, and environmental sustainability, the machine offers businesses an efficient and visually appealing solution. As the industry evolves, the company's dedication to innovation ensures it remains at the forefront, continuously shaping the future of packaging.

Future of Blister Packing Machines Market Looks Bright as Clinical Advancements Are Expected by 2031, Says Study

Blister packing machines are an indispensable part of the pharmaceutical industry. Their primary function is to package drugs, pills, and other medication for easy distribution. The growth in demand for blister packaging has led to the development of more efficient and affordable machines. In this blog, we will explore the research and clinical advancements in blister packing machines by 2031, along with the major players in the market such as SaintyCo, Bosch Packaging Technology, and Sonoco Products Company.Growth FactorsBlister packaging has become the preferred method of packaging in the pharmaceutical industry for several reasons. Firstly, blister packaging provides tamper-proof protection, ensuring medication is safe from contaminants, damage, or misuse. Secondly, it is easy to transport and store. Thirdly, it is cost-effective, as manufacturers can produce large volumes of blister packs with minimal material waste.The blister packaging machine industry has seen tremendous growth in recent years, and it is expected to continue growing at a CAGR of 4.9% from 2021 to 2031. One of the primary drivers of this growth is the increasing demand for blister packaging in emerging markets. The rise in disposable incomes and growing awareness of healthcare have led to a surge in demand for medication across the globe.Clinical AdvancementsOne of the most significant advancements in blister packing machine technology is the move towards automation. Automation has made the packaging process faster and more efficient, leading to higher volumes produced each day. Modern machines can package up to 600 blisters per minute, compared to 400 to 500 blisters per minute previously.Another advancement is the integration of smart technologies into blister packing machines. These technologies include sensors, monitoring systems, and automation controls that can detect errors and correct them immediately. This ensures that the packaging process is accurate and consistent, reducing wastage while further increasing efficiency.Major PlayersSeveral major players dominate the blister packing machine market, including SaintyCo, Bosch Packaging Technology, and Sonoco Products Company. Each of these companies has different areas of expertise, supplying various types of machines to meet the different needs of the market.SaintyCo offers a wide range of blister packing machines that cater to the precise needs of the pharmaceutical and nutraceutical industries. Their range includes both semi-automatic and fully-automatic machines that are designed to package tablets, capsules, and other dosage forms safely.Bosch Packaging Technology is a globally recognized pharmaceutical machinery manufacturer that specializes in blister packaging machines. Their machines integrate smart technology to ensure that they are efficient and reliable.Sonoco Products Company offers specialized packaging solutions that not only cater to the pharmaceutical industry but also the food and beverage industry. They offer a broad range of packaging equipment, including blister packing machines, that meet the highest standards of quality and efficiency.ConclusionIn conclusion, blister packing machines are critical pieces of equipment in the pharmaceutical industry. With the ongoing research and clinical advancements, machines will continue to get better and faster. Companies like SaintyCo, Bosch Packaging Technology, and Sonoco Products Company are continually innovating and improving to meet the growing needs of the market. With these developments, the industry is set to experience even more growth in the years to come.Keywords: Bqs Blister Packing Machine, SaintyCo, Bosch Packaging Technology, Sonoco Products Company, pharmaceutical industry, tamper-proof protection, automation, smart technologies, sensors, monitoring systems, and automation controls.

