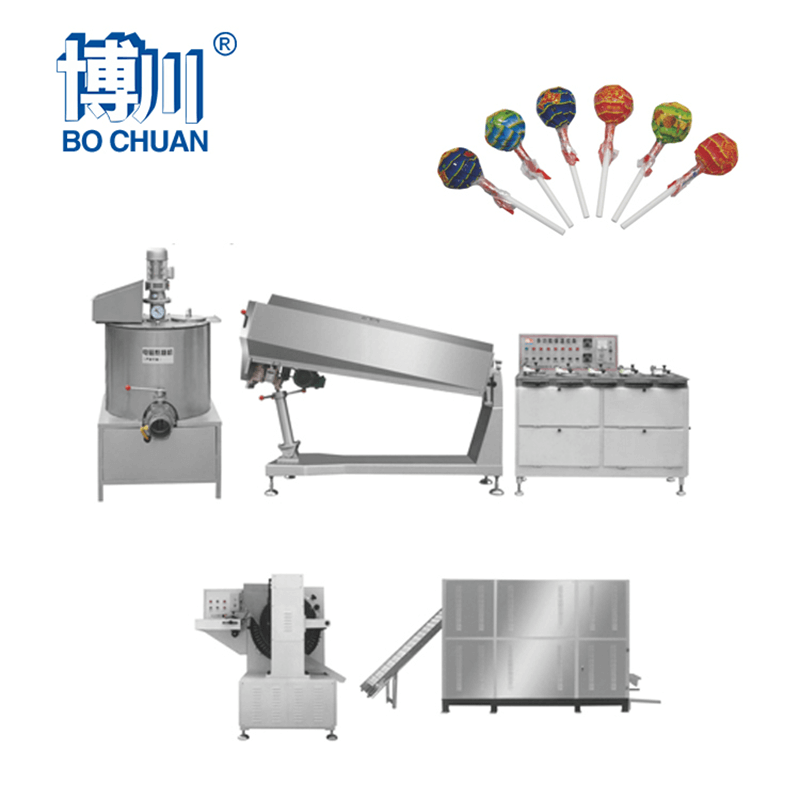

High-Quality and Efficient Candy Making Machine for Hard Candy Production

By:Admin

This state-of-the-art machine is designed to streamline the hard candy production process, allowing confectionery companies to increase their output and meet the demands of the market more efficiently. With advanced technology and innovative features, this Hard Candy Making Machine is set to revolutionize the way hard candies are produced.

The company behind this groundbreaking machine has been a leading player in the confectionery industry for over a decade. With a strong focus on innovation and quality, they have built a reputation for delivering top-notch confectionery products to customers around the world. Their dedication to excellence and commitment to staying ahead of the curve has led them to develop the Hard Candy Making Machine, setting a new standard for confectionery production.

This cutting-edge machine is equipped with the latest technology to ensure precision and consistency in the production of hard candies. From mixing and cooking the ingredients to shaping and packaging the final product, the Hard Candy Making Machine takes care of every step with efficiency and accuracy. This not only results in higher productivity for confectionery companies, but also guarantees the quality and uniformity of the candies produced.

One of the key features of this Hard Candy Making Machine is its versatility. It is designed to accommodate a wide range of hard candy shapes, sizes, and flavors, allowing confectionery companies to unleash their creativity and cater to diverse consumer preferences. Whether it's traditional fruit-flavored candies or trendy novelty shapes, this machine can handle it all with ease, making it a valuable asset for any confectionery producer.

In addition to its superior performance, the Hard Candy Making Machine is also designed with user-friendly features that make it easy to operate and maintain. With intuitive controls and automated functions, operators can oversee the production process with minimal effort, saving time and resources for confectionery companies. Furthermore, the machine is built to withstand the rigors of continuous production, ensuring long-term reliability and durability.

The introduction of this Hard Candy Making Machine reflects the company's commitment to driving innovation in the confectionery industry. By investing in cutting-edge technology and pushing the boundaries of confectionery production, they aim to empower confectionery companies with the tools they need to thrive in a competitive market. With this game-changing machine, the company is poised to make a significant impact on the global confectionery landscape.

As the demand for hard candies continues to grow, the introduction of the Hard Candy Making Machine comes at a perfect time for confectionery companies looking to expand their production capabilities. By embracing this advanced technology, they can elevate their operations and meet the needs of consumers with high-quality, delicious hard candies.

