How to Make Jelly Chocolate with a Chocolate Making Machine?

By:Admin

Introduction:

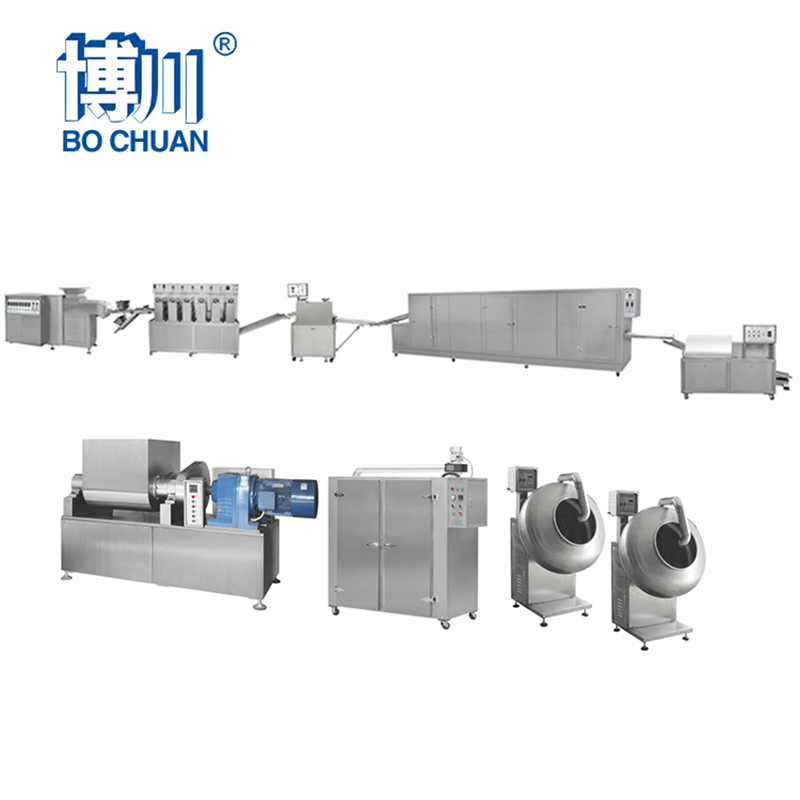

In a groundbreaking endeavor to enhance the confectionery manufacturing process, a leading company in the food processing industry has developed an innovative Jelly Chocolate Making Machine. The technologically advanced equipment is set to revolutionize the production of jelly chocolates, offering a convenient solution for manufacturers to meet increasing consumer demand for their favorite treats.

Company Overview:

The company behind the development of the Jelly Chocolate Making Machine is a recognized leader in the food processing industry. With a strong commitment to innovation and a dedication to deliver state-of-the-art solutions, the company has consistently introduced cutting-edge technologies to streamline and optimize various food production processes. With a focus on enhancing efficiency, quality, and sustainability, they have successfully revolutionized the way confectionery manufacturers operate globally.

The Jelly Chocolate Making Machine:

The Jelly Chocolate Making Machine represents the latest addition to the company's impressive portfolio of food processing equipment. Tailored specifically for the production of jelly chocolates, this revolutionary machine boasts exceptional features and functionalities that ensure efficiency, precision, and superior-quality end products.

1. Increased Production Capacity:

One of the standout features of this cutting-edge machine is its ability to significantly increase the production capacity of jelly chocolates. It utilizes advanced automation technology, offering an unbeatable speed and throughput. With its streamlined processes, manufacturers can now fulfill larger orders without compromising on quality and taste.

2. Enhanced Customization Options:

The Jelly Chocolate Making Machine offers manufacturers the flexibility to create a wide range of customized jelly chocolates. With adjustable molds, sizes, shapes, and flavors, confectioners can cater to evolving consumer preferences and offer a diverse selection of mouthwatering treats.

3. Precise Ingredient Dosage Control:

Accurate dosage of ingredients plays a crucial role in ensuring consistent taste and quality. The Jelly Chocolate Making Machine excels in this aspect, employing state-of-the-art sensors and controllers that precisely measure and control the dosage of ingredients. This eliminates any variations in taste and texture, resulting in a uniform product experience for consumers.

4. Rapid Production Processes:

With the Jelly Chocolate Making Machine, manufacturers can now produce jelly chocolates at an unprecedented pace. The advanced machinery's quick cooling and setting processes significantly reduce production time, enabling confectioners to meet strict deadlines and efficiently respond to high demand.

