Candy Molding Machine: The Latest Innovation in Confectionery Production

By:Admin

In the world of confectionery manufacturing, the process of creating delightful and delicious candies is both an art and a science. From the careful selection of ingredients to the precise timing of each step, the production of high-quality candies requires skill, expertise, and reliable machinery. For many confectionery manufacturers, the candy molding machine has become an essential tool in streamlining the production process and ensuring consistent results.

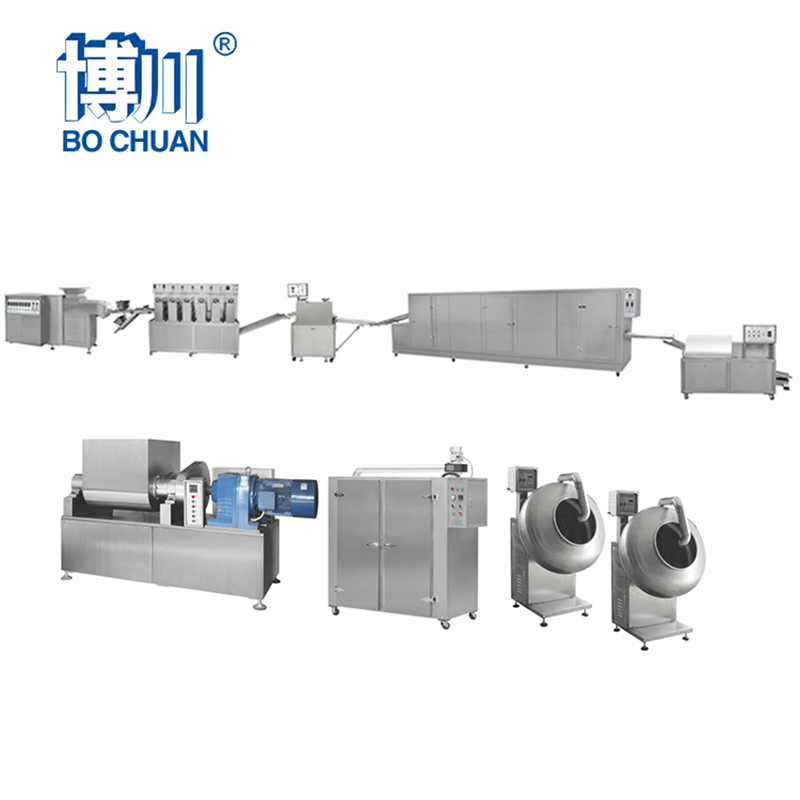

One company at the forefront of candy molding machine innovation is {}. With a long history of excellence in confectionery machinery, the company has established itself as a leader in the industry, providing cutting-edge solutions for candy manufacturers around the world. In this article, we will explore the revolutionary candy molding machine developed by {} and the ways in which it is transforming the confectionery manufacturing process.

The {} candy molding machine is a state-of-the-art piece of equipment that has been designed to meet the unique needs of modern confectionery production. Featuring advanced technology and a user-friendly interface, this machine is capable of producing a wide variety of candies with exceptional precision and efficiency. Whether it's gummies, hard candies, or chocolate-filled delights, the {} candy molding machine is equipped to handle a diverse range of confectionery products, making it a versatile and indispensable asset for candy manufacturers.

One of the key advantages of the {} candy molding machine is its high level of automation. With advanced robotic arms and precise molding mechanisms, this machine can produce candies with remarkable speed and consistency, reducing the need for manual labor and minimizing the risk of human error. This not only improves the overall efficiency of the production process but also ensures that every candy that comes off the line meets the highest standards of quality and consistency.

In addition to its automation capabilities, the {} candy molding machine is also highly customizable, allowing confectionery manufacturers to tailor the machine to their specific production needs. Whether it's adjusting the size, shape, or flavor profile of the candies, this machine offers a high degree of flexibility, enabling manufacturers to create unique and innovative confectionery products that stand out in the market.

Furthermore, the {} candy molding machine is equipped with advanced quality control features that allow manufacturers to monitor and adjust the production process in real-time. From temperature and humidity control to ingredient dosing and molding pressure, this machine ensures that every aspect of the candy-making process is closely monitored and optimized for optimal results. This level of precision and control not only enhances the overall quality of the candies but also minimizes waste and production costs, making it a highly cost-effective solution for confectionery manufacturers.

