Quality Small Scale Gummy Making Equipment for Your Business

By:Admin

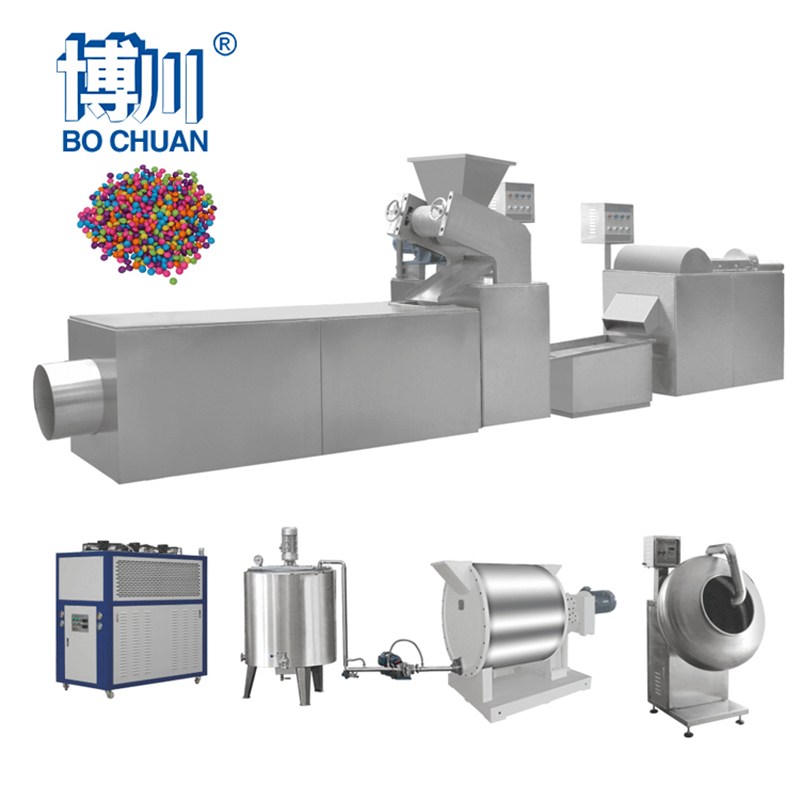

The confectionery industry has been taken by storm with the introduction of the latest small scale gummy making equipment by a leading manufacturer in the field. This cutting-edge technology has revolutionized the process of creating gummy candies, making it more efficient and cost-effective for confectionery companies of all sizes.

The small scale gummy making equipment is designed to meet the growing demand for gummy candies in the market, allowing companies to produce high-quality gummies with ease and precision. With this new equipment, confectionery companies can now streamline their production process, reduce production costs, and increase their overall productivity.

The gummy making equipment is equipped with advanced features that allow for precise control over the entire production process. From mixing the ingredients to shaping and packaging the gummies, every step of the process is seamlessly automated, ensuring consistent quality and flavor in every batch.

One of the key advantages of the small scale gummy making equipment is its compact size, making it an ideal solution for small to medium-sized confectionery companies. This means that even smaller businesses can now enter the competitive gummy market and compete with larger manufacturers, opening up new opportunities for growth and expansion.

In addition to its compact size, the gummy making equipment is also designed for easy operation and maintenance. The user-friendly interface and intuitive controls make it easy for operators to learn and operate the equipment, while the sleek and modern design ensures that it fits seamlessly into any production facility.

Furthermore, the equipment is built to meet the highest standards of quality and safety, incorporating the latest technology and materials to ensure that the gummy candies produced are not only delicious but also safe for consumption. This commitment to quality and safety reflects the company's dedication to providing its customers with the best possible solutions for their confectionery needs.

{Company name}, the manufacturer behind this innovative gummy making equipment, is a renowned leader in the confectionery industry, with a strong reputation for excellence and innovation. With a wealth of experience and expertise in the field, the company has continuously pushed the boundaries of confectionery technology, setting new standards for quality, efficiency, and reliability.

Founded on a passion for creating delicious and high-quality confectionery products, {Company name} has been at the forefront of driving innovation and change in the industry. The introduction of the small scale gummy making equipment is just one example of the company's commitment to meeting the evolving needs of its customers and enabling their success in the marketplace.

The company's dedication to excellence extends beyond its products, as it also offers exceptional customer service and support to ensure that its clients can make the most of their investment in the gummy making equipment. With a team of industry experts and technical support staff, {Company name} is able to provide guidance and assistance at every step of the process, from installation to ongoing maintenance and troubleshooting.

