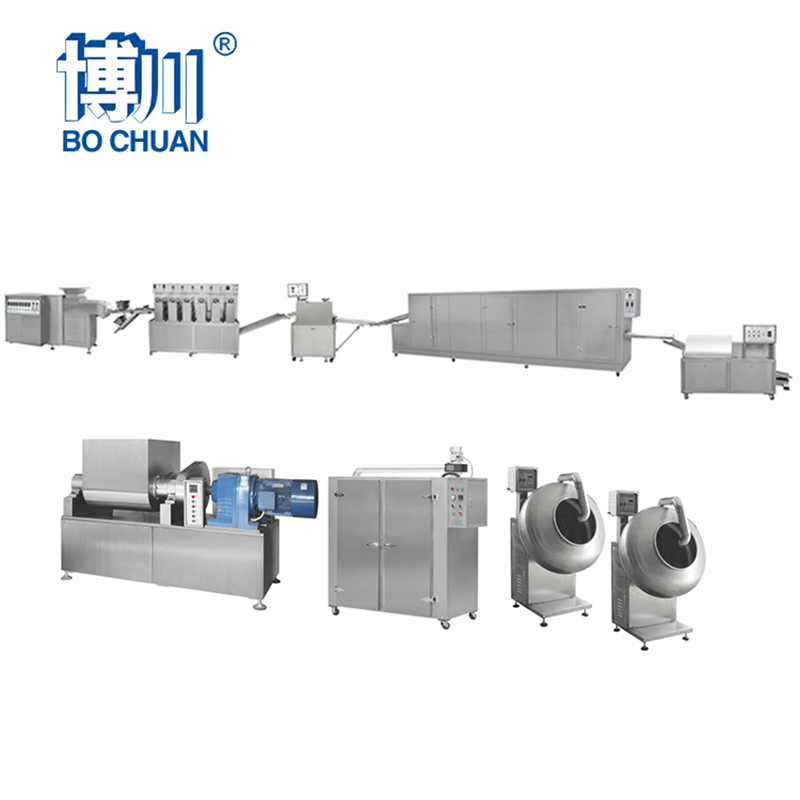

High-Quality Candy Making Equipment for Professional Use

By:Admin

Candy making is both an art and a science, requiring precision and skill to create delicious and visually appealing treats. Whether you are a small artisanal candy maker or a large-scale confectionery company, having the right equipment is essential to produce high-quality candies. That's where Professional Candy Making Equipment comes in.

With a focus on providing top-of-the-line candy making equipment, Professional Candy Making Equipment has established itself as a leading supplier in the confectionery industry. The company offers a wide range of machinery and tools that cater to the needs of candy makers of all sizes, from small home-based businesses to large-scale production facilities.

One of the key factors that set Professional Candy Making Equipment apart from its competitors is its commitment to providing innovative and high-quality products. The company works closely with candy makers to understand their specific needs and continuously develops new equipment to meet those requirements. From traditional copper kettles for artisanal candy making to high-capacity tempering machines for industrial production, the company offers a comprehensive selection of equipment to suit a variety of candy making processes.

In addition to its focus on innovation, Professional Candy Making Equipment also places a strong emphasis on the durability and reliability of its products. The company understands that candy making is a demanding process that requires equipment to withstand high temperatures, constant use, and rigorous cleaning. As such, all of its machinery is built to last, using high-quality materials and robust construction to ensure longevity and consistent performance.

Furthermore, Professional Candy Making Equipment is dedicated to providing exceptional customer service and support. The company's team of experts is readily available to provide guidance and assistance to candy makers, whether it's helping them choose the right equipment for their needs, providing technical support, or offering maintenance and repair services. This commitment to customer satisfaction has earned the company a loyal and satisfied customer base throughout the confectionery industry.

One of the flagship products offered by Professional Candy Making Equipment is its cutting-edge chocolate tempering machine. This machine is designed to streamline the tempering process, allowing candy makers to achieve perfectly tempered chocolate with ease. The machine's advanced technology ensures precise temperature control, resulting in chocolates that have a smooth texture, glossy appearance, and a satisfying snap when bitten into. With its user-friendly interface and efficient performance, the chocolate tempering machine has become a staple in confectionery kitchens around the world.

Another popular product in the company's lineup is its range of candy molding and shaping equipment. Whether candy makers are looking to create traditional hard candies, gummies, or chocolate pralines, Professional Candy Making Equipment offers a variety of molding and shaping tools to bring their confectionery creations to life. These machines are designed to deliver precise shapes and intricate designs, allowing candy makers to unleash their creativity and produce visually stunning candies.

