Industrial Hard Boiled Candy Making Machine for Mass Production

By:Admin

Hard boiled candy has been a popular treat for centuries, and its production has evolved over time to meet the demands of modern consumers. One company that has been at the forefront of this evolution is a leading manufacturer of confectionery machinery, providing innovative solutions to confectionery producers worldwide.

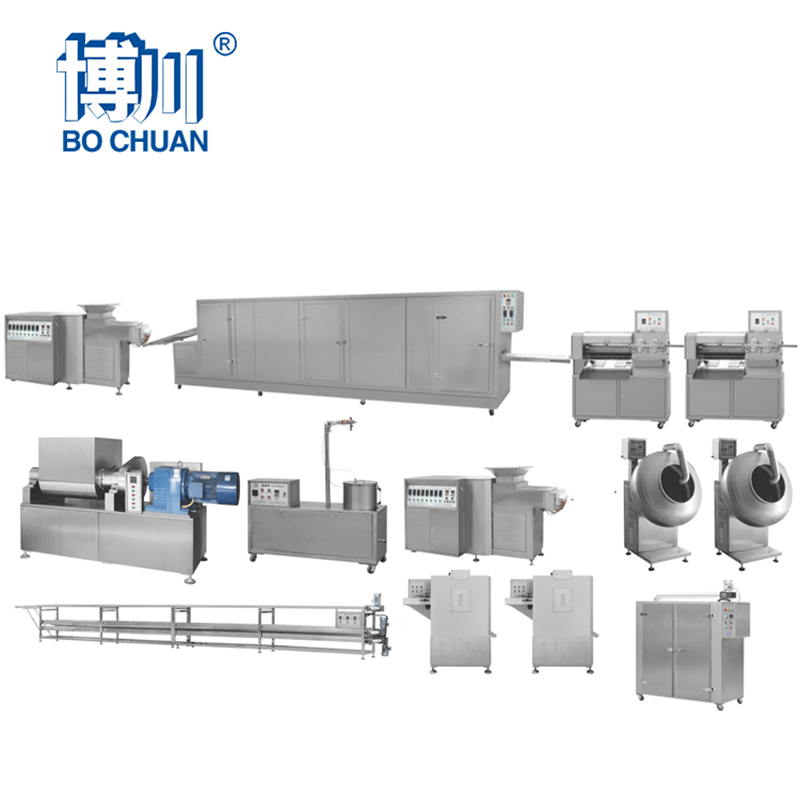

The latest offering from this company is the Hard Boiled Candy Making Machine, a state-of-the-art piece of equipment that has revolutionized the way hard boiled candy is produced. This machine incorporates cutting-edge technology and advanced manufacturing processes to create a seamless and efficient production process.

The Hard Boiled Candy Making Machine is designed to ensure that every batch of candy produced is of the highest quality, with consistent texture, color, and flavor. It is capable of producing a wide variety of hard boiled candies, including fruit-flavored, mint, and novelty shapes, catering to the diverse preferences of consumers.

With this machine, confectionery producers can streamline their production processes, increase output, and reduce wastage, ultimately leading to cost savings and improved profitability. The machine is also equipped with advanced monitoring and control systems, allowing operators to adjust production parameters in real time and ensure optimal product quality.

In addition to its cutting-edge features, the Hard Boiled Candy Making Machine is designed with efficiency and ease of use in mind. Its intuitive control interface and user-friendly design make it accessible to both experienced confectionery producers and those new to the industry, eliminating the steep learning curve traditionally associated with confectionery machinery.

Furthermore, the machine is built with durability and reliability at its core, ensuring minimal downtime and maximum productivity for confectionery producers. Its robust construction and high-quality components are designed to withstand the rigors of continuous operation, providing peace of mind to operators.

It's no surprise that the Hard Boiled Candy Making Machine has garnered attention and acclaim within the confectionery industry. Its cutting-edge technology, efficiency, and reliability have set a new standard for hard boiled candy production, making it the go-to choice for confectionery producers seeking to elevate their production capabilities.

The company behind the Hard Boiled Candy Making Machine has a long history of innovation in the confectionery machinery sector. With a track record of delivering high-quality and reliable solutions to confectionery producers globally, it has earned a reputation as a trusted partner in the industry.