5. Easy Maintenance and Automation:

The machine's user-friendly interface and automation capabilities simplify operation and maintenance processes, ensuring even novice operators can efficiently control the production line. Intuitive software controls streamline operations and allow for remote monitoring, further enhancing convenience and productivity.

Implications for the Confectionery Industry:

The introduction of the Jelly Chocolate Making Machine carries several implications for the confectionery industry:

1. Market Competitiveness:

Manufacturers equipped with this advanced technology gain a competitive edge by boosting production capacity, fulfilling orders promptly, and staying ahead of the competition.

2. Profitability and Cost Efficiency:

Enhanced production efficiency and reduced labor requirements contribute to overall cost savings for manufacturers. This increased profitability can be reinvested into further research and development, expansion, and employee welfare.

3. Improved Product Quality:

The precise ingredient dosage control and streamlined processes ensure consistent taste, texture, and quality, enhancing customer satisfaction and loyalty.

4. Meeting Consumer Demand:

As the demand for jelly chocolates continues to surge, the Jelly Chocolate Making Machine enables manufacturers to efficiently cater to consumer preferences, diversify their product offerings, and expand their market share.

Conclusion:

The Jelly Chocolate Making Machine represents a significant leap forward in confectionery manufacturing technology. Its exceptional features and benefits empower manufacturers to meet consumer demand more efficiently, increase profitability, and maintain a competitive edge in the ever-evolving confectionery industry. With this innovation, the company continues to spearhead advancements that revolutionize the way food production processes are approached and executed globally.

Company News & Blog

Automated Cotton Candy Machines: Making Sweet Treats Faster and Easier Than Ever Before

Cotton Candy Machine Revolutionizes the Art of Sugar-SpinningCatering to the ever-growing demand for delicious treats at parties, events, and amusement parks, an innovative company has developed a cutting-edge Cotton Candy Machine Automatic. With its sleek design and advanced features, this state-of-the-art device promises to revolutionize the art of sugar-spinning, offering an unforgettable culinary experience.Cotton candy, also known as fairy floss or candy floss, has been a beloved sweet treat for generations. The process of creating these fluffy confections involves melting and spinning sugar, resulting in delicate webs of sugary delight. Traditionally, cotton candy was made by hand, requiring skill and dexterity to produce the perfect fluffy texture. However, with the new Cotton Candy Machine Automatic, this process becomes significantly more efficient and accessible to all.Featuring a compact and user-friendly design, this innovative machine is perfect for both professional caterers and enthusiastic amateurs alike. With just a click of a button, the Cotton Candy Machine Automatic begins its mesmerizing sugar-spinning process. The device combines a built-in heater that quickly melts the sugar with a high-powered fan that propels the spun sugar into delicate candy floss wisps.One of the standout features of this revolutionary machine is its ability to produce cotton candy in a variety of flavors and colors. The company offers a wide range of pre-packaged sugar flavors, including classics like raspberry and blueberry, as well as more exotic options like bubblegum and passion fruit. This allows users to customize their cotton candy creations to suit any taste or event theme.In addition to its versatility, the Cotton Candy Machine Automatic also boasts several safety features to ensure worry-free operation. Equipped with an automatic shut-off mechanism, the machine will power down when it reaches a certain temperature to prevent overheating. This feature not only protects the device but also provides peace of mind for the users, allowing them to focus on serving up sugary goodness without any concerns.Moreover, this innovative device is easy to clean and maintain, thanks to its removable components that are dishwasher-safe. The machine's detachable spinning head and collection tray can be quickly disassembled and cleaned, ensuring a hygienic experience for every batch of cotton candy produced.The company behind this groundbreaking creation, known for its dedication to quality and innovation, has been a leading force in the confectionery industry for several decades. With a strong commitment to customer satisfaction, they have successfully developed a range of cutting-edge devices that cater to the needs of professional chefs and home cooks alike. Their goal is to consistently provide culinary tools that combine functionality, ease of use, and impeccable design.Recognizing the need for efficiency and convenience in the cotton candy industry, this forward-thinking company invested significant time and resources in research and development to create the Cotton Candy Machine Automatic. By harnessing the power of technology and utilizing high-quality materials, they have succeeded in developing a machine that promises to reshape the way cotton candy is made and enjoyed.Industry experts and enthusiasts have already expressed their excitement for this groundbreaking product. With its sleek design, advanced features, and unparalleled ease of use, the Cotton Candy Machine Automatic is poised to become the new standard in the world of sugar-spinning. As more and more individuals and businesses seek to provide unique and memorable culinary experiences, this cutting-edge device is set to lead the way, satisfying the sweet tooth of every customer it serves.

