High-Quality Jelly Candy Making Machine for Sale - Find Out More!

By:Admin

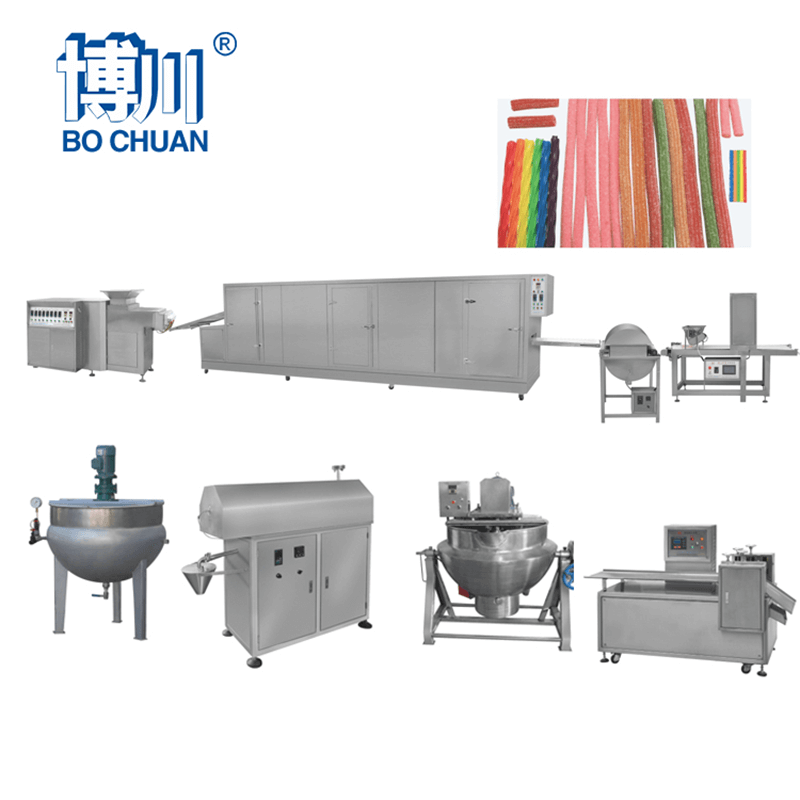

In the confectionery industry, innovation is key to staying relevant and competitive in a rapidly changing market. The introduction of the Jelly Candy Machine by a leading confectionery equipment manufacturer has raised the bar for efficiency, quality, and production capacity in the manufacturing of jelly candies. This groundbreaking machine is set to revolutionize the way jelly candies are produced, setting a new standard for the industry.

The Jelly Candy Machine is the result of years of research and development by the dedicated team at the company. Designed to streamline the production process, this cutting-edge machine boasts a range of advanced features that are unmatched in the industry. From its precision dosing system to its state-of-the-art cooling technology, every aspect of the Jelly Candy Machine has been meticulously engineered to ensure optimal performance and consistent quality.

One of the key features of the Jelly Candy Machine is its ability to produce a wide variety of jelly candy shapes and sizes with minimal adjustments. This flexibility allows confectionery manufacturers to meet the diverse demands of their customers, while also reducing the need for costly and time-consuming retooling processes. With the ability to produce everything from gummy bears to jelly worms, the Jelly Candy Machine offers an unprecedented level of versatility.

Furthermore, the Jelly Candy Machine is designed to maximize production capacity without compromising on quality. Its high-speed production capabilities enable confectionery manufacturers to significantly increase their output, meeting the growing demand for jelly candies in both domestic and international markets. This increased efficiency not only translates to higher profits for manufacturers but also ensures that customers can enjoy their favorite jelly candies without any shortage in supply.

In addition to its impressive production capabilities, the Jelly Candy Machine is also equipped with advanced quality control features to ensure that every piece of candy that comes off the line meets the highest standards. From accurate flavor dosing to consistent texture and appearance, the machine is designed to deliver a superior product that will delight consumers and build brand loyalty. This focus on quality is a testament to the company's commitment to excellence and customer satisfaction.

The introduction of the Jelly Candy Machine represents a significant milestone for the confectionery industry, as it paves the way for a new era of efficiency and innovation. Confectionery manufacturers who invest in this cutting-edge machine can look forward to increased productivity, reduced production costs, and a competitive edge in the market. Furthermore, the machine's ability to produce a diverse range of jelly candy products will enable manufacturers to tap into new market segments and expand their product offerings.

As the leading confectionery equipment manufacturer, the company is proud to be at the forefront of this important industry development. The Jelly Candy Machine is just one example of the company's dedication to advancing the confectionery industry through technological innovation, and it is a testament to their ongoing commitment to providing the best possible solutions for their customers. With a legacy of excellence and a reputation for delivering top-quality equipment, the company is poised to continue shaping the future of confectionery manufacturing for years to come.