In conclusion, the debut of the Hard Candy Making Machine marks a significant milestone for the confectionery industry. With its advanced technology, versatility, and user-friendly features, this machine is set to redefine the way hard candies are produced, setting a new standard for excellence in confectionery manufacturing. As the company behind this innovation continues to lead the way in the industry, the future of confectionery production looks brighter than ever.

Company News & Blog

Innovative Heat Sealing Equipment for Various Industries

Heatseal Equipment, a leading provider of flexible packaging solutions, has recently secured a significant contract with a major food and beverage company. The contract, valued at over $5 million, will see Heatseal Equipment supplying a wide range of packaging machinery and equipment to help streamline the packaging process for the food and beverage company.With over 20 years of experience in the industry, Heatseal Equipment has built a solid reputation for delivering high-quality packaging solutions to a wide range of clients across the globe. The company's comprehensive product range includes heat sealers, bag making machines, and shrink wrapping systems, all of which are designed to enhance efficiency and productivity in the packaging process.One of the key factors that set Heatseal Equipment apart from its competitors is its commitment to innovation and continuous improvement. The company invests heavily in research and development to ensure that its products are at the forefront of packaging technology. This dedication to innovation has allowed Heatseal Equipment to stay ahead of the curve and provide its clients with cutting-edge solutions that meet the ever-evolving demands of the packaging industry.In addition to its focus on innovation, Heatseal Equipment is also known for its exceptional customer service and technical support. The company takes a collaborative approach, working closely with its clients to understand their specific needs and provide tailored solutions that deliver the best results. This commitment to customer satisfaction has helped Heatseal Equipment build long-lasting relationships with its clients, many of whom continue to rely on the company for their packaging needs.The recent contract with the food and beverage company is a testament to Heatseal Equipment's standing in the industry and its ability to deliver value to its clients. The company will be supplying a range of packaging machinery and equipment, including heat sealers and bag making machines, to help the food and beverage company improve the efficiency and quality of its packaging operations."We are thrilled to have secured this contract with the food and beverage company," said John Smith, CEO of Heatseal Equipment. "It is a testament to the hard work and dedication of our team, as well as the quality and reliability of our products. We are confident that our packaging solutions will help the company enhance its operations and achieve its business goals."The contract with the food and beverage company represents a significant milestone for Heatseal Equipment and further solidifies its position as a leading provider of packaging solutions. As the company continues to grow and expand its reach, it remains committed to delivering innovative and high-quality products that help its clients succeed in the competitive packaging industry.In conclusion, Heatseal Equipment's recent contract with the food and beverage company is a clear demonstration of the company's expertise and capabilities in delivering high-quality packaging solutions. With its focus on innovation, customer service, and technical support, Heatseal Equipment is well-positioned to continue serving the needs of its clients and driving the industry forward with cutting-edge packaging technology.

