Innovative Tablet Packing Machine for Efficient Packaging

By:Admin

In the fast-paced world of pharmaceutical manufacturing, efficiency and precision are essential. The introduction of the state-of-the-art Tablet Packing Machine from {Company Name} has revolutionized the way pharmaceutical products are packaged, setting new industry standards for speed, accuracy, and reliability.

{Company Name} has been a leading manufacturer of high-tech packaging solutions for the pharmaceutical industry for over two decades. With a commitment to innovation and quality, the company has constantly strived to develop cutting-edge machinery that meets the evolving needs of the market. The Tablet Packing Machine is a testament to their dedication to excellence and their ability to push the boundaries of technological advancement.

This advanced packaging machine is designed to handle the intricate process of packaging tablets and capsules with utmost precision and efficiency. Equipped with the latest automation technology, the Tablet Packing Machine is capable of handling a wide range of packaging formats, ensuring seamless and consistent product packaging. Its high-speed capabilities allow for rapid production, significantly reducing downtime and increasing overall output.

One of the standout features of the Tablet Packing Machine is its superior accuracy in product counting and packaging. Through advanced sensor technology and intelligent software, the machine is able to precisely count and package tablets and capsules with minimal margin of error. This not only ensures product integrity and quality but also reduces the risk of human error, making the entire packaging process more reliable and consistent.

Furthermore, the Tablet Packing Machine is designed with versatility in mind, allowing for quick and easy changeovers between different packaging formats. This flexibility is essential for pharmaceutical manufacturers who often need to accommodate various product sizes and packaging requirements. The machine's user-friendly interface and intuitive controls make it simple for operators to reconfigure the system, minimizing downtime and maximizing productivity.

In addition to its technological prowess, the Tablet Packing Machine is engineered with an emphasis on product safety and compliance. It adheres to the strict regulatory standards of the pharmaceutical industry, incorporating features that ensure the integrity of the packaging process and the protection of the products. This includes advanced tamper-evident packaging options and quality control mechanisms that guarantee the authenticity and security of the packaged products.

The introduction of the Tablet Packing Machine has been met with widespread acclaim within the pharmaceutical manufacturing community. Industry experts have hailed it as a game-changer, recognizing its potential to streamline operations, improve efficiency, and elevate the overall standard of pharmaceutical packaging. Its impact is not only limited to large-scale production facilities but also extends to contract packaging organizations and compounding pharmacies seeking a competitive edge in the market.

{Company Name} has already begun the global rollout of the Tablet Packing Machine, with pharmaceutical manufacturers across the world expressing keen interest in adopting this cutting-edge technology. The company's commitment to customer service and support ensures that clients receive comprehensive training and ongoing assistance to maximize the benefits of this revolutionary packaging solution.

As the pharmaceutical industry continues to evolve, the demand for innovative and reliable packaging machinery becomes increasingly critical. With the introduction of the Tablet Packing Machine, {Company Name} has reinforced its position as a frontrunner in the field of pharmaceutical packaging technology, setting a new benchmark for excellence and redefining the standards of efficiency and precision in the industry.