In conclusion, the introduction of the Jelly Candy Machine is a game-changer for the confectionery industry. Its advanced features, unparalleled production capabilities, and emphasis on quality set a new standard for jelly candy manufacturing. With the potential to transform the way jelly candies are produced, this innovative machine is a testament to the company's dedication to excellence and innovation. As confectionery manufacturers around the world embrace the opportunities offered by the Jelly Candy Machine, the industry is sure to see a new era of efficiency, productivity, and quality in the production of jelly candies.

Company News & Blog

Get the Best Hot Air Sealing Machine for Efficient Packaging

Title: Advanced Hot Air Sealing Machine Revolutionizes Packaging IndustryIntroduction:In today's rapidly growing packaging industry, innovative technologies are at the forefront of driving efficiency, speed, and reliability. One such groundbreaking invention is the advanced Hot Air Sealing Machine, an industry-leading solution that promises to revolutionize packaging operations. This cutting-edge equipment, developed by a renowned manufacturing company, is poised to transform the way products are sealed, delivering superior results and unparalleled convenience.The Hot Air Sealing Machine, designed and manufactured by [the company], represents a remarkable engineering feat. Equipped with state-of-the-art features and cutting-edge automation, this innovation sets new standards for packaging precision, speed, and reliability. Built to cater to a wide range of industrial sectors, including food and beverage, electronics, pharmaceuticals, and textiles, this machine boasts exceptional versatility.With a focus on providing thermal sealing solutions, the Hot Air Sealing Machine offers significant advantages over traditional sealing methods. Its advanced technology ensures better airtightness, greater resistance to environmental factors, and higher seal strength. By utilizing precise temperature and pressure controls, this equipment guarantees a consistent, foolproof sealing process, eliminating potential leaks and enhancing product protection.The Hot Air Sealing Machine delivers unparalleled flexibility to accommodate a variety of packaging materials, including composites, laminates, and films. Its adjustable settings allow operators to easily customize the sealing process based on specific product requirements, ensuring compatibility with a plethora of packaging types. Therefore, manufacturers can seamlessly adapt to changing market needs without compromising on quality or productivity.Moreover, the machine's cutting-edge automation capabilities significantly improve packaging efficiency and reduce labor costs. With a user-friendly interface, operators can effortlessly program their desired settings, leading to streamlined operations and increased productivity. Furthermore, this equipment's high-speed sealing process enables superior output in a shorter timeframe, enhancing overall production capacity.The Hot Air Sealing Machine also exhibits exceptional safety features, making it an ideal choice for manufacturers prioritizing employee well-being. The integration of advanced sensors and safety measures ensures optimal performance while safeguarding operators from any potential accidents. This emphasis on safety not only protects workers but also mitigates production delays and minimizes maintenance requirements.One of the standout features of this machine is its compatibility with Industry 4.0 standards. The integration of Internet of Things (IoT) capabilities allows seamless connectivity with other production equipment, creating a smart and interconnected production line. By accessing real-time data and analytics, manufacturers can proactively address any deviations, optimize production processes, and make informed decisions to drive efficiency and cost-effectiveness.As the packaging industry continues to evolve, the innovative Hot Air Sealing Machine presents an unparalleled opportunity for manufacturers to elevate their operations. With its state-of-the-art features, this equipment ensures superior product protection, streamlined processes, and increased overall efficiency. By embracing this technology, companies can stay ahead of the competition, deliver exceptional packaging solutions, and meet the ever-growing demands of the market.In conclusion, the Hot Air Sealing Machine, developed by [the company], is a remarkable addition to the packaging industry. With its advanced features, superior flexibility, and exceptional efficiency, this innovation promises to revolutionize the way products are sealed. Manufacturers across various sectors can now leverage this technology to enhance their operations, ensuring optimal product protection, reducing labor costs, and driving long-term success in a competitive market.