With its advanced technology, high level of automation, and customizable features, the {} candy molding machine has quickly become a game-changer in the confectionery manufacturing industry. By streamlining the production process, improving quality and consistency, and offering a high level of flexibility, this machine is helping candy manufacturers around the world stay competitive in an increasingly demanding market.

As the demand for innovative and high-quality confectionery products continues to grow, the {} candy molding machine is poised to play a pivotal role in shaping the future of the industry. With its unparalleled capabilities and advanced features, this machine is not only revolutionizing the way candies are made but also setting new standards for excellence in confectionery manufacturing. As {} continues to push the boundaries of innovation in the confectionery machinery industry, the future looks bright for candy manufacturers seeking to elevate their production capabilities and deliver exceptional candies to consumers worldwide.

Company News & Blog

High-Quality Industrial Packaging Machines for Efficient Production

Industrial Packaging Machines is a leading provider of innovative packaging solutions for businesses across a wide range of industries. With a commitment to quality, reliability, and efficiency, Industrial Packaging Machines has established itself as a trusted partner for countless companies looking to optimize their packaging processes.Founded in 1995, Industrial Packaging Machines has been at the forefront of the packaging industry for over 25 years. The company's dedication to research and development has led to the creation of cutting-edge packaging machines that are designed to meet the diverse needs of modern businesses. From food and beverage packaging to pharmaceutical and industrial packaging, Industrial Packaging Machines offers a comprehensive range of machines that are tailored to deliver exceptional results.In addition to its extensive product line, Industrial Packaging Machines also provides custom packaging solutions to address unique challenges faced by its clients. With a team of experienced engineers and technicians, the company is capable of designing and manufacturing custom packaging machines that are specifically tailored to individual business requirements. This level of customization allows Industrial Packaging Machines to deliver solutions that are perfectly aligned with the needs of its clients, ensuring maximum efficiency and performance.One of the key strengths of Industrial Packaging Machines is its unwavering commitment to quality. The company utilizes state-of-the-art manufacturing processes and the highest quality materials to produce packaging machines that are durable, reliable, and built to last. This dedication to quality has earned Industrial Packaging Machines a stellar reputation in the industry, and has positioned the company as a preferred choice for businesses seeking top-of-the-line packaging solutions.Industrial Packaging Machines also places a strong emphasis on customer satisfaction. The company's team of experts works closely with clients to understand their unique packaging needs, and to provide tailored solutions that deliver exceptional results. Whether it's optimizing existing packaging processes or implementing new machinery, Industrial Packaging Machines is dedicated to helping businesses achieve their packaging goals with a high level of professionalism and expertise.In recent news, Industrial Packaging Machines has unveiled its latest innovation - the [product name], a revolutionary packaging machine that is set to redefine the industry standards. This cutting-edge machine features advanced technology and a host of innovative features that are designed to streamline the packaging process and deliver superior results. With its versatility, efficiency, and reliability, the [product name] is poised to become the go-to solution for businesses looking to elevate their packaging capabilities."We are thrilled to introduce the [product name] to the market," said [spokesperson], [title] at Industrial Packaging Machines. "This machine represents the culmination of years of research and development, and we believe it will set a new benchmark for packaging efficiency and performance. We are confident that the [product name] will make a significant impact for businesses across various industries, and we are excited to see the positive results it will deliver for our clients."The introduction of the [product name] further demonstrates Industrial Packaging Machines' ongoing commitment to innovation and excellence. By consistently pushing the boundaries of what is possible in the packaging industry, the company has solidified its position as a leader in the market, and as a trusted partner for businesses seeking best-in-class packaging solutions.As businesses continue to strive for greater efficiency and productivity, the role of packaging machines has become increasingly critical. With its extensive product line, commitment to quality, and dedication to customer satisfaction, Industrial Packaging Machines is well-positioned to meet the evolving needs of the industry, and to empower businesses with the tools they need to succeed in the competitive market landscape.

