Compact Packaging Machine for Small Businesses

By:Admin

In today's fast-paced and ever-changing world, the need for efficient and effective packaging solutions has never been greater. With the rise of e-commerce and the increasing demand for convenient, on-the-go products, companies are constantly seeking ways to streamline their packaging processes. The introduction of the Small Packaging Machine by {Company Name} is set to revolutionize the industry and provide a much-needed solution for businesses looking to optimize their operations.

{Company Name} is a leading manufacturer of innovative packaging solutions, with a strong focus on providing high-quality and cost-effective products for businesses of all sizes. With a dedication to research and development, {Company Name} has continuously pushed the boundaries of packaging technology, and the Small Packaging Machine is a testament to their commitment to excellence.

This cutting-edge machine is designed to provide businesses with a compact and efficient packaging solution that is tailored to their specific needs. With its small footprint and versatile capabilities, the Small Packaging Machine is suitable for a wide range of industries, including food and beverage, pharmaceuticals, cosmetics, and more. From sealing and labeling to filling and capping, this machine is able to streamline the entire packaging process, saving businesses time and money.

One of the key features of the Small Packaging Machine is its user-friendly interface, which allows businesses to easily customize their packaging settings and monitor the entire process in real-time. This level of control and flexibility is invaluable for businesses looking to adapt to changing market demands and streamline their operations.

Additionally, the Small Packaging Machine is built with durability and reliability in mind, ensuring that businesses can rely on it for continuous and consistent performance. With minimal maintenance requirements and a strong focus on efficiency, this machine is a long-term investment that will provide businesses with a substantial return on their investment.

{Company Name} has also placed a strong emphasis on sustainability in the development of the Small Packaging Machine. By incorporating eco-friendly materials and energy-efficient technology, this machine not only helps businesses reduce their environmental impact but also provides them with a competitive edge in today's eco-conscious market.

The Small Packaging Machine is also backed by {Company Name}'s exceptional customer support and service, ensuring that businesses can rely on prompt assistance and technical expertise whenever they need it. This level of commitment to customer satisfaction sets {Company Name} apart as a trusted partner in the industry.

The introduction of the Small Packaging Machine by {Company Name} marks a significant milestone in the packaging industry, providing businesses with a game-changing solution that is tailored to their needs. With its compact design, versatile capabilities, and focus on sustainability, this machine is set to revolutionize the way businesses approach packaging, and establish {Company Name} as a leading provider of cutting-edge packaging solutions.