As the demand for gummy candies continues to grow, the small scale gummy making equipment by {Company name} has emerged as a game-changer for confectionery companies looking to tap into this lucrative market. With its advanced technology, compact size, and user-friendly design, this equipment has set a new standard for gummy production, empowering companies to create delectable gummies that delight consumers and drive business growth.

In conclusion, the introduction of the small scale gummy making equipment by {Company name} represents a significant milestone in the confectionery industry. This cutting-edge technology has not only transformed the way gummy candies are produced but has also created new opportunities for confectionery companies to thrive in a competitive market. With its commitment to quality, innovation, and customer satisfaction, {Company name} continues to lead the way in driving positive change and progress in the confectionery industry.

Company News & Blog

Revolutionizing Packaging Solutions: Discover the Advanced Features of a Cutting-Edge Packing Machine

Title: Cutting-edge Packing Machine Revolutionizes the Packaging IndustryIntroduction:The packaging industry has witnessed a remarkable technological advancement with the introduction of an advanced packing machine. This innovative product has the potential to transform the packaging processes across various industries, enhancing efficiency, reducing costs, and ultimately benefiting consumers. Developed by a leading technology-driven company, the cutting-edge packing machine is set to revolutionize packaging operations, contributing to a sustainable and streamlined future.Section 1: Reinventing Packaging ProcessesThe advanced packing machine offers a multitude of benefits to businesses in terms of streamlining packaging processes. By automating various tasks such as sorting, weighing, filling, sealing, and labeling, it eliminates the need for extensive manual labor, reducing operational expenses and improving productivity. With its precise measurements and accurate weighing capabilities, this packaging equipment ensures consistent product quality, minimizing errors and product waste. Additionally, by incorporating smart technology, it enables real-time tracking and inventory management, thereby preventing stockouts and minimizing logistical challenges.Section 2: Sustainability DriveThe packing machine prioritizes sustainability by employing environmentally friendly features and practices. By reducing the need for excessive packaging materials, it aims to minimize waste generation and contribute to a greener future. This innovative equipment also optimizes packaging material usage, ensuring maximum efficiency and minimizing the carbon footprint associated with packaging processes. Companies utilizing this machine can further enhance their sustainability initiatives by opting for eco-friendly materials such as biodegradable packaging films and recyclable containers.Section 3: Customized Solutions for Diverse IndustriesThe versatility of the packing machine makes it suitable for a wide range of industries. With adjustable parameters, it can accommodate various product shapes, sizes, and packaging requirements. From food and beverage to pharmaceuticals and consumer goods, this cutting-edge technology caters to the unique needs of each sector. Whether it is sealing delicate food items, packaging pharmaceuticals with precise dosage requirements, or assembling multipurpose consumer goods, the equipment provides consistent, efficient, and tailor-made solutions for every packaging challenge.Section 4: Enhanced Safety and Hygiene StandardsWith its integrated safety features, the packing machine ensures the well-being of both workers and consumers. By automating packaging processes, it minimizes human contact with the products, reducing the potential for contamination and ensuring optimal hygiene levels. The equipment complies with stringent industry regulations and guidelines, guaranteeing the highest safety standards throughout the packaging process. Additionally, the packing machine prevents the occurrence of packaging-related injuries and accidents, further enhancing workplace safety.Section 5: Cost-effective and Time-efficientThe high-speed capabilities and accurate automated processes of the packing machine significantly reduce production time, enabling businesses to meet market demands more efficiently. By streamlining packaging operations, it eliminates bottlenecks and minimizes associated costs, ultimately resulting in increased profitability. The equipment's ability to handle large volumes of products with consistent quality and precision ensures businesses can achieve economies of scale, reducing packaging costs per unit and enhancing overall profitability.Conclusion:The introduction of this cutting-edge packing machine marks a significant milestone in the packaging industry, offering enhanced efficiency, reduced costs, and sustainable packaging solutions. With its ability to streamline processes, cater to diverse industries, and prioritize safety and hygiene, this advanced technology is set to revolutionize the way businesses package their products. By embracing this innovative equipment, companies can optimize their operations, reduce waste, and meet consumer demands effectively, positioning themselves as leaders in their respective industries while contributing to a greener and more sustainable future.