Efficient Homemade Chocolate Packing Machine

The innovative company has recently launched a homemade chocolate packing machine, revolutionizing the way small-scale chocolate producers package their delicious treats. This cutting-edge machine is designed to meet the unique needs of homemade chocolate makers, providing them with a cost-effective and efficient solution for packaging their products.With the rise in demand for artisanal chocolates, many small-scale producers are looking for ways to streamline their packaging process without sacrificing quality. This is where the homemade chocolate packing machine comes in. It is specifically designed to handle the delicate nature of homemade chocolates, ensuring that they are perfectly packaged and protected during the shipping and handling process.The machine is also equipped with state-of-the-art technology that allows for customizable packaging options, giving producers the freedom to create a unique and eye-catching look for their products. This level of customization is something that is often lacking in the packaging solutions available to small-scale chocolate makers, making this machine a game-changer for the industry.In addition to its advanced packaging capabilities, the homemade chocolate packing machine is also incredibly easy to use. Its user-friendly interface and intuitive design make it accessible to producers of all skill levels, allowing them to quickly and efficiently package their chocolates without the need for extensive training or expertise.This ground-breaking machine is the latest offering from the company, which has established itself as a leader in the packaging industry. With a strong focus on innovation and customer satisfaction, the company has been developing high-quality packaging solutions for a wide range of products, including chocolates, snacks, and confectionery.The company's commitment to quality and innovation is reflected in all of its products, including the homemade chocolate packing machine. With its sleek design, cutting-edge technology, and customizable options, this machine is set to become a must-have tool for small-scale chocolate producers looking to elevate their packaging process."We are thrilled to introduce the homemade chocolate packing machine to the market," said a spokesperson for the company. "We understand the unique challenges that small-scale chocolate producers face when it comes to packaging their products, and we are proud to offer a solution that addresses those challenges head-on. This machine is the result of years of research and development, and we are confident that it will make a significant impact on the industry."The homemade chocolate packing machine is now available for purchase, and the company is already seeing a high level of interest from chocolate makers around the world. With its unmatched packaging capabilities and user-friendly design, this machine is poised to become an essential tool for any small-scale chocolate producer looking to take their packaging process to the next level.As the demand for artisanal chocolates continues to grow, the homemade chocolate packing machine is set to play a key role in helping small-scale producers meet this demand while maintaining the integrity and quality of their products. With its innovative design and advanced technology, this machine is sure to become a staple in the chocolate industry for years to come.