Doypack Packing Machines: Innovative Solutions for Packaging Needs

Possible 800-word news article:PROBLEND Ltd. Leads the Way in Packaging and Distribution SolutionsPROBLEND Ltd., a company founded in 1990, has become a global leader in providing innovative and reliable packaging equipment for various industries, including food and beverage, pharmaceuticals, chemicals, and cosmetics. With more than 1000 machines installed in different parts of the world, PROBLEND has gained a reputation for excellence in designing, manufacturing, servicing, and customizing machines based on customer needs. In addition, the company has expanded its portfolio to include its own supplementary products, such as stick packing machines and flow pack machines, and has become a top distributor of a popular brand of premium coffee.According to the General Manager of PROBLEND, Mr. Ivan Petrov, the success of the company stems from its commitment to quality, innovation, and customer satisfaction. “We strive to provide our clients with the best solution for their packaging challenges, whether it is a standard machine or a special project that requires a tailored approach. We work closely with our customers to understand their requirements and offer them a complete package, from the design and development to the installation and servicing of the machines. We take pride in our machines’ durability, efficiency, and flexibility, which allow our clients to increase their productivity, reduce their costs, and improve their brand image.”PROBLEND’s range of machines includes several types of filling and sealing machines, such as the doypack packing machine, which can handle different shapes and sizes of pouches with various materials and closures, enabling customers to pack liquids, powders, and solids. The doypack machine is also equipped with advanced features, such as a touch screen panel, servo motors, automatic alarms, and easy changeover systems, to ensure the smooth operation and maintenance of the machine. The doypack machine has been installed in many countries, such as the USA, Canada, Brazil, Russia, Turkey, Iran, Malaysia, and Australia, among others, and has been praised for its versatility and reliability.PROBLEND also offers other types of machines, such as the stick packing machine, which can produce sugar sticks, honey sticks, coffee creamer sticks, and other similar products, with high accuracy and speed. The stick packing machine utilizes a volumetric or gravimetric dosing method, depending on the product, and can pack up to 1000 sticks per minute. The stick packing machine has been widely used by food manufacturers, hotels, cafes, and airlines, among others, and has contributed to the improvement of the packaging industry by reducing waste, improving hygiene, and enhancing convenience.PROBLEND’s distribution of premium coffee is another success story that reflects the company’s vision and values. PROBLEND has partnered with a leading brand of coffee, which has won numerous awards for its quality, taste, and sustainability. PROBLEND has become the exclusive distributor of the brand in its home country and has expanded its reach to other markets, such as Europe, Asia, Africa, and Latin America. PROBLEND’s coffee is available in different forms, such as whole beans, ground, pods, and capsules, and can be customized to meet the specific needs of its clients, such as hotels, restaurants, offices, and retailers. The coffee is roasted in small batches to preserve its flavor and aroma and is packaged in eco-friendly materials that respect the environment.Mr. Petrov emphasizes that PROBLEND’s success is not only measured by its machines or products but also by its people, who are dedicated, skilled, and motivated to provide the best service to its customers. “PROBLEND is a family-owned company that cherishes its employees as much as its clients. We believe that our staff is our most valuable asset, and we invest in their training, development, and well-being. We also foster a culture of innovation, creativity, and collaboration, which enables us to keep improving and expanding our business. We are proud of our achievements, and we look forward to facing new challenges and opportunities in the future.”PROBLEND’s story is a testament to the power of entrepreneurship, innovation, and customer-centricity. The company has proven that by combining technical expertise, quality standards, and commercial savvy, one can succeed in a competitive industry and become a role model for others. PROBLEND’s machines and products have made a difference in the lives of many individuals and organizations, by facilitating their daily operations, creating jobs, and promoting sustainability. PROBLEND shows that a small idea can grow into a big impact, and that a big impact can last for decades.