In addition to the Hard Boiled Candy Making Machine, the company offers a comprehensive range of confectionery machinery, including chocolate processing equipment, candy depositing machines, and packaging solutions. Its commitment to excellence and continuous improvement has cemented its position as a leader in the confectionery machinery market.

As the confectionery industry continues to evolve, the demand for advanced and efficient production solutions will only continue to grow. With the Hard Boiled Candy Making Machine, confectionery producers have access to a tool that not only meets their current production needs but also positions them for future success in a competitive market.

In conclusion, the introduction of the Hard Boiled Candy Making Machine represents a significant milestone in the confectionery industry. Its innovative technology, efficiency, and reliability make it a game-changer for confectionery producers worldwide, and its impact is sure to be felt for years to come. As the demand for high-quality hard boiled candy continues to rise, this machine is poised to lead the way in shaping the future of confectionery production.

Company News & Blog

Highly Efficient Fully Automatic Packing Machine for Streamlined Packaging

Fully Automatic Packing Machine Revolutionizes Packaging Process for CompanyIn the fast-paced world of manufacturing and packaging, efficiency is key. Companies are constantly searching for innovative solutions to streamline their processes and improve overall productivity. That's where the fully automatic packing machine comes in. This cutting-edge technology is revolutionizing the way companies package their products, and one company that is leading the way in harnessing the power of this technology is {Company Name}.{Company Name} is a leading manufacturer and distributor of a wide range of consumer goods, including food products, beverages, and personal care items. With a commitment to delivering high-quality products to their customers, the company is always on the lookout for the latest advancements in packaging technology. That's why they have recently invested in a state-of-the-art fully automatic packing machine that is set to transform their packaging process.This advanced packing machine is equipped with a range of features that set it apart from traditional packaging systems. One of the key benefits of this technology is its ability to operate without the need for human intervention. This means that the packaging process can run continuously, without the need for manual labor, resulting in significant time and cost savings for the company. Additionally, the machine is capable of handling a wide variety of packaging materials, from cardboard boxes to plastic containers, making it incredibly versatile for {Company Name}'s diverse product range.The fully automatic packing machine is also designed to provide precise and consistent packaging, ensuring that each product is securely sealed and properly labeled. This level of accuracy is essential for {Company Name}, as they strive to maintain the highest standards of quality and safety for their products. With this technology, the company can have peace of mind knowing that their products are being packaged efficiently and effectively every time.In addition to its efficiency and precision, the fully automatic packing machine is also incredibly user-friendly. With intuitive controls and a user-friendly interface, the machine can be easily operated by {Company Name}'s staff with minimal training. This ensures that the company can quickly integrate this new technology into their existing packaging processes and start reaping the benefits right away.{Company Name} is already seeing the positive impact of this fully automatic packing machine on their operations. With the ability to package products at a much faster rate, the company has been able to increase their overall output without compromising on quality. This has allowed them to meet growing customer demand and expand their market reach, all while maintaining their high standards for product quality and safety.Furthermore, the fully automatic packing machine has enabled {Company Name} to reduce their labor costs and allocate their resources more efficiently. By automating the packaging process, the company has been able to redeploy their workforce to other areas of the business, where their skills and expertise can be better utilized. This has not only improved the company's overall productivity but has also had a positive impact on employee morale and satisfaction.Looking ahead, {Company Name} is excited about the potential for further advancements in packaging technology. They are committed to staying at the forefront of innovation and are eager to explore how they can continue to leverage new technologies to enhance their packaging processes and improve their overall business operations.In conclusion, the fully automatic packing machine has revolutionized the way {Company Name} packages their products. This advanced technology has brought about significant improvements in efficiency, accuracy, and productivity, allowing the company to meet customer demand and maintain their high standards for product quality and safety. As they continue to invest in the latest advancements in packaging technology, {Company Name} is poised to remain a leader in their industry and provide their customers with top-quality products for years to come.