Furthermore, Professional Candy Making Equipment is dedicated to sustainability and environmental responsibility. The company ensures that its manufacturing processes are energy-efficient and minimally impact the environment. Additionally, it offers a range of eco-friendly equipment options, such as energy-saving tempering machines and efficient candy cooling systems, to help candy makers reduce their environmental footprint.

With its unwavering commitment to quality, innovation, and customer satisfaction, Professional Candy Making Equipment continues to be a trusted partner for candy makers worldwide. Whether it's providing cutting-edge machinery, reliable support, or eco-friendly solutions, the company is dedicated to helping candy makers achieve excellence in their craft.

In conclusion, Professional Candy Making Equipment is a leading supplier of top-quality candy making equipment, offering a wide range of innovative and reliable machinery to meet the diverse needs of candy makers. From its state-of-the-art chocolate tempering machines to its eco-friendly production solutions, the company has established itself as a trusted partner in the confectionery industry. With its focus on quality, innovation, and customer satisfaction, Professional Candy Making Equipment is poised to continue shaping the future of candy making.

Company News & Blog

Innovative Packaging Machine Revolutionizes Cover Packing Process

[Company Introduction]Founded in 2005, our company is a leading manufacturer and supplier of packaging machinery solutions. We specialize in developing and manufacturing a wide range of advanced packaging equipment, catering to the needs of various industries such as food and beverage, pharmaceuticals, cosmetics, and more. Our commitment to innovation, quality, and customer satisfaction has propelled us to the forefront of the packaging industry.The recent introduction of our latest product, the Cover Packing Machine, has once again demonstrated our dedication to providing state-of-the-art solutions to our customers. This cutting-edge machine is designed to streamline the packaging process, offering efficiency, reliability, and versatility for businesses of all sizes. With a strong focus on automation and precision, our Cover Packing Machine is set to revolutionize the packaging industry.[News Content]In a significant development for the packaging industry, our company has unveiled its latest innovation – the Cover Packing Machine. This advanced piece of equipment is set to redefine the packaging process, offering unprecedented efficiency and versatility for businesses across various sectors.The Cover Packing Machine is a testament to our unwavering commitment to delivering cutting-edge solutions that meet the evolving needs of our customers. Designed to cater to a wide range of products, including but not limited to food, beverages, pharmaceuticals, and cosmetics, this machine is poised to set new standards for packaging efficiency and quality.One of the key features of the Cover Packing Machine is its advanced automation capabilities. With an intuitive interface and smart controls, the machine can handle the entire packaging process with minimal human intervention, reducing the margin of error and improving overall productivity. This level of automation is a game-changer for businesses looking to streamline their packaging operations and achieve higher output rates.Moreover, the flexibility of the Cover Packing Machine is another standout feature. Whether it’s packaging different sizes and shapes of products or adapting to various packaging materials, this machine can easily accommodate diverse needs. This versatility ensures that businesses can rely on the Cover Packing Machine to handle a wide range of packaging requirements, making it a valuable addition to any production line.In addition to its automation and flexibility, the Cover Packing Machine has been engineered with a strong emphasis on precision and reliability. Each packaging process is executed with utmost accuracy, ensuring that products are securely and neatly packed every time. This level of consistency and quality assurance is invaluable for businesses seeking to maintain high standards of product presentation and customer satisfaction.Furthermore, the Cover Packing Machine is designed with efficiency in mind. By optimizing the packaging process and minimizing wastage, this machine enables businesses to maximize their resource utilization and minimize their operational costs. As a result, companies can achieve a higher return on investment while delivering superior packaging outcomes.The unveiling of the Cover Packing Machine marks a significant milestone for our company and the packaging industry as a whole. With its unparalleled automation, flexibility, precision, and efficiency, this innovative machine is poised to revolutionize the way products are packaged across various sectors. We are proud to offer this state-of-the-art solution to our customers, reaffirming our position as a leader in the packaging machinery market.In conclusion, the Cover Packing Machine represents a new era of packaging excellence, and we are excited to witness its impact on businesses worldwide. As we continue to push the boundaries of innovation, our commitment to delivering superior packaging machinery solutions remains unwavering. We are confident that the Cover Packing Machine will not only meet the current needs of our customers but also exceed their expectations, setting a new standard for packaging efficiency and quality.