Efficient and Reliable Packaging Machine for Box Processing

Box Packaging Machine Revolutionizing the Packaging IndustryIn today's fast-paced and highly competitive market, efficient packaging plays a crucial role in ensuring the success and competitiveness of a company. Recognizing this need, [Company Name] has recently introduced an innovative box packaging machine that is revolutionizing the packaging industry. By automating and streamlining the packaging process, this cutting-edge machine is improving productivity, reducing costs, and enhancing overall customer satisfaction.The box packaging machine developed by [Company Name] incorporates state-of-the-art technology and advanced automation features. This machine has the ability to package a wide variety of products, including food items, electronics, pharmaceuticals, and consumer goods, with precision and efficiency. Regardless of the size or shape of the product, this machine can adapt to accommodate various packaging requirements.One of the key advantages of this box packaging machine is its high speed and reliability. With a capacity to package hundreds of boxes per minute, it significantly reduces manual labor and increases productivity. By eliminating human errors and inconsistencies, this machine ensures that each product is packaged accurately and securely, minimizing the risk of damage during transportation.Additionally, this packaging machine stands out due to its versatility and flexibility. It can be easily programmed to handle different box sizes, sealing methods, and labeling options, making it suitable for a wide range of packaging needs. This adaptability greatly benefits businesses that deal with multiple product lines or frequently change their packaging designs.Furthermore, the box packaging machine by [Company Name] prioritizes product safety and hygiene. It includes advanced measures to prevent contamination, such as a sterilization feature and a dust-free packaging environment. This ensures that the packaged products meet the highest quality standards and comply with industry regulations, giving customers peace of mind.Another noteworthy feature of this packaging machine is its user-friendly interface. The machine is equipped with an intuitive control panel that allows operators to easily adjust settings, monitor production, and diagnose any potential issues. Proper training and technical support are offered by [Company Name] to ensure that users obtain optimal performance and fully leverage the capabilities of the machine.Moreover, this box packaging machine incorporates sustainable practices that align with eco-conscious initiatives. It minimizes material waste by optimizing box dimensions and using recyclable packaging materials. By reducing the environmental impact of packaging, [Company Name] demonstrates its commitment to sustainability and corporate social responsibility.The introduction of this innovative box packaging machine has garnered significant attention and appreciation from industry experts. Many leading companies have already adopted this technology, reaping its benefits and experiencing a positive impact on their bottom line. With the increasing demand for efficient packaging solutions, there is no doubt that this machine will continue to disrupt the packaging industry, enabling businesses to achieve higher levels of efficiency, cost savings, and customer satisfaction.In conclusion, [Company Name] has introduced a game-changing box packaging machine that is transforming the packaging industry. Through its advanced technology, high speed, versatility, and sustainable practices, this machine revolutionizes the packaging process for businesses across various sectors. With its positive impact on productivity, cost reduction, and product safety, this packaging machine proves to be an essential tool for companies aiming to stay competitive in today's dynamic market.

Efficient and Dependable Case Sealer Machine Makes Packaging a Breeze

In the fast-paced world of manufacturing, every second counts. With so much competition, companies are constantly searching for ways to maximize efficiency and productivity while minimizing costs. For this reason, many businesses have turned to automated solutions such as case sealers to streamline their operations.One of the companies at the forefront of this trend is [Company Name Goes Here]. Founded in [Year Founded], [Company Name] specializes in the design and manufacture of innovative packaging equipment for a variety of industries, including food and beverage, pharmaceuticals, and consumer goods. Their products are known for their reliability, efficiency, and ease of use, making them a top choice for businesses seeking to optimize their packaging processes.One of [Company Name]'s most popular products is their Case Sealer Machine, a versatile and robust system that can handle a wide range of case sizes and packaging materials. Designed with the end user in mind, the Case Sealer Machine is simple to operate and requires minimal maintenance, making it an ideal choice for businesses of all sizes.At the heart of the Case Sealer Machine is a powerful motor that drives the sealing mechanism. The system uses a hot melt adhesive to seal the flaps of the case securely, ensuring that the contents are protected during transport. The adhesive is applied precisely and evenly, minimizing waste and reducing the risk of leaks or damage to the products inside.One of the key advantages of the Case Sealer Machine is its flexibility. The system can handle both uniform and random case sizes, and can be easily adjusted to accommodate changes in packaging requirements. This means that businesses can adapt quickly to evolving market conditions and maintain a competitive edge.Another important feature of the Case Sealer Machine is its compact design. The system has a small footprint, making it easy to integrate into existing packaging lines and minimizing the amount of floor space required. This is especially beneficial for businesses that need to maximize production in a limited area.In addition to its technical capabilities, [Company Name]'s Case Sealer Machine is backed by a team of experienced engineers and technicians who provide comprehensive support and training to customers. This ensures that users are able to operate the system effectively and get the most out of its features and capabilities.Overall, the Case Sealer Machine is an excellent choice for businesses seeking to optimize their packaging processes and minimize costs. With its efficiency, flexibility, and ease of use, it offers a powerful tool for improving productivity and enhancing the bottom line. As competition continues to intensify in the manufacturing industry, companies that invest in automation solutions like the Case Sealer Machine are well positioned to succeed and thrive in the years to come.