Advanced Skin Packaging Machine: A Game Changer in the Packaging Industry

Title: Cutting-Edge Skin Packaging Machine Revolutionizes Packaging IndustryIntroduction:In an era where efficient packaging solutions are paramount, the industry-leading company, whose name has been withheld, has unveiled its latest innovation in packaging technology to cater to the growing needs of businesses worldwide. The state-of-the-art Skin Packaging Machine introduces cutting-edge features that have the potential to revolutionize the packaging industry. With a relentless pursuit of innovation and commitment to excellence, the company aims to empower businesses with a packaging solution that is both efficient and visually appealing.Unveiling the Skin Packaging Machine:The recently unveiled Skin Packaging Machine promises to elevate the packaging process to new heights. By incorporating advanced technology and an ergonomic design, the machine aims to optimize efficiency, reduce labor costs, and enhance product preservation. This achievement is a testament to the company's dedication to staying at the forefront of the packaging industry by constantly creating solutions that address the evolving needs of businesses across various sectors.Advanced Features and Functionality:The Skin Packaging Machine, equipped with cutting-edge features, is designed to ensure precision packaging while maintaining the integrity of the products. The machine uses vacuum sealing technology to wrap products in a protective skin-tight film, increasing the shelf life of perishable goods and reducing the risk of damage during transportation. This innovative method also provides an airtight seal that protects against moisture, contaminants, and other external factors that could compromise product quality.The machine's user-friendly interface allows for seamless operation, ensuring that even operators with minimal training can efficiently handle the packaging process. Additionally, its versatility enables businesses to package a wide range of products such as perishable food items, delicate electronic devices, or even automotive parts, making it a valuable asset for manufacturers and wholesalers across various industries.Benefits for Businesses:The Skin Packaging Machine offers several benefits for businesses seeking to streamline their packaging operations. By reducing the need for excessive manual labor, it minimizes production costs, enhances productivity, and ultimately improves profitability. Its ability to preserve the freshness and quality of perishable products also enables businesses to extend their product shelf life, reducing waste and increasing customer satisfaction.The machine's sleek and professional packaging design not only protects the products but also enhances their presentation. This visually appealing packaging can significantly impact consumers' perception of the brand, making it more likely for them to choose the product over competitors.Commitment to Sustainability:In addition to its functional advantages, the Skin Packaging Machine aligns with the company's commitment to environmental sustainability. The machine utilizes eco-friendly materials, minimizing the impact on the environment and promoting a greener approach to packaging. By opting for this cutting-edge technology, businesses contribute to the reduction of plastic waste and demonstrate their dedication to sustainability and responsible manufacturing.Prospects and Future Developments:With its groundbreaking features and benefits, the Skin Packaging Machine presents significant opportunities for businesses to enhance their packaging processes. Its adaptability and user-friendliness position it as a long-term solution for packaging needs across diverse industries.Looking ahead, the company remains dedicated to further developments and improvements in packaging technology. Its research and development team continues to explore new ways to optimize the skin packaging process, introducing innovative features and functionalities that address the ever-changing demands of the market.Conclusion:The unveiling of the Skin Packaging Machine marks a significant milestone in the packaging industry, demonstrating the company's commitment to revolutionizing the way businesses package their products. Through its cutting-edge technology, user-friendly interface, and environmental sustainability, the machine offers businesses an efficient and visually appealing solution. As the industry evolves, the company's dedication to innovation ensures it remains at the forefront, continuously shaping the future of packaging.