Efficient and Automated Packing Machines for Mushrooms

[Title]: Advanced Mushroom Packing Machine Revolutionizes Packaging Processes for Mushroom Producers[Subtitle]: The Cutting-Edge Technology Enhances Efficiency and Maximizes Product Quality in the Mushroom Industry[date], [location] - In recent times, the mushroom industry has witnessed a revolutionary transformation in its packaging processes with the introduction of an advanced mushroom packing machine. Developed by an innovative company that specializes in packaging solutions, this state-of-the-art machine focuses on enhancing efficiency and maximizing product quality for mushroom producers worldwide.The mushroom packing machine, which boasts cutting-edge technology and a host of groundbreaking features, has quickly become a game-changer in the industry. Its development stems from the company's commitment to providing innovative packaging solutions that address the unique requirements of mushroom producers.One of the standout features of this mushroom packing machine is its ability to handle a wide variety of mushroom types. The machine is designed to carefully pack different varieties, including white, portobello, shiitake, oyster, and cremini mushrooms, without compromising their quality or appearance. This versatility allows mushroom producers to streamline their packing processes and cater to a more diverse market.Furthermore, the mushroom packing machine incorporates advanced sorting mechanisms to ensure only the highest quality mushrooms make it into the final packaging. By employing cutting-edge technology, including image recognition and artificial intelligence, the machine can identify and sort mushrooms based on size, shape, and color. This feature not only enhances the overall quality of the packed mushrooms but also reduces the need for manual sorting, saving valuable time and resources for mushroom producers.In addition to its exceptional sorting capabilities, the packing machine also employs state-of-the-art packaging materials to extend the shelf life of mushrooms. With the inclusion of moisture-absorbent and breathable packaging, the machine creates an optimal environment for mushrooms, preserving their freshness and flavor for an extended period. This technological advancement plays a crucial role in reducing food waste and ensuring that end consumers receive mushrooms of the highest quality.The mushroom packing machine also emphasizes efficiency and productivity. With automated processes and minimal human intervention, mushroom producers can significantly reduce labor costs and increase production output. The machine's user-friendly interface allows operators to easily modify settings, monitor production progress, and identify any potential issues, ensuring a seamless and hassle-free packing experience.Furthermore, the company behind this groundbreaking technology provides comprehensive after-sales support and maintenance services. This commitment to customer satisfaction ensures that mushroom producers can rely on the machine's consistent performance and receive prompt assistance whenever required.As a result of these innovative features and the company's dedication to excellence, the mushroom packing machine has garnered widespread acclaim within the industry. Mushroom producers worldwide have embraced this advanced technology, enhancing their competitiveness in the market and ensuring that consumers receive mushrooms of exceptional quality.In conclusion, the introduction of the advanced mushroom packing machine has revolutionized the packaging processes within the mushroom industry. With its ability to handle various mushroom varieties, advanced sorting mechanisms, premium packaging materials, and emphasis on efficiency, this machine has raised the bar for mushroom producers worldwide. By integrating cutting-edge technology into their packaging operations, mushroom producers can now meet the increasing demands of the market while ensuring the delivery of fresh and high-quality mushrooms to consumers.

Bottle Washing Solutions: ROPP/Screw Cap Sealing Machines, Air Jet & Vacuum Cleaning Machines - India's Top Exporter