Efficient and Precise Sealing and Cutting Machine for Various Applications

Title: Advanced Sealing and Cutting Machine Enhances Efficiency and Productivity in Various IndustriesIntroduction:In recent times, the demand for advanced manufacturing technologies has increased drastically across various industries. Companies are constantly seeking innovative solutions to enhance efficiency and productivity in their operations. One such solution is the state-of-the-art Sealing and Cutting Machine, developed by a leading manufacturing company.Company Overview:Established in (year), the (company name) is renowned for its commitment to technological advancements and delivering high-quality machinery for industrial applications. With an extensive range of cutting-edge equipment, the company has gained a solid reputation in the market. Backed by a team of engineers and experts, (company name) strives to provide innovative solutions that optimize production processes and drive business success.Introduction to the Sealing and Cutting Machine:The Sealing and Cutting Machine by (company name) is a versatile and efficient equipment designed to benefit a myriad of industries, including packaging, medical, food, and textile. With its cutting-edge technology and robust manufacturing, this machine is capable of performing various functions such as sealing, cutting, and bagging, thereby streamlining the production process.Key Features and Benefits:1. Precise Sealing Techniques:The Sealing and Cutting Machine employs cutting-edge sealing techniques, ensuring precise and reliable seals. Equipped with advanced heat sealing technology, the machine allows for consistent sealing strength across a wide range of materials, including plastics, laminates, and foils. This feature not only enhances product quality but also minimizes the risk of leakage and contamination.2. Versatile Cutting Options:The machine offers versatile cutting options, allowing for customized cuts based on product requirements. Whether it's straight, zigzag, or custom-designed cuts, the Sealing and Cutting Machine ensures accuracy, enabling manufacturers to meet the diverse needs of their customers.3. Integrated Bagging System:A noteworthy feature of this machine is its integrated bagging system. It enables seamless bagging after the sealing and cutting process, reducing manual labor and increasing operational efficiency. The automatic bagging feature saves time and enhances productivity, making it an ideal choice for high-volume production.4. User-Friendly Interface:The Sealing and Cutting Machine features an intuitive user interface that simplifies operation and reduces the learning curve. The machine's interface allows easy adjustments of settings such as sealing time, temperature, and cutting preferences, making it suitable for both experienced operators and novices.5. Enhanced Safety Measures:With safety being a top priority, the Sealing and Cutting Machine incorporates several safety features. Some of them include emergency stop buttons, safety sensors, and lockout/tagout systems to prevent accidents and ensure operator well-being. These safety measures conform to international standards and regulations in place to protect workers.Applications in Various Industries:1. Packaging Industry:The Sealing and Cutting Machine effectively seals and cuts packaging materials, including films, pouches, and bags. Its versatility in handling different packaging sizes and materials makes it highly advantageous for both small and large-scale packaging operations.2. Medical Industry:Medical instrument manufacturers can benefit from the machine's ability to seal and cut medical-grade packaging materials, ensuring the sterility and integrity of products. Its precision sealing capabilities help maintain a contaminant-free environment and comply with stringent industry regulations.3. Food Industry:In the food industry, the Sealing and Cutting Machine plays a crucial role in efficiently and securely sealing food products such as snacks, frozen items, and beverages. The machine's ability to handle various packaging materials ensures the longevity and freshness of the food.4. Textile Industry:In the textile industry, the Sealing and Cutting Machine aids in sealing and cutting fabrics, preventing fraying and unraveling. This enhances the durability and visual appeal of finished textile products, allowing manufacturers to deliver superior quality to their customers.Conclusion:With its advanced features and multiple benefits, the Sealing and Cutting Machine developed by (company name) has emerged as a game-changer in various industries. From packaging to medical and food to textiles, this cutting-edge machinery enhances productivity, reduces labor costs, and improves product quality. As businesses continue to seek innovative solutions, this equipment proves to be an invaluable asset in driving efficiency and success in today's demanding manufacturing landscape.

Delicious Candy Manufacturing Process Unveiled

article.Candy Production Industry – A Sweet Business!Candies have always been an integral part of our lives. From childhood to adulthood, these sweet treats have never failed to bring a smile to our faces. The candy production industry is one of the oldest and most successful industries across the world, with numerous players offering sweet delights to their customers. Amongst all, one name stands out - {brand name removed} - a company that has been satisfying the sweet cravings of people for over 100 years.{Brand name removed} is a leading candy production company that has come a long way since its inception in 1909. The company has its headquarters in (location) and has always been focused on producing the highest quality sweets for their customers. {Brand name removed} believes in innovation and has continuously experimented with new flavors, colors, and shapes to cater to different tastes and preferences.The candy production industry is highly competitive, and {brand name removed} has always stayed ahead of the game with its unique approach to candy-making. The company produces a wide range of products, including gummies, hard candies, and chocolate bars, among others. Each of these products is made with the finest ingredients and with the utmost care, which is why {brand name removed} has become a household name across the globe.It takes a lot of effort and dedication to produce the perfect candy, and {brand name removed} takes this very seriously. The company's manufacturing process is of the highest standard, and it ensures that all its products are free from artificial colors, allergens, and genetically modified organisms. {Brand name removed} has also invested in state-of-the-art technology that guarantees consistency, flavor, and texture across all its candy products.In addition to producing high-quality sweets, {brand name removed} is also dedicated to sustainable candy production. The company ensures that all its manufacturing processes are sustainable and minimize waste. From using eco-friendly packaging to reducing greenhouse gas emissions, the company is committed to protecting the environment. {Brand name removed} also believes in ethical business practices and follows fair-trade policies to ensure that all its ingredients are sourced responsibly.The candy production industry has faced several challenges in recent times, with the outbreak of the COVID-19 pandemic affecting businesses across the world. However, {brand name removed} has been able to stay afloat and has even managed to boost candy sales during these difficult times. The company has adopted online sales channels and has also focused on innovative marketing strategies to engage with their customers.As lockdowns and travel restrictions have affected many people's ability to go out and socialize, {brand name removed} has introduced virtual tasting sessions, where their customers can experience their products from the comfort of their own homes. The company has also offered special discounts and promotions to keep their sales going during these tough times.In conclusion, the candy production industry is a sweet business, and {brand name removed} has proven to be a leader in this field. With its commitment to high-quality, sustainable, and ethical candy production, the company has set a benchmark for others to follow. Its dedication to innovation and its customer-centric approach have allowed {brand name removed} to stay ahead of the curve, even amidst challenging times. We look forward to seeing what the company has in store for us in the future and what new sweet treats we can expect from them.