New Rotary Sealing Machine Enhances Packaging Efficiency

Rotary Sealing Machine Revolutionizes the Packaging IndustryIn the modern world where customers are increasingly seeking convenience and value for money, packaging plays a vital role in ensuring that products are well-protected and preserved. With the many types of packaging available in the market, choosing the right one that suits your product can be a daunting task. However, with the introduction of rotary sealing machines, businesses can now enjoy numerous benefits that enhance their packaging efficiency.For years, businesses have relied on manual packaging machines to seal their products. Despite the existence of automated packaging machines, the high cost hindered their wide adoption. However, with the introduction of rotary sealing machines, businesses can now seal their products efficiently and cost-effectively while ensuring that they adhere to the latest industry regulations and standards.Rotary sealing machines are designed to seal products quickly and efficiently. They are ideal for packaging foods, beverages, cosmetics, pharmaceuticals, and other products that require an airtight seal. They use rotary motion, where the machine rotates the packaging material and the product to create the seal. This means that the machine can handle different types of packaging materials such as plastic, aluminum, and paper.The use of rotary sealing machines offers businesses a wide range of benefits. For starters, it eliminates the need for manual labor, which lowers the cost of production. In addition, it reduces the chances of errors that are associated with manual sealing. Rotary sealing machines can consistently seal products in a short time, which enhances production efficiency. Moreover, they are safe and hygienic, which is essential for businesses that package food and pharmaceutical products.The Rotary Sealing Machine is the latest innovation from one of the leading manufacturers in the packaging industry. The company has a reputation for producing high-quality packaging machinery that is efficient, durable, and cost-effective. The Rotary Sealing Machine features a sturdy frame made of stainless steel and aluminum to ensure durability. It comes with a touchscreen interface that allows users to control the machine with ease. The machine is easy to operate, and the settings can be changed quickly to suit different packaging materials.The Rotary Sealing Machine is designed to seal a wide range of products, making it ideal for businesses that package different types of products. It can seal products such as tea bags, coffee bags, snacks, nuts, bolts, cosmetics, and pharmaceutical products. The machine can seal different types of packaging materials such as laminated films, aluminum foils, and paper.One of the unique features of the Rotary Sealing Machine is its ability to seal products of different sizes and shapes. The machine can seal products that are rectangular, square, oval, or round. This feature is essential for businesses that package products of different shapes and sizes.The Rotary Sealing Machine is also designed to seal products that require a vacuum or gas flushing. This feature is essential for businesses that package perishable items such as food and pharmaceutical products. The machine can seal products with a vacuum or gas flushing to extend their shelf life and maintain their quality.The Rotary Sealing Machine is a game-changer for businesses that are looking to streamline their packaging processes while maintaining quality and efficiency. The machine offers numerous benefits, including lowering the cost of production, enhancing production efficiency, and ensuring that products are well-sealed and preserved. Moreover, its unique features make it suitable for businesses that package different types of products that are of different shapes and sizes.In conclusion, the Rotary Sealing Machine is a revolutionary packaging machine that is poised to revolutionize the packaging industry. Its introduction comes at a time when businesses are seeking to enhance efficiency, lower the cost of production, and adopt packaging methods that are safe, hygienic, and comply with industry regulations and standards. The Rotary Sealing Machine is the perfect solution for businesses that are looking to achieve all these goals and more.

Revolutionary Packing Machine: Streamline Your Packaging Process with Cutting-Edge Technology!