Company News & Blog

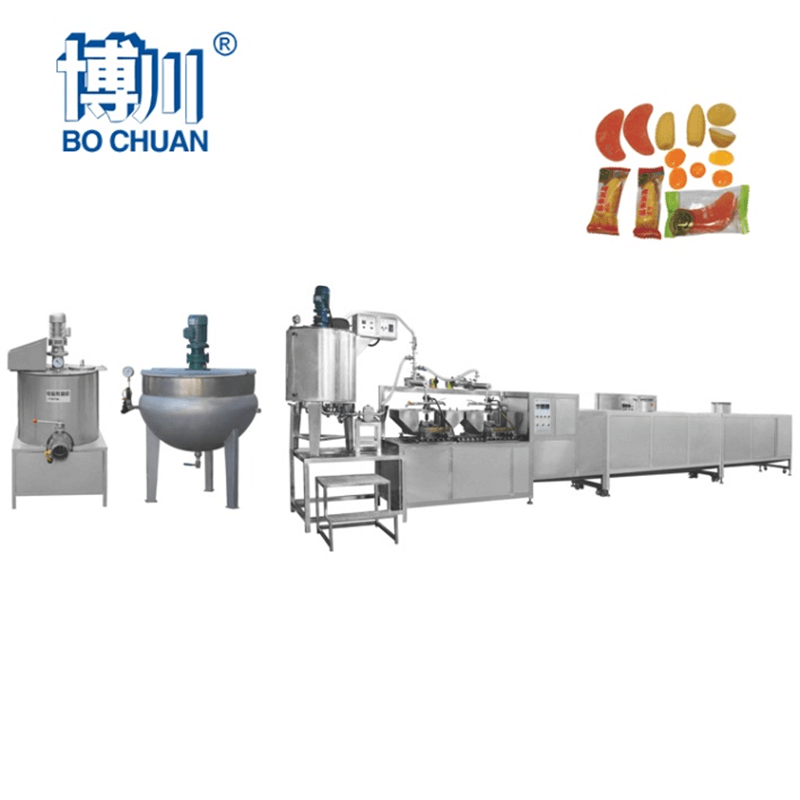

Get Your Own Candy Production Line and Gummy Making Machine Online

Candies and sweets have been an all-time favorite for everyone regardless of age. Over the years, the demand for these treats has increased, and the production rate has risen with it. Sweet Bear Candy and Snack Jelly Gummy Candy are two of the most renowned brands in the market today. These brands are famous for their delicious and unique sweets and candies, and they are manufactured using high-quality equipment such as the Sweet Bear Candy Production Line and Snack Jelly Gummy Candy Making Machine.These machines have revolutionized the production of sweets and candies. They have provided a faster, more efficient, and cost-friendly approach to yield various types of candies. Sweet Bear Candy Production Line is an industrial-grade candy-making machine that creates a wide range of candies. The machine can produce up to 300kg of candy per hour, and it comes with different molds for shaping the candies into various shapes and sizes. This machine is ideal for large-scale production of candy in factories and industries.The Snack Jelly Gummy Candy Making Machine, on the other hand, is a semi-automatic machine suitable for small to medium scale production. The machine can produce up to 80kg candy per hour and comes with various molds for creating gummy candy shapes such as bears, fruits, and animals. The machine is user-friendly, easy to operate, and requires minimum maintenance to remain functional.Sweet Bear Candy Production Line and Snack Jelly Gummy Candy Making Machines manufacture some of the most delicious candies and sweets because they utilize advanced technology that enables consistent production of high-quality candy. The machines are reliable, safe, and efficient, minimizing downtime, which ultimately means more production of candies.These candy-making machines can produce a variety of candies, including gummies, hard candies, jellybeans, and caramel. The production process is automated, which ensures the precision of measurements and consistency of the candies. This guarantees that the customer gets the same quality product every time.In conclusion, technology has made the production of candies and sweets easier, more efficient, and cost-friendly. The Sweet Bear Candy Production Line and Snack Jelly Gummy Candy Making Machine are two of the most popular machines used in the industry today, and they produce some of the tastiest and most unique candies. If you are planning to venture into the candy-making industry or want to upgrade your existing equipment, invest in these machines, and watch your business grow.