Efficient Small Sachet Packing Machine for Your Packaging Needs

Small Sachet Packing Machine Boosts Production Efficiency for CompanyAs the demand for small sachet products continues to grow, companies are constantly seeking ways to streamline their production processes in order to meet market demands. In response to this need, {Company Name}, a leading provider of packaging solutions, has introduced the latest addition to their product line – the Small Sachet Packing Machine.The Small Sachet Packing Machine is designed to cater to the packaging needs of various industries such as food and beverage, pharmaceutical, and cosmetic. Its compact and versatile design makes it ideal for packaging small portions of products such as sugar, salt, pepper, coffee, tea, condiments, and more. The machine ensures precision and efficiency in the packaging process, thus increasing productivity and reducing manual labor.With its state-of-the-art technology and user-friendly interface, the Small Sachet Packing Machine is capable of producing a high volume of sachets per minute, making it an ideal solution for companies with high production demands. Its ability to accommodate different sachet sizes and packaging materials further enhances its flexibility and convenience for a wide range of products.{Company Name} takes pride in its commitment to providing innovative solutions to the packaging industry, and the Small Sachet Packing Machine is a testament to this dedication. The company's advanced research and development team has worked tirelessly to design a machine that not only meets the current market needs but also anticipates future trends and challenges.In addition to its cutting-edge technology, {Company Name} is also known for its exceptional customer service and support. The company offers comprehensive training and installation services for the Small Sachet Packing Machine, ensuring that their clients can maximize the benefits of this new addition to their production line. Furthermore, {Company Name} provides ongoing technical assistance and maintenance to ensure the seamless operation of the machine.The introduction of the Small Sachet Packing Machine is poised to have a significant impact on the packaging industry, particularly for companies seeking to enhance their production efficiency and meet growing market demands. With its innovative features and robust performance, this machine is set to become a game-changer for many businesses across various sectors.In response to the unveiling of the Small Sachet Packing Machine, industry experts have already expressed their optimism about its potential to transform the packaging landscape. In particular, the machine's ability to improve production capacity and reduce operational costs has garnered widespread attention and raised expectations for its widespread adoption.Furthermore, {Company Name} has already received positive feedback from early adopters of the Small Sachet Packing Machine, with many clients reporting significant improvements in their production processes and overall efficiency. The machine's ability to deliver consistent and precise packaging has been particularly praised, highlighting its potential to elevate product quality and customer satisfaction.In conclusion, the introduction of the Small Sachet Packing Machine by {Company Name} represents a significant milestone in the packaging industry. As companies continue to seek ways to enhance their production efficiency and meet evolving market demands, this innovative solution is set to play a pivotal role in driving progress and innovation. With its advanced technology, versatile design, and strong support services, the Small Sachet Packing Machine is poised to make a lasting impact on the industry, setting a new standard for packaging excellence.