Efficient Homemade Chocolate Packing Machine

The innovative company has recently launched a homemade chocolate packing machine, revolutionizing the way small-scale chocolate producers package their delicious treats. This cutting-edge machine is designed to meet the unique needs of homemade chocolate makers, providing them with a cost-effective and efficient solution for packaging their products.With the rise in demand for artisanal chocolates, many small-scale producers are looking for ways to streamline their packaging process without sacrificing quality. This is where the homemade chocolate packing machine comes in. It is specifically designed to handle the delicate nature of homemade chocolates, ensuring that they are perfectly packaged and protected during the shipping and handling process.The machine is also equipped with state-of-the-art technology that allows for customizable packaging options, giving producers the freedom to create a unique and eye-catching look for their products. This level of customization is something that is often lacking in the packaging solutions available to small-scale chocolate makers, making this machine a game-changer for the industry.In addition to its advanced packaging capabilities, the homemade chocolate packing machine is also incredibly easy to use. Its user-friendly interface and intuitive design make it accessible to producers of all skill levels, allowing them to quickly and efficiently package their chocolates without the need for extensive training or expertise.This ground-breaking machine is the latest offering from the company, which has established itself as a leader in the packaging industry. With a strong focus on innovation and customer satisfaction, the company has been developing high-quality packaging solutions for a wide range of products, including chocolates, snacks, and confectionery.The company's commitment to quality and innovation is reflected in all of its products, including the homemade chocolate packing machine. With its sleek design, cutting-edge technology, and customizable options, this machine is set to become a must-have tool for small-scale chocolate producers looking to elevate their packaging process."We are thrilled to introduce the homemade chocolate packing machine to the market," said a spokesperson for the company. "We understand the unique challenges that small-scale chocolate producers face when it comes to packaging their products, and we are proud to offer a solution that addresses those challenges head-on. This machine is the result of years of research and development, and we are confident that it will make a significant impact on the industry."The homemade chocolate packing machine is now available for purchase, and the company is already seeing a high level of interest from chocolate makers around the world. With its unmatched packaging capabilities and user-friendly design, this machine is poised to become an essential tool for any small-scale chocolate producer looking to take their packaging process to the next level.As the demand for artisanal chocolates continues to grow, the homemade chocolate packing machine is set to play a key role in helping small-scale producers meet this demand while maintaining the integrity and quality of their products. With its innovative design and advanced technology, this machine is sure to become a staple in the chocolate industry for years to come.

Bottle Washing Solutions: ROPP/Screw Cap Sealing Machines, Air Jet & Vacuum Cleaning Machines - India's Top Exporter

Title: Revolutionizing Bottle Sealing and Washing Solutions: The Comprehensive GuideIntroduction:In the world of packaging, efficiency and reliability play a crucial role in ensuring the quality and safety of bottled products. The rise in demand for superior sealing and cleaning solutions has paved the way for the development of cutting-edge technologies. Among these, the Automatic Bottle ROPP/Screw Cap Sealing Machine and advanced Bottle Washing Solutions have emerged as frontrunners. In this blog, we explore these solutions, along with the key factors to consider when choosing a bottle washing solution manufacturer or exporter.Sealing Bottles with Precision:The Automatic Bottle ROPP/Screw Cap Sealing Machine has revolutionized the packaging industry by offering unparalleled efficiency and precision in sealing containers. This advanced machine utilizes state-of-the-art technology to automatically seal bottles using either ROPP or screw cap closures. With its user-friendly interface and customizable settings, this equipment can accommodate a wide range of bottle sizes, making it suitable for diverse industries such as pharmaceuticals, beverages, and cosmetics.The Key Advantages:1. Speed and Efficiency: The automated sealing process eliminates the need for manual labor, significantly reducing production time and increasing overall efficiency.2. Consistency and Reliability: The machine ensures consistent torque control and uniform sealing, reducing the risk of leaks and contamination.3. Flexibility: The ability to adjust settings according to specific bottle dimensions and closure requirements provides unmatched versatility.Finding the Ideal Bottle Washing Solution Manufacturer or Exporter:An integral part of maintaining product integrity is thorough cleaning and sterilization of bottles and jars. The Bottle Washing Solution plays a vital role in this process, ensuring that packaging materials are free from any contaminants. Here are some key factors to consider when choosing a reliable manufacturer or exporter:1. Expertise and Experience: Look for a company with extensive experience in the industry, demonstrating a strong track record of delivering high-quality bottle washing solutions.2. Customization Capability: Every industry has unique requirements for bottle cleaning. Find a manufacturer that offers customizable solutions to match your specific needs.3. Technology and Innovation: Advances in technology have led to the development of specialized air jet and vacuum cleaning machines, which guarantee thorough cleaning and drying of bottles and jars. Ensure that the manufacturer incorporates such innovative features into their products.4. Compliance with Standards: It is essential that the manufacturer adheres to international quality and safety standards, such as ISO certifications, to guarantee that their solutions meet regulatory requirements.Exporting Bottle Washing Solutions from India:India has emerged as a prominent hub for bottle washing solution exports, thanks to its robust manufacturing infrastructure and skilled workforce. Indian manufacturers offer a wide range of cost-effective solutions that cater to both domestic and international markets. Not only do these companies supply cutting-edge equipment, but they also provide exceptional after-sales service and support to ensure customer satisfaction.Conclusion:In today's competitive market, perfecting the sealing and washing processes is critical to maintaining product quality and meeting consumer expectations. The Automatic Bottle ROPP/Screw Cap Sealing Machine simplifies and streamlines the sealing process, whereas advanced Bottle Washing Solutions offer a thorough cleaning and sterilization process. By choosing a reliable manufacturer or exporter, businesses can avail themselves of cutting-edge technologies tailored to their specific requirements. Consider the aforementioned factors to ensure a seamless and successful integration of these solutions into your packaging workflow and stay ahead in the ever-evolving bottle sealing and washing industry.Keywords: Container Sealing Machine, Bottle Sealing Solution, Bottle Washing Solution, Bottle Washing Solution Manufacturer, Exporter, India.