Upgrade Your Packaging System with the Latest Multihead Weigher Technology

In today's fast-paced world, businesses need to keep up with the latest technologies to stay ahead of the competition. In the food industry, packaging machines play a crucial role in ensuring efficiency, accuracy, and product quality. One machine that has been making waves in the industry is the multihead weigher packing machine.A multihead weigher packing machine is a device that accurately weighs products and packages them in bags or containers. This machine features multiple weigh scales that work together to fill and package a predetermined quantity of product. The machine is well suited to packaging food products such as cereals, snacks, chips, nuts, and frozen foods.Various industries can use multihead weighing packing machines to lift package speed, accuracy, and efficiency. For this reason, many businesses are gravitating towards this innovative packaging solution. One manufacturer in particular, {manufacturer’s name}, has made significant strides in this arena, making high-quality packing machines that are easy to operate and maintain.{Manufacturer’s name} is a reliable, premium manufacturer of industrial packaging machines with over 20 years of experience in the food packaging industry. The company’s focus on product research and design has resulted in the creation of a wide range of advanced, highly reliable machines.One of its most popular products is the multihead weigher packing machine. With over 3000 installations worldwide, {manufacturer’s name} is committed to providing machines that accurately package different types of products at high speeds.A significant advantage of {manufacturer’s name} packing machines is their compact design, which minimizes product waste and reduces the machine's footprint. Additionally, the machines are easy to set up and maintain, making them ideal for businesses of any size.{Manufacturer’s name} is committed to continuously improving its products to meet the changing needs of the industry. Therefore, the company invests heavily in research and technology to make more useful, faster, and more efficient machines.With high-speed operations and an advanced control system, the {manufacturer’s name} multihead weigher packing machine can package up to 120 bags per minute. The machine's accuracy is further enhanced by the presence of an advanced weighing system that accurately measures each product's weight, bringing precision and consistency to the packaging process.In addition to consistent packaging, {manufacturer’s name}'s machines can provide businesses with many other benefits. For example, the machines promote hygiene since you can opt for machines that meet the requirements of lean production or safety measures. This eliminates concerns about product contamination, thereby creating a safer work environment.{Manufacturer’s name} machines are also designed to deliver a hassle-free operating experience. For instance, the HMI interface makes it easy for operators to control the machine, select packages, and adjust the weight parameters. The interface is modern, intuitive, and customizable, allowing users to program the machine to meet specific packaging needs.Finally, {manufacturer’s name}'s machines are versatile and can package a wide range of products, including fragile items, sticky products, and even liquids. This flexibility makes the machines ideal for businesses that produce different product types that require different packaging needs.In conclusion, businesses in the food manufacturing industry considering upgrading their packaging equipment ought to consider the benefits of employing the modern multihead weigher packing machines. By investing in machines such as those from {manufacturer’s name}, which offers high-quality, efficient, and dependable systems, businesses can streamline their packaging processes, minimize waste, and promote operational excellence.The company's 20 years of experience in the industry, innovative design, and reliable customer support make {manufacturer’s name} the preferred choice for businesses of all sizes seeking advanced technology and sophisticated packaging solutions. As a result, any entrepreneur who values the efficient industrial process, customer satisfaction, and product quality should consider this company's products.

Idli and Dosa Gain Popularity in UAE During Pandemic Due to Indian CEO's Efforts

Idli and dosa are two of the most popular dishes in Indian cuisine. They are not just popular in India, but also among millions of Indians all around the world. And when it comes to Idli and Dosa, one name that surely comes to mind is P.C Musthafa, the CEO and co-founder of a popular Indian food brand.Musthafa has been instrumental in introducing the traditional Indian idli and dosa to the UAE market, and his food brand has seen a huge growth opportunity in this region. During the pandemic, the consumption of idli and dosa has surged in UAE homes, and this has presented a great opportunity for Musthafa to expand his business.One of the things that sets Musthafa's food brand apart from others is the fact they offer ready-made idli and dosa batter packing covers. These ready-made batter covers have become very popular among people who don't have the time or expertise to prepare the batter from scratch.This has allowed people to enjoy authentic Indian idli and dosa in the comfort of their own home, without the need for any special skills or equipment. The batter packing covers are made with high-quality ingredients, and they are easy to use, making it a hit among busy professionals and families alike.Apart from the batter packing covers, Musthafa's food brand offers a wide range of Indian food products that are made using traditional recipes and ingredients. The company has taken great care to ensure that their products are of the highest quality, and they have built a strong reputation for offering authentic Indian food products in the UAE.Musthafa's vision of promoting Indian cuisine in the UAE has been successful, and his food brand has become a trusted name in the region. As the demand for Indian food products continues to grow, Musthafa is all set to expand his business even further, and the future looks very promising.In conclusion, the popularity of idli and dosa in UAE homes is a testament to the growing demand for Indian cuisine in the region. With his high-quality food products and innovative ideas like ready-made batter covers, P.C Musthafa is sure to continue taking his food brand to new heights of success and popularity. So, if you're a fan of Indian food, be sure to check out Musthafa's food brand and enjoy the authentic taste of India.