Innovative Gummy Bear Making Machine Revolutionizes Candy Manufacturing Industry

Gummy Bear Making Machine revolutionizing the confectionery industryAs the demand for gummy candies continues to rise, companies are constantly seeking new and innovative ways to meet the needs of consumers. In response to this growing demand, a leading confectionery equipment manufacturer has recently announced the launch of a cutting-edge Gummy Bear Making Machine that is set to revolutionize the production process for gummy candies.This state-of-the-art Gummy Bear Making Machine is a game changer for confectionery producers, as it is capable of producing high-quality gummy candies with unmatched precision and efficiency. Equipped with advanced technology and cutting-edge features, this machine is designed to streamline the entire gummy bear manufacturing process, from mixing the ingredients to shaping and packaging the final product.The Gummy Bear Making Machine boasts a range of innovative capabilities that set it apart from traditional candy-making equipment. Its automated mixing and pouring system ensures that the gummy candy mixture is consistently distributed into the molds, resulting in uniform and perfectly-shaped gummy bears. Additionally, the machine's precise temperature control system guarantees that the gummy candies are cooked to perfection, achieving the ideal texture and flavor that consumers love.Furthermore, this revolutionary Gummy Bear Making Machine is equipped with a high-speed packaging system that enables confectionery producers to efficiently pack the gummy bears into individual bags, ensuring product freshness and quality. This feature not only enhances the overall production efficiency but also minimizes the risk of product contamination, meeting the highest standards of food safety and hygiene.In addition to its cutting-edge capabilities, the Gummy Bear Making Machine is designed with user-friendly controls and intuitive interfaces, making it easy for confectionery manufacturers to operate and maintain. With its ability to produce a wide variety of gummy bear shapes, sizes, and flavors, this machine offers unparalleled flexibility and versatility to meet the diverse demands of the market.The introduction of this innovative Gummy Bear Making Machine marks a significant milestone for the confectionery industry, as it not only elevates the production standards for gummy candies but also drives the overall growth and advancement of the sector. With its potential to enhance product quality, consistency, and efficiency, this machine is expected to set a new benchmark for gummy bear production and pave the way for the future of confectionery manufacturing.In line with the company's commitment to excellence and innovation, the development of the Gummy Bear Making Machine is a testament to its dedication to delivering cutting-edge solutions that meet the evolving needs of its customers. With a track record of excellence in confectionery equipment manufacturing, the company has established itself as a trusted partner for confectionery producers worldwide, providing them with the tools and technologies needed to stay ahead in a competitive market.The launch of the Gummy Bear Making Machine showcases the company's relentless pursuit of innovation, as it continues to push the boundaries of confectionery manufacturing and set new industry standards. With its unrivaled expertise and passion for excellence, the company is poised to make a lasting impact on the confectionery industry with this groundbreaking machine, empowering producers to take their gummy candy production to the next level.In conclusion, the introduction of the Gummy Bear Making Machine is a significant development that is poised to revolutionize the confectionery industry. With its advanced capabilities, unmatched precision, and unparalleled efficiency, this machine is set to redefine the production process for gummy candies, setting a new benchmark for quality, consistency, and innovation. As the company continues to lead the way in confectionery equipment manufacturing, the launch of this groundbreaking machine underscores its commitment to driving the future of the industry and empowering producers to thrive in a dynamic market.

How to Make Chocolate Using a Homemade Chocolate Making Machine

Mike Williams, a chocolate enthusiast and amateur chocolatier, has taken his love for chocolate to a whole new level by creating his own chocolate making machine at home. This innovative and creative project has gained a lot of attention in the chocolate-making community, and Mike's machine has even caught the eye of a well-known chocolate company.Mike's journey into chocolate making began at a young age, as he developed a fascination with the process of turning cocoa beans into delectable chocolate bars. Over the years, he honed his skills and knowledge in the art of chocolate making, experimenting with different techniques and recipes to create unique and delicious chocolate creations.Inspired by his passion for chocolate and a desire to streamline the chocolate-making process at home, Mike set out to build his own chocolate making machine. Using his background in engineering and his expertise in chocolate making, he meticulously designed and assembled a custom machine that could transform raw cocoa beans into high-quality chocolate bars.The machine features a series of carefully calibrated processes, including roasting, grinding, conching, and tempering, all of which are essential steps in the chocolate-making process. With the use of his machine, Mike is able to control the entire chocolate-making process from start to finish, ensuring that the end result is a perfectly smooth and flavorful chocolate bar.What sets Mike's machine apart from other home chocolate making devices is its ability to produce chocolate on a larger scale, making it suitable for small-scale commercial production. This has piqued the interest of a renowned chocolate company, who sees the potential for collaboration with Mike to further develop and refine his invention for wider use.The company was impressed with Mike's ingenuity and the quality of the chocolate his machine produces. They were particularly drawn to the machine's potential to revolutionize the way chocolate is made at home, offering enthusiasts the ability to create professional-grade chocolate in their own kitchens.In response to the company's interest, Mike has entered into discussions with them to explore the possibility of a partnership that could see his machine being produced and sold to fellow chocolate enthusiasts. This exciting prospect has opened up a world of possibilities for Mike, as he contemplates the potential impact his invention could have on the chocolate-making industry.For Mike, the opportunity to collaborate with a established chocolate company is a dream come true. He is thrilled at the prospect of seeing his machine being used by chocolate lovers and professionals alike, and the thought of contributing to the advancement of chocolate-making technology fills him with a sense of pride and accomplishment.As discussions between Mike and the chocolate company continue, both parties are optimistic about the potential of their partnership and are eager to see where this collaboration may lead. The prospect of bringing Mike's chocolate making machine to the market represents a significant milestone for both parties, and they are both eager to see this exciting project come to fruition.For now, Mike is continuing to fine-tune his machine, making adjustments and improvements based on feedback from the company and other chocolate experts. His dedication to his craft and his unwavering passion for chocolate making have driven him to push the boundaries of what is possible, and it is this drive and determination that have brought him to the attention of the chocolate industry at large.Looking to the future, Mike is excited about the potential of his machine to make a meaningful impact on the world of chocolate making. Whether it's enabling individuals to create their own chocolate delights at home or revolutionizing the way small-scale chocolate production is carried out, Mike's machine has the potential to change the landscape of chocolate making for years to come. With the support and expertise of the company, this prospect is closer to becoming a reality than ever before.