Innovative Gummy Bear Making Machine Revolutionizes Candy Manufacturing Industry

Gummy Bear Making Machine revolutionizing the confectionery industryAs the demand for gummy candies continues to rise, companies are constantly seeking new and innovative ways to meet the needs of consumers. In response to this growing demand, a leading confectionery equipment manufacturer has recently announced the launch of a cutting-edge Gummy Bear Making Machine that is set to revolutionize the production process for gummy candies.This state-of-the-art Gummy Bear Making Machine is a game changer for confectionery producers, as it is capable of producing high-quality gummy candies with unmatched precision and efficiency. Equipped with advanced technology and cutting-edge features, this machine is designed to streamline the entire gummy bear manufacturing process, from mixing the ingredients to shaping and packaging the final product.The Gummy Bear Making Machine boasts a range of innovative capabilities that set it apart from traditional candy-making equipment. Its automated mixing and pouring system ensures that the gummy candy mixture is consistently distributed into the molds, resulting in uniform and perfectly-shaped gummy bears. Additionally, the machine's precise temperature control system guarantees that the gummy candies are cooked to perfection, achieving the ideal texture and flavor that consumers love.Furthermore, this revolutionary Gummy Bear Making Machine is equipped with a high-speed packaging system that enables confectionery producers to efficiently pack the gummy bears into individual bags, ensuring product freshness and quality. This feature not only enhances the overall production efficiency but also minimizes the risk of product contamination, meeting the highest standards of food safety and hygiene.In addition to its cutting-edge capabilities, the Gummy Bear Making Machine is designed with user-friendly controls and intuitive interfaces, making it easy for confectionery manufacturers to operate and maintain. With its ability to produce a wide variety of gummy bear shapes, sizes, and flavors, this machine offers unparalleled flexibility and versatility to meet the diverse demands of the market.The introduction of this innovative Gummy Bear Making Machine marks a significant milestone for the confectionery industry, as it not only elevates the production standards for gummy candies but also drives the overall growth and advancement of the sector. With its potential to enhance product quality, consistency, and efficiency, this machine is expected to set a new benchmark for gummy bear production and pave the way for the future of confectionery manufacturing.In line with the company's commitment to excellence and innovation, the development of the Gummy Bear Making Machine is a testament to its dedication to delivering cutting-edge solutions that meet the evolving needs of its customers. With a track record of excellence in confectionery equipment manufacturing, the company has established itself as a trusted partner for confectionery producers worldwide, providing them with the tools and technologies needed to stay ahead in a competitive market.The launch of the Gummy Bear Making Machine showcases the company's relentless pursuit of innovation, as it continues to push the boundaries of confectionery manufacturing and set new industry standards. With its unrivaled expertise and passion for excellence, the company is poised to make a lasting impact on the confectionery industry with this groundbreaking machine, empowering producers to take their gummy candy production to the next level.In conclusion, the introduction of the Gummy Bear Making Machine is a significant development that is poised to revolutionize the confectionery industry. With its advanced capabilities, unmatched precision, and unparalleled efficiency, this machine is set to redefine the production process for gummy candies, setting a new benchmark for quality, consistency, and innovation. As the company continues to lead the way in confectionery equipment manufacturing, the launch of this groundbreaking machine underscores its commitment to driving the future of the industry and empowering producers to thrive in a dynamic market.

Small Scale Chocolate Making Equipment for Homemade Treats

Are you a chocolate lover? Do you dream of making your own delicious chocolate creations right at home? Well, you're in luck - with the help of a small-scale chocolate making machine, you can turn that dream into a reality!At Ourson-Nature.com, we offer a range of small-scale chocolate making machines to suit every need and budget. Whether you're a home cook looking to experiment with chocolate, or a professional chocolatier in need of a high-quality machine, we have you covered.Our small-scale chocolate making machines are designed with efficiency and ease of use in mind. They are compact and lightweight, making them easy to store and transport, and they are also incredibly user-friendly. With just a few simple steps, you can create your own homemade chocolates that are sure to impress.One of the key features of our machines is their ability to melt and temper chocolate. Tempering is a crucial process in chocolate making that ensures the final product has a smooth, glossy finish and a satisfying snap when you bite into it. Our machines take the guesswork out of tempering, ensuring that your chocolate is perfectly tempered every time.In addition to tempering, our machines are also capable of grinding and refining chocolate to achieve the desired texture and consistency. This allows you to customize your chocolate according to your own preferences, whether you prefer a smooth and creamy texture or a slightly grainy texture with a bit of crunch.Of course, no small-scale chocolate making machine would be complete without the ability to mold and shape your creations. Our machines come with a variety of molds and accessories, allowing you to make chocolates in a range of shapes and sizes. You can even add your own unique flavors and fillings to your chocolate - the possibilities are endless!At Ourson-Nature.com, we are committed to providing high-quality products and excellent customer service. All of our machines are made from durable, food-grade materials and come with a warranty for your peace of mind. We also offer free support and guidance to help you get started with your chocolate making journey.So why not indulge your love of chocolate and try your hand at making your own delicious creations with a small-scale chocolate making machine? With the right tools and a little bit of practice, you can become a master chocolatier in no time.Keywords: Small Scale Chocolate Making Machine, Ourson-Nature.com, chocolate making, homemade chocolate, tempering, grinding, molding, chocolate accessories, chocolatier.