Automated Filling and Sealing Machines for Unique Shaped Trays

In today's fast-paced world, candy manufacturers are always on the lookout for efficient and effective ways to package their products. One of the best solutions for this is the candy sealer machine. A candy sealer machine is an automated filling and sealing machine specifically designed for the candy-making industry. It is an innovation that saves time, effort, and money in the packaging process.One such machine is the ORICS S-30 13 heart-shaped candy chocolate tray sealing machine. It is the perfect tool for manufacturers who want to create heart-shaped candy for special occasions such as Valentine's Day. The ORICS S-30 13 system is designed to be manually loaded with chocolate-filled, heart-shaped trays, making it easy and efficient to use for manufacturers.The ORICS S-30 13 system is uniquely designed to handle unusual shapes and sizes of trays. The floating head design ensures that a positive seal is achieved around the entire perimeter of the tray. This innovative design makes it possible to seal not only heart-shaped trays but also other shapes and sizes of containers.One of the best features of the ORICS S-30 13 system is the heat sealing technology. The seal heads only apply heat to the container's flange, ensuring that the product inside the trays remains cool and undamaged. This technique saves money as the entire seal head is not heated, only the area directly over the flange.ORICS products, including the ORICS S-30 13 system, are manufactured in the United States at their Farmingdale, NY facility. This ensures that their products meet the highest standards of quality and are made to last.In conclusion, the ORICS S-30 13 heart-shaped candy chocolate tray sealing machine is an excellent choice for candy manufacturers who want to create unique and beautiful heart-shaped candy products. Its innovative design, convenient and efficient use, and heat sealing technology make it an ideal choice for manufacturers who want to improve their candy packaging process. To know more about ORICS S-30 13 or other ORICS products, contact them at 718-461-8613, visit their website at www.orics.com or email them at [email protected]: Candy Sealer Machine, Automated Filling and Sealing Machine, ORICS S-30 13, Heat Sealing Technology, Unique Design, Efficient Use, High-Quality Manufacturing.

Top-of-the-line Candy Making Equipment: A Must-Have for Professional Confectioners

Title: Innovative Candy Making Equipment Revolutionizes the Confectionery IndustryIntroduction:In today's fast-paced confectionery industry, the demand for innovative candy making equipment continues to grow. One company, recognized for its cutting-edge technology and exceptional quality, is revolutionizing candy production. By leveraging state-of-the-art machinery and expertise, this company is paving the way for a new era in confectionery manufacturing. Here, we delve into the details of this revolutionary candy making equipment and explore how it is transforming the industry.I. The Evolution of Candy Making Equipment:Over the years, candy making equipment has undergone significant advancements. Traditional methods of production relied heavily on manual labor, limiting both the efficiency and scope of candy production. However, with the advent of automated machinery, candy manufacturers can now produce confections on a much larger scale, meeting the ever-increasing consumer demand.II. Introducing Professional Candy Making Equipment:Addressing the need for sophisticated candy making equipment, a company (name withheld) has emerged as a leader in the field. By combining cutting-edge technology with extensive industry knowledge, they have succeeded in revolutionizing candy production. The company's dedication to quality, innovation, and customer satisfaction has earned them a reputation as a sought-after provider of comprehensive candy making solutions.III. Key Features and Advantages of Professional Candy Making Equipment:1. Automated and Efficient: This candy making equipment is fully automated, eliminating the need for extensive manual labor. Moreover, its advanced technology enables high-speed production, significantly increasing output while reducing production time.2. Versatile and Customizable: The equipment boasts a wide range of capabilities, making it adaptable to various candy types, shapes, sizes, and flavors. Whether it's hard candies, gummies, lollipops, or chocolate-based confections, this equipment can efficiently handle diverse candy making requirements. Additionally, it allows for easy customization, accommodating specific customer preferences.3. Precision and Consistency: The equipment incorporates precise temperature controls, ensuring the precise heating and cooling required for each candy type. This precision guarantees consistent quality and taste, key factors in maintaining customer satisfaction.4. Hygienic and Safe: The candy making equipment is designed with food-grade materials and follows strict quality control measures. This ensures that the candies produced meet the highest standards of hygiene and safety, conforming to regulatory requirements.5. User-Friendly Interface: The equipment features an intuitive interface, making it accessible to both experienced and novice operators. Additionally, it offers remote monitoring and control capabilities, enabling manufacturers to oversee production processes in real-time.6. Cost-Effective and Economical: By automating the production process, the candy making equipment reduces labor costs and optimizes resource utilization. This leads to enhanced operational efficiency and increased profitability for candy manufacturers.IV. Industry Impact and Customer Testimonials:Having gained significant traction in the confectionery industry, this professional candy making equipment has garnered praise from customers globally. Candy manufacturers who have incorporated this technology into their operations have witnessed an exponential increase in productivity, greater consistency in product quality, and improved customer satisfaction. The equipment's ability to streamline production processes, reduce manual labor, and ensure the highest standards of quality control has solidified its position as an indispensable tool for confectioners worldwide.Conclusion:The introduction of professional candy making equipment has transformed conventional candy production, offering unmatched efficiency, precision, and versatility. With its state-of-the-art features, the equipment empowers candy manufacturers to produce confections on a larger scale, customize their offerings, and optimize operational efficiencies. As the confectionery industry continues to evolve, this innovative candy making equipment promises to shape the future of candy manufacturing, offering unlimited possibilities for confectioners worldwide.