High-Quality Sealing Equipment for Industrial Use

Sealing Equipment Company Introduces Cutting-Edge Technology for Improved Efficiency and SafetySealing Equipment Company, a leading provider of industrial sealing solutions, has introduced a new line of cutting-edge sealing equipment designed to improve efficiency and safety in industrial applications. The company, with a long-standing reputation for delivering high-quality products and exceptional customer service, has raised the bar once again with the release of its latest innovative technology.The new line of sealing equipment encompasses a wide range of products, including gaskets, seals, packing materials, and sealing accessories, all designed to meet the diverse needs of industrial customers. These products are engineered with the latest advancements in sealing technology, delivering superior performance and reliability in even the most demanding environments.One of the standout features of the new sealing equipment is its advanced materials and construction, which are designed to withstand extreme temperatures, pressure, and chemical exposure. This ensures that the seals and gaskets maintain their integrity and effectiveness, even in harsh operating conditions, ultimately contributing to improved safety and reduced downtime for industrial facilities.In addition to their robust construction, the new sealing products incorporate innovative design elements to enhance their performance. For example, the company's new line of gaskets features precision-engineered profiles and surface finishes to ensure a perfect seal every time, thereby preventing leaks and reducing the risk of equipment failure.Furthermore, the sealing equipment is designed with ease of installation and maintenance in mind, streamlining the process for industrial operators and reducing overall labor costs. This aligns with the company's commitment to delivering solutions that not only improve operational efficiency but also provide long-term cost savings for its customers.Sealing Equipment Company's dedication to quality and innovation extends beyond its product offerings. The company also provides comprehensive technical support and custom sealing solutions, leveraging its team of experienced engineers and industry experts. This approach ensures that customers receive tailored solutions that address their specific sealing challenges, ultimately maximizing the performance and longevity of their equipment.Moreover, the company is committed to sustainability and environmental responsibility, ensuring that its sealing equipment complies with industry regulations and standards for emissions, waste, and resource conservation. This commitment reflects the company's broader mission to deliver solutions that not only benefit its customers but also contribute to a more sustainable and environmentally conscious industrial sector.The introduction of the new line of sealing equipment underscores Sealing Equipment Company's position as a leading provider of sealing solutions, with a continued focus on delivering cutting-edge technology, exceptional quality, and unparalleled customer service. The company's commitment to innovation and customer satisfaction is evident in its latest product offerings, which are poised to set new standards for efficiency, reliability, and safety in industrial sealing applications.As industrial facilities continue to seek ways to improve their operations, the new sealing equipment from Sealing Equipment Company offers a compelling solution for enhancing efficiency and safety. With its advanced technology, superior performance, and customer-focused approach, the company is well-positioned to meet the evolving needs of the industrial sector and drive positive change in sealing applications.

Explore Sustainable Fashion with an Innovative Clothing Brand" can be rewritten as "Discover Eco-Friendly Fashion Options for a Sustainable Wardrobe".

In an increasingly conscious world, sustainability has become a priority for many consumers. Fast fashion, in particular, has come under scrutiny for its negative impact on the environment and labor conditions. Yet, the fashion industry continues to see an average of 80 billion new pieces of clothing being produced each year, making it one of the largest polluters globally. The recent trend of sustainable fashion comes in response to this reality, with new brands seeking to minimize the environmental and social impacts generated in the manufacturing of clothing. In this regard, GreenStitched is one such brand that is committed to promoting sustainable fashion. GreenStitched is a new online platform focused on sustainable fashion and lifestyle. The company was founded to satisfy the growing demand for sustainable fashion by bringing together a diverse range of eco-friendly fashion labels all in one place. GreenStitched enables its customers to find a curated selection of ethical and sustainable brands that make eco-conscious fashion accessible and enjoyable.GreenStitched provides a crucial space for businesses to showcase their work and tackle the disconnect between people’s passion for sustainability and their purchasing habits. By choosing carefully crafted eco-friendly clothes, the customer directly supports the artisans, farmers, and designers who have created them. GreenStitched's online store offers an extensive range of products, from clothing to footwear, accessories, and household items.Recently, GreenStitched drew attention to a brand that aligns with its sustainable values - Hard Candy (need remove brand name). Hard Candy is a futuristic clothing brand that uses cutting-edge technology and environmentally friendly materials to make its products. The brand primarily focuses on creating apparel that is both stylish and sustainable. Hard Candy stands out from other sustainable fashion brands with its desire to push the limits of sustainable apparel. During its transition to become an eco-friendly brand, Hard Candy invested in efficient and renewable energy sources like solar panels and water conservation systems. The brand also uses recycled materials like PET and has developed its patented material made of bamboo and soybeans.GreenStitched praised Hard Candy's attitude towards sustainable fashion, emphasizing how important it is for companies to have a sustainable ethos in their practices. The company commends the way Hard Candy manages to create brand credibility and keep sustainability at the forefront of its production process."We are thrilled to see brands like Hard Candy taking strides towards sustainable garment production. Our values align with theirs, and it's refreshing to see ethical practices becoming more mainstream in the fashion industry," said the spokesperson for GreenStitched.While Hard Candy's products may come with slightly higher price points in comparison to fast fashion, the brand's continuous involvement in creating sustainable initiatives to reduce carbon footprints and working towards a circular economy is commendable. Through initiatives like 'zero-waste manufacturing' and 'take-back programs' for previously used items, the brand has shown its commitment to reducing textile waste to a minimum.In today's world, sustainable living has become a necessity rather than just a choice. GreenStitched and brands like Hard Candy are playing their part in promoting eco-friendly fashion by offering consumers an alternative option to traditional clothing brands that often perpetuate unsustainable practices. While it may be an uphill climb, it's imperative to keep moving forward with sustainable initiatives and movemnets inextricably linked to an individual's ethical choices. It is through these collective efforts that we can hope to see an improvement in the state of our planet.