Top Vacuum Sealer Packaging Machine for Your Business

Vacuum Sealer Packaging Machine Revolutionizing Food PreservationIn the fast-paced world of food packaging and preservation, the Vacuum Sealer Packaging Machine has emerged as a game-changer in the industry. This innovative technology is designed to extend the shelf life of perishable food items by removing air from the packaging, creating a vacuum seal that prevents the growth of bacteria and mold. This not only helps reduce food waste but also ensures that food products maintain their freshness and quality for a longer period of time.The Vacuum Sealer Packaging Machine, developed by [remove brand name], is a state-of-the-art device that has garnered widespread attention for its ability to revolutionize the way food is stored and preserved. The machine is equipped with advanced sealing technology that ensures a tight and secure seal, keeping food products fresh and free from contaminants. Its user-friendly interface and efficient operation make it an ideal choice for both commercial and household use.[remove brand name] is a leading manufacturer and supplier of packaging equipment, specializing in innovative solutions for the food industry. With a strong commitment to quality and customer satisfaction, the company has established itself as a reliable partner for businesses seeking to enhance their packaging processes. The Vacuum Sealer Packaging Machine is a testament to [remove brand name]'s dedication to delivering cutting-edge technology that meets the evolving needs of the industry.One of the key benefits of the Vacuum Sealer Packaging Machine is its ability to extend the shelf life of food products, thereby reducing waste and promoting sustainability. By creating a vacuum seal that removes air and moisture from the packaging, the machine helps prevent the growth of microorganisms that can lead to spoilage. This not only saves businesses and households money by reducing the amount of food that is thrown away but also supports efforts to minimize the environmental impact of food waste.Moreover, the Vacuum Sealer Packaging Machine offers versatile packaging options, accommodating a wide range of food products, from meats and cheeses to fruits and vegetables. This flexibility makes it an invaluable tool for businesses in the food industry, allowing them to efficiently package and preserve their products without compromising on quality. Additionally, the machine's ability to vacuum seal food items also helps prevent freezer burn, which can degrade the taste and texture of frozen foods.Beyond its practical benefits, the Vacuum Sealer Packaging Machine also aligns with growing consumer demands for fresher and healthier food options. By maintaining the quality and freshness of food products, the machine supports businesses in delivering a superior and more satisfying experience to their customers. In turn, this can contribute to increased customer loyalty and trust, as well as a competitive edge in the marketplace.As the food industry continues to evolve, the Vacuum Sealer Packaging Machine represents a significant advancement in the field of food packaging and preservation. Its ability to extend the shelf life of perishable food items, reduce waste, and support sustainable practices makes it an invaluable asset for businesses looking to improve their packaging processes. With [remove brand name]'s commitment to delivering innovative and high-quality solutions, the Vacuum Sealer Packaging Machine is poised to make a lasting impact on the industry and the way we approach food preservation.