Title: Cutting-Edge Packaging Solutions Arrive in the MarketIntroduction:In today's fast-paced world, efficient and reliable packaging solutions have become paramount. One such groundbreaking product hitting the market is a highly advanced packaging machine, aiming to revolutionize the industry by providing unmatched efficiency and productivity. Combining cutting-edge technology with years of expertise, this revolutionary packaging solution guarantees to streamline operations, improve product quality, and enhance overall customer satisfaction. Let us dive deeper into the attributes of this pioneering packaging machine.Advanced Technology and Features:Introducing an innovative packaging machine that integrates state-of-the-art technology, this industry-leading solution presents several remarkable features. By leveraging advanced sensors and artificial intelligence, the machine ensures precise and consistent measurements, minimizing wastage and maximizing product efficiency. Additionally, the packaging process is effortless and swift, allowing for increased productivity and reduced labor costs.High Customizability:One of the key highlights of this packaging machine is its adaptability to various packaging requirements. From adjustable sealing depths to variable packing speeds, it effortlessly caters to the diverse packaging needs of different industries. This versatility brings a whole new level of convenience and efficiency to businesses of all sizes, especially in the food and consumer goods sectors.Uncompromised Quality:Taking product safety and quality to heart, this revolutionary packaging machine guarantees exceptional standards. By meticulously monitoring each step of the packaging process, it ensures optimal seal integrity, thereby prolonging product shelf life and minimizing potential spoilage. The machine also boasts user-friendly controls, allowing operators to check and adjust parameters accurately, ensuring consistent packaging quality.Streamlined Maintenance:Recognizing the importance of reducing downtime, the creators of this packaging equipment have developed an intuitive maintenance system. Regular maintenance checks are simplified through an integrated diagnostic tool. Integrated self-cleaning mechanisms further enhance the machine's longevity and eliminate the time-consuming cleaning processes typically associated with such equipment.Energy Efficiency:In line with evolving environmental concerns, this pioneering packaging machine has been engineered to prioritize energy efficiency. Cutting-edge thermal insulation materials minimize heat loss, while smart energy management systems optimize power consumption. These eco-conscious features not only reduce operational costs but also contribute to a greener and more sustainable future.Enhanced Safety Measures:Safety is of paramount importance in any manufacturing process, and this packaging machine ensures a secure working environment for operators. Equipped with comprehensive safety measures, including advanced sensors and emergency stops, the machine minimizes potential accidents and promotes occupational safety. Additionally, it adheres to international safety standards, ensuring compliance with regulatory requirements.Industry Applications and Future Prospects:With its vast range of capabilities and customizable features, this innovative packaging machine finds applications in various industries. From food and beverage packaging to pharmaceutical and personal care products, its versatility appeals to an array of businesses. Additionally, the machine's ability to adapt to emerging packaging trends positions it as a promising investment for the future.Conclusion:In a rapidly evolving market, businesses must stay ahead of the curve by embracing cutting-edge technologies. The forthcoming packaging machine sets a new standard for efficiency, quality, and sustainability. It represents a significant advancement in the industry and aims to revolutionize packaging operations. By streamlining processes, improving product quality, and minimizing waste, this innovation will undoubtedly shape the future of packaging.

Flexible and Modern Multifunctional Packing Machine for Various Beverage Containers