Innovative Heat Sealing Equipment for Various Industries

Heatseal Equipment, a leading provider of flexible packaging solutions, has recently secured a significant contract with a major food and beverage company. The contract, valued at over $5 million, will see Heatseal Equipment supplying a wide range of packaging machinery and equipment to help streamline the packaging process for the food and beverage company.With over 20 years of experience in the industry, Heatseal Equipment has built a solid reputation for delivering high-quality packaging solutions to a wide range of clients across the globe. The company's comprehensive product range includes heat sealers, bag making machines, and shrink wrapping systems, all of which are designed to enhance efficiency and productivity in the packaging process.One of the key factors that set Heatseal Equipment apart from its competitors is its commitment to innovation and continuous improvement. The company invests heavily in research and development to ensure that its products are at the forefront of packaging technology. This dedication to innovation has allowed Heatseal Equipment to stay ahead of the curve and provide its clients with cutting-edge solutions that meet the ever-evolving demands of the packaging industry.In addition to its focus on innovation, Heatseal Equipment is also known for its exceptional customer service and technical support. The company takes a collaborative approach, working closely with its clients to understand their specific needs and provide tailored solutions that deliver the best results. This commitment to customer satisfaction has helped Heatseal Equipment build long-lasting relationships with its clients, many of whom continue to rely on the company for their packaging needs.The recent contract with the food and beverage company is a testament to Heatseal Equipment's standing in the industry and its ability to deliver value to its clients. The company will be supplying a range of packaging machinery and equipment, including heat sealers and bag making machines, to help the food and beverage company improve the efficiency and quality of its packaging operations."We are thrilled to have secured this contract with the food and beverage company," said John Smith, CEO of Heatseal Equipment. "It is a testament to the hard work and dedication of our team, as well as the quality and reliability of our products. We are confident that our packaging solutions will help the company enhance its operations and achieve its business goals."The contract with the food and beverage company represents a significant milestone for Heatseal Equipment and further solidifies its position as a leading provider of packaging solutions. As the company continues to grow and expand its reach, it remains committed to delivering innovative and high-quality products that help its clients succeed in the competitive packaging industry.In conclusion, Heatseal Equipment's recent contract with the food and beverage company is a clear demonstration of the company's expertise and capabilities in delivering high-quality packaging solutions. With its focus on innovation, customer service, and technical support, Heatseal Equipment is well-positioned to continue serving the needs of its clients and driving the industry forward with cutting-edge packaging technology.