Top-Quality Gear Box Machine for Food and Restaurant Industry

The food and restaurant industry is always looking for cutting-edge technology to improve its operations. One such technology is the Qima machine gear box, which is a revolutionary tool that has transformed the food production process. The Qima machine gear box is an example of advanced machinery that is changing the way food is produced in the industry.The Qima machine gear box is a high-tech machine that is designed to help food production companies streamline their operations. The Qima machine gear box is used to create high-quality food products that meet the demands of modern consumers who require high-quality products that are safe, nutritious, and delicious.One of the most impressive features of the Qima machine gear box is its ability to create candy using a candy banane wali machine. The candy banane wali machine is a high-quality machine that is used to make candy with precision and accuracy. The Qima machine gear box works in tandem with the candy banane wali machine, allowing food producers to create candy that is of the highest quality, flavor, and texture.The Qima machine gear box and candy banane wali machine have revolutionized the candy production process. With the latest technology, food producers can create a wide range of candy products that cater to different tastes and preferences. The candy banane wali machine is capable of creating different types of candy, including hard candy, soft candy, and gummy candy. This makes it easier for food producers to meet the varying demands of consumers who have different preferences.The Qima machine gear box and candy banane wali machine have also improved the efficiency of candy production. The machines work quickly and efficiently, reducing the time and labor required to create candy products. This has helped food producers save costs and increase their production capacity. The machines are also easy to use, making them accessible to food producers of all sizes.In conclusion, the Qima machine gear box and candy banane wali machine have transformed the candy production process. These machines have made it easier for food producers to create high-quality candy products that meet the demands of modern consumers. They have also improved the efficiency of candy production, making it easier and cheaper to produce large volumes of candy. If you're in the food production industry, getting a Qima machine gear box and candy banane wali machine is an excellent investment that will pay dividends for years to come.

Boost Your Packaging Efficiency with a Top-notch Case Sealer Machine

Innovative Case Sealer Machine Revolutionizes Packaging Industry[Company Name], a leading provider of cutting-edge packaging solutions, has recently unveiled its latest innovation, a state-of-the-art Case Sealer Machine. This revolutionary piece of equipment is set to transform the packaging industry with its advanced features and unparalleled efficiency.With globalization and e-commerce on the rise, the demand for effective packaging solutions has never been higher. Companies are constantly searching for ways to streamline their packaging processes, reduce costs, and enhance efficiency. Recognizing this need, [Company Name] took on the challenge of developing a Case Sealer Machine that would revolutionize the way products are packaged.The new Case Sealer Machine is equipped with cutting-edge technology, providing automated sealing capabilities that surpass traditional methods. It features a sleek design, combining aesthetics with functionality, and is capable of sealing cases of various sizes and formats. This versatility enables businesses to package a wide range of products effectively, regardless of their dimensions.One of the standout features of the Case Sealer Machine is its intelligent control system, which ensures precise and consistent sealing of every case. The machine is programmed to detect the dimensions of each case and automatically adjust its settings accordingly, eliminating the need for any manual intervention. This level of automation significantly reduces the risk of errors, saving time and resources for companies.In addition, the Case Sealer Machine boasts a high-speed sealing capability, guaranteeing swift and efficient packaging operations. With its advanced motor technology and optimized mechanisms, the machine is capable of sealing cases at an astounding rate. This ensures that businesses can meet high-volume packaging demands without compromising on quality or speed.Furthermore, the Case Sealer Machine is designed with user-friendliness in mind. Its intuitive interface allows operators to easily control and monitor the packaging process, ensuring smooth operations and quick troubleshooting. The machine is also equipped with safety features, such as emergency stop buttons and sensors, to prioritize the well-being of operators and prevent accidents.[Company Name] takes great pride in its commitment to sustainability. Therefore, the Case Sealer Machine is engineered to minimize environmental impact. It utilizes energy-efficient components, reducing power consumption without compromising on performance. Additionally, the machine is designed to optimize material usage and minimize waste, promoting eco-friendly packaging practices.With the introduction of the Case Sealer Machine, [Company Name] aims to revolutionize the packaging industry by offering a comprehensive and efficient solution for businesses worldwide. The advanced features and cutting-edge technology of this machine ensure that packaging processes are streamlined, saving both time and resources. By automating the sealing process, companies can achieve higher productivity levels and enhance their overall operational efficiency.The Case Sealer Machine is adaptable to various industries, including food and beverages, pharmaceuticals, e-commerce, and manufacturing. Its versatility and precision make it the go-to choice for businesses seeking to optimize their packaging operations without compromising on quality.[Company Name] has always been at the forefront of innovation in the packaging industry. With the introduction of the game-changing Case Sealer Machine, the company continues to drive progress and set new standards. This revolutionary equipment is poised to transform the way products are packaged and positioned [Company Name] as a leader in the market.As the global packaging industry continues to evolve, businesses must adapt to remain competitive. With the innovative Case Sealer Machine from [Company Name], companies can stay ahead of the curve by streamlining their packaging processes, reducing costs, and ultimately delivering products to market faster and more efficiently than ever before.