DIY Chocolate Maker: Create Your Own Chocolate at Home

In an era where people are increasingly looking for ways to create delicious treats at home, a new homemade chocolate machine has been making waves in the market. This innovative machine, brought to you by a leading company in the kitchen appliances industry, is set to revolutionize the way chocolate lovers indulge in their favorite sweets.With the {Company} Homemade Chocolate Machine, chocolate enthusiasts can now create their own delectable treats at the comfort of their own homes. The machine boasts a sleek and modern design, making it a stylish addition to any kitchen. Its user-friendly interface and intuitive controls make it easy for even amateur chocolatiers to create professional-quality chocolates.The {Company} is known for its commitment to creating high-quality and innovative kitchen appliances that cater to the needs of modern consumers. With a strong focus on research and development, the company has been able to stay ahead of the curve and consistently deliver products that exceed customer expectations. The Homemade Chocolate Machine is a prime example of this dedication to innovation and excellence.One of the standout features of the Homemade Chocolate Machine is its ability to temper chocolate with precision. Temper chocolate is a crucial step in chocolate making that involves heating and cooling the chocolate to specific temperatures, ensuring that the final product has a smooth and glossy finish. With the Homemade Chocolate Machine, this process is made simple and foolproof, allowing users to achieve professional results every time.Furthermore, the machine also comes with a variety of molds and accessories that allow users to create chocolates in different shapes and sizes. Whether it's classic chocolate bars, truffles, or custom-shaped confections, the Homemade Chocolate Machine provides endless possibilities for experimentation and creativity.In addition to its functionality, the {Company} Homemade Chocolate Machine is also designed with convenience in mind. The machine is easy to clean and maintain, with dishwasher-safe parts that make post-chocolate-making cleanup a breeze. This ensures that users can enjoy the creative process without the hassle of tedious cleanup afterwards.For those who enjoy experimenting with flavors, the Homemade Chocolate Machine provides the perfect platform for customization. Users can add their favorite ingredients, such as nuts, fruits, or spices, to create unique and personalized chocolate creations. This level of flexibility allows for a truly individualized chocolate-making experience.In a world where store-bought sweets are often laden with preservatives and artificial ingredients, the ability to create homemade chocolates offers a healthier and more wholesome alternative. With the {Company} Homemade Chocolate Machine, individuals can have full control over the ingredients that go into their chocolates, ensuring a pure and natural end product.The Homemade Chocolate Machine is not just a tool for creating delectable treats, but also a gateway to a fun and rewarding hobby. It provides a creative outlet for individuals to express themselves through the art of chocolate making, and the sense of accomplishment that comes with mastering the craft is truly gratifying.In conclusion, the {Company} Homemade Chocolate Machine is a game-changer for chocolate lovers everywhere. With its user-friendly design, precise tempering capabilities, and endless customization options, it offers an unparalleled chocolate-making experience for both amateurs and seasoned chocolatiers. As the demand for at-home culinary experiences continues to rise, the Homemade Chocolate Machine is poised to become a must-have appliance for anyone with a sweet tooth and a passion for creativity in the kitchen.

Packaging Equipment Market Witnessing Growth and Innovation: Key Insights into Modern Solutions

Packaging Equipment Provider Delivers Unmatched Quality and EfficiencyFor businesses of all sizes, the right packaging equipment can be a game-changer. With the right tools, companies can streamline their packaging processes and quickly scale their operations. Enter Packaging Equipment Provider, a leading provider of high-quality packaging equipment for businesses of all sizes.With a range of packaging equipment solutions, including sealing machines, strapping machines, and carton sealing machines, the Packaging Equipment Provider has been delivering unmatched quality and efficiency to a wide range of clients. From small businesses to large corporations, their machines are designed to streamline packaging processes, reduce downtime, and improve overall efficiency.But what makes the Packaging Equipment Provider stand out from the crowd?First and foremost, the company is committed to delivering the highest quality equipment to their clients. All of their machines are built with premium materials and are designed to last, ensuring that your packaging process never misses a beat.Furthermore, the Packaging Equipment Provider understands that every business has unique packing needs. As such, they offer customized solutions for clients, tailoring their machines to fit each client's specific needs. With an experienced team of engineers and technicians, the company can create packaging equipment solutions that perfectly meet their clients' requirements.But the company goes beyond just delivering excellent products. Superior customer service and support are hallmarks of the Packaging Equipment Provider. From the first inquiry to post-installation support, their team is committed to providing the best possible experience for their clients.One of the Packaging Equipment Provider's satisfied clients is a large food manufacturer in the United States. The company sought to streamline its packaging process by implementing an automated carton sealing solution. With the help of the Packaging Equipment Provider, the company implemented an innovative solution with a carton sealing machine that could handle different sized boxes quickly and efficiently.According to the company's spokesperson, "the machine has transformed our packaging process, greatly reducing our downtime and labor costs. The Packaging Equipment Provider team worked closely with us to understand our unique needs and delivered a customized solution that perfectly met our requirements."Whether it's sealing machines, strapping machines, or carton sealing machines, the Packaging Equipment Provider delivers best-in-class solutions for businesses. Their commitment to quality, customization, and excellent customer service sets them apart from the competition.The company's spokesperson added, "We are passionate about delivering the best possible packaging equipment solutions to our clients. Our goal is to help businesses of all sizes streamline their packaging process, reduce downtime, and improve overall efficiency."With the Packaging Equipment Provider on your side, you can be sure that your packaging process is in good hands. The company's commitment to quality, customization, and customer service ensures that you get the best possible solutions for your business's packaging needs. So, whether you're a small business just starting or a large corporation looking to scale, the Packaging Equipment Provider has got you covered.