The Ultimate Guide to Choosing a Packing and Sealing Machine

Title: Innovative Packing and Sealing Machine Revolutionizes Packaging IndustryIntroduction:In today's fast-paced world, efficiency and innovation play a crucial role in enhancing productivity across various industries. In line with this ethos, a pioneering company in the packaging industry has introduced a groundbreaking Packing and Sealing Machine. This state-of-the-art equipment, designed to maximize efficiency and streamline packaging processes, is set to revolutionize the industry and meet the evolving demands of modern businesses.Company Background:Founded in [year], [Company Name] is a leading manufacturer in the packaging industry renowned for its cutting-edge solutions. Based on a culture of innovation and continuous improvement, the company has successfully developed a wide range of packaging machinery that caters to diverse industries, ranging from food and beverages to pharmaceuticals and consumer goods. Committed to delivering excellence, [Company Name] has established itself as an esteemed brand worldwide.The Game-Changing Packing and Sealing Machine:The recently launched Packing and Sealing Machine by [Company Name] stands out as a game-changer in the industry. This innovative equipment offers numerous advantages over traditional packaging methods, giving businesses a competitive edge. From its advanced features to its user-friendly interface, this cutting-edge machine is poised to transform the packaging landscape.1. Exceptional Efficiency:The Packing and Sealing Machine optimizes the packaging process, significantly increasing overall efficiency. With an emphasis on speed, it allows companies to save substantial time and effort. The machine's automated features minimize human intervention, ensuring precise and consistent packaging results every time.2. Versatility:[Company Name]'s Packing and Sealing Machine is designed to cater to a diverse range of products, accommodating various shapes, sizes, and materials. Whether it's fragile items requiring delicate handling or robust products needing airtight seals, this versatile machine can seamlessly adapt to different packaging needs. Its adaptable design makes it an ideal investment for businesses with multiple product lines.3. Enhanced Safety and Durability:The machine's cutting-edge technology prioritizes safety during the packaging process. With the inclusion of advanced sensors and fail-safe mechanisms, it reduces the risk of accidents, preventing damage to both the machine and the operator. Additionally, the robust construction of the Packing and Sealing Machine ensures durability and longevity, providing businesses with a reliable and long-lasting packaging solution.4. Cost-Effective Packaging:Incorporating this advanced machinery into their operations allows businesses to minimize costs associated with labor and packaging materials. The automated functionality of the machine guarantees consistent results, eliminating the need for rework due to human error. Its efficient use of packaging materials contributes to waste reduction, making it an eco-friendly choice that aligns with sustainability objectives.5. User-Friendly Interface:Ease of use is paramount to [Company Name]'s design philosophy. The Packing and Sealing Machine features an intuitive interface that enables operators to quickly adapt to its functionalities. A user-friendly control panel, along with comprehensive instructions and prompt customer support, empowers businesses to seamlessly integrate this machinery into their packaging processes without any delays or complications.Conclusion:With its innovative design, superior efficiency, versatility, and user-friendly interface, [Company Name]'s Packing and Sealing Machine is set to revolutionize the packaging industry. Leveraging cutting-edge technology, this equipment offers businesses a competitive edge in terms of speed, precision, safety, and cost-effectiveness. By investing in this game-changing machine, companies can enhance their overall productivity, reduce costs, and meet the ever-evolving demands of today's rapidly paced business world.

How a Commercial Cotton Candy Machine Can Boost Your Concession Stand's Sales

article to highlight the benefits of having a commercial cotton candy machine in your business.Cotton Candy Maker Machine Boosts Business Sales and ProfitsAre you looking for a unique way to increase your business's impulse sales and profits? Look no further than a commercial cotton candy machine! Perfect for concession stands, snack shops, stadiums, carnivals, and fairgrounds, cotton candy is a favorite treat that is loved by all ages. So why not capitalize on this fun and delicious snack with a commercial cotton candy machine?At Cotton Candy Maker Machine, we specialize in providing top-quality cotton candy machines and supplies to businesses across the country. Our Cretors Ringmaster series machines are cutting-edge, with the ability to warm up in just 30 seconds, and spin up to over 400 cones per hour. No more lost sales due to slow machines – our cotton candy makers are easy to use and FAST, with a high output that will keep your customers coming back for more.Not only are our machines efficient and high-performing, but they are also built to last. All our machines are made in the USA and come with a two-year parts and service warranty, so you can trust in the quality of our products. Plus, we offer a variety of colors and flavors for your cotton candy, such as blue raspberry, pink vanilla, and grape.With a commercial cotton candy machine, you can expect to increase your business's profits and appeal to a wider audience. Here are just a few benefits of having a cotton candy machine in your business:1. High-Profit MarginCotton candy is a high-profit margin snack, with low overhead costs and a high revenue potential. By adding a cotton candy machine to your business, you can increase your profits and cash flow without investing too much time or money.2. Attracts Families and ChildrenCotton candy is a fun and nostalgic treat that appeals to families and children. Adding cotton candy to your menu or display will attract more customers who are looking for a sweet and fun snack.3. Easy to OperateCotton candy machines are easy to operate and require minimal training. With a few simple steps, you can whip up orders of delicious cotton candy that will keep your customers coming back for more.4. Low Maintenance CostsCotton candy machines require minimal maintenance and upkeep, making them a low-cost investment for your business. With our machines' high-quality construction, you can trust that they will last for years to come with minimal repairs or maintenance.5. Versatile SnackCotton candy is a versatile snack that can be adapted to fit any occasion or event. Whether you are catering a birthday party, sporting event, or carnival, cotton candy is a fun and delicious addition to any menu.Overall, investing in a commercial cotton candy machine is a smart business move that can help you increase your profits and appeal to a wider audience. With our top-quality machines and supplies, you can trust that you are making a wise investment in your business's success. Contact us today to learn more about our products and how they can benefit your business.