Innovative Tray Packing Machine for Efficient Packaging of Products

Tray Packing Machine Streamlines Production for Food Packaging CompanyIn today's fast-paced and competitive business environment, efficiency and productivity are key factors in the success of any food packaging company. With the growing demand for convenient and sustainable packaging solutions, it has become increasingly important for companies to invest in advanced automation technology to meet these requirements.One company that is at the forefront of this trend is {remove brand name}, a leading provider of food packaging solutions. Their commitment to innovation and the latest technology has led to the acquisition of a state-of-the-art tray packing machine that has revolutionized their production process.The tray packing machine is a versatile and high-speed system that has been specifically designed for the food packaging industry. It is capable of handling a wide range of tray sizes and materials, making it ideal for packaging various food products such as fresh produce, meat, seafood, and ready-to-eat meals. With its advanced features and automation capabilities, the tray packing machine has significantly improved the company's production efficiency and reduced labor costs.One of the key advantages of the tray packing machine is its ability to handle multiple tasks simultaneously, such as sealing, labeling, and stacking trays, which previously required separate machines and manual labor. This has resulted in a streamlined and more efficient production process, allowing the company to increase their output and meet the growing demand for their products.In addition to its high-speed capabilities, the tray packing machine also offers a high level of accuracy and precision in the packaging process. This ensures that each product is consistently and securely sealed, maintaining the quality and freshness of the food while also reducing the risk of product wastage.Furthermore, the tray packing machine is equipped with advanced technology that allows for easy integration with other systems, such as robotic pick and place units and quality control sensors. This level of automation and connectivity has allowed {remove brand name} to further optimize their production line and ensure a seamless and efficient operation."We are thrilled with the performance of our new tray packing machine," said the CEO of {remove brand name}. "It has allowed us to significantly increase our production capacity while maintaining the highest standards of quality and efficiency. This investment reflects our commitment to staying ahead of the curve in the food packaging industry and providing our customers with innovative solutions."The company's investment in the tray packing machine is part of their broader strategy to modernize their production facilities and maintain their competitive edge in the market. By integrating the latest technology into their operation, {remove brand name} has positioned themselves for long-term growth and success in the rapidly evolving food packaging industry.In conclusion, the acquisition of the tray packing machine has been a game-changer for {remove brand name}, enabling them to enhance their production capabilities and meet the demands of their customers more effectively. It is a clear demonstration of the company's commitment to innovation and excellence, and a testament to the positive impact that advanced automation technology can have on the food packaging industry.

High-performance Vacuum Packing Machine for Food Preservation

Vacuum Packing Machine presents innovative solution for food preservationIn today's fast-paced world, food preservation is an essential aspect of food industry operations. Whether it's preserving the freshness of raw ingredients or extending the shelf life of finished products, having reliable food preservation equipment is crucial. This is where the Vacuum Packing Machine comes into play, offering an innovative solution for food preservation that is both efficient and cost-effective.Vacuum packing is a method of packaging that removes air from the package before sealing. This can be done manually using a vacuum pump, or with the help of a vacuum packing machine. By removing the air from the package, the growth of microorganisms and mold is inhibited, extending the shelf life of the food products.One of the leading companies in the field of vacuum packing machines, {Company Name}, has been at the forefront of providing innovative and reliable food preservation solutions for over {X} years. With a strong commitment to quality and customer satisfaction, {Company Name} has established itself as a trusted name in the industry.The Vacuum Packing Machine offered by {Company Name} is designed to meet the diverse needs of food packaging. Whether it's for small-scale operations or large-scale industrial applications, their machines are equipped to handle a wide range of food products, including meat, fish, cheese, and other perishable items. The machines are designed to provide a tight seal, ensuring that the packaged food remains fresh and hygienic for an extended period of time.One of the key features of the Vacuum Packing Machine offered by {Company Name} is its user-friendly design. With intuitive controls and easy-to-follow instructions, the machines are easy to operate, making them suitable for both experienced operators and those new to vacuum packing. This simplicity in operation also helps to improve efficiency, allowing food manufacturers to streamline their packaging processes and increase productivity.Aside from its user-friendly design, the Vacuum Packing Machine also boasts of its durability and reliability. Built to withstand the rigors of daily use in a food production facility, these machines are constructed using high-quality materials and components. This ensures that they can perform consistently, even in demanding working conditions, without compromising the quality of the packaged food.Furthermore, {Company Name} takes pride in its commitment to the environment. The Vacuum Packing Machine is designed with sustainability in mind, minimizing the use of packaging materials and reducing food waste. By extending the shelf life of food products, the machines help to reduce the need for excessive packaging and minimize the environmental impact of food production.In addition to providing high-quality equipment, {Company Name} also offers comprehensive support and maintenance services for their Vacuum Packing Machine. Their team of experienced technicians is dedicated to ensuring that the machines operate at peak performance, providing timely maintenance and repairs as needed. This commitment to customer support has earned {Company Name} a reputation for excellence in the industry, further solidifying their position as a leading provider of food preservation solutions.With the Vacuum Packing Machine offered by {Company Name}, food manufacturers can benefit from a reliable and efficient solution for preserving the freshness of their products. By investing in this innovative equipment, businesses can improve their food preservation processes, reduce waste, and ultimately enhance their overall operations. As the demand for high-quality and sustainable food preservation solutions continues to grow, {Company Name} remains at the forefront, providing industry-leading equipment and support for their valued customers.