High-Quality Seam Sealing Machine for Hot Air Applications

Hot Air Seam Sealing Machine Revolutionizes Waterproof Clothing IndustryIn a world where outdoor activities are becoming increasingly popular, the demand for high-quality waterproof clothing has never been higher. Waterproof jackets, pants, and shoes have become essential items for outdoor enthusiasts, hikers, and even everyday commuters. One of the key components in the production of these garments is the seam sealing process, which ensures that the clothing remains completely water-resistant even in the most extreme conditions.Traditionally, seam sealing has been done using a variety of methods, including heat sealing and tape sealing. However, a new technology has emerged that is revolutionizing the industry – the Hot Air Seam Sealing Machine. This state-of-the-art machine is capable of producing incredibly strong and durable seams that are completely waterproof, making it an essential tool for manufacturers of outdoor clothing and gear.The Hot Air Seam Sealing Machine has been developed by a leading company in the textile machinery industry. With a strong focus on innovation and technology, the company has been at the forefront of developing cutting-edge equipment for the production of technical textiles. With a team of experienced engineers and textile experts, the company has been able to create a machine that is not only highly efficient but also incredibly versatile, making it suitable for a wide range of applications in the textile industry.The Hot Air Seam Sealing Machine utilizes a combination of heat and pressure to create a waterproof seal on the seams of the garment. By using hot air to activate the adhesive tape, the machine is able to produce seams that are not only waterproof but also flexible and comfortable to wear. This is a huge advantage for manufacturers, as it allows them to produce high-quality waterproof clothing that meets the demands of the modern consumer.What sets the company's Hot Air Seam Sealing Machine apart from other similar products on the market is its advanced technology and precision engineering. The machine is equipped with a state-of-the-art control system that allows for precise temperature and pressure control, ensuring that each seam is sealed to perfection. Additionally, the machine is designed to be easy to operate, with a user-friendly interface that allows operators to set the machine for different types of fabrics and seams.In addition to its technical capabilities, the Hot Air Seam Sealing Machine is also designed with efficiency and sustainability in mind. The machine is equipped with energy-saving features that reduce power consumption during operation, making it an environmentally friendly choice for manufacturers. This aligns with the company's commitment to sustainability and reducing its environmental impact, making the Hot Air Seam Sealing Machine an attractive option for companies looking to improve their green credentials.Overall, the Hot Air Seam Sealing Machine is a game-changer for the waterproof clothing industry. Its advanced technology, precision engineering, and commitment to sustainability make it the ideal choice for manufacturers looking to produce high-quality, waterproof garments that meet the demands of today's consumer. As the popularity of outdoor activities continues to grow, the need for reliable and durable waterproof clothing will only increase, and the Hot Air Seam Sealing Machine is poised to play a vital role in meeting this demand.