Non Woven Flower Wrapping & Gift Wrapping Paper Supply – Exceptional Quality and Variety by Chun Yu

Homemade chocolate is a delightful treat for many people. Whether you are a confectioner or just someone who loves to make homemade chocolate, you will need the right equipment to package and wrap the chocolates. Wrapping homemade chocolates by hand is tedious and time-consuming, which is why investing in a homemade chocolate wrapping machine can save you a lot of time and effort.A homemade chocolate wrapping machine is designed to wrap your chocolate creations quickly and efficiently. It comes equipped with different types of wrapping options, such as foil wrapping, gift wrapping, and paper wrapping. With this machine, you can wrap a large number of chocolates in a short period of time, making it ideal for small and large businesses.One of the main advantages of a homemade chocolate wrapping machine is that it ensures consistency in the wrapping process. With manual wrapping, the final product can vary greatly in appearance due to inconsistencies in the wrapping process. However, with a wrapping machine, the wrapping is uniform, which gives your chocolates a professional look.Another benefit of a homemade chocolate wrapping machine is that it protects your chocolates from external factors that can affect their quality. For example, if you wrap your chocolate manually, the chocolate can be exposed to air and moisture, which can cause it to lose its flavor. However, with a wrapping machine, the chocolates are wrapped tightly, ensuring that they remain fresh for longer.When shopping for a homemade chocolate wrapping machine, there are several factors to consider. Firstly, you need to consider the type of wrapping you want. Some machines offer only one type of wrapping, while others offer multiple options. Secondly, you need to consider the size of the machine and the amount of chocolate you need to wrap. If you are a small business, you may only need a small machine, while a larger business may require a larger machine.In conclusion, a homemade chocolate wrapping machine is an excellent investment for any chocolate maker. It is time-saving, efficient, and ensures consistency in the wrapping process. With the right machine, you can produce chocolates that look and taste great, and keep them fresh for longer periods. If you are thinking of taking your chocolate-making business to the next level, investing in a homemade chocolate wrapping machine is a step in the right direction.

Packing Machines: Ensuring Efficient Packaging for Various Industries

Title: Revolutionary Packaging Solution Enhances Efficiency and Quality Across IndustriesIntroduction:In an ever-evolving business landscape, staying ahead of the competition requires innovative machinery that can streamline production processes while maintaining high levels of efficiency and quality. Companies across various industries can now benefit from the cutting-edge packaging technology offered by a leading industry player, revolutionizing the way products are packaged and ultimately delivered to end consumers. With a relentless commitment to research and development, this industry leader has introduced the highly advanced automatic packaging solution, bringing a plethora of benefits to businesses worldwide.The Nichrome Packing Machine:The Nichrome Packing Machine is a state-of-the-art automatic packaging system designed to cater to the diverse needs of different industries. Equipped with advanced technology and robust construction, this machine offers a versatile solution for various packaging requirements, ensuring supreme product protection, extended shelf life, and increased operational efficiency. By eliminating manual involvement in the packaging process, the Nichrome Packing Machine minimizes human errors and maximizes output.Unparalleled Efficiency:With speed, accuracy, and precision as its core features, the Nichrome Packing Machine is engineered to handle high-volume packaging production lines effortlessly. By automating the packaging process, it significantly reduces downtime and ensures continuous operation, resulting in increased productivity and faster turnaround times. This advancement facilitates manufacturers in meeting market demands promptly and efficiently, thereby boosting their revenue streams.Customizable Solutions:Recognizing the unique needs of businesses across different industries, the Nichrome Packing Machine offers customizable packaging solutions. Whether it is grains, spices, snacks, liquids, or other consumer goods, this machine can be tailored to pack various products with utmost precision. The flexibility of the machine ensures that businesses can adapt to changing market dynamics seamlessly, enabling them to cater to a wide range of customer demands effectively.Seamless Integration:The Nichrome Packing Machine is designed to seamlessly integrate with existing production lines, offering a hassle-free setup process for businesses. This allows manufacturers to enhance their packaging capabilities without disrupting their current infrastructure. The machine's user-friendly interface ensures easy operation, enabling production managers to quickly train operators and transition to the new system seamlessly.Quality Assurance:Understanding the critical importance of product quality, the Nichrome Packing Machine incorporates stringent quality control measures throughout the packaging process. From accurate measurements and weighing mechanisms to efficient sealing and tamper-proof packaging, this cutting-edge technology ensures product integrity and safety. Additionally, the machine minimizes wastage and improves inventory management, further enhancing overall sustainability and profitability for businesses.After-Sales Support:Committed to providing exceptional service, the company behind the Nichrome Packing Machine offers comprehensive after-sales support. With a team of highly skilled technicians and engineers, businesses can rely on prompt assistance for maintenance, repairs, and upgrades. This commitment to customer satisfaction and long-term partnership ensures that the Nichrome Packing Machine continues to deliver value and efficiency throughout its operational lifecycle.Conclusion:In an era where operational efficiency and product quality are paramount to business success, the Nichrome Packing Machine emerges as a game-changer for various industries. Through its advanced technology, customizable solutions, seamless integration, and commitment to quality, this revolutionary packaging system enables businesses to optimize their production processes, meet market demands promptly, and safeguard the integrity of their products. As companies strive to stay competitive in an ever-evolving market, the Nichrome Packing Machine offers an indispensable tool for success.