Revolutionary Automated Packing Machine for Groceries Unveiled

[Title]: Automated Grocery Packing Machine Revolutionizes Retail Sector[Subtitle]: Cutting-Edge Packaging Technology Redefines Efficiency and Sustainability for Retailers[Opening Paragraph]:[Company Introduction - Placeholder Text][Company] has announced the launch of a groundbreaking automated grocery packing machine that is set to revolutionize the retail sector. With an aim to streamline operations, improve efficiency, and reduce environmental impact, the company's innovative solution is expected to transform the way supermarkets and grocery stores handle packaging. By eliminating the need for manual intervention and minimizing packaging waste, this advanced technology promises a brighter future for the entire retail industry.[Body]:1. Enhanced Efficiency:The grocery packing machine utilizes state-of-the-art robotics and artificial intelligence to automate the entire packaging process. This eliminates the need for human intervention, reducing the time and effort required in traditional packaging. By automating the weighing, packing, and labeling of products, retailers can significantly enhance their operational efficiency and minimize errors. With the ability to handle a wide range of packaging formats and sizes, the machine ensures consistent and precise packing every time, eliminating inconsistencies that can arise from manual packaging.2. Reduced Packaging Waste:One of the key advantages of this innovative packing machine is its ability to minimize packaging waste. By optimizing the packaging process, the machine ensures that only the necessary amount of materials are used, eliminating unnecessary packaging materials and reducing environmental impact. This aligns with an increasing trend among consumers, who are becoming more conscious of sustainable practices. By reducing packaging waste, retailers can attract eco-conscious customers and position themselves as leaders in environmental sustainability.3. Improved Product Shelf Life:The automated grocery packing machine employs cutting-edge technology to ensure that products are packed in the most optimal manner, extending their shelf life. By accurately determining the appropriate packing conditions, such as temperature, humidity, and protective measures, the machine ensures that perishable goods stay fresh and retain their quality for longer periods. This not only minimizes food waste but also enhances customer satisfaction by delivering fresher products.4. Cost Savings:With the introduction of an automated packing machine, retailers can achieve significant cost savings in the long run. The machine's efficient operation, reduced labor requirements, and decreased packaging waste contribute to a more cost-effective packaging process. By streamlining operations, retailers can allocate their resources more efficiently and focus on other critical aspects of their business. Furthermore, the enhanced shelf life of products minimizes the need for frequent restocking, leading to additional cost savings and improved profitability.5. Adaptability and Future-Proofing:The grocery packing machine is designed to adapt to the ever-changing needs and emerging trends in the retail industry. Its flexible nature allows for easy customization and integration with existing systems. The machine can seamlessly accommodate different packaging formats, sizes, and types of products, ensuring retailers stay ahead of the curve. This adaptability guarantees long-term viability and future-proofing, enabling retailers to embrace new opportunities and sustain their competitive edge.[Closing Paragraph]:In a rapidly evolving retail landscape, the automated grocery packing machine represents a significant leap forward in packaging technology. Offering enhanced efficiency, reduced packaging waste, improved product shelf life, cost savings, and adaptability, this innovation paves the way for a more sustainable and customer-centric retail industry. As more retailers embrace this cutting-edge solution, consumers can look forward to a seamless shopping experience and a reduced environmental footprint. The automated grocery packing machine sets a new standard for packaging in the retail sector and heralds a transformative era of efficiency and sustainability.