Innovative Tray Packing Machine for Efficient Packaging of Products

Tray Packing Machine Streamlines Production for Food Packaging CompanyIn today's fast-paced and competitive business environment, efficiency and productivity are key factors in the success of any food packaging company. With the growing demand for convenient and sustainable packaging solutions, it has become increasingly important for companies to invest in advanced automation technology to meet these requirements.One company that is at the forefront of this trend is {remove brand name}, a leading provider of food packaging solutions. Their commitment to innovation and the latest technology has led to the acquisition of a state-of-the-art tray packing machine that has revolutionized their production process.The tray packing machine is a versatile and high-speed system that has been specifically designed for the food packaging industry. It is capable of handling a wide range of tray sizes and materials, making it ideal for packaging various food products such as fresh produce, meat, seafood, and ready-to-eat meals. With its advanced features and automation capabilities, the tray packing machine has significantly improved the company's production efficiency and reduced labor costs.One of the key advantages of the tray packing machine is its ability to handle multiple tasks simultaneously, such as sealing, labeling, and stacking trays, which previously required separate machines and manual labor. This has resulted in a streamlined and more efficient production process, allowing the company to increase their output and meet the growing demand for their products.In addition to its high-speed capabilities, the tray packing machine also offers a high level of accuracy and precision in the packaging process. This ensures that each product is consistently and securely sealed, maintaining the quality and freshness of the food while also reducing the risk of product wastage.Furthermore, the tray packing machine is equipped with advanced technology that allows for easy integration with other systems, such as robotic pick and place units and quality control sensors. This level of automation and connectivity has allowed {remove brand name} to further optimize their production line and ensure a seamless and efficient operation."We are thrilled with the performance of our new tray packing machine," said the CEO of {remove brand name}. "It has allowed us to significantly increase our production capacity while maintaining the highest standards of quality and efficiency. This investment reflects our commitment to staying ahead of the curve in the food packaging industry and providing our customers with innovative solutions."The company's investment in the tray packing machine is part of their broader strategy to modernize their production facilities and maintain their competitive edge in the market. By integrating the latest technology into their operation, {remove brand name} has positioned themselves for long-term growth and success in the rapidly evolving food packaging industry.In conclusion, the acquisition of the tray packing machine has been a game-changer for {remove brand name}, enabling them to enhance their production capabilities and meet the demands of their customers more effectively. It is a clear demonstration of the company's commitment to innovation and excellence, and a testament to the positive impact that advanced automation technology can have on the food packaging industry.

Innovative Foam Packaging Machine for Efficient Packaging Operations

Foam Packaging Machine Revolutionizes Packaging Process for CompaniesIn the fast-paced and competitive world of business, companies are constantly seeking new and innovative ways to improve their packaging processes and increase efficiency. One company that is leading the way in this endeavor is {}.{} is a leading provider of cutting-edge packaging solutions, specializing in foam packaging machines that are revolutionizing the way companies approach their packaging processes. With a strong focus on innovation and customer satisfaction, {} has established itself as a trusted partner for businesses looking to streamline their packaging operations.The foam packaging machine offered by {} is a game-changer for companies looking to improve the protection and presentation of their products. This advanced machine is capable of producing custom-fit foam packaging materials that provide unmatched protection for delicate and valuable items. With the ability to create precise and durable foam packaging inserts, {}'s machine ensures that products arrive at their destination in perfect condition, reducing the risk of damage and increasing customer satisfaction.Furthermore, {}'s foam packaging machine is incredibly versatile, able to accommodate a wide range of product shapes and sizes. This flexibility is a significant advantage for companies with diverse product lines, as it eliminates the need for multiple packaging solutions and simplifies the overall packaging process.In addition to its impressive functionality, {}'s foam packaging machine is also designed with efficiency in mind. The machine's automated operation and high-speed production capabilities enable companies to significantly increase their packaging output while reducing labor and material costs. This not only improves the bottom line for businesses but also allows them to meet the demands of a growing market quickly and effectively.By implementing {}'s foam packaging machine, companies can also demonstrate their commitment to sustainability. The machine's precise foam production process results in minimal material wastage, contributing to a reduction in environmental impact. This aligns with the growing consumer preference for eco-friendly packaging solutions and helps businesses enhance their brand reputation as responsible corporate citizens.Furthermore, {} offers comprehensive support and training for companies that invest in their foam packaging machine. Their team of experts is dedicated to ensuring that customers maximize the benefits of the machine, providing guidance on its operation, maintenance, and troubleshooting. This commitment to customer success has earned {} a reputation for delivering exceptional value and support to businesses across various industries.In summary, {}'s foam packaging machine has emerged as a groundbreaking solution for companies seeking to optimize their packaging processes and improve the protection of their products. With its advanced technology, versatility, efficiency, and focus on sustainability, the machine represents a significant leap forward in the world of packaging solutions. Businesses that partner with {} can expect to enhance their competitiveness, reduce costs, and exceed customer expectations, positioning themselves for long-term success in today's dynamic market.For companies looking to elevate their packaging operations, {}'s foam packaging machine offers a compelling opportunity to transform their approach and achieve exceptional results. For more information on {} and its innovative packaging solutions, visit their website or contact their team directly.