Multifunctional Packing Machine Launched by Beverage CompanyA renowned beverage company has recently launched a highly efficient and versatile packing machine for their beverage products. The newly developed packing machine is designed to meet the requirements of modern packing technology and is highly flexible for the packing and unpacking of a wide range of beverage containers.The advanced packing machine is manufactured by an experienced and well-known engineering company specializing in the production of high-quality packing solutions for the beverage industry. The team of skilled engineers and technicians involved in the development of this innovative machine have aimed to create a unique product that can offer reliable and efficient packing and unpacking capabilities.The new packing machine, known as KHS Innopack PPZ, offers multifunctional and all-round packing capabilities. This machine has been designed for maximum flexibility, allowing it to reliably pack and unpack a variety of different beverage containers. This includes bottles, cans, and cartons, among others.One of the key features of the KHS Innopack PPZ packing machine is its modern and innovative design, which ensures the handling of all types of containers. The machine is designed to offer high precision and accurate positioning of containers, enabling efficient handling of both full and empty bottles or cans.The Innopack PPZ machine can handle a variety of container types and formats, including PET bottles, cans, cartons, as well as glass bottles. This excellent flexibility is achieved through a modular design approach that enables the machine to adapt to various packaging formats easily.Its outstanding capabilities in terms of reliability and flexibility make the Innopack PPZ machine the perfect solution for both small and large scale production operations in the beverage industry.It is notable that the Innopack PPZ machine is also designed to offer high efficiency and produce a minimal environmental footprint. The machine features a high level of automation, which offers the opportunity to run it with minimal human intervention, saving time and reducing labor costs significantly.Furthermore, the machine also employs advanced technology and components that help reduce energy consumption and production waste. It is an eco-friendly packing machine with safe and cost-effective operations.Moreover, the KHS Group also offers excellent after-sales support such as maintenance, repair, and spare parts supply, ensuring proper and long-term operation of the packing machine.The KHS Group is committed to providing innovative and sustainable packaging solutions for its customers worldwide. From filling to labeling, packing to palletizing, the company provides a comprehensive range of products and services for the beverage industry.In summary, the KHS Innopack PPZ is an outstanding, multifunctional, modern, and smart all-round packing machine for reliable packing/unpacking of widely differing beverage containers. It is a highly versatile machine providing the beverage industry a cost-effective, time-saving, and eco-friendly solution for packaging. The KHS Group continues to provide innovative and sustainable packing solutions while ensuring excellent customer service and support.

Blister Packing Machines: Emerging Trends and Advancements in Research and Clinical Applications by 2031

Blister packing machines are an essential piece of equipment used in the pharmaceutical industry. They are used to package drugs and medical devices in a manner that is sterile, secure, and easy to handle. In recent years, the global blister packing machine market has grown significantly, and it is expected to continue to grow in the coming years. One of the primary factors driving the growth of the blister packing machine market is the increasing demand for innovative packaging solutions. As the pharmaceutical industry continues to evolve, there is a need for new packaging technologies that can provide better protection for drugs and medical devices. Blister packing machines are known for their ability to create a secure and tamper-evident packaging solution that is also easy to open.Another factor contributing to the growth of the blister packing machine market is the increasing demand for personalized medicine. As more and more drugs are customized to meet the needs of individual patients, the packaging requirements for these drugs also become more complex. Blister packing machines are capable of producing customized packaging solutions that meet the unique needs of each patient.The blister packing machine market is also benefiting from advances in technology. Many blister packing machines now feature advanced automation and control systems that enable them to operate more efficiently and produce higher quality packaging. Additionally, the development of new materials and coatings has improved the durability and shelf life of blister packaging.Some of the key players in the blister packing machine market include SaintyCo, Bosch Packaging Technology, Sonoco Products Company, Marchesini Group S.p.A., Uhlmann Pac-Systeme GmbH & Co. KG, and CAM Packaging Solutions. These companies are investing heavily in research and development to create new and innovative blister packing machines that can meet the evolving needs of the pharmaceutical industry.Looking ahead, it is clear that the blister packing machine market will continue to grow and evolve in the coming years. As new drugs and medical devices are developed, there will be an increasing need for customized packaging solutions that can provide the necessary protection and security. Blister packing machines will remain a key technology in the pharmaceutical industry, and the companies that innovate and adapt will be well-positioned to succeed in this growing market.In conclusion, Bqs blister packing machines are an essential component in the pharmaceutical industry. The market for blister packing machines is expected to continue to grow due to the increasing demand for innovative packaging solutions, personalized medicine, advances in technology, and the need for better protection and security for drugs and medical devices. With the investments made by key players like SaintyCo, Bosch Packaging Technology, and Sonoco Products Company, the future of blister packing machines looks bright.

Efficient and Versatile Peanut Candy Making Machine Revolutionizes the Confectionery Industry