Title: Revolutionizing Bottle Sealing and Washing Solutions: The Comprehensive GuideIntroduction:In the world of packaging, efficiency and reliability play a crucial role in ensuring the quality and safety of bottled products. The rise in demand for superior sealing and cleaning solutions has paved the way for the development of cutting-edge technologies. Among these, the Automatic Bottle ROPP/Screw Cap Sealing Machine and advanced Bottle Washing Solutions have emerged as frontrunners. In this blog, we explore these solutions, along with the key factors to consider when choosing a bottle washing solution manufacturer or exporter.Sealing Bottles with Precision:The Automatic Bottle ROPP/Screw Cap Sealing Machine has revolutionized the packaging industry by offering unparalleled efficiency and precision in sealing containers. This advanced machine utilizes state-of-the-art technology to automatically seal bottles using either ROPP or screw cap closures. With its user-friendly interface and customizable settings, this equipment can accommodate a wide range of bottle sizes, making it suitable for diverse industries such as pharmaceuticals, beverages, and cosmetics.The Key Advantages:1. Speed and Efficiency: The automated sealing process eliminates the need for manual labor, significantly reducing production time and increasing overall efficiency.2. Consistency and Reliability: The machine ensures consistent torque control and uniform sealing, reducing the risk of leaks and contamination.3. Flexibility: The ability to adjust settings according to specific bottle dimensions and closure requirements provides unmatched versatility.Finding the Ideal Bottle Washing Solution Manufacturer or Exporter:An integral part of maintaining product integrity is thorough cleaning and sterilization of bottles and jars. The Bottle Washing Solution plays a vital role in this process, ensuring that packaging materials are free from any contaminants. Here are some key factors to consider when choosing a reliable manufacturer or exporter:1. Expertise and Experience: Look for a company with extensive experience in the industry, demonstrating a strong track record of delivering high-quality bottle washing solutions.2. Customization Capability: Every industry has unique requirements for bottle cleaning. Find a manufacturer that offers customizable solutions to match your specific needs.3. Technology and Innovation: Advances in technology have led to the development of specialized air jet and vacuum cleaning machines, which guarantee thorough cleaning and drying of bottles and jars. Ensure that the manufacturer incorporates such innovative features into their products.4. Compliance with Standards: It is essential that the manufacturer adheres to international quality and safety standards, such as ISO certifications, to guarantee that their solutions meet regulatory requirements.Exporting Bottle Washing Solutions from India:India has emerged as a prominent hub for bottle washing solution exports, thanks to its robust manufacturing infrastructure and skilled workforce. Indian manufacturers offer a wide range of cost-effective solutions that cater to both domestic and international markets. Not only do these companies supply cutting-edge equipment, but they also provide exceptional after-sales service and support to ensure customer satisfaction.Conclusion:In today's competitive market, perfecting the sealing and washing processes is critical to maintaining product quality and meeting consumer expectations. The Automatic Bottle ROPP/Screw Cap Sealing Machine simplifies and streamlines the sealing process, whereas advanced Bottle Washing Solutions offer a thorough cleaning and sterilization process. By choosing a reliable manufacturer or exporter, businesses can avail themselves of cutting-edge technologies tailored to their specific requirements. Consider the aforementioned factors to ensure a seamless and successful integration of these solutions into your packaging workflow and stay ahead in the ever-evolving bottle sealing and washing industry.Keywords: Container Sealing Machine, Bottle Sealing Solution, Bottle Washing Solution, Bottle Washing Solution Manufacturer, Exporter, India.

Top-of-the-line Candy Making Equipment: A Must-Have for Professional Confectioners

Title: Innovative Candy Making Equipment Revolutionizes the Confectionery IndustryIntroduction:In today's fast-paced confectionery industry, the demand for innovative candy making equipment continues to grow. One company, recognized for its cutting-edge technology and exceptional quality, is revolutionizing candy production. By leveraging state-of-the-art machinery and expertise, this company is paving the way for a new era in confectionery manufacturing. Here, we delve into the details of this revolutionary candy making equipment and explore how it is transforming the industry.I. The Evolution of Candy Making Equipment:Over the years, candy making equipment has undergone significant advancements. Traditional methods of production relied heavily on manual labor, limiting both the efficiency and scope of candy production. However, with the advent of automated machinery, candy manufacturers can now produce confections on a much larger scale, meeting the ever-increasing consumer demand.II. Introducing Professional Candy Making Equipment:Addressing the need for sophisticated candy making equipment, a company (name withheld) has emerged as a leader in the field. By combining cutting-edge technology with extensive industry knowledge, they have succeeded in revolutionizing candy production. The company's dedication to quality, innovation, and customer satisfaction has earned them a reputation as a sought-after provider of comprehensive candy making solutions.III. Key Features and Advantages of Professional Candy Making Equipment:1. Automated and Efficient: This candy making equipment is fully automated, eliminating the need for extensive manual labor. Moreover, its advanced technology enables high-speed production, significantly increasing output while reducing production time.2. Versatile and Customizable: The equipment boasts a wide range of capabilities, making it adaptable to various candy types, shapes, sizes, and flavors. Whether it's hard candies, gummies, lollipops, or chocolate-based confections, this equipment can efficiently handle diverse candy making requirements. Additionally, it allows for easy customization, accommodating specific customer preferences.3. Precision and Consistency: The equipment incorporates precise temperature controls, ensuring the precise heating and cooling required for each candy type. This precision guarantees consistent quality and taste, key factors in maintaining customer satisfaction.4. Hygienic and Safe: The candy making equipment is designed with food-grade materials and follows strict quality control measures. This ensures that the candies produced meet the highest standards of hygiene and safety, conforming to regulatory requirements.5. User-Friendly Interface: The equipment features an intuitive interface, making it accessible to both experienced and novice operators. Additionally, it offers remote monitoring and control capabilities, enabling manufacturers to oversee production processes in real-time.6. Cost-Effective and Economical: By automating the production process, the candy making equipment reduces labor costs and optimizes resource utilization. This leads to enhanced operational efficiency and increased profitability for candy manufacturers.IV. Industry Impact and Customer Testimonials:Having gained significant traction in the confectionery industry, this professional candy making equipment has garnered praise from customers globally. Candy manufacturers who have incorporated this technology into their operations have witnessed an exponential increase in productivity, greater consistency in product quality, and improved customer satisfaction. The equipment's ability to streamline production processes, reduce manual labor, and ensure the highest standards of quality control has solidified its position as an indispensable tool for confectioners worldwide.Conclusion:The introduction of professional candy making equipment has transformed conventional candy production, offering unmatched efficiency, precision, and versatility. With its state-of-the-art features, the equipment empowers candy manufacturers to produce confections on a larger scale, customize their offerings, and optimize operational efficiencies. As the confectionery industry continues to evolve, this innovative candy making equipment promises to shape the future of candy manufacturing, offering unlimited possibilities for confectioners worldwide.