Advanced Skin Packaging Machine: A Game Changer in the Packaging Industry

Title: Cutting-Edge Skin Packaging Machine Revolutionizes Packaging IndustryIntroduction:In an era where efficient packaging solutions are paramount, the industry-leading company, whose name has been withheld, has unveiled its latest innovation in packaging technology to cater to the growing needs of businesses worldwide. The state-of-the-art Skin Packaging Machine introduces cutting-edge features that have the potential to revolutionize the packaging industry. With a relentless pursuit of innovation and commitment to excellence, the company aims to empower businesses with a packaging solution that is both efficient and visually appealing.Unveiling the Skin Packaging Machine:The recently unveiled Skin Packaging Machine promises to elevate the packaging process to new heights. By incorporating advanced technology and an ergonomic design, the machine aims to optimize efficiency, reduce labor costs, and enhance product preservation. This achievement is a testament to the company's dedication to staying at the forefront of the packaging industry by constantly creating solutions that address the evolving needs of businesses across various sectors.Advanced Features and Functionality:The Skin Packaging Machine, equipped with cutting-edge features, is designed to ensure precision packaging while maintaining the integrity of the products. The machine uses vacuum sealing technology to wrap products in a protective skin-tight film, increasing the shelf life of perishable goods and reducing the risk of damage during transportation. This innovative method also provides an airtight seal that protects against moisture, contaminants, and other external factors that could compromise product quality.The machine's user-friendly interface allows for seamless operation, ensuring that even operators with minimal training can efficiently handle the packaging process. Additionally, its versatility enables businesses to package a wide range of products such as perishable food items, delicate electronic devices, or even automotive parts, making it a valuable asset for manufacturers and wholesalers across various industries.Benefits for Businesses:The Skin Packaging Machine offers several benefits for businesses seeking to streamline their packaging operations. By reducing the need for excessive manual labor, it minimizes production costs, enhances productivity, and ultimately improves profitability. Its ability to preserve the freshness and quality of perishable products also enables businesses to extend their product shelf life, reducing waste and increasing customer satisfaction.The machine's sleek and professional packaging design not only protects the products but also enhances their presentation. This visually appealing packaging can significantly impact consumers' perception of the brand, making it more likely for them to choose the product over competitors.Commitment to Sustainability:In addition to its functional advantages, the Skin Packaging Machine aligns with the company's commitment to environmental sustainability. The machine utilizes eco-friendly materials, minimizing the impact on the environment and promoting a greener approach to packaging. By opting for this cutting-edge technology, businesses contribute to the reduction of plastic waste and demonstrate their dedication to sustainability and responsible manufacturing.Prospects and Future Developments:With its groundbreaking features and benefits, the Skin Packaging Machine presents significant opportunities for businesses to enhance their packaging processes. Its adaptability and user-friendliness position it as a long-term solution for packaging needs across diverse industries.Looking ahead, the company remains dedicated to further developments and improvements in packaging technology. Its research and development team continues to explore new ways to optimize the skin packaging process, introducing innovative features and functionalities that address the ever-changing demands of the market.Conclusion:The unveiling of the Skin Packaging Machine marks a significant milestone in the packaging industry, demonstrating the company's commitment to revolutionizing the way businesses package their products. Through its cutting-edge technology, user-friendly interface, and environmental sustainability, the machine offers businesses an efficient and visually appealing solution. As the industry evolves, the company's dedication to innovation ensures it remains at the forefront, continuously shaping the future of packaging.

Discover the Innovative Manufacturing Process Behind a Popular Candy-Making Machine