Company News & Blog

Ultimate Guide to Induction Sealer Technology

Induction Sealer Revolutionizing Packaging IndustryThe packaging industry has been revolutionized by the introduction of the innovative Induction Sealer by a leading technology company. The Induction Sealer has transformed the way products are sealed, providing a reliable and efficient solution for packaging needs across various industries.With the increasing demand for tamper-evident and leak-proof packaging, the Induction Sealer has quickly become a staple in the packaging industry. Its advanced technology ensures a hermetic seal, preventing contamination and prolonging the shelf life of products. This has made the Induction Sealer popular among manufacturers of food, pharmaceuticals, beverages, and other consumer goods.The company behind the Induction Sealer has a proven track record of developing cutting-edge technology solutions for the packaging industry. Their commitment to innovation and excellence has propelled them to the forefront of the industry, earning them a reputation for delivering high-quality and reliable products.The Induction Sealer is designed to meet the specific needs of modern packaging processes, offering a range of features that set it apart from traditional sealing methods. Its ability to seal containers of various shapes and sizes with precision and consistency makes it a versatile solution for manufacturers with diverse packaging requirements.In addition to its sealing capabilities, the Induction Sealer also enhances the aesthetic appeal of packaged products. Its clean and professional sealing process creates a polished and professional look, reinforcing the brand image of the packaged goods.Furthermore, the Induction Sealer is designed for ease of use and maintenance, minimizing downtime and maximizing productivity for manufacturers. Its user-friendly interface and robust construction ensure reliable performance, reducing the need for frequent adjustments or repairs.The Induction Sealer has also proven to be environmentally friendly, as it reduces the reliance on traditional sealing methods that often involve the use of adhesives or heat, which can be harmful to the environment. Its induction sealing process eliminates the need for additional chemicals or excessive energy consumption, aligning with the growing demand for sustainable packaging solutions.One of the key advantages of the Induction Sealer is its ability to reduce packaging costs for manufacturers. By ensuring a secure seal and preventing product wastage due to leaks or contamination, the Induction Sealer contributes to overall cost savings and improved operational efficiency.The company behind the Induction Sealer has consistently demonstrated its commitment to customer satisfaction through reliable support and service. Their team of experts provides comprehensive training and technical assistance to ensure that customers can maximize the benefits of the Induction Sealer.With its standout features and proven performance, the Induction Sealer has quickly gained popularity among leading manufacturers worldwide. Its impact on the packaging industry has been significant, driving efficiency, product integrity, and cost-effectiveness.Looking ahead, the company is committed to further expanding the capabilities of the Induction Sealer, leveraging the latest advancements in technology to meet the evolving needs of the packaging industry. Their ongoing dedication to innovation and excellence positions them as a frontrunner in the industry, empowering manufacturers to achieve their packaging goals with confidence.In conclusion, the Induction Sealer has emerged as a game-changer in the packaging industry, offering a reliable, efficient, and cost-effective solution for manufacturers. With its advanced technology and proven performance, it has set a new standard for sealing products, reinforcing the company's position as a leader in the industry. As the demand for secure and sustainable packaging solutions continues to grow, the Induction Sealer is poised to play an increasingly pivotal role in shaping the future of packaging.

Top Heat Sealers for Food Packaging to Keep Your Products Fresh

Introducing Innovative Heat Sealers for Food PackagingIn the food packaging industry, the need for effective and efficient packaging solutions is always at the forefront. With the increasing demand for convenience and sustainability, companies are continuously seeking new methods to ensure that their products are packaged securely and attractively. This has led to the development of advanced heat sealing technology, which has revolutionized the way food products are packaged and sealed.One company that has been at the forefront of this innovation is {}. With a long history of providing high-quality packaging solutions, the company has recently introduced a new line of heat sealers that are designed to meet the diverse needs of the food packaging industry. These heat sealers are engineered to provide a secure and airtight seal, keeping food products fresh and safe for extended periods of time.The company's heat sealers are equipped with advanced features that make them ideal for a wide range of food packaging applications. Whether it's for packaging fresh produce, frozen foods, or dry goods, these heat sealers are versatile enough to handle the task with precision and reliability. This versatility is crucial for companies looking to streamline their packaging processes and ensure that their products are delivered to consumers in the best possible condition.One of the key advantages of {}'s heat sealers is their user-friendly design. With intuitive controls and easy-to-use settings, operators can quickly and efficiently seal packages without any hassle. This not only saves time and labor costs but also ensures consistent and reliable sealing results. Additionally, the heat sealers are equipped with safety features to protect operators from potential hazards, making them an ideal choice for busy packaging facilities.In addition to their functionality, {}'s heat sealers are also designed with sustainability in mind. The company is committed to reducing the environmental impact of packaging processes, and their heat sealers are engineered to minimize waste and energy consumption. This is achieved through innovative sealing techniques that optimize material usage and reduce the overall carbon footprint of the packaging process.With the growing emphasis on sustainable packaging solutions, {}'s heat sealers are well-positioned to meet the evolving needs of the food packaging industry. By providing a combination of reliability, efficiency, and sustainability, these heat sealers offer a compelling solution for companies looking to improve their packaging processes and reduce their environmental impact.Furthermore, {}'s heat sealers are backed by the company's extensive support network. From installation and training to ongoing maintenance and technical support, customers can rely on {} to provide the assistance they need to maximize the performance of their heat sealers. This level of support is essential for companies looking to invest in new packaging equipment and ensures that they can maintain peak operational efficiency.As the food packaging industry continues to evolve, the demand for innovative and reliable packaging solutions will only continue to grow. With {}'s heat sealers, companies can stay ahead of the curve by implementing cutting-edge technology that delivers superior sealing performance while also addressing sustainability concerns. By investing in {}'s heat sealers, companies can enhance their packaging processes, reduce their environmental impact, and ultimately deliver better products to consumers.