Top Sealing Machines for Various Industrial Needs

article about the importance of sealing machines in the food packaging industry.In the food packaging industry, ensuring that the products are properly sealed and packaged is crucial. The food industry is highly regulated and any breach in safety protocols could result in severe consequences. This is where sealing machines come into play, as they are essential in maintaining the freshness, quality, and hygiene of food products.Barnco Pty Ltd is a leading provider of sealing machines in Australia, offering a wide range of high-quality sealing equipment that is designed to meet the varying needs of the food packaging industry. Their products include impulse bench-top sealers, overwrappers, and many more.The impulse bench-top sealer is one of their most popular products, and it is designed to seal a variety of packaging materials such as polyethylene, polypropylene, and laminated foil. The sealing process is done by applying heat to the packaging material, which melts the surface and creates a strong bond that seals the package.The bench-top sealer is perfect for small to medium-sized operations, providing an efficient and cost-effective solution for sealing products. The device is easy to use and compact in size, making it a popular choice for businesses that are looking to save on space while still maintaining high-quality standards.Another popular product offered by Barnco Pty Ltd is the Grange GRTW500XL overwrapper. This is a high-speed overwrapping machine that is designed to wrap products in a tight and secure manner, ensuring that the packaging is tamper-proof, dust-proof, and moisture-proof.The machine operates at a speed of up to 25 packs per minute, making it ideal for businesses that are looking to optimize their production processes. It is also designed to handle a variety of packaging materials, making it a versatile solution for any business.In addition to the Grange GRTW500XL, Barnco Pty Ltd also offers the Acom AW500 Overwrapper. This machine is designed to wrap large products such as cakes, pizzas, and sandwiches, providing a tight and secure seal that keeps the product fresh and free from contamination.The Acom AW500 is also easy to use and maintain, making it a popular choice for businesses that are looking to reduce their operating costs. It is also designed to handle a variety of packaging materials, making it a versatile solution for any business.In conclusion, sealing machines are essential in the food packaging industry, ensuring that products are properly sealed and packaged to maintain freshness, quality, and hygiene. Barnco Pty Ltd is a leading provider of sealing machines in Australia, offering a wide range of high-quality sealing equipment that is designed to meet the varying needs of the food packaging industry.Their products are designed to be efficient, cost-effective, and easy to use, providing businesses with a reliable solution to their packaging needs. With their commitment to quality and customer service, Barnco Pty Ltd has become a trusted partner for businesses in the food packaging industry.

Efficient and Automated Rice Packing Machine for Streamlined Packaging Operations