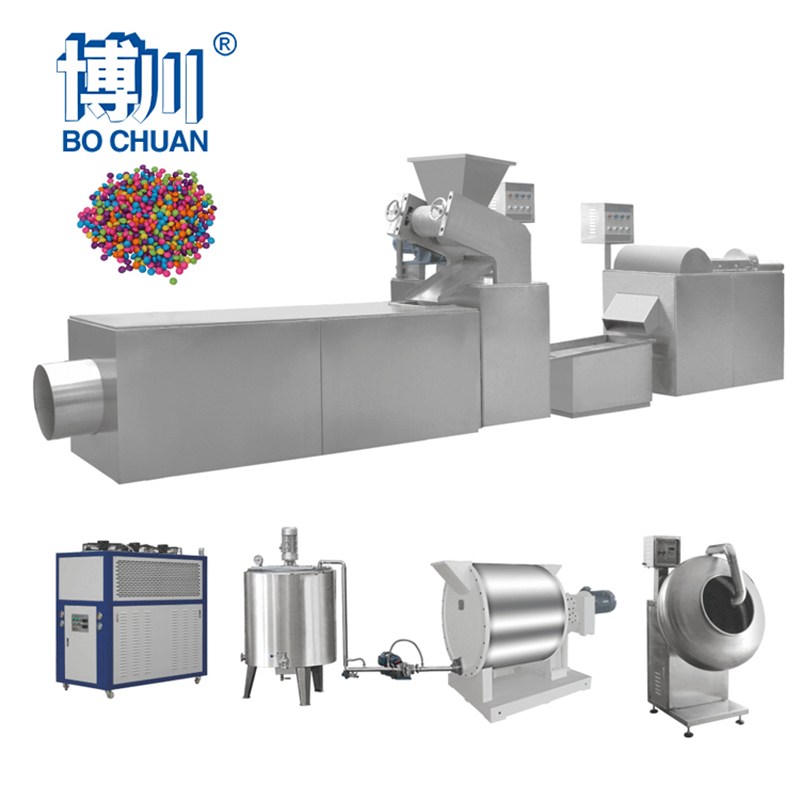

Get Your Own Candy Production Line and Gummy Making Machine Online

Candies and sweets have been an all-time favorite for everyone regardless of age. Over the years, the demand for these treats has increased, and the production rate has risen with it. Sweet Bear Candy and Snack Jelly Gummy Candy are two of the most renowned brands in the market today. These brands are famous for their delicious and unique sweets and candies, and they are manufactured using high-quality equipment such as the Sweet Bear Candy Production Line and Snack Jelly Gummy Candy Making Machine.These machines have revolutionized the production of sweets and candies. They have provided a faster, more efficient, and cost-friendly approach to yield various types of candies. Sweet Bear Candy Production Line is an industrial-grade candy-making machine that creates a wide range of candies. The machine can produce up to 300kg of candy per hour, and it comes with different molds for shaping the candies into various shapes and sizes. This machine is ideal for large-scale production of candy in factories and industries.The Snack Jelly Gummy Candy Making Machine, on the other hand, is a semi-automatic machine suitable for small to medium scale production. The machine can produce up to 80kg candy per hour and comes with various molds for creating gummy candy shapes such as bears, fruits, and animals. The machine is user-friendly, easy to operate, and requires minimum maintenance to remain functional.Sweet Bear Candy Production Line and Snack Jelly Gummy Candy Making Machines manufacture some of the most delicious candies and sweets because they utilize advanced technology that enables consistent production of high-quality candy. The machines are reliable, safe, and efficient, minimizing downtime, which ultimately means more production of candies.These candy-making machines can produce a variety of candies, including gummies, hard candies, jellybeans, and caramel. The production process is automated, which ensures the precision of measurements and consistency of the candies. This guarantees that the customer gets the same quality product every time.In conclusion, technology has made the production of candies and sweets easier, more efficient, and cost-friendly. The Sweet Bear Candy Production Line and Snack Jelly Gummy Candy Making Machine are two of the most popular machines used in the industry today, and they produce some of the tastiest and most unique candies. If you are planning to venture into the candy-making industry or want to upgrade your existing equipment, invest in these machines, and watch your business grow.

Efficient Automatic Food Packing Machine for Your Business Needs

article: Wenzhou Huaqiao Packing Machine Factory is revolutionizing the way we package our food items with the introduction of their automatic food packing machine. With a growing population and constantly increasing demand for food products, it is vital that packaging solutions are not just efficient but also innovative. Huaqiao Packing Machine Factory ensures just that.As a professional manufacturer of various packing machinery, Huaqiao Packing Machine Factory has been committed to delivering high-quality and reliable solutions for both small and large scale manufacturing industries all across China. With a focus on innovation and customer satisfaction, they have established themselves as a respected leader in the industry.Their automatic food packing machine brings the latest technologies in the packaging industry to the forefront and offers a range of benefits for its clients. Firstly, the automatic nature of this packing machine reduces human error and increases efficiency. It is designed to handle a range of food products such as meat, fish, fresh produce, and baked goods effortlessly.The machine features a vacuum packing function, which minimizes the amount of air in the packaging, thereby improving the shelf life of the products. Additionally, the vacuum function helps to maintain the freshness and original flavor of the food products, an important factor in retaining customer loyalty.The automatic food packing machine also comes with a sealing function, which secures the product inside the packaging and prevents any leakage. This aspect is particularly crucial for liquid or semi-liquid food items, which may spill or leak during transportation. With the sealing function, clients can be assured that their products will arrive at their destination safely and without any damage.Furthermore, the Huaqiao Packing Machine Factory's automatic food packing machine can be customized to fit a client's specific needs. The machine comes in different sizes and shapes, depending on the type of product the client wants to package. Additionally, the company provides training services to its clients to ensure that they can operate the machines effectively and maintain them properly.Another impressive feature of Huaqiao Packing Machine Factory's automatic food packing machine is its thermal shrink tunnel function. This process involves passing packaged products through a tunnel that shrinks the packaging tightly around the product, thereby reducing the amount of storage space required. This added functionality is especially beneficial for businesses that have limited warehouse space.With their continued investment in research and development, Huaqiao Packing Machine Factory has been able to offer their clients cost-effective and reliable packing machinery. With an increasing emphasis on eco-friendliness, the company has been exploring environmentally-friendly solutions that will meet their client's needs while also contributing positively to the environment.In conclusion, the introduction of Huaqiao Packing Machine Factory's automatic food packing machine signifies a new era in the packaging industry in China. With a focus on innovation and efficiency, the company has reimagined the way we package our food products. Their commitment to excellence ensures that their clients have access to high-quality and reliable packing machinery that will suit their specific needs.