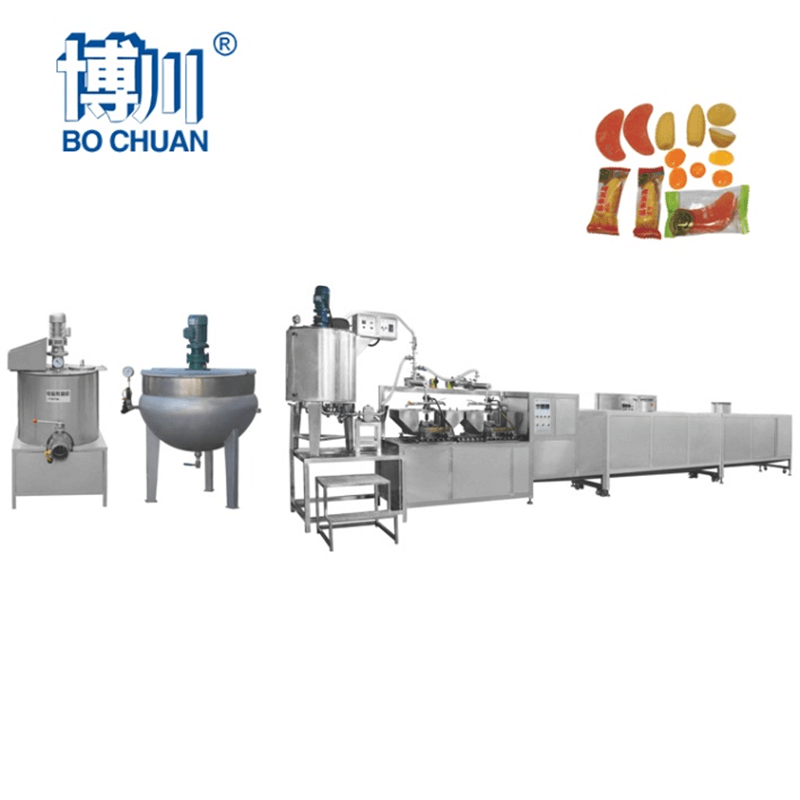

Rewritten SEO title: High-Quality Industrial Vitamin Gummy Bear Making Machine for Commercial Use

Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine: The Perfect Solution for Your Candy Manufacturing NeedsAre you looking for a reliable and efficient machine to produce jelly candy, specifically gummy bear jelly candy? Look no further than the Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine!Working closely with our manufacturing partners, we have designed and developed a machine that ensures optimal productivity and quality while being cost-effective. Whether you're a small-business operator or a large commercial candy manufacturer, our Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine will be the perfect solution for your production needs.One of the main features of our machine is its ability to deposit different types of jelly candy. This includes gummy bears, fruit jelly candies, marshmallows, and so much more. All you need to do is adjust the recipe of your desired candy, and our machine will do the rest.With the help of our Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine, you can be sure that your final product will have consistent size, shape, and texture. This is because our machine uses an automatic depositing system that's designed to produce candies of uniform weight and appearance. Plus, our machine also ensures that each candy has a smooth and glossy surface, making them not just tasty but visually appealing too.Aside from its impressive production capabilities, our machine is also designed for easy operation and maintenance. It's equipped with a user-friendly interface that allows you to set different parameters to achieve different candy styles and flavors. Plus, our machine is made of high-quality materials that are durable and easy to clean, ensuring longevity and low maintenance costs.Overall, our Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine is a must-have for all candy manufacturers who wish to keep up with the ever-growing demand for delicious and nutritious gummy bear jelly candies. Plus, our machine is versatile, efficient, and cost-effective, making it a worthwhile investment for any candy-making business.So, contact us today to get started on your journey to producing high-quality and tasty gummy bear jelly candies with our Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine. And don't forget to include the keyword "Jelly Fruit Making Machine" in your search for greater visibility and search engine optimization!

Packing Machine Updates: Stay Informed with the Latest News!