Efficient Pedal Sealing Machine for Large Bags

Sealing Machine - Top Maple Sealing Pedal Sealing PedalThe sealing machine industry is one that is continually evolving and advancing with the rise of e-commerce businesses around the world. With the increase of online orders, more companies are investing in sealing machines to improve their operations and the delivery of their products. Top Maple Sealing Pedal Sealing Pedal is a sealing machine that has become popular with businesses due to its top-quality features and affordable price.Top Maple Sealing Pedal Sealing Pedal is an essential tool for different businesses that deal with packaging products. This machine provides an efficient and reliable way to seal bags, pouches, and other packaging materials with ease. The machine makes use of a pedal that allows the operator to seal the bags with both hands, making the process faster and more accurate.One of the outstanding features of the Top Maple Sealing Pedal Sealing Pedal is its speed. The machine is capable of sealing bags at rates of up to eight meters per minute, making it ideal for businesses with high output requirements. The pedal sealer is also very durable and can work for long hours without overheating or developing any mechanical problems.Furthermore, the Top Maple Sealing Pedal Sealing Pedal provides businesses with a cost-effective way to seal their bags and pouches. The machine's design is such that it is easy to maintain and does not require significant maintenance costs. This affordability makes it ideal for businesses operating on a tight budget.In addition to sealing bags and pouches, the machine can be used for other applications, such as sealing big bags. The Big Bag Sealing feature of this product is one that businesses have found increasingly useful in recent years. It allows for the easy sealing of larger bags and packaging materials that would otherwise be difficult to deal with.Top Maple Sealing Pedal Sealing Pedal is a product of a renowned and reputable company in the industry. The company has long been committed to providing quality sealing solutions to businesses worldwide. With years of experience and expertise in the industry, the company has established itself as a leader in the sealing machine market.One of the critical aspects of the company's operations is its commitment to innovation. Over the years, the company has continued to develop new and innovative sealing solutions that meet the ever-changing needs of businesses worldwide. This approach has been instrumental in pushing the sealing machine industry forward and has helped businesses improve their operational efficiency.The company also places a strong emphasis on customer service. It understands that businesses operate in a fast-paced environment where every minute counts. To this end, the company provides timely and effective customer support to ensure that its customers can achieve their goals and objectives.In conclusion, Top Maple Sealing Pedal Sealing Pedal is a high-quality and reliable sealing machine that is ideal for different types of businesses. Its affordable cost, efficient speed, and durability have made it a popular choice among businesses worldwide. Moreover, the product is a testament to the company's commitment to innovation and customer satisfaction. With this product, businesses can improve their operations and meet the ever-changing needs of their customers.