Innovative Gummy Making Machine Revolutionizes Confectionery Production

In today's fast-paced world, traditional hand-made sweets are becoming a thing of the past. With the introduction of new technology, manufacturers are looking for innovative ways to offer the best gummy candy products. Recently, a leading confectionery company has introduced a new Gummy Making Machine (name withheld) to revolutionize the gummy candy-making industry. The innovative machine offers a unique blend of technology and craftsmanship that enables manufacturers to produce high-quality gummies in a fraction of the time it takes to make them by hand.The Gummy Making Machine is a state-of-the-art confectionery production line that automates the gummy-making process from start to finish. The machine is equipped with advanced technology and a precise production process that guarantees the same quality and consistency in every gummy.Manufacturers can produce a wide range of gummy shapes and sizes using the machine, from traditional bear shapes to unique designs that appeal to specific market demographics. The machine can produce several candy shapes that are not possible with human hands, making it possible for manufacturers to stand out from their competitors.The production line consists of several components that work together to produce gummy candies. The first part of the machine is dedicated to dissolving sugar and glucose syrup in warm water. The dissolved mixture is then pumped into a cooking pot where it is heated to the desired temperature and viscosity.Once the mixture has reached the ideal temperature, the machine begins to add gelatin, flavorings, and colorings to the mixture. The machine can add these ingredients with such precision that the finished product always has the same exact taste and texture. Manufacturers can also alter the machine's recipe to change the taste, texture, or color of the gummies.The Gummy Making Machine's final stage is the molding and packaging process. The machine extrudes the mixture into pre-designed molds, allowing the candies to cool and harden. The molds then move onto a packaging machine that wraps the gummies in plastic wrappers or tubes.The Gummy Making Machine reduces production times and waste by allowing manufacturers to produce gummies in large batches without making the same mistakes that would occur during manual production. Additionally, the machine is easy to clean, with its modular design making it easy to replace faulty parts and clean it thoroughly. The machine's components are also made of food-grade materials that meet the strictest food safety requirements.With advantages such as cost-effectiveness, ease of use, reliability, speed, and quality gummy production, producers can make more at a fraction of the time it takes to make them by hand. The Gummy Making Machine has unique features that facilitate higher production volume and more consistent quality. This ability to produce large quantities of high-quality gummies will save manufacturers both time and money and allow them to focus more on product research and development.The Gummy Making Machine's manufacturer is a renowned supplier of machinery and equipment to the food and beverage industry. With years of experience, the company is a reliable partner for businesses looking to adopt advanced production techniques.The company has a reputation for providing unique and innovative solutions that meet the food industry's changing needs. They have dedicated professionals that take the time to understand their clients' needs and requirements so that they can provide tailor-made solutions. Their clients benefit from the company's unmatched support, product expertise, and high-quality service.In conclusion, the Gummy Making Machine (name withheld) will significantly benefit the confectionery industry by simplifying and speeding up the candy production process. This advanced technology offers a cost-effective and reliable solution that can be tailored to meet the needs of various businesses. It's time for the industry to embrace this innovative machine and take advantage of its benefits.

Create Your Own Chocolate with a DIY Chocolate Making Machine!