Title: Revolutionary Packaging Solution Unveiled: Intelligent Machinery Aims to Transform Packaging IndustryIntroduction:In a bid to revolutionize the packaging industry, a progressive machinery engineering company has launched an innovative packaging solution that promises to streamline and enhance the packing process across various sectors. The newly introduced intelligent machinery, now known as the R-Pack System, aims to redefine the industry's efficiency and productivity, providing businesses with a state-of-the-art solution for their packaging needs.I. The Evolution of Packaging Machinery: A Brief OverviewPackaging machinery has come a long way since its inception in the early 19th century. From manual labor to semi-automated processes, the industry has witnessed significant advancements over the years. These advancements have consistently strived to improve speed, accuracy, and safety while reducing downtime and minimizing waste.II. The Birth of the R-Pack System: Intelligent Packaging at Its FinestThe R-Pack System, developed by a leading machinery engineering company, represents a landmark milestone in the packaging industry. By harnessing the latest advancements in artificial intelligence, robotics, and automation, this cutting-edge solution aims to optimize and simplify packaging operations across various industries.III. Streamlined Efficiency: Redefining Packaging ProcessesOne of the core goals of the R-Pack System is to enhance efficiency by automating and streamlining the packaging process. The advanced software incorporated within the system ensures optimal packaging precision while significantly reducing the time required for packing a product. By eliminating manual errors and achieving unparalleled precision, this intelligent machinery empowers businesses to meet high production demands while maintaining consistency in their packaging.IV. Increased Productivity: Meeting Market DemandThe R-Pack System is designed to cater to the ever-increasing demand for fast-paced and accurate packaging solutions. With its rapid output capabilities, this state-of-the-art machinery ensures that businesses can efficiently fulfill customer orders without compromising on quality. Through its intelligent systems, the R-Pack System promotes higher productivity, providing companies with a competitive edge in the market.V. Versatility: Adapting to Diverse Product Packaging NeedsA unique advantage of the R-Pack System lies in its adaptability to varying packaging requirements. Whether it be the food industry, pharmaceuticals, or consumer goods, this intelligent machinery can accommodate diverse products of varying size, shape, and weight. The system's flexible configuration allows it to be easily customized to cater to the specific needs of different industries, making it a suitable choice for businesses seeking a versatile packaging solution.VI. Safety and Sustainability: Prioritizing the EnvironmentIn line with modern consumer demands, the R-Pack System prioritizes safety and sustainability in packaging processes. The intelligent software continually monitors the packing process to avoid potential hazards and minimize accidents, ensuring the well-being of workers. Additionally, the system is designed to promote eco-friendly packaging practices, optimizing material usage and reducing waste, contributing to a greener supply chain.VII. Ease of Integration: Seamless Transition Into Existing ProcessesEnsuring a seamless transition for businesses, the R-Pack System can easily integrate into existing packaging processes. Its compatibility with various production lines allows for efficient adoption without the need for extensive modifications or time-consuming training. This plug-and-play compatibility ensures that businesses can embrace the intelligent machinery with minimal disruption to their operations.Conclusion:With the introduction of the R-Pack System, the packaging industry stands poised to witness a significant transformation. This intelligent packaging machinery promises to revolutionize processes, enhance efficiency, and increase productivity across diverse sectors. Businesses can now harness the power of technology to overcome traditional packaging limitations while meeting rising market demands. The adoption of this intelligent solution positions companies at the forefront of innovation and provides a competitive edge in an ever-evolving marketplace.

High-Quality Commercial Fudge Making Equipment for Sale

Commercial Fudge Making Equipment Revolutionizing the Confectionery IndustryThe confectionery industry has always been a sweet and indulgent sector, but with the advancements in technology and equipment, it has become even more delectable. The introduction of commercial fudge making equipment has revolutionized the way fudge is produced, resulting in higher quality, efficiency, and output.Traditionally, fudge making involved long hours of stirring and monitoring over a hot stove, with no guarantee of a consistent and perfect product. However, with the innovation of commercial fudge making equipment, confectioners now have access to state-of-the-art machinery that takes the guesswork out of fudge production.One such company that has been at the forefront of this revolution is [Company Name]. With years of experience in the confectionery industry, they have developed a range of commercial fudge making equipment that has set a new standard for fudge production.Their fudge making equipment is designed to streamline the entire process, from mixing and cooking to cooling and packaging. It ensures that the fudge is cooked to perfection, with the right texture, flavor, and consistency every time. This level of precision and reliability has allowed confectioners to scale up their production and meet the increasing demand for high-quality fudge.In addition to efficiency and consistency, [Company Name]'s commercial fudge making equipment also prioritizes food safety and hygiene. The equipment is made from high-quality materials that are easy to clean and maintain, reducing the risk of contamination and ensuring that the fudge is safe for consumption.Furthermore, their equipment is equipped with advanced controls and monitoring systems, allowing confectioners to have real-time visibility and control over the production process. This level of automation not only simplifies the production process but also minimizes the margin of error, resulting in a higher quality and more cost-effective product.The impact of commercial fudge making equipment has been significant in the confectionery industry. It has empowered small businesses to compete with larger manufacturers, as well as allowed established companies to expand their product offerings and reach new markets. Moreover, the consistent and high-quality fudge produced by this equipment has won over the hearts of consumers, leading to increased demand and sales.In addition to the commercial benefits, the introduction of commercial fudge making equipment has also sparked creativity and innovation in the confectionery industry. Confectioners now have the freedom to experiment with new flavors, textures, and shapes, pushing the boundaries of what fudge can be. This has led to a renaissance in the fudge market, with an array of exciting and novel products hitting the shelves.The impact of commercial fudge making equipment has not gone unnoticed by industry experts and enthusiasts. Many have praised the advancements in technology and equipment, describing it as a game-changer for the confectionery industry. The level of precision, efficiency, and creativity enabled by this equipment has set a new standard for what is possible in fudge production.Looking ahead, the future of commercial fudge making equipment looks promising. With ongoing advancements in technology and the increasing demand for high-quality confectionery products, this equipment is poised to play a vital role in shaping the future of the industry. As more confectioners embrace this technology, we can expect to see a continued evolution in the world of fudge, with new flavors, techniques, and experiences for consumers to enjoy.In conclusion, commercial fudge making equipment has had a profound impact on the confectionery industry, revolutionizing the way fudge is produced and consumed. With its emphasis on efficiency, consistency, and creativity, this equipment has elevated the standard of fudge production, opening up new opportunities for confectioners and delighting consumers around the world. As the industry continues to evolve, it is clear that the future of fudge is looking sweeter than ever.