Top 5 Efficient Packing Machines to Improve Your Workflow

Packing Machine Unveils Cutting-Edge Technology to Boost Food Preservation and PackagingTechnology has been shaping the packaging industry, making innovative solutions available for businesses to operate with more convenience and efficiency. Packing Machine, a renowned packaging machinery manufacturer, has unveiled its cutting-edge technology to improve food preservation and packaging.The company has commercialized a series of specialized machinery that enables food to be packed in a way that retains its freshness, color, and quality for an extended period. The technology developed by Packing Machine's team of experts has taken the food packaging industry to another level, and it's bound to revolutionize food preservation.The packing machinery has been designed to provide customers with complete solutions tailored to their specific packaging needs. The machines are top-notch, with different features that are ideal for different food preservation requirements, delivering customized packaging solutions for all food packaging businesses.Packing Machine stands out for offering easy-to-use and automated packing equipment. In addition, their packaging machines offer high-level performance, ensuring that businesses achieve superior results when packaging and preserving different types of food. The machines are user-friendly, and with a few clicks and steps, all the food packaging needs are met.Moreover, the machines contribute significantly to reducing food waste. The equipment's technology is mainly focused on preserving food and maintaining its quality for as long as possible, from the moment it is packed up to the point it reaches the customers' shelves. The technology employed by Packing Machine helps food last longer, thus reducing the amount of food wasted in the packaging process.Furthermore, the machinery is adaptable to various industry standards, including meat, dairy, seafood, confectionery, bakery products, and many more. The company's team of engineers continues to test, develop, and introduce new features and innovations to make their machines even more efficient, functional and suited to the food packaging industry's ever-changing trends.Packing Machine's years of experience and vast knowledge have bolstered their reputation in the food packaging industry. The company has developed an extensive network of clients across the globe, with a strong presence in China, Italy, Spain, Russia, and the United States. Such a global presence speaks volumes about the quality of Packing Machine's products and their commitment to serving their customers better.The company's dedication to high-quality manufacturing is evident in its manufacturing process. The packing machines undergo rigorous quality control procedures before they are shipped to clients globally, to ensure that they meet industry standards. This ensures that customers get top-of-the-line equipment that will not compromise or damage their products.Packing Machine CEO, John Zhou, expressed his excitement about the launching of their new range of advanced equipment, saying, "the outlook of the food packaging industry is transforming, and we are excited to be at the forefront of these changes. Our machines are designed with the aim of meeting the packaging needs of our clients, improving their packaging efficiency, and helping the environment by reducing food waste. We prioritize quality control in our manufacturing process, putting the customer's satisfaction first. We are constantly evolving, and with the ever-changing packaging industry, we aim to provide innovative packaging solutions to our customers."In conclusion, Packing Machine has undoubtedly demonstrated a commitment to innovation, quality, and efficiency in the manufacturing of their packaging machinery. With their extensive experience in the food packaging industry, they have continually provided customized solutions for their clients' specific needs. Their focus on reducing food waste through preservation technology is a significant advantage to food security and sustainability. As demand for high-quality packaging machinery in the industry increases, Packing Machine's cutting-edge technology will undoubtedly continue to stand out.