Discovering the Mysterious History of Jelly Beans

Jelly Beans - A Sweet Treat Through History Jelly beans are a small bite of happiness, with their colorful candy shells and soft chewy centers. They are a popular snack that has been around for generations, adored by a wide range of people, young and old. But the history of the tiny confectionery treat stretches back further than most of us might imagine. The exact origins of the jelly bean are difficult to trace, with only a small part of its history known. Most experts believe the jelly center is a descendant of a Turkish confection called Turkish Delight that dates back to biblical times. Over time, this sweet treat evolved into a sugary and brightly colored snack of its own, with a history as diverse and fascinating as the people who enjoy it. The Jelly Bean's Early History During the 1800s, jelly beans were sold in small confectionery shops and on street corners, often by candy sellers who carried them around in glass jars. They were a favorite of children, who would beg their parents for a penny to buy a handful of the colorful sweets. When the Civil War broke out in 1861, both Union and Confederate soldiers enjoyed the tiny treats, which were often included in their rations. It wasn't until 1905 that jelly beans received their first big break, thanks to a company called Goelitz Confectionery Company. The company was founded in 1869 by Gustav Goelitz, who first experimented with jelly beans in the 1870s. By 1905, Goelitz had perfected the recipe for the jelly bean, and the company began producing them on a commercial scale. The first jelly beans were sold in small glass jars and were marketed as an upscale product. The Jelly Bean Goes Mainstream Jelly beans really took off in the 1930s when they were sold in bulk on the shelves of candy stores across America. During World War II, they were once again included in the rations given to soldiers, who were known to trade them for cigarettes and other valuable items. In the 1960s, the popularity of jelly beans surged again when President Ronald Reagan admitted they were his favorite snack. In 1976, the Goelitz Confectionery Company began producing jelly beans in a wide variety of flavors, including buttered popcorn, licorice, and even green apple. Today, jelly beans are enjoyed by people all over the world and have become a staple of holidays like Easter and Halloween. The Goelitz Confectionery Company, now known as Jelly Belly Candy Company, has been at the forefront of innovation in the jelly bean industry for over 150 years. The company's commitment to quality and creativity has resulted in new flavors and products that have captured the attention of candy lovers everywhere. Today, Jelly Belly Candy Company offers over 100 flavors of jelly beans, including unique combinations like peanut butter and jelly and beer. They also produce a range of candy products, including gummies and chocolates, that are just as beloved as their jelly beans. As the popularity of jelly beans continues to grow, the sweet treat remains as colorful and diverse as ever, with new flavors and innovations appearing every year. Whether you enjoy the classic flavors or the more adventurous ones, the story behind the jelly bean is a testament to the joy and sweetness they bring to our lives. In conclusion, the history of jelly beans stretches back to ancient times, evolving over the years into the small but much-loved candy we enjoy today. Companies like Jelly Belly Candy Company have played a vital role in its success, bringing creativity and innovation to a snack that has captured the hearts of people all over the world. Long may the jelly bean continue to spread happiness, one sweet bite at a time.