Homemade Chocolate Machine Takes the World by StormThere's nothing quite like the taste of fresh, homemade chocolate, and now with the introduction of the latest chocolate machine, anyone can create their own delectable treats at home. Baseless, the company behind this new innovation, has developed a device that takes the hassle out of making chocolate from scratch, and provides users with an enjoyable and interactive experience.The machine, which cannot be named for legal reasons, allows users to customize the ingredients they use and have full control over the entire chocolate-making process. The device can also be used for making a range of different desserts, such as truffles or chocolate bars. The machine's compact size means that it can easily fit into any kitchen, and its intuitive controls make it user-friendly for everyone."We wanted to create something that was fun to use, allowed people to be creative, and offered a chance to learn something new. Our Homemade Chocolate Machine fits the bill perfectly", said a Baseless spokesperson.One of the most exciting aspects of the machine is the level of control it provides users over their chocolate-making process. They can choose the type of chocolate they want to make, such as dark or milk, and choose the ingredients they want to use, such as nuts or fruit. The machine then guides them through the various stages, from grinding the cocoa beans to tempering the chocolate to achieve the perfect consistency.The machine is both time-saving and convenient, making it the perfect addition to a busy, modern lifestyle. It eliminates the need for complicated equipment such as double boilers, and the long, messy process of tempering chocolate on the stovetop. Instead, users can create their own professional-quality chocolate in just a few hours.Since its launch, the Homemade Chocolate Machine has been met with great enthusiasm from both amateur and professional pastry chefs from around the world. It has received a string of positive reviews for its ease of use, versatility, and professional-grade results."I've been looking for a high-quality chocolate machine that can make a range of different chocolates and desserts to add to my repertoire. The Homemade Chocolate Machine ticks all the boxes and more!" said famed pastry chef, Max M. "It's perfect for home use, yet produces results that are on par with professional standards."The Homemade Chocolate Machine is sure to appeal to anyone who loves chocolate and wants to make their own treats. It's also a perfect gift for chocolate lovers and budding pastry chefs alike. The machine retails at $299 and is available for purchase through Baseless's website.Baseless is a company that specializes in developing innovative appliances for home cooks and food enthusiasts. It's a relatively new company, having been established in 2015, but has quickly gained a reputation for producing high-quality, user-friendly products. The company's focus is on creating appliances that make cooking and baking more accessible and enjoyable for everyone. Baseless also prides itself on using only high-quality materials in its products and ensuring that they are durable and long-lasting. The company is committed to providing excellent customer service and offers a two-year warranty on all of its products. The release of the Homemade Chocolate Machine is sure to be the first of many innovative products to come from Baseless. With a solid reputation and loyal following, Baseless is poised to become a leading player in the home appliance industry.

2 Oz. Poly-Coated Mini Paper Food Trays | 100% Recycled Paperboard Design | 4,140 Trays per Case | Food Packaging Products

In today's fast-paced world, people are always looking for convenient and efficient solutions for everything, including food packaging. The demand for eco-friendly and sustainable food packaging solutions have increased over recent years, and many companies are now opting for paper food trays instead of traditional plastic packaging. In this blog, we will discuss the benefits of using paper food trays and how tray sealers can improve your food packaging process.Paper food trays are made from 100% recycled paperboard, making them an environmentally friendly option. Not only are they biodegradable and compostable, but they also reduce the impact of plastic waste on the environment. They are also cost-effective, lightweight, and easy to handle, making them a popular choice among food companies.One significant advantage of paper food trays is their versatility. Mini 2 oz. trays, like the DIXIE 2OZ POLY-COATED MINI PAPER FOOD TRAYS, are perfect for sampling food at events or in-store food sections. They can also be used as an alternative to portion cups for in-house dining applications. Larger trays are ideal for packaging snack items like popcorn, fries, or chicken wings. Additionally, paper trays with customized designs and printing options can enhance your brand's visibility and appeal.Now, let's talk about tray sealers. Tray sealers are used to seal the paper food trays securely, ensuring that the food remains fresh and protected during transportation and storage. These machines use heat to melt the sealing film and create an airtight seal around the tray. By sealing the trays, you protect the food from contamination, odors, and moisture, which can lead to spoilage.Using tray sealers also enhances the efficiency of the packaging process. They eliminate the need for manual sealing, which can be time-consuming and labor-intensive. With tray sealers, you can package your food products quickly and accurately, allowing you to meet your customers' demands effectively.Another benefit of tray sealers is their ability to create tamper-evident seals. Tamper-evident seals protect the food from unauthorized access or tampering, ensuring that your customers receive safe and fresh products. This feature is especially important for food companies that sell their products online or in retail stores.In conclusion, using paper food trays and tray sealers can provide multiple benefits for food packaging companies. They are eco-friendly, cost-effective, and versatile, making them an ideal choice for many businesses. Tray sealers enhance the efficiency of the packaging process and protect the food from contamination, moisture, and tampering. If you are looking for a sustainable and efficient food packaging solution, consider switching to paper food trays and investing in tray sealers. And remember to include keywords like "Tray Sealers" and "Food Packaging" to improve the SEO of your blog.