Top Quality Candy Forming Machines with Excellent After Sales Service from China Manufacturers

China Forming Machine Manufacturers Witnessing Increasing DemandChina has been at the forefront of manufacturing various machines and equipment for various industries globally. One such sector that has witnessed immense growth in recent times in China is the candy industry. As the demand for hard candies and various other forms of candies sees an upswing, China has emerged as a leading player in the candy-forming machine manufacturing industry.According to reports, the global candy market is estimated to reach $160 billion by 2023 with a growth rate of 3.7%. This rise in demand for candies, particularly hard candies, has opened up a plethora of opportunities for candy forming machine manufacturers in China.Leading Chinese manufacturers in this field have been at the forefront of supplying superior quality hard candy forming machines to global markets. A hard candy forming machine is primarily used to shape hard candies and other confectionery products into various creative designs. The machine works on a vacuum pump that helps shape the candy mixture into different shapes and sizes according to the mold used.Leading players in this industry offer rotary hard candy forming machines and flat hard candy forming machines. They also custom-make machines according to the specific requirements of their clients.One of the hardest parts of producing hard candies is the forming; it requires a lot of precision, accuracy, and speed. With China's candy-forming machine manufacturers, this tedious task is easier to handle, and with automatic machines, it is further streamlined.The machines' quality is assured, and the companies provide excellent after-sales service to their clients. Their machines are equipped with advanced controls systems that make them user-friendly and easy for operators to navigate.The machines can produce around 200-400 candy pieces per minute, depending on their model's make and the candy's requirement. The machines are designed to handle various hard candy recipes, from both liquid- and powder-based sugar ingredients.China's forming machine manufacturers specialize in producing rotary hard candy forming machines that use a drum for the molding process. The drum rotates during the process, and vacuum pumps shape the hard candy against the molds. The machines have an output capacity of 200-400 pieces per minute.Flat hard candy forming machines are also very popular in the industry. Some manufacturers offer customized machines that can create up to ten different layers, producing candies with multilayered looks.It is interesting to note that most of the hard candy forming machine manufacturers in China also supply to other countries where their products are highly sought after. They have successfully managed to capture a considerable share of world markets and provide unmatched quality to users at competitive pricing.It is no surprise, given the growth potential in the candy market, that China's candy-forming machine manufacturers are experiencing increasing demand from across the globe. Besides, the companies are continually innovating, developing, and improving their products to suit the ever-changing market demands.In conclusion, one can confidently say that the future of hard candy forming machines made in China is bright, and the country is well-positioned to meet diverse requirements and dominate the global candy market.About the company (fill in with company details)We are a leading manufacturer of forming machines for hard candies and other confectionery products in China. Our company has more than ten years of experience in the industry and provides unparalleled quality and service to our customers globally.We specialize in producing rotary hard candy forming machines and flat hard candy forming machines, and custom-made machines according to our customers' specific requirements.Our machines are equipped with advanced controls systems that make them user-friendly and easy for operators to navigate. With an output capacity of 200-400 pieces per minute, our machines deliver high speed and precision for our customers' satisfaction.We are committed to continuous innovation, development, and improvement of our products to meet the ever-changing market demands. With us, you are assured of the highest quality and the best after-sales service.