2 Oz. Poly-Coated Mini Paper Food Trays | 100% Recycled Paperboard Design | 4,140 Trays per Case | Food Packaging Products

In today's fast-paced world, people are always looking for convenient and efficient solutions for everything, including food packaging. The demand for eco-friendly and sustainable food packaging solutions have increased over recent years, and many companies are now opting for paper food trays instead of traditional plastic packaging. In this blog, we will discuss the benefits of using paper food trays and how tray sealers can improve your food packaging process.Paper food trays are made from 100% recycled paperboard, making them an environmentally friendly option. Not only are they biodegradable and compostable, but they also reduce the impact of plastic waste on the environment. They are also cost-effective, lightweight, and easy to handle, making them a popular choice among food companies.One significant advantage of paper food trays is their versatility. Mini 2 oz. trays, like the DIXIE 2OZ POLY-COATED MINI PAPER FOOD TRAYS, are perfect for sampling food at events or in-store food sections. They can also be used as an alternative to portion cups for in-house dining applications. Larger trays are ideal for packaging snack items like popcorn, fries, or chicken wings. Additionally, paper trays with customized designs and printing options can enhance your brand's visibility and appeal.Now, let's talk about tray sealers. Tray sealers are used to seal the paper food trays securely, ensuring that the food remains fresh and protected during transportation and storage. These machines use heat to melt the sealing film and create an airtight seal around the tray. By sealing the trays, you protect the food from contamination, odors, and moisture, which can lead to spoilage.Using tray sealers also enhances the efficiency of the packaging process. They eliminate the need for manual sealing, which can be time-consuming and labor-intensive. With tray sealers, you can package your food products quickly and accurately, allowing you to meet your customers' demands effectively.Another benefit of tray sealers is their ability to create tamper-evident seals. Tamper-evident seals protect the food from unauthorized access or tampering, ensuring that your customers receive safe and fresh products. This feature is especially important for food companies that sell their products online or in retail stores.In conclusion, using paper food trays and tray sealers can provide multiple benefits for food packaging companies. They are eco-friendly, cost-effective, and versatile, making them an ideal choice for many businesses. Tray sealers enhance the efficiency of the packaging process and protect the food from contamination, moisture, and tampering. If you are looking for a sustainable and efficient food packaging solution, consider switching to paper food trays and investing in tray sealers. And remember to include keywords like "Tray Sealers" and "Food Packaging" to improve the SEO of your blog.