Today, we are thrilled to introduce our latest innovation, the advanced Rice Packing Machine. This state-of-the-art machine is set to revolutionize the rice packaging industry with its cutting-edge technology and efficient packaging capabilities.The new Rice Packing Machine is a result of years of research and development, aimed at creating a high-performance and reliable packaging solution for rice producers. This machine is designed to streamline the packaging process, increase efficiency, and ensure the quality and freshness of the packaged rice.One of the key features of the Rice Packing Machine is its automated operation, which reduces the need for manual labor and minimizes the risk of human error. The machine is equipped with advanced sensors and precision control systems, allowing for accurate weighing and filling of rice into bags or containers. This not only speeds up the packaging process but also eliminates the variability in packaging weights, ensuring that every bag or container is filled to the exact specifications.Furthermore, the Rice Packing Machine is designed to handle a wide range of rice varieties, including long-grain, short-grain, white, brown, and specialty rice. Its versatile design allows for quick and easy changeovers between different types of rice, making it suitable for rice producers with diverse product lines.In addition to its advanced packaging capabilities, the Rice Packing Machine is also built with the highest standards of food safety and hygiene in mind. The machine is constructed with food-grade materials and features a smooth, easy-to-clean surface to prevent contamination and maintain the integrity of the packaged rice.“We are proud to unveil the Rice Packing Machine as the latest addition to our line of packaging solutions,” said the spokesperson of the company. “This machine represents our commitment to innovation and our dedication to meeting the evolving needs of the rice industry. We believe that the Rice Packing Machine will offer a competitive edge to rice producers, allowing them to optimize their packaging processes and deliver high-quality products to their customers.”The company behind the Rice Packing Machine has established itself as a leader in the packaging industry, with a track record of delivering innovative and reliable solutions to its customers. With a focus on technological advancement and customer satisfaction, the company has built a reputation for excellence and has gained the trust of rice producers around the globe.The introduction of the Rice Packing Machine is a testament to the company's ongoing commitment to research and development, as well as its dedication to providing top-of-the-line packaging solutions for the food industry. By leveraging cutting-edge technology and industry expertise, the company continues to set new standards for packaging quality and efficiency.As the rice industry continues to grow and evolve, the demand for advanced packaging solutions has never been greater. The Rice Packing Machine comes at a time when rice producers are seeking ways to improve their packaging processes, enhance their product offerings, and meet the increasing demands of their customers. With its advanced technology and user-friendly design, the Rice Packing Machine is well-positioned to address these needs and drive greater efficiency and profitability for rice producers.In conclusion, the introduction of the Rice Packing Machine represents a significant milestone for the company and the rice packaging industry as a whole. With its advanced features, versatile capabilities, and commitment to food safety, the Rice Packing Machine is set to become the go-to solution for rice producers looking to elevate their packaging operations. It is indeed a game-changer that will reshape the way rice is packaged and delivered to consumers, setting new standards for quality, efficiency, and reliability in the process.

Automatic Mini Portable Vacuum Sealer Machine for Food Preservation/Starter Kit with Led Indicator Lights and Sealer Bags

Moer Sky Launches Mini Portable Vacuum Sealer Machine for Food PreservationMoer Sky has announced the launch of its latest product, the Moer Sky Automatic Mini Portable Home Vacuum Sealer System. This innovative product offers a hassle-free solution for food storage and preservation, designed for home use. The vacuum sealer helps to keep food fresh for longer, preventing spoilage and food wastage. This newest addition to Moer Sky's product line comes with LED indicator lights, dual capacitance design, and 25 sealing bags to optimize the user experience.With its compact design, the Moer Sky Mini Vacuum Sealer Machine enables users to preserve different types of food items such as fruits, vegetables, meat, fish, and cooked meals, among others. The vacuum sealer removes air from the packaging, which in turn keeps food fresh 5-6 times longer than traditional storage methods. This makes the Moer Sky Mini Vacuum Sealer Machine a worthwhile investment, especially for those looking for a convenient and practical solution for preserving food at home.The Moer Sky Mini Vacuum Sealer Machine offers multiple benefits that justify its importance. Firstly, it helps to save time and money, which is invaluable to most homeowners. With the ability to keep food fresh longer, one can buy groceries in bulk and preserve them, preventing decay. The vacuum sealer ensures that the food is free from bacteria, eliminating the need for frequent trips to the store. This is even more relevant, given the current global pandemic, where minimizing contact with others is recommended.The vacuum sealer also ensures that homeowners can eat healthy at all times. Preserving fruits and vegetables for longer periods means that one can maintain a nutritious diet that is essential for good health. Cooking meals in advance and sealing them means that one can enjoy different types of dishes as and when they need them. Given the busy lives that most people lead, the Moer Sky Mini Vacuum Sealer Machine provides a hassle-free way of meal preparation and storage.The LED indicator lights on the vacuum sealer indicate when there's air pressure inside the sealing bags, indicating that the sealing process is complete. The dual capacitance design ensures that the sealing bags are always secure, ensuring that the food is always free from contamination. This feature also minimizes the risk of freezer burn, and the design allows for easy and effortless operations, ensuring that users of all ages can use it to preserve food.In conclusion, the Moer Sky Automatic Mini Portable Home Vacuum Sealer System is a remarkable addition to the market of food preservation machines. Its unique features and design make it a perfect investment for homeowners looking to reduce food wastage, save time and money, and maintain a healthy lifestyle. It offers an easy, efficient, and cost-effective way to preserve food while avoiding contamination. With the impending shortages that may arise in the food industry due to the ongoing pandemic, the Moer Sky Mini Vacuum Sealer Machine is a timely product that will offer peace of mind to homeowners. About the Company Moer Sky is a leading manufacturer of home and kitchen products. They pride themselves on innovation, creativity, and customer satisfaction. Moer Sky's vast product line includes kitchen appliances, home accessories, and other useful items that are designed to improve the quality of life for its customers. Moer Sky is committing to offering customers practical solutions to everyday problems. They are continually researching and developing new products to enhance the lives of their customers, and the Moer Sky Automatic Mini Portable Home Vacuum Sealer System is one of their recent inventions.