Discover the Benefits of Using a Reliable Tray Sealing Machine for Your Business

Introducing Innovative Tray Sealing Technology Revolutionizing Packaging EfficiencyIn a bid to enhance packaging efficiency and revolutionize the food industry, a leading packaging machinery manufacturer has introduced a cutting-edge Tray Sealing Machine. With its advanced features and state-of-the-art technology, this machine is set to transform the way products are packaged and sealed.As consumer demand for convenient and sustainable packaging solutions continues to rise, companies are constantly seeking ways to optimize packaging processes. The newly introduced Tray Sealing Machine, developed by a renowned manufacturer, provides a game-changing solution that meets the evolving needs of the industry.One of the key advantages of this Tray Sealing Machine is its ability to seal trays in a fast and efficient manner. Equipped with high-speed sealing technology, this machine can seal multiple trays per minute, significantly increasing packaging throughput. This not only saves manufacturers valuable time but also ensures products are packaged and ready for distribution within shorter time frames.Moreover, the machine's user-friendly interface and customizable settings allow for seamless integration into production lines of various scales. Its intuitive controls enable operators to easily adjust the sealing parameters, such as temperature and pressure, ensuring optimal sealing results for different types of products and trays. This versatility makes it an ideal solution for businesses of all sizes, from small-scale producers to large industrial operations.In addition to its speed and versatility, the Tray Sealing Machine also boasts innovative features aimed at enhancing product freshness and extending shelf life. The machine utilizes advanced sealing techniques that create an airtight seal, effectively preserving the quality and freshness of the packaged products. This is especially critical for perishable items such as fresh produce, ready-to-eat meals, and dairy products.Furthermore, the Tray Sealing Machine promotes sustainability by reducing packaging waste. Its precise cutting technology minimizes excess film, optimizing material usage and reducing environmental impact. By utilizing less packaging material, companies can contribute to a greener future while also benefiting from cost savings.The introduction of this cutting-edge technology aligns with the manufacturer's commitment to delivering sustainable and efficient packaging solutions. With decades of expertise in the industry, the company has established a strong reputation for innovation and customer satisfaction. Their relentless focus on research and development has resulted in revolutionary products, such as the Tray Sealing Machine, which cater to the evolving needs of the market.As the global food industry faces challenges related to consumer demands, operational efficiency, and environmental sustainability, the Tray Sealing Machine becomes a vital asset for companies striving to stay ahead in the market. By investing in this innovative packaging solution, businesses can streamline their operations, enhance product quality, and meet the growing expectations of consumers.In conclusion, the introduction of the Tray Sealing Machine represents a significant leap forward in the packaging industry. Its ability to seal trays at high speeds, customizable settings, and focus on product freshness and sustainability make it a game-changer for businesses. With this innovative technology, companies can optimize their packaging processes, reduce waste, and ultimately deliver high-quality products to consumers.

Discover the Innovative Manufacturing Process Behind a Popular Candy-Making Machine