Highly Efficient Fully Automatic Packing Machine for Streamlined Packaging

Fully Automatic Packing Machine Revolutionizes Packaging Process for CompanyIn the fast-paced world of manufacturing and packaging, efficiency is key. Companies are constantly searching for innovative solutions to streamline their processes and improve overall productivity. That's where the fully automatic packing machine comes in. This cutting-edge technology is revolutionizing the way companies package their products, and one company that is leading the way in harnessing the power of this technology is {Company Name}.{Company Name} is a leading manufacturer and distributor of a wide range of consumer goods, including food products, beverages, and personal care items. With a commitment to delivering high-quality products to their customers, the company is always on the lookout for the latest advancements in packaging technology. That's why they have recently invested in a state-of-the-art fully automatic packing machine that is set to transform their packaging process.This advanced packing machine is equipped with a range of features that set it apart from traditional packaging systems. One of the key benefits of this technology is its ability to operate without the need for human intervention. This means that the packaging process can run continuously, without the need for manual labor, resulting in significant time and cost savings for the company. Additionally, the machine is capable of handling a wide variety of packaging materials, from cardboard boxes to plastic containers, making it incredibly versatile for {Company Name}'s diverse product range.The fully automatic packing machine is also designed to provide precise and consistent packaging, ensuring that each product is securely sealed and properly labeled. This level of accuracy is essential for {Company Name}, as they strive to maintain the highest standards of quality and safety for their products. With this technology, the company can have peace of mind knowing that their products are being packaged efficiently and effectively every time.In addition to its efficiency and precision, the fully automatic packing machine is also incredibly user-friendly. With intuitive controls and a user-friendly interface, the machine can be easily operated by {Company Name}'s staff with minimal training. This ensures that the company can quickly integrate this new technology into their existing packaging processes and start reaping the benefits right away.{Company Name} is already seeing the positive impact of this fully automatic packing machine on their operations. With the ability to package products at a much faster rate, the company has been able to increase their overall output without compromising on quality. This has allowed them to meet growing customer demand and expand their market reach, all while maintaining their high standards for product quality and safety.Furthermore, the fully automatic packing machine has enabled {Company Name} to reduce their labor costs and allocate their resources more efficiently. By automating the packaging process, the company has been able to redeploy their workforce to other areas of the business, where their skills and expertise can be better utilized. This has not only improved the company's overall productivity but has also had a positive impact on employee morale and satisfaction.Looking ahead, {Company Name} is excited about the potential for further advancements in packaging technology. They are committed to staying at the forefront of innovation and are eager to explore how they can continue to leverage new technologies to enhance their packaging processes and improve their overall business operations.In conclusion, the fully automatic packing machine has revolutionized the way {Company Name} packages their products. This advanced technology has brought about significant improvements in efficiency, accuracy, and productivity, allowing the company to meet customer demand and maintain their high standards for product quality and safety. As they continue to invest in the latest advancements in packaging technology, {Company Name} is poised to remain a leader in their industry and provide their customers with top-quality products for years to come.