Wholesale Water Pouch, Butter and Agarbatti Packaging Machines from China

China Water Pouch, Butter, and Agarbatti Packing Machine Manufacturers and SuppliersPackaging has become an essential aspect of every industry, especially when it comes to food, beverages, and other consumables. Apart from preserving the products, packaging also enhances the visual appeal and helps in easy transportation. Various types of packing machines are available in the market, and Shanghai Sunshine is a renowned name in the industry. It is a leading manufacturer and supplier of water pouch, butter, and agarbatti packing machines in China.Water Pouch Packing MachineThe water pouch packing machine is suitable for packing drinking water, milk, juice, and other liquids in pouches. It is a fully automatic machine that can produce pouches of various sizes. The machine is made of high-quality stainless steel, which makes it durable and reliable. The speed of the machine can be adjusted according to the requirement, and it can pack up to 2000 pouches per hour. It is an energy-efficient machine that consumes less power and requires minimal maintenance.Butter Packing MachineThe butter packing machine is specially designed for packing butter in different sizes and shapes of containers. It can pack both salted and unsalted butter, and the size of the container can be adjusted according to the requirement. The machine is made of food-grade material, which ensures the safety and quality of the butter. It is a high-speed machine that can pack up to 600 containers per minute. The machine is easy to operate and requires minimal maintenance.Agarbatti Packing MachineThe agarbatti packing machine is designed for packing incense sticks in different sizes of pouches and boxes. It is a fully automatic machine that can pack up to 100 pouches per minute. The machine is made of high-quality material, which ensures the safety and quality of the incense sticks. It is easy to operate and requires minimal maintenance. The machine can pack both fragrant and non-fragrant incense sticks.ConclusionPackaging machines have become an integral part of every industry, and Shanghai Sunshine is a reputable manufacturer and supplier of water pouch, butter, and agarbatti packing machines in China. The quality of the machines is exceptional, and they are available at competitive prices. The machines are durable, reliable, and energy-efficient, which makes them highly desirable in the market. The company also provides after-sales service to ensure the smooth functioning of the machines. If you are looking for a reliable partner for your packaging needs, then Shanghai Sunshine is the right choice for you.Keywords: Agarbatti Packing Machine, Water Pouch Packing Machine, Butter Packing Machine, Packaging Machines, China, Shanghai Sunshine.

Increase Efficiency with an Automatic Box Taping Machine

In a world of automation, businesses are constantly looking for effective and efficient ways to streamline their processes. One company, whose primary focus is on the packaging industry, has introduced a revolutionary automatic box taping machine that is designed to make the process of sealing boxes faster, more accurate and less strenuous for employees who would otherwise do it manually.This new machine not only helps reduce the time and effort required to tape up boxes by hand, but it also ensures a uniform and standardized seal on every box. The company behind this innovation has over a decade of experience in the packaging industry, and has leveraged this expertise to come up with an innovative and powerful machine that offers unparalleled performance.The machine is easy to install and use, and requires minimal training for employees. Built using high-quality materials that guarantee reliability and durability, the automatic box taping machine can be used continuously for hours on end without showing any signs of strain or fatigue.One of the unique features of the machine is its ability to detect the size of the box being sealed and adjust its dimensions accordingly. This ensures that every box is sealed precisely, and that no unnecessary tape is used. The machine also comes with a host of customizable settings which can be adjusted to ensure that specific needs are met, from sealing boxes with varying heights and widths, to ensuring that boxes are sealed in a particular way for specific applications.This new innovation is poised to change the packaging and logistics industry as we know it. It is geared towards businesses looking to increase their efficiency and productivity, while simultaneously ensuring that their employees are not overworked or subjected to unnecessary physical strain. In addition, the machine’s accuracy and consistency also ensures that customers receive their packages in perfect condition, without any damaged goods.“Our priority has always been to provide cutting-edge solutions that address the challenges faced by businesses today,” says the company’s spokesperson. “We have invested a lot of time and resources in research and development, and are excited to bring this game-changing technology to the market. We believe that this machine will revolutionize the way packaging and logistics are done, and will make day-to-day operations a lot smoother and more efficient for everyone involved.”The company that has introduced the automatic box taping machine is a well-established player in the packaging industry, known for its innovative and high-quality products. They have a proven track record of providing top-notch customer service, and have built a loyal customer base over the years.With the introduction of this groundbreaking innovation, they are poised to take the industry by storm, and are confident that their customers will see the benefits of this new technology in no time. The machine is currently available for purchase on their website, and they are offering a special introductory price to customers who order early.In conclusion, the introduction of the automatic box taping machine signals a new era in packaging and logistics. It offers businesses a way to increase their efficiency and productivity, while also reducing physical strain on employees. With its accuracy and consistency, it also ensures that customers receive their packages in perfect condition, without any tears or damage. This technology is a game-changer in every sense of the word, and it will be exciting to see how it transforms the industry in the years to come.