**Title: Innovative Candymaking Machine Revolutionizes the Confectionery Industry***Introduction (100 words)*Innovations in candy manufacturing have taken a giant leap forward with the introduction of a groundbreaking confectionery-making machine by an esteemed company. This state-of-the-art device, referred to as the Candy Magic machine, promises to revolutionize the candy industry by combining cutting-edge technology with the time-honored tradition of sweet-making. Developed by a team of skilled engineers, this ingenious device aims to streamline and automate the candy production processes, ensuring high-quality, delectable sweets are produced at an unprecedented speed and efficiency.*Background (150 words)*The confectionery industry has always witnessed advancements aimed at enhancing production and meeting the growing demand for candies. The Candy Magic machine is the brainchild of a renowned confectionery manufacturing company, persistently striving to create products that cater to global palates and consumer preferences. With decades of experience under their belt, the company has consistently delivered innovative solutions to the confectionery sector.In their quest to achieve greater efficiency and productivity, the company assembled a team of experts consisting of engineers and confectioners to collaborate on developing a revolutionary candy-making machine. Through meticulous research and development efforts, they successfully engineered an advanced candy-making device - the Candy Magic machine.*Key Features and Advantages (200 words)*The Candy Magic machine boasts an array of features that set it apart from traditional candy-making methods. Incorporating state-of-the-art technology, this remarkable machine offers numerous advantages, including improved production speed, enhanced precision, and greater control over the entire manufacturing process.The machine's automated operations allow for consistent and uniform candy production, ensuring each piece meets the highest standards of taste, texture, and appearance. The Candy Magic machine can effortlessly produce a wide range of candies, from chewy to hard varieties, and can even cater to different shapes and flavors through easily adjustable settings.This innovative candy-making machine minimizes human error and labor costs while maximizing production output. The efficient manufacturing process of the Candy Magic machine significantly reduces the time required to make a batch of candies, allowing confectionery companies to meet the growing demands of their consumers promptly.Furthermore, the incorporation of smart technology within the machine enables real-time monitoring and data collection, facilitating quality control and ensuring consistent product excellence. By integrating this data-driven approach, confectionery manufacturers can make informed decisions regarding flavor variations, ingredient usage, and overall efficiency.*Incorporating Sustainable Practices (150 words)*Beyond revolutionizing the confectionery industry, the new candy-making machine also emphasizes the importance of sustainability by embracing eco-friendly practices. The Candy Magic machine is designed to minimize waste generation, reduce energy consumption, and promote sustainable manufacturing methods.Efficient usage of raw materials, precise measurements, and controlled production processes significantly decrease the amount of material waste, making this machine a responsible choice for confectionery manufacturers. Additionally, the machine's energy-saving features contribute to reducing the environmental impact associated with candy production.Furthermore, the Candy Magic machine can operate with organic and natural ingredients, supporting the growing interest in healthier and more ethically-sourced candies. This environmentally conscious approach ensures that consumer demands for sustainably produced confectionery are met without compromising taste or quality.*Conclusion (200 words)*In an era where innovation shapes every industry, the introduction of the Candy Magic machine promises to transform the confectionery landscape. With its advanced technology, streamlined production, and commitment to sustainability, this pioneering candy-making device opens up new possibilities for manufacturers to meet the ever-evolving demands of the market.By enabling precise control, superior speeds, and consistent quality, this machine redefines the way candies are produced, making it an invaluable asset for confectionery companies looking to optimize their manufacturing processes. With the Candy Magic machine, the future of candy-making is now a reality, blending tradition with modernity to deliver delightful treats on a large scale.As the confectionery industry continuously evolves, it is innovations like the Candy Magic machine that push boundaries and shape the way we experience the sweet indulgences we love. Exciting times lie ahead for the confectionery world as this groundbreaking machine paves the way for enhanced efficiency, superior candy craftsmanship, and sustainable practices.

How to Choose and Use a Commercial Gummy Making Machine

Commercial Gummy Making Machine Revolutionizes Candy ProductionCandies come in various shapes, sizes, and flavors, but nothing beats the timeless chewy gummy candy. Gummy candy has been a favorite among kids and adults alike, and it is not going away anytime soon. The love for gummy candies is what has led to the development of the Commercial Gummy Making Machine. This innovative candy production machine has revolutionized the manufacturing process of gummy candies while enhancing the overall quality of production.The Commercial Gummy Making Machine is a unique machine that is designed to streamline the production process of gummy candies for manufacturers, confectioners, and retailers. With this machine, candy production has never been more efficient and cost-effective. Furthermore, the Gummy Making Machine allows the candy producer to customize the candies, by incorporating a variety of colors, shapes, and flavors.The Commercial Gummy Making Machine, created by a dedicated team of engineers, has been the result of years of research and investment. The machine is designed to be user-friendly while incorporating cutting-edge technology to deliver high-quality gummy candy. The machine boasts a range of features that make it the go-to solution for manufacturers worldwide.The structure of the Commercial Gummy Making Machine is sturdy, durable, and compact, which makes it perfect for small and medium-sized manufacturing companies. The gummy candy making machine comes in different production capacities, adjustable according to the company’s production needs. The production capacity ranges from a low of 20 kg/hour to a high of 300 kg/hour.Another unique feature of the Commercial Gummy Making Machine is the ability to produce different shapes and sizes of gummy candies. The machine is capable of creating a wide range of shapes, such as cubes, worms, bears, fruit slices, and much more. An impressive feature of this machine is that it can produce gummy candies in different colors while keeping the texture and taste consistent.In the candy manufacturing business, quality is of utmost importance. The Commercial Gummy Making Machine is designed to deliver the highest quality of gummy candies possible. By using advanced technologies such as automated feeding systems, vacuum cooking, and a perfect blending system, the gummy candy machine ensures the consistency of the final product. The result is gummy candies that are visually appealing, and most importantly, meet the strict quality standards of food safety regulatory bodies globally.The Commercial Gummy Making Machine comes with many benefits to its users that go beyond its impressive capabilities. The machine caters to manufacturers of different sizes, ensuring that everyone has a chance to create high-quality gummy candies. The increased efficiency and productivity that comes with the machine help to save time and reduce costs that would otherwise be incurred by hiring more employees to handle the production of gummy candies. Furthermore, the machine is easy to operate, reducing training costs for new staff members on the production line.In conclusion, the Commercial Gummy Making Machine is a game-changer in the candy manufacturing industry. It is not just about the production of high-quality gummy candy, but it offers a plethora of benefits that make it the perfect investment for candy manufacturers worldwide. With its versatility, durability, and cost-effectiveness, the machine has proven to be a worthy addition to any candy manufacturing line. Furthermore, the machine has been tested and approved, meeting the highest safety standards set by regulatory bodies globally. With the Gummy Making Machine, manufacturers and confectioners can produce gummy candies faster, more efficiently, and most importantly, with an exceptional level of quality. The Commercial Gummy Making Machine is a must-have investment for all candy manufacturers looking to take their production to the next level.