High-Quality Tablet Press Machine for Candy Production

Candy Press Tablet Press Machine, a leading manufacturer of pharmaceutical machinery, has recently unveiled its latest tablet press machine that promises to revolutionize the production of candy and pharmaceutical tablets. The new machine, which was developed after years of research and development, is expected to set new standards for efficiency and reliability in the industry.The company behind the new tablet press machine, with a long history of providing innovative solutions for the pharmaceutical industry, has established itself as a trusted and respected name in the field. With a strong commitment to quality and customer satisfaction, the company has continually strived to improve its products and services to meet the evolving needs of the market.The new tablet press machine is the culmination of years of hard work and dedication by the company's team of experienced engineers and technicians. Equipped with state-of-the-art technology and advanced features, the machine is designed to deliver exceptional performance and precision in the production of tablets. Its innovative design allows for high-speed production, resulting in increased output and reduced production time.One of the key features of the new tablet press machine is its versatility. It is capable of producing a wide range of tablet sizes and shapes, making it suitable for use in various applications, including candy and pharmaceutical manufacturing. This flexibility allows manufacturers to meet the diverse demands of the market without the need for multiple machines, thereby streamlining production and reducing costs.In addition to its versatility, the new tablet press machine is also designed to ensure the highest levels of product quality and consistency. With advanced control systems and monitoring features, the machine can maintain precise pressure and weight control, resulting in uniform tablets with minimal variations. This level of precision is crucial in the production of pharmaceuticals, where product quality and accuracy are of utmost importance.Furthermore, the new tablet press machine incorporates advanced safety features to safeguard both the equipment and the operators. With enhanced protection mechanisms and safety interlocks, the machine minimizes the risk of accidents and ensures a secure working environment. This focus on safety aligns with the company's commitment to prioritizing the well-being of its customers and employees.The launch of the new tablet press machine represents a significant milestone for Candy Press Tablet Press Machine, demonstrating the company's dedication to innovation and excellence. By introducing this cutting-edge product to the market, the company aims to empower manufacturers with the tools they need to enhance their production capabilities and stay ahead of the competition."With the introduction of our new tablet press machine, we are excited to bring a game-changing solution to the candy and pharmaceutical manufacturing industry," said a spokesperson for the company. "We are confident that this machine will deliver unparalleled performance and reliability, setting a new standard for tablet production."As the industry continues to evolve, Candy Press Tablet Press Machine remains committed to staying at the forefront of innovation and providing customers with the best solutions for their production needs. With its latest tablet press machine, the company is poised to make a lasting impact on the industry and help manufacturers elevate their production processes to new heights.

High-Quality Cardboard Packaging for Sandwiches Extends Shelf Life

Sandwich packing is a crucial aspect of any sandwich making operation. Whether you run a small sandwich shop or a large-scale food manufacturing unit, you need to ensure that your product remains fresh and appetizing for as long as possible. This requires the use of high-quality sandwich packaging materials and sealing machines that can provide the perfect seal, thus prolonging the shelf life of your sandwiches.One such sealing machine that stands out in the market today is the Enterpack sandwich sealing machine. This unique and innovative machine has been designed to provide the perfect seal for your sandwiches, thereby prolonging their shelf life by up to three days. The Enterpack sandwich packaging system is compatible with a wide range of cardboard sandwich packaging, making it an ideal choice for sandwich makers who place a high value on quality.Unlike plastic containers that are commonly used in sandwich packaging, cardboard sandwich packs are much higher in quality. They offer superior insulation, which protects the sandwiches from moisture, heat, and UV light, all of which contribute to food spoilage. Cardboard sandwich packaging is also much more environmentally friendly, as it can be easily disposed of and recycled.Using the Enterpack sandwich sealing machine, you can seal any type of sandwich, from cold and hot sandwiches, wraps, paninis, baguettes, and more. The machine comes with adjustable sealing and cutting functions to accommodate different sandwich sizes and shapes. This makes it an ideal machine for businesses with a diverse sandwich production line.In addition to ensuring the freshness and quality of your sandwiches, cardboard sandwich packaging provided by Enterpack also serve as an excellent marketing tool. They can be customized with your brand colors, logo, and tagline, thus promoting your brand to potential customers. This can be particularly useful for businesses that rely on takeout and delivery services, where customers are more likely to judge the quality of the food by its packaging.Overall, the Enterpack sandwich sealing machine is a must-have for any sandwich maker who values quality, freshness, and sustainability. It offers a cost-effective and efficient way of prolonging the shelf life of your sandwiches, while also providing an excellent marketing opportunity. So whether you are running a small sandwich shop or a large-scale food manufacturing unit, be sure to invest in the Enterpack sandwich sealing machine for all your sandwich packaging needs.Keywords: Sandwich Sealer Machine, Enterpack sandwich packaging system, cardboard sandwich packs, plastic containers, sandwich making operation, sandwich packaging materials, food spoilage, environmentally friendly, adjustable sealing and cutting functions, sandwich production line.