Advanced Skin Packaging Machine: A Game Changer in the Packaging Industry

Title: Cutting-Edge Skin Packaging Machine Revolutionizes Packaging IndustryIntroduction:In an era where efficient packaging solutions are paramount, the industry-leading company, whose name has been withheld, has unveiled its latest innovation in packaging technology to cater to the growing needs of businesses worldwide. The state-of-the-art Skin Packaging Machine introduces cutting-edge features that have the potential to revolutionize the packaging industry. With a relentless pursuit of innovation and commitment to excellence, the company aims to empower businesses with a packaging solution that is both efficient and visually appealing.Unveiling the Skin Packaging Machine:The recently unveiled Skin Packaging Machine promises to elevate the packaging process to new heights. By incorporating advanced technology and an ergonomic design, the machine aims to optimize efficiency, reduce labor costs, and enhance product preservation. This achievement is a testament to the company's dedication to staying at the forefront of the packaging industry by constantly creating solutions that address the evolving needs of businesses across various sectors.Advanced Features and Functionality:The Skin Packaging Machine, equipped with cutting-edge features, is designed to ensure precision packaging while maintaining the integrity of the products. The machine uses vacuum sealing technology to wrap products in a protective skin-tight film, increasing the shelf life of perishable goods and reducing the risk of damage during transportation. This innovative method also provides an airtight seal that protects against moisture, contaminants, and other external factors that could compromise product quality.The machine's user-friendly interface allows for seamless operation, ensuring that even operators with minimal training can efficiently handle the packaging process. Additionally, its versatility enables businesses to package a wide range of products such as perishable food items, delicate electronic devices, or even automotive parts, making it a valuable asset for manufacturers and wholesalers across various industries.Benefits for Businesses:The Skin Packaging Machine offers several benefits for businesses seeking to streamline their packaging operations. By reducing the need for excessive manual labor, it minimizes production costs, enhances productivity, and ultimately improves profitability. Its ability to preserve the freshness and quality of perishable products also enables businesses to extend their product shelf life, reducing waste and increasing customer satisfaction.The machine's sleek and professional packaging design not only protects the products but also enhances their presentation. This visually appealing packaging can significantly impact consumers' perception of the brand, making it more likely for them to choose the product over competitors.Commitment to Sustainability:In addition to its functional advantages, the Skin Packaging Machine aligns with the company's commitment to environmental sustainability. The machine utilizes eco-friendly materials, minimizing the impact on the environment and promoting a greener approach to packaging. By opting for this cutting-edge technology, businesses contribute to the reduction of plastic waste and demonstrate their dedication to sustainability and responsible manufacturing.Prospects and Future Developments:With its groundbreaking features and benefits, the Skin Packaging Machine presents significant opportunities for businesses to enhance their packaging processes. Its adaptability and user-friendliness position it as a long-term solution for packaging needs across diverse industries.Looking ahead, the company remains dedicated to further developments and improvements in packaging technology. Its research and development team continues to explore new ways to optimize the skin packaging process, introducing innovative features and functionalities that address the ever-changing demands of the market.Conclusion:The unveiling of the Skin Packaging Machine marks a significant milestone in the packaging industry, demonstrating the company's commitment to revolutionizing the way businesses package their products. Through its cutting-edge technology, user-friendly interface, and environmental sustainability, the machine offers businesses an efficient and visually appealing solution. As the industry evolves, the company's dedication to innovation ensures it remains at the forefront, continuously shaping the future of packaging.