New Packaging Machine for Pharmaceuticals now available, enhancing production process

Pharma Packaging Machine: Revolutionizing the Pharmaceutical IndustryWith the increasing demand for pharmaceutical products worldwide, ensuring the efficacy and safety of such drugs became a paramount concern for both producers and consumers alike. To meet the stringent standards set by regulatory bodies, the pharmaceutical industry employs sophisticated packaging machines that help ensure drugs are packaged with utmost precision, reliability, and efficiency.One leading name in this sector is the Pharma Packaging Machine, a cutting-edge equipment that boasts highly advanced technology and innovative features. This automated machine is designed to handle a wide range of pharmaceutical products, including tablets, capsules, injections, and powders, among others.Founded by a group of seasoned engineers, this brand is renowned for its high-quality and user-friendly packaging machines, which are integrated with state-of-the-art systems that offer superior efficiency, flexibility, and accuracy. The company has an extensive network of distributors and representatives, and its products are widely used and trusted by leading pharmaceutical companies across the globe.With its commitment to innovation and excellence, Pharma Packaging Machine continuously strives to improve its products and services based on customer feedback and market trends. Its machines are customizable, fully automated, and designed to provide maximum output with minimal downtime, making them ideal for medium to large-scale pharmaceutical operations.What sets Pharma Packaging Machine apart is its focus on providing customized solutions that cater to the unique needs of each customer. The company offers a wide range of packaging machines, including blister packaging machines, cartoning machines, and capsule filling machines, among others. Its machines are designed to handle various dosage forms and packaging formats, including single-dose, unit dose, and multi-dose packaging.Pharma Packaging Machine's blister packaging machines, for instance, are designed to handle thermoformed blister packs, which are widely used for tablets, capsules, and other solid dose products. These machines are fully automated and can handle high-volume production, with features such as automatic feeding, filling, sealing, and cutting. They are also equipped with advanced quality control systems that ensure accurate filling, high-speed packaging, and minimal operator intervention.With its cartoning machines, Pharma Packaging Machine offers a flexible and economical solution for packaging pharmaceutical products in various carton formats, such as tuck end, reverse tuck end, and straight tuck end styles. These machines are designed to handle both automatic and manual feeding and feature advanced systems for detecting and rejecting faulty cartons.Pharma Packaging Machine's capsule filling machines, on the other hand, are designed to handle various sizes and shapes of capsules, offering fully automated filling, sealing, and polishing operations. These machines are ideal for producing high-quality capsules with consistent weight, size, and shape, and come with advanced quality control systems that ensure accurate dosage and minimal wastage.One of the major advantages of choosing Pharma Packaging Machine is its focus on quality control and compliance. All the company's machines are designed and manufactured in compliance with international standards such as cGMP, FDA, and CE, and are subjected to rigorous testing and validation processes. This ensures that the machines meet the highest levels of reliability, accuracy, and safety, and are suitable for use in any pharmaceutical manufacturing environment.Pharma Packaging Machine's commitment to excellence is further demonstrated by its customer-centric approach, which includes comprehensive after-sales support and service. The company offers installation, training, and maintenance services, as well as a 24/7 customer support hotline, which provides prompt assistance and troubleshooting for any issues that customers may encounter.Overall, Pharma Packaging Machine's innovative solutions and customer-focused approach make it a leader in the pharmaceutical packaging industry. With its high-quality machines, advanced technology, and excellent customer support, the company is well-positioned to help pharmaceutical companies meet their packaging needs and ensure the safety and efficacy of their products.