**Title: Innovative Candymaking Machine Revolutionizes the Confectionery Industry***Introduction (100 words)*Innovations in candy manufacturing have taken a giant leap forward with the introduction of a groundbreaking confectionery-making machine by an esteemed company. This state-of-the-art device, referred to as the Candy Magic machine, promises to revolutionize the candy industry by combining cutting-edge technology with the time-honored tradition of sweet-making. Developed by a team of skilled engineers, this ingenious device aims to streamline and automate the candy production processes, ensuring high-quality, delectable sweets are produced at an unprecedented speed and efficiency.*Background (150 words)*The confectionery industry has always witnessed advancements aimed at enhancing production and meeting the growing demand for candies. The Candy Magic machine is the brainchild of a renowned confectionery manufacturing company, persistently striving to create products that cater to global palates and consumer preferences. With decades of experience under their belt, the company has consistently delivered innovative solutions to the confectionery sector.In their quest to achieve greater efficiency and productivity, the company assembled a team of experts consisting of engineers and confectioners to collaborate on developing a revolutionary candy-making machine. Through meticulous research and development efforts, they successfully engineered an advanced candy-making device - the Candy Magic machine.*Key Features and Advantages (200 words)*The Candy Magic machine boasts an array of features that set it apart from traditional candy-making methods. Incorporating state-of-the-art technology, this remarkable machine offers numerous advantages, including improved production speed, enhanced precision, and greater control over the entire manufacturing process.The machine's automated operations allow for consistent and uniform candy production, ensuring each piece meets the highest standards of taste, texture, and appearance. The Candy Magic machine can effortlessly produce a wide range of candies, from chewy to hard varieties, and can even cater to different shapes and flavors through easily adjustable settings.This innovative candy-making machine minimizes human error and labor costs while maximizing production output. The efficient manufacturing process of the Candy Magic machine significantly reduces the time required to make a batch of candies, allowing confectionery companies to meet the growing demands of their consumers promptly.Furthermore, the incorporation of smart technology within the machine enables real-time monitoring and data collection, facilitating quality control and ensuring consistent product excellence. By integrating this data-driven approach, confectionery manufacturers can make informed decisions regarding flavor variations, ingredient usage, and overall efficiency.*Incorporating Sustainable Practices (150 words)*Beyond revolutionizing the confectionery industry, the new candy-making machine also emphasizes the importance of sustainability by embracing eco-friendly practices. The Candy Magic machine is designed to minimize waste generation, reduce energy consumption, and promote sustainable manufacturing methods.Efficient usage of raw materials, precise measurements, and controlled production processes significantly decrease the amount of material waste, making this machine a responsible choice for confectionery manufacturers. Additionally, the machine's energy-saving features contribute to reducing the environmental impact associated with candy production.Furthermore, the Candy Magic machine can operate with organic and natural ingredients, supporting the growing interest in healthier and more ethically-sourced candies. This environmentally conscious approach ensures that consumer demands for sustainably produced confectionery are met without compromising taste or quality.*Conclusion (200 words)*In an era where innovation shapes every industry, the introduction of the Candy Magic machine promises to transform the confectionery landscape. With its advanced technology, streamlined production, and commitment to sustainability, this pioneering candy-making device opens up new possibilities for manufacturers to meet the ever-evolving demands of the market.By enabling precise control, superior speeds, and consistent quality, this machine redefines the way candies are produced, making it an invaluable asset for confectionery companies looking to optimize their manufacturing processes. With the Candy Magic machine, the future of candy-making is now a reality, blending tradition with modernity to deliver delightful treats on a large scale.As the confectionery industry continuously evolves, it is innovations like the Candy Magic machine that push boundaries and shape the way we experience the sweet indulgences we love. Exciting times lie ahead for the confectionery world as this groundbreaking machine paves the way for enhanced efficiency, superior candy craftsmanship, and sustainable practices.

Unlock Your Inner Chef: How to Make Cotton Candy at Home

Title: Innovative Cotton Candy Machine Revolutionizing the Confectionery IndustryIntroduction:In today's fast-paced world, where innovation and creativity go hand in hand, {need to remove brand name} has introduced an extraordinary invention into the confectionery industry. The new Sweet Cotton Candy Machine has captured the attention of both confectionery enthusiasts and industry professionals alike. With its cutting-edge technology and unique features, this revolutionary machine is set to transform the way cotton candy is made and enjoyed.Elevating the Cotton Candy Experience:Traditional cotton candy machines are known for their simplistic operation and limited capabilities. However, the Sweet Cotton Candy Machine takes this concept to a whole new level. Incorporating advanced engineering, this device combines precision with convenience, ensuring an elevated cotton candy experience for consumers and entrepreneurs alike.Advanced Technology:The Sweet Cotton Candy Machine boasts state-of-the-art technology that guarantees exceptional results. Equipped with a powerful motor, this machine efficiently spins sugar into delectable cotton candy strands, providing a fluffy and luscious treat for customers. The machine's intelligent controls allow users to adjust the temperature, rotation speed, and sugar quantities, offering unparalleled customization options.Ease of Use:One of the distinguishing features of this innovative cotton candy machine is its user-friendly design. With a sleek and intuitive interface, even novices can create mouthwatering cotton candy in no time. This accessibility makes it an attractive option for small business owners, events, and parties, adding a touch of sweetness to any occasion.Versatility:The Sweet Cotton Candy Machine's versatility sets it apart from traditional machines. Unlike the conventional models restricted to spinning only standard-sized cotton candy onto sticks, this device offers unparalleled flexibility. From miniature bite-sized treats to large creations, the machine allows users to explore various shapes and sizes, expanding the possibilities of cotton candy presentation.Enhancing Taste with Flavor Options:Realizing the importance of offering a diverse range of flavors, {need to remove brand name} has developed a range of delicious cotton candy flavors. From classic choices like strawberry and blueberry to unconventional options like bubblegum and green apple, these flavors are meticulously crafted to enhance the overall cotton candy experience. With the Sweet Cotton Candy Machine's compatibility with a variety of sugars and flavorings, customers can enjoy a multitude of tantalizing tastes.Durability and Safety:Built with durability in mind, the Sweet Cotton Candy Machine guarantees longevity, essential for businesses with high production demands. The stainless steel construction ensures resistance to wear and tear, making it an investment that stands the test of time. Additionally, the machine incorporates safety features such as automatic shut-off, overheat protection, and a sturdy base, ensuring operational and consumer safety.Eco-Friendly Approach:Acknowledging the growing concern for the environment, {need to remove brand name} has incorporated an eco-friendly approach in the manufacturing process of the Sweet Cotton Candy Machine. Utilizing energy-efficient technology and recyclable materials, the company aims to minimize its ecological footprint while delivering exceptional confectionery equipment.Conclusion:With its state-of-the-art technology, user-friendly design, and versatility, the Sweet Cotton Candy Machine offers a new way to create, present, and enjoy cotton candy. Its advanced features, paired with an extensive range of flavors and customizable options, make it a game-changer in the confectionery industry. As a result, entrepreneurs, event organizers, and confectionery enthusiasts can expect an enhanced cotton candy experience that is sure to leave a sweet, lasting impression.