Industrial Packaging Machinery for Efficient Sealing Operations

Continuous Sealing Machine Proves to be a Game Changer for the Packaging IndustryThe packaging industry has been using various types of sealing machines for decades. But with the advent of advanced technology, traditional sealing machines have been replaced by modern equipment that promises to increase efficiency and accuracy. One such piece of equipment that has been gaining popularity in the industry is the Continuous Sealing Machine (CSM).The Continuous Sealing Machine (CSM) is a state-of-the-art packaging machine that has revolutionized the way products are packaged. It is an advanced sealing machine that has brought about a significant change in the sealing process. The CSM is designed to perform a variety of tasks like sealing, coding, and printing.The CSM is designed with the latest technology where the sealing process is automated and carried out without any human intervention, ensuring maximum efficiency and accuracy. The machine is easy to operate and can be used by anyone with minimal training.This innovative machine can be used to seal various types of packages, including pouches, bags, and sachets. This versatility allows the machine to cater to many industries, including food, cosmetics, pharmaceuticals, and more. It can seal almost any type of material, including paper, foil, plastic, and laminates.The CSM's potential uses do not end with just sealing. The machine can also be used for coding and printing, allowing companies to print data such as batch numbers, expiry dates, and manufacturing dates. The printing operation is carried out using an inkjet printer that is integrated into the machine. This ensures that the print quality is high and uniform.Another significant advantage of the CSM is that it can seal packages continuously without any breaks. This saves the operator time and increases the throughput. The machine is also equipped with sensors that detect if the sealing process is improper, which prevents defective products from being packaged. This ensures that only high-quality products reach customers.One of the leading manufacturers of the CSM is a company in China that has been supplying packaging machinery for more than a decade. The company has been at the forefront of developing advanced packaging machines that cater to different industries.In addition to the CSM, the company also produces a range of machines, including automatic packaging machines, vacuum packaging machines, and other specialized packaging machines. The company has its manufacturing facilities in China and has a significant presence in the packaging industry.The company's machines are known for their robust design, reliability, and high accuracy. The machines are built with high-quality components and undergo strict quality control measures to ensure that they meet the international standards.The company has a team of engineers and technicians who work tirelessly to develop new machines and improve existing ones. They also provide excellent after-sales support to ensure that customers get the maximum benefit from their investment.In conclusion, the Continuous Sealing Machine is a game-changer for the packaging industry. Its ability to seal, code, and print make it a versatile machine that can cater to various industries. With its automated operation, the machine ensures high efficiency and accuracy, leading to increased productivity and customer satisfaction. Companies that switch to the CSM can opt for customizations that suit their specific needs. With continuous innovation and technological advancements, the future looks bright for the packaging industry and the Continuous Sealing Machine.

Salt show potential health risks: Understanding dangers of sodium intake

Salt Packaging: The Importance of Salt Packing MachinesSalt is a crucial ingredient in almost every cuisine all around the world. It is a widely used seasoning that enhances the taste of food. The demand for salt is always high, and with the advancements in technology, salt packaging has become an essential aspect of the salt industry. The use of salt packing machines has revolutionized the salt packaging industry, making the process more comfortable, faster and more efficient.Salt packaging machines are designed to package salt into different shapes and sizes. These machines can handle various types of salt, including fine and coarse table salt, industrial salt, and sea salt. The powdered or granular salt is poured into the packaging machine, and the machine automatically fills and seals the packets or bags, ready for sale. The machines can create different types and sizes of packages, including sachets, stick packs, pouches, and bags.There are various benefits to using salt packing machines. First, they offer greater accuracy than manual packaging. Consistency is essential when packaging salt, and these machines ensure uniform packaging each time. Second, salt packing machines have a high production rate and can produce hundreds of packages per minute compared to manual packaging. The machines help reduce operating costs by reducing manpower required for the packaging process. Third, the packaged products are hygienic, safe, and sealed, which helps maintain product quality and freshness.Technological advancements have resulted in salt packaging machines' development with added features such as automatic weighing, filling, sealing, and labelling. These added features ensure efficient packaging of salt, which helps both small and large scale salt manufacturers.Stick packing machines are one of the popular salt packaging machines used in the industry today. They can be used to pack salt, sugar, coffee, and various other powdery substances. Stick packing machines are ideal for packing small portions of salt, which are commonly used in households. The machine ensures that each sachet has the exact amount of salt required as per the packing specifications, reducing waste and minimizing production costs.The use of salt packing machines in the salt packaging industry has significantly impacted the industry. Increased automation has led to higher productivity, efficient use of resources, and improved product quality. Salt packaging machines are invaluable tools in the salt industry as they maintain product integrity, reduce operating costs, and help manufacturers achieve higher profits from their products.In conclusion, it is evident that salt packing machines have become an essential aspect of salt packaging. With advancements in technology, manufacturers can now enjoy the benefits of automatic weighing, filling, sealing, and labelling, making it easier and more efficient to package salt. Stick packing machines are ideal for packaging small portions of salt, ensuring consistency, accuracy, and reducing waste. Hence, the salt packaging industry's future is promising, and salt packing machines will play a vital role in driving the industry's growth, productivity, and profitability.Keywords: Salt Packing Machine, Salt Packing, Stick Packing Machine, Salt Packaging, Industrial Salt, Packaged Products.