Innovative Spices Packing Machine Revolutionizes Packaging Process

The demand for spices packing machines has been on the rise in recent years due to the increasing popularity of packaged spices in the market. Spices packing machines are used to efficiently pack various spices such as turmeric, coriander, cumin, and chili powder, among others, into pouches or containers, thereby increasing the production capacity and reducing manual labor.With the growing demand for spices packing machines, {Company Name} has emerged as a leading manufacturer and supplier of high-quality packaging machines for the spice industry. Established in {year}, {Company Name} has garnered a strong reputation for delivering reliable and efficient packaging solutions to its customers worldwide.The {Company Name} spices packing machine is designed to meet the specific requirements of the spice industry. It is equipped with advanced technology that ensures accurate weighing, filling, and sealing of spice pouches at a high speed. The machine is capable of handling a wide variety of spices and can be customized to accommodate different packaging sizes and formats.One of the key features of the {Company Name} spices packing machine is its user-friendly interface, which allows operators to easily control and monitor the packaging process. The machine also incorporates safety measures to ensure the protection of workers and the integrity of the packaged spices.In addition to its advanced technology, {Company Name} is committed to providing exceptional customer service and support. The company offers comprehensive training and technical assistance to its clients to ensure the smooth operation and maintenance of the spices packing machine. Furthermore, {Company Name} has a dedicated team of experts who are readily available to address any inquiries or issues related to the packaging equipment.Furthermore, {Company Name} takes pride in its environmentally friendly approach to manufacturing packaging machines. The company emphasizes the use of sustainable and energy-efficient practices in its production processes, thereby contributing to a greener and healthier environment."Customer satisfaction and product quality are our top priorities," says {Spokesperson}, the CEO of {Company Name}. "We are constantly innovating and improving our packaging solutions to meet the evolving needs of the spice industry. Our spices packing machine is a testament to our commitment to delivering superior performance and reliability."The {Company Name} spices packing machine has received accolades from customers for its efficiency, durability, and cost-effectiveness. Its ability to streamline the packaging process and improve productivity has made it a sought-after choice among spice manufacturers and suppliers.As the demand for packaged spices continues to grow, {Company Name} remains at the forefront of providing cutting-edge packaging solutions to meet the industry's requirements. With its unwavering dedication to excellence, {Company Name} is poised to continue its success in delivering top-notch spices packing machines to customers around the globe.

Boost Your Packaging Efficiency with a Top-notch Case Sealer Machine

Innovative Case Sealer Machine Revolutionizes Packaging Industry[Company Name], a leading provider of cutting-edge packaging solutions, has recently unveiled its latest innovation, a state-of-the-art Case Sealer Machine. This revolutionary piece of equipment is set to transform the packaging industry with its advanced features and unparalleled efficiency.With globalization and e-commerce on the rise, the demand for effective packaging solutions has never been higher. Companies are constantly searching for ways to streamline their packaging processes, reduce costs, and enhance efficiency. Recognizing this need, [Company Name] took on the challenge of developing a Case Sealer Machine that would revolutionize the way products are packaged.The new Case Sealer Machine is equipped with cutting-edge technology, providing automated sealing capabilities that surpass traditional methods. It features a sleek design, combining aesthetics with functionality, and is capable of sealing cases of various sizes and formats. This versatility enables businesses to package a wide range of products effectively, regardless of their dimensions.One of the standout features of the Case Sealer Machine is its intelligent control system, which ensures precise and consistent sealing of every case. The machine is programmed to detect the dimensions of each case and automatically adjust its settings accordingly, eliminating the need for any manual intervention. This level of automation significantly reduces the risk of errors, saving time and resources for companies.In addition, the Case Sealer Machine boasts a high-speed sealing capability, guaranteeing swift and efficient packaging operations. With its advanced motor technology and optimized mechanisms, the machine is capable of sealing cases at an astounding rate. This ensures that businesses can meet high-volume packaging demands without compromising on quality or speed.Furthermore, the Case Sealer Machine is designed with user-friendliness in mind. Its intuitive interface allows operators to easily control and monitor the packaging process, ensuring smooth operations and quick troubleshooting. The machine is also equipped with safety features, such as emergency stop buttons and sensors, to prioritize the well-being of operators and prevent accidents.[Company Name] takes great pride in its commitment to sustainability. Therefore, the Case Sealer Machine is engineered to minimize environmental impact. It utilizes energy-efficient components, reducing power consumption without compromising on performance. Additionally, the machine is designed to optimize material usage and minimize waste, promoting eco-friendly packaging practices.With the introduction of the Case Sealer Machine, [Company Name] aims to revolutionize the packaging industry by offering a comprehensive and efficient solution for businesses worldwide. The advanced features and cutting-edge technology of this machine ensure that packaging processes are streamlined, saving both time and resources. By automating the sealing process, companies can achieve higher productivity levels and enhance their overall operational efficiency.The Case Sealer Machine is adaptable to various industries, including food and beverages, pharmaceuticals, e-commerce, and manufacturing. Its versatility and precision make it the go-to choice for businesses seeking to optimize their packaging operations without compromising on quality.[Company Name] has always been at the forefront of innovation in the packaging industry. With the introduction of the game-changing Case Sealer Machine, the company continues to drive progress and set new standards. This revolutionary equipment is poised to transform the way products are packaged and positioned [Company Name] as a leader in the market.As the global packaging industry continues to evolve, businesses must adapt to remain competitive. With the innovative Case Sealer Machine from [Company Name], companies can stay ahead of the curve by streamlining their packaging processes, reducing costs, and ultimately delivering products to market faster and more efficiently than ever before.