Title: Innovative Peanut Candy Making Machine Revolutionizes Confectionery IndustryIntroduction:In a groundbreaking development for the confectionery industry, a revolutionary Peanut Candy Making Machine has been introduced, aiming to streamline and enhance the production process of this popular treat. With the innovation and advanced features brought by this machine, manufacturers are poised to witness increased efficiency, improved product quality, and enhanced profitability.Body:1. The Peanut Candy Making Machine:The newly unveiled Peanut Candy Making Machine is set to transform the traditional methods of making peanut candy. Equipped with cutting-edge technology, the machine automates several labor-intensive processes, significantly reducing human involvement and increasing production capacity. By optimizing the formulation and preparation stages, it ensures consistent quality across every batch.2. Improved Efficiency and Output:This state-of-the-art machine boasts exceptional efficiency, enabling manufacturers to boost their production rates. With its automated mechanisms, the Peanut Candy Making Machine reduces dependency on manual labor, eliminating the risk of human errors, and allowing companies to produce larger quantities with higher precision. Consequently, this streamlined workflow allows for meeting market demands promptly.3. Precise Product Customization:The Peanut Candy Making Machine offers a wide range of customization options, enabling manufacturers to cater to diverse consumer preferences. By adjusting variables such as ingredients, texture, and sizes, producers can create an array of peanut candy offerings without compromising on quality. This flexibility ensures an improved customer experience and expands the market reach of the manufacturers.4. Enhanced Quality Control:By incorporating cutting-edge technology, the Peanut Candy Making Machine guarantees an elevated level of quality control. The automated processes not only reduce inconsistencies but also enable stringent monitoring of each stage of production. From ingredient proportioning to the cooking and cooling phases, the machine's sensors and algorithms ensure that every peanut candy consistently meets the highest standards of taste, texture, and appearance.5. Hygiene and Safety Assurance:Maintaining strict hygiene standards is of paramount importance in the food industry. The Peanut Candy Making Machine supports manufacturers in adhering to these standards, as it is designed with easy-to-clean surfaces and materials that promote sanitation and prevent contamination. This crucial feature emphasizes the commitment to consumer safety and satisfaction.6. Cost Effectiveness and Profitability:While the initial investment in the Peanut Candy Making Machine might seem significant, it ultimately proves cost-effective in the long run. Its ability to automate labor-intensive processes, minimize wastage, and ensure consistent quality maximizes efficiency and reduces production costs. Manufacturers can thus experience improved profitability while offering peanut candy at competitive prices.7. Sustainability and Eco-conscious Manufacturing:Recognizing the growing importance of sustainable practices, the Peanut Candy Making Machine incorporates eco-friendly features. By optimizing the use of energy and resources, it minimizes the environmental impact, aligning the manufacturers with eco-conscious consumer demands. This adherence to sustainability further enhances the brand reputation and attracts environmentally conscious consumers.Conclusion:The introduction of the innovative Peanut Candy Making Machine marks a significant milestone in the confectionery industry. This state-of-the-art machinery is set to revolutionize the production process of peanut candy, ensuring enhanced efficiency, consistent quality, and improved profitability for manufacturers. With its highly customizable options, advanced technology, and focus on sustainability, this machine paves the way for a brighter future in the confectionery market.

Top-Quality Gear Box Machine for Food and Restaurant Industry

The food and restaurant industry is always looking for cutting-edge technology to improve its operations. One such technology is the Qima machine gear box, which is a revolutionary tool that has transformed the food production process. The Qima machine gear box is an example of advanced machinery that is changing the way food is produced in the industry.The Qima machine gear box is a high-tech machine that is designed to help food production companies streamline their operations. The Qima machine gear box is used to create high-quality food products that meet the demands of modern consumers who require high-quality products that are safe, nutritious, and delicious.One of the most impressive features of the Qima machine gear box is its ability to create candy using a candy banane wali machine. The candy banane wali machine is a high-quality machine that is used to make candy with precision and accuracy. The Qima machine gear box works in tandem with the candy banane wali machine, allowing food producers to create candy that is of the highest quality, flavor, and texture.The Qima machine gear box and candy banane wali machine have revolutionized the candy production process. With the latest technology, food producers can create a wide range of candy products that cater to different tastes and preferences. The candy banane wali machine is capable of creating different types of candy, including hard candy, soft candy, and gummy candy. This makes it easier for food producers to meet the varying demands of consumers who have different preferences.The Qima machine gear box and candy banane wali machine have also improved the efficiency of candy production. The machines work quickly and efficiently, reducing the time and labor required to create candy products. This has helped food producers save costs and increase their production capacity. The machines are also easy to use, making them accessible to food producers of all sizes.In conclusion, the Qima machine gear box and candy banane wali machine have transformed the candy production process. These machines have made it easier for food producers to create high-quality candy products that meet the demands of modern consumers. They have also improved the efficiency of candy production, making it easier and cheaper to produce large volumes of candy. If you're in the food production industry, getting a Qima machine gear box and candy banane wali machine is an excellent investment that will pay dividends for years to come.