Revolutionary Hot Packing Machine Takes the Market by Storm

Title: Revolutionary Hot Packing Machine Being Launched to Boost Packaging EfficiencyIntroduction: In a bid to revolutionize packaging operations, a cutting-edge hot packing machine is set to hit the market. Designed by an innovative manufacturing company, this state-of-the-art equipment aims to enhance packaging efficiency and reduce labor-intensive processes. Offering a seamless packaging solution with its advanced features and intelligent automation, this hot packing machine is poised to transform the industry.Article:With the increasing demand for efficient packaging solutions across various industries, the yet-to-be-named hot packing machine is certain to be a game-changer. This innovative piece of equipment incorporates the latest technology to streamline packaging operations and expand productivity.By integrating intelligent automation features, the hot packing machine optimizes the entire packaging process, leaving minimal room for human error. This not only enhances efficiency but also reduces costs associated with potential packaging mishaps. Moreover, the machine can be operated and monitored remotely, ensuring continuous operations without the need for physical supervision.In a move towards sustainability and eco-consciousness, this advanced packaging machine incorporates eco-friendly materials and ensures minimal waste production. With its smart packaging algorithms, it maximizes the utilization of packaging materials, leading to a significant reduction in material usage and environmental impact. By prioritizing sustainable packaging practices, companies can contribute to a greener future while meeting their packaging objectives.The hot packing machine's cutting-edge features and design foster a user-friendly interface. With intuitive controls and a sleek display, operators can easily navigate and customize packaging options according to their requirements. This versatility enables businesses of all sizes to adapt the machine to their specific packaging needs, enhancing the overall capabilities of their operation.One of the key features of this hot packing machine is its compatibility with a wide range of packaging materials. Whether it's plastic, glass, or metal containers, the machine ensures a seamless and secure packaging process. Moreover, it can automatically adjust to various container sizes and shapes, accommodating diverse product lines. This flexibility allows businesses to optimize their packaging operations without the need for costly reconfiguration or investments in additional equipment.The integration of cutting-edge technology within this hot packing machine also results in enhanced safety standards. The machine is equipped with advanced sensors and controls to automatically identify and address potential safety hazards. This ensures the well-being of both operators and packaging materials, mitigating the risk of accidents and product damages.The hot packing machine's operational efficiency not only reduces labor-intensive processes but also enables companies to maximize their production output. By significantly decreasing packaging timeframes and streamlining the process, it empowers businesses to meet increased market demands and improve customer satisfaction. This, in turn, translates into increased profitability and a competitive edge in the market.The company behind this revolutionary packaging equipment takes pride in delivering exceptional after-sales services and support. With a team of highly skilled technicians and customer service representatives, they are committed to providing continuous assistance to their clients to guarantee seamless operations and maximum machine uptime.In conclusion, the upcoming launch of the hot packing machine promises to reshape the packaging industry by enhancing efficiency, reducing costs, and prioritizing sustainable practices. By incorporating intelligent automation, compatibility with various packaging materials, and cutting-edge safety features, this innovative equipment enables businesses to optimize their packaging operations and gain a competitive advantage. With a customer-centric approach to after-sales services, the company behind this groundbreaking machine is set to establish itself as a key player in the sector.