Revolutionizing Packaging: Discover the Efficient Skin Packing Machine

Innovative Skin Packing Machine Revolutionizes Packaging IndustryWith the continuous advancement of technology, the packaging industry has seen significant progress in recent years. One such innovation making waves in the industry is the revolutionary Skin Packing Machine. This machine, developed by a renowned company in the packaging sector, has redefined the way products are packaged and delivered to customers.The Skin Packing Machine, which for the purposes of this article will be referred to as the SP-2000, is a state-of-the-art piece of equipment that promises to streamline the packaging process for various industries. Utilizing cutting-edge technology and efficient design, the SP-2000 is set to become a game-changer for businesses looking to improve their packaging operations.The company behind this groundbreaking invention is a global leader in the packaging industry, with decades of experience and a reputation for delivering innovative solutions. They have a deep understanding of the challenges faced by businesses when it comes to packaging, and the SP-2000 is a testament to their commitment to providing tangible solutions.The SP-2000 boasts exceptional capabilities that set it apart from traditional packaging machines. One of its key features is its ability to create a strong and secure seal around products, thus ensuring their safety during transit. This seal, known as a 'skin pack,' provides an additional layer of protection, preventing damage and reducing the risk of contamination.Furthermore, the SP-2000 offers significant customization options, allowing businesses to tailor the packaging process to their specific needs. This flexibility ensures that products of various shapes and sizes can be easily accommodated, making the machine suitable for a wide range of industries such as food, electronics, and medical equipment.In addition to its efficiency and versatility, the SP-2000 is also designed with ease of use in mind. The intuitive user interface and user-friendly controls make it accessible to both experienced operators and those new to the packaging industry. This simplicity contributes to increased productivity and reduced training time, ultimately saving businesses valuable time and resources.Moreover, the SP-2000 has been developed with sustainability in mind. In an era of increasing environmental awareness, businesses are under pressure to adopt sustainable practices. The SP-2000 addresses this challenge by utilizing recyclable packaging materials and minimizing waste, making it an attractive choice for eco-conscious companies aiming to reduce their carbon footprint.The company behind the SP-2000 has a strong commitment to customer satisfaction and offers comprehensive after-sales support. Their team of experts is available round the clock to provide guidance, assistance, and maintenance services, ensuring that businesses can maximize the benefits offered by the SP-2000 while minimizing any potential downtime.In conclusion, the Skin Packing Machine developed by this industry-leading company represents a significant breakthrough in the packaging industry. The SP-2000's innovative design, efficiency, customization options, ease of use, and sustainability make it a compelling choice for businesses of all sizes. By investing in this cutting-edge technology, businesses can enhance their packaging processes, improve product safety, boost productivity, and contribute to a greener future. With the SP-2000, the future of packaging is now within reach.

Top Quality Candy Forming Machines with Excellent After Sales Service from China Manufacturers

China Forming Machine Manufacturers Witnessing Increasing DemandChina has been at the forefront of manufacturing various machines and equipment for various industries globally. One such sector that has witnessed immense growth in recent times in China is the candy industry. As the demand for hard candies and various other forms of candies sees an upswing, China has emerged as a leading player in the candy-forming machine manufacturing industry.According to reports, the global candy market is estimated to reach $160 billion by 2023 with a growth rate of 3.7%. This rise in demand for candies, particularly hard candies, has opened up a plethora of opportunities for candy forming machine manufacturers in China.Leading Chinese manufacturers in this field have been at the forefront of supplying superior quality hard candy forming machines to global markets. A hard candy forming machine is primarily used to shape hard candies and other confectionery products into various creative designs. The machine works on a vacuum pump that helps shape the candy mixture into different shapes and sizes according to the mold used.Leading players in this industry offer rotary hard candy forming machines and flat hard candy forming machines. They also custom-make machines according to the specific requirements of their clients.One of the hardest parts of producing hard candies is the forming; it requires a lot of precision, accuracy, and speed. With China's candy-forming machine manufacturers, this tedious task is easier to handle, and with automatic machines, it is further streamlined.The machines' quality is assured, and the companies provide excellent after-sales service to their clients. Their machines are equipped with advanced controls systems that make them user-friendly and easy for operators to navigate.The machines can produce around 200-400 candy pieces per minute, depending on their model's make and the candy's requirement. The machines are designed to handle various hard candy recipes, from both liquid- and powder-based sugar ingredients.China's forming machine manufacturers specialize in producing rotary hard candy forming machines that use a drum for the molding process. The drum rotates during the process, and vacuum pumps shape the hard candy against the molds. The machines have an output capacity of 200-400 pieces per minute.Flat hard candy forming machines are also very popular in the industry. Some manufacturers offer customized machines that can create up to ten different layers, producing candies with multilayered looks.It is interesting to note that most of the hard candy forming machine manufacturers in China also supply to other countries where their products are highly sought after. They have successfully managed to capture a considerable share of world markets and provide unmatched quality to users at competitive pricing.It is no surprise, given the growth potential in the candy market, that China's candy-forming machine manufacturers are experiencing increasing demand from across the globe. Besides, the companies are continually innovating, developing, and improving their products to suit the ever-changing market demands.In conclusion, one can confidently say that the future of hard candy forming machines made in China is bright, and the country is well-positioned to meet diverse requirements and dominate the global candy market.About the company (fill in with company details)We are a leading manufacturer of forming machines for hard candies and other confectionery products in China. Our company has more than ten years of experience in the industry and provides unparalleled quality and service to our customers globally.We specialize in producing rotary hard candy forming machines and flat hard candy forming machines, and custom-made machines according to our customers' specific requirements.Our machines are equipped with advanced controls systems that make them user-friendly and easy for operators to navigate. With an output capacity of 200-400 pieces per minute, our machines deliver high speed and precision for our customers' satisfaction.We are committed to continuous innovation, development, and improvement of our products to meet the ever-changing market demands. With us, you are assured of the highest quality and the best after-sales service.