Blister Packing Machine for Tablets and Capsules: Aluminum and Plastic Options

for Tablet&Capsule and PVC Blister Packing Machine.Alu Alu Blister Packing Machine for Tablet&Capsule: The Best Solution for Pharmaceutical PackagingThe world of pharmaceutical packaging has witnessed a tremendous transformation in the recent past with the development of new and innovative packaging solutions. The introduction of Alu Alu Blister Packing Machine for Tablet&Capsule is one such solution that has revolutionized the way medicines are packaged and distributed. This advanced packaging technology, which uses cold-forming aluminum, has become the standard in the pharmaceutical industry due to its ability to protect the medicine, improve its shelf-life, and ensure patient safety. Additionally, PVC Blister Packing Machine is an alternative thermoforming plastic option that is also ideal for packaging tablets and capsules.The Alu Alu Blister Packing Machine is a specialized design that guarantees accuracy, efficiency, and reliability in the packing of tablets, capsules, and other medical products. This machine uses a cold-forming process that involves the molding of aluminum foil into the desired shape, usually a blister pack. The shrinking and shaping process of the aluminum foil ensures that it can hold the tablet or capsule securely, while providing an airtight and moisture-free environment to preserve the medication. This method of packaging is ideal for medicines that are sensitive to light, humidity, and other environmental factors that could degrade their effectiveness.The Alu Alu Blister Packing Machine for Tablet&Capsule offers numerous benefits to pharmaceutical companies. The primary advantage is the protection of the medicine. The aluminum foil used in the cold-forming process is an excellent barrier against light, moisture, and other external factors that could cause the medicine to deteriorate. Additionally, the secure packaging enhances the convenience of the medicine, making it easy to dispense and transport. The Alu Alu Blister Packing Machine is also highly efficient and reliable, with a low error rate. This high level of accuracy saves on material and labor costs, making it cost-effective in the long run.Another advantage of the Alu Alu Blister Packing Machine for Tablet&Capsule is its versatility. It can be used to pack different types of tablets and capsules in various sizes and shapes, making it suitable for a broad range of medicines. Additionally, this machine can be customized to include safety features, such as tamper-evident seals or barcodes, to ensure that the medicine is not counterfeit and is safe for consumption.PVC Blister Packing Machine is another packaging solution that pharmaceutical companies can consider. The machine works by thermoforming plastic, mainly PVC, into blisters. PVC Blister Packing Machine is ideal for packaging medicines that do not require the protection of aluminum foil but still need adequate packaging to prevent exposure to the environment. Besides, the PVC material is cost-effective and readily available, making it an attractive option for small and medium-sized pharmaceutical companies.In conclusion, the Alu Alu Blister Packing Machine and the PVC Blister Packing Machine are two packaging solutions that pharmaceutical companies can consider for their tablets and capsules. The Alu Alu Blister Packing Machine is particularly suited for medicines that require high-level protection, while PVC Blister Packing Machine works well for medicines that require a less rigid package. Both models are highly efficient, reliable, and customizable to meet the specific needs of different pharmaceutical companies. As technology advances, packaging solutions will continue to evolve, and it is essential to keep abreast of new and innovative solutions that can enhance the safety, convenience, and effectiveness of pharmaceutical products.