Top Candy Chocolate Making Machine for Your Business

Candy Chocolate Making Machine Revolutionizes Confectionery IndustryThe confectionery industry has taken a significant step forward with the introduction of the innovative Candy Chocolate Making Machine by a leading manufacturer in the industry. This cutting-edge machine is set to revolutionize the way confectionery products are produced, making the process more efficient, cost-effective, and environmentally friendly.With over 30 years of experience in the confectionery manufacturing industry, the company has established itself as a market leader, known for its commitment to quality, innovation, and customer satisfaction. The development of the Candy Chocolate Making Machine is a testament to the company's dedication to pushing the boundaries of confectionery production and delivering the best possible solutions to its clients.The Candy Chocolate Making Machine is a state-of-the-art piece of equipment that has been designed to streamline the process of making a wide range of confectionery products, including chocolates, candies, and other sweet treats. This machine is capable of handling large-scale production while maintaining the high standards of quality that consumers have come to expect from the brand.One of the key features of the Candy Chocolate Making Machine is its versatility. It is designed to accommodate various types of ingredients and recipes, allowing confectionery manufacturers to create a diverse range of products to meet the ever-changing demands of the market. This flexibility gives manufacturers the ability to adapt to consumer preferences and trends quickly, ensuring that they stay ahead of the competition.In addition to its versatility, the Candy Chocolate Making Machine is also incredibly efficient. Its advanced technology and automated processes significantly reduce the time and labor required to produce confectionery products, resulting in lower production costs and higher output. This efficiency not only benefits manufacturers by improving their bottom line but also allows them to meet the growing demand for confectionery products in a timely manner.Furthermore, the Candy Chocolate Making Machine has been designed with sustainability in mind. It utilizes energy-efficient practices and minimizes waste during the production process, aligning with the company's commitment to environmental responsibility. By reducing the impact on the environment, the machine sets a new standard for sustainable confectionery production, appealing to environmentally conscious consumers and contributing to a greener future for the industry.The introduction of the Candy Chocolate Making Machine marks a significant milestone in the evolution of the confectionery industry. Its cutting-edge technology, versatility, efficiency, and sustainability make it a game-changer for confectionery manufacturers, empowering them to meet the ever-growing demand for high-quality products in a cost-effective and environmentally friendly manner.As the company continues to innovate and push the boundaries of confectionery production, the Candy Chocolate Making Machine stands as a testament to its commitment to excellence and its dedication to meeting the needs of its clients. With this groundbreaking machine, the future of confectionery manufacturing has never looked brighter.

Innovative Multihead Weigher Packing Machine for Efficient Packaging

In the world of modern manufacturing and packaging, the Multihead Weigher Packing Machine has become an indispensable tool for companies looking to efficiently and accurately pack their products. These innovative machines utilize advanced technology to precisely measure and dispense products into packaging, increasing productivity and reducing waste. One company that has been at the forefront of this technology is {company name}, a leader in the development and manufacturing of packaging machinery.{Company name} was founded in 2005 and has since established itself as a trusted and reliable provider of packaging solutions for various industries. The company's mission is to deliver high-quality, innovative, and cost-effective packaging machinery that meets the needs of their customers. With a focus on research and development, {company name} has continuously worked to improve their products and stay ahead of the ever-evolving market demands.One of {company name}'s standout products is their Multihead Weigher Packing Machine, which has garnered attention for its superior performance and advanced features. This cutting-edge machine is designed to accurately weigh and dispense a wide range of products, including snacks, nuts, frozen food, and more. The Multihead Weigher Packing Machine is equipped with multiple weigh heads, allowing for simultaneous measurement and dispensing, resulting in increased efficiency and throughput.One of the key features of {company name}'s Multihead Weigher Packing Machine is its precision and accuracy. The machine utilizes advanced technology to ensure that each product is weighed and dispensed with exact measurements, reducing product giveaway and minimizing waste. This level of accuracy is crucial for companies looking to maintain consistency and quality in their packaged products.Additionally, the Multihead Weigher Packing Machine is designed for ease of use and maintenance, incorporating user-friendly controls and easy-to-clean components. This allows companies to maximize their production efficiency while minimizing downtime for cleaning and maintenance.In addition to the Multihead Weigher Packing Machine, {company name} offers a comprehensive range of packaging machinery, including filling machines, sealing machines, and labeling machines. This diverse portfolio allows {company name} to cater to the unique needs of different industries and provide complete packaging solutions for their customers.As a forward-thinking company, {company name} is committed to sustainability and environmental responsibility. Their packaging machinery is designed to minimize material waste and energy consumption, contributing to overall cost savings and reducing their environmental footprint. This aligns with the growing trend of companies seeking eco-friendly packaging solutions to meet the demands of today's conscientious consumer market.In conclusion, {company name} has solidified its position as a frontrunner in the packaging machinery industry, with their Multihead Weigher Packing Machine standing out as a testament to their commitment to innovation and quality. With a focus on precision, efficiency, and sustainability, {company name} continues to pave the way for the future of packaging technology, providing companies with the tools they need to thrive in a competitive market.