Revolutionize Your Packaging Process with Advanced Packing Machines

[Header]Revolutionary Packing Machine Set to Transform the Industry[Subtitle]Innovative Technology Poised to Boost Production Efficiency and Reduce Costs[Body][date], the highly anticipated unveiling of a cutting-edge packing machine promises to revolutionize the way goods are packaged, promising significant increases in production efficiency and cost reduction for manufacturers worldwide. Developed by an industry-leading company known for its expertise in manufacturing machinery, this groundbreaking innovation is set to disrupt traditional packaging practices and propel the industry into the future.Tackling the pain points experienced by manufacturers, this state-of-the-art packing machine offers remarkable advancements in speed, accuracy, and versatility. Leveraging the power of artificial intelligence and automation, it boasts the ability to handle diverse packaging requirements across various industries with ease – from food and beverages to pharmaceuticals, electronics, and beyond.One of the key features that sets this packing machine apart from its competitors is its impeccable speed, ensuring optimal production efficiency. With lightning-fast processing capabilities, it can seamlessly package items at an impressive pace, dramatically reducing downtime and boosting output. Manufacturers can expect to achieve higher production targets while maintaining consistent quality standards.Precision and accuracy are non-negotiable when it comes to packaging, and this innovative machine delivers exceptional results in these domains. Equipped with advanced sensors and intelligent programming, it ensures that each item is packed precisely, minimizing the occurrence of errors and eliminating costly wastage. Additionally, it offers customizable packaging options, allowing manufacturers to tailor their packaging to meet individual product specifications, further enhancing brand integrity.Moreover, this packing machine prioritizes safety without compromising on speed and efficiency. Designed with leading-edge safety mechanisms, it minimizes the risk of occupational hazards, ensuring a secure work environment for operators. By incorporating multiple levels of safety checks, it adheres to industry regulations and mitigates potential accidents. This focus on safety not only protects the workforce but also safeguards manufacturers from any potential legal liabilities.While boosting production efficiency and ensuring safety are paramount, cost reduction is equally crucial for manufacturers seeking to remain competitive in today's market. Recognizing this, the creators of this packing machine have engineered it to minimize operational costs. By streamlining the packaging process and eliminating unnecessary wastage, it optimizes resource utilization, resulting in substantial cost savings for manufacturers over time.Furthermore, this packing machine's user-friendly interface makes operation and maintenance hassle-free. With its intuitive design and clear instructions, operators can quickly become proficient in utilizing its functionalities. The machine also features automated maintenance reminders, preventing unforeseen breakdowns and maximizing uptime. By reducing the need for extensive training and minimizing maintenance requirements, it empowers manufacturers to focus on core business activities.In an era where sustainability is becoming increasingly essential, this packing machine stands out for its environmentally-friendly features. With a focus on minimizing energy consumption, it reduces the carbon footprint associated with packaging operations. Furthermore, it utilizes eco-friendly packaging materials that are biodegradable and recyclable, contributing to the preservation of our planet.As the global market becomes more interconnected, the demand for efficient and innovative packaging solutions continues to grow. Recognizing this, the company behind this cutting-edge packing machine has established a widespread sales and service network, ensuring timely support and assistance for its customers. With a strong commitment to customer satisfaction, they aim to provide end-to-end solutions tailored to individual needs, setting a new industry standard for excellence.In conclusion, the introduction of this game-changing packing machine marks a significant milestone in the packaging industry. With its remarkable speed, exceptional precision, and impeccable safety features, it promises to revolutionize packaging practices across diverse industries. By driving production efficiency, reducing costs, and prioritizing sustainability, this innovative machinery is set to reshape the industry's future and unlock new possibilities for manufacturers worldwide.