Toffee Candy Making Machinery Takes the Confectionery Industry by Storm

Toffee Candy Making Machine, Revolutionizing Confectionery ProductionIn recent years, the confectionery industry has witnessed a tremendous demand for toffee candies worldwide. These delectable treats, loved by individuals of all ages, have become a staple in the confectionery market. With this surge in popularity, manufacturers are constantly seeking innovative solutions to meet the increasing consumer demand. Introducing the revolutionary Toffee Candy Making Machine, a cutting-edge technology that has redefined the way toffee candies are produced.Developed by a leading manufacturing company (please remove brand name), the Toffee Candy Making Machine has garnered attention for its impressive automation capabilities and streamlined production processes. With its state-of-the-art features, this machine has become an essential tool for confectionery manufacturers, enabling them to produce high-quality toffee candies efficiently and effortlessly.One of the key highlights of the Toffee Candy Making Machine is its ability to automate the entire candy-making process. Traditionally, the production of toffee candies involved numerous manual steps, which were time-consuming and required a significant amount of labor. However, with the advent of this innovative machine, manufacturers can now produce toffee candies at a much faster rate, thus increasing overall productivity.Additionally, the Toffee Candy Making Machine boasts an impeccable level of precision, ensuring consistent and uniform candy sizes. With its advanced technology, this machine can precisely measure and portion the toffee mixture, resulting in candies that are flawless in shape and size. This standardization not only enhances the visual appeal of the candies but also improves the customer's overall experience.Furthermore, the Toffee Candy Making Machine is known for its versatility and flexibility. Manufacturers are able to customize the machine according to their specific requirements, allowing them to produce a wide range of toffee candy flavors, shapes, and designs. Whether it is classic toffee, fruit-flavored, or even novelty-shaped candies, this machine can adapt and cater to diverse consumer preferences, thereby expanding the market for toffee candies.In terms of efficiency, the Toffee Candy Making Machine surpasses conventional production methods by reducing wastage significantly. The machine operates with minimal raw material wastage, ensuring maximum utilization and cost-effectiveness. With the rising concerns for sustainability and reducing environmental impact, this machine addresses these issues by optimizing resource allocation.Moreover, the Toffee Candy Making Machine also prioritizes hygiene and food safety. It is constructed using high-quality materials that are resistant to contamination and easy to clean. This feature is vital in ensuring the production of safe and hygienic toffee candies, meeting the stringent quality standards set by regulatory authorities.As the market for toffee candies continues to grow, the Toffee Candy Making Machine has become a game-changer for manufacturers worldwide. Its efficiency, precision, and adaptability have transformed the production landscape, revolutionizing the confectionery industry. Additionally, with its emphasis on sustainability and food safety, this machine aligns with the growing consumer demand for responsible manufacturing processes.In conclusion, the Toffee Candy Making Machine, developed by (please remove brand name), has become an indispensable tool for confectionery manufacturers in meeting the increasing global demand for toffee candies. With its automation capabilities, precision, versatility, and efficiency, this machine has significantly improved the candy production process. As the confectionery industry continues to evolve, the Toffee Candy Making Machine stands as a testament to the power of innovation in shaping the future of confectionery production.