High-Quality Cardboard Packaging for Sandwiches Extends Shelf Life

Sandwich packing is a crucial aspect of any sandwich making operation. Whether you run a small sandwich shop or a large-scale food manufacturing unit, you need to ensure that your product remains fresh and appetizing for as long as possible. This requires the use of high-quality sandwich packaging materials and sealing machines that can provide the perfect seal, thus prolonging the shelf life of your sandwiches.One such sealing machine that stands out in the market today is the Enterpack sandwich sealing machine. This unique and innovative machine has been designed to provide the perfect seal for your sandwiches, thereby prolonging their shelf life by up to three days. The Enterpack sandwich packaging system is compatible with a wide range of cardboard sandwich packaging, making it an ideal choice for sandwich makers who place a high value on quality.Unlike plastic containers that are commonly used in sandwich packaging, cardboard sandwich packs are much higher in quality. They offer superior insulation, which protects the sandwiches from moisture, heat, and UV light, all of which contribute to food spoilage. Cardboard sandwich packaging is also much more environmentally friendly, as it can be easily disposed of and recycled.Using the Enterpack sandwich sealing machine, you can seal any type of sandwich, from cold and hot sandwiches, wraps, paninis, baguettes, and more. The machine comes with adjustable sealing and cutting functions to accommodate different sandwich sizes and shapes. This makes it an ideal machine for businesses with a diverse sandwich production line.In addition to ensuring the freshness and quality of your sandwiches, cardboard sandwich packaging provided by Enterpack also serve as an excellent marketing tool. They can be customized with your brand colors, logo, and tagline, thus promoting your brand to potential customers. This can be particularly useful for businesses that rely on takeout and delivery services, where customers are more likely to judge the quality of the food by its packaging.Overall, the Enterpack sandwich sealing machine is a must-have for any sandwich maker who values quality, freshness, and sustainability. It offers a cost-effective and efficient way of prolonging the shelf life of your sandwiches, while also providing an excellent marketing opportunity. So whether you are running a small sandwich shop or a large-scale food manufacturing unit, be sure to invest in the Enterpack sandwich sealing machine for all your sandwich packaging needs.Keywords: Sandwich Sealer Machine, Enterpack sandwich packaging system, cardboard sandwich packs, plastic containers, sandwich making operation, sandwich packaging materials, food spoilage, environmentally friendly, adjustable sealing and cutting functions, sandwich production line.

Top Quality Candy Forming Machines with Excellent After Sales Service from China Manufacturers

China Forming Machine Manufacturers Witnessing Increasing DemandChina has been at the forefront of manufacturing various machines and equipment for various industries globally. One such sector that has witnessed immense growth in recent times in China is the candy industry. As the demand for hard candies and various other forms of candies sees an upswing, China has emerged as a leading player in the candy-forming machine manufacturing industry.According to reports, the global candy market is estimated to reach $160 billion by 2023 with a growth rate of 3.7%. This rise in demand for candies, particularly hard candies, has opened up a plethora of opportunities for candy forming machine manufacturers in China.Leading Chinese manufacturers in this field have been at the forefront of supplying superior quality hard candy forming machines to global markets. A hard candy forming machine is primarily used to shape hard candies and other confectionery products into various creative designs. The machine works on a vacuum pump that helps shape the candy mixture into different shapes and sizes according to the mold used.Leading players in this industry offer rotary hard candy forming machines and flat hard candy forming machines. They also custom-make machines according to the specific requirements of their clients.One of the hardest parts of producing hard candies is the forming; it requires a lot of precision, accuracy, and speed. With China's candy-forming machine manufacturers, this tedious task is easier to handle, and with automatic machines, it is further streamlined.The machines' quality is assured, and the companies provide excellent after-sales service to their clients. Their machines are equipped with advanced controls systems that make them user-friendly and easy for operators to navigate.The machines can produce around 200-400 candy pieces per minute, depending on their model's make and the candy's requirement. The machines are designed to handle various hard candy recipes, from both liquid- and powder-based sugar ingredients.China's forming machine manufacturers specialize in producing rotary hard candy forming machines that use a drum for the molding process. The drum rotates during the process, and vacuum pumps shape the hard candy against the molds. The machines have an output capacity of 200-400 pieces per minute.Flat hard candy forming machines are also very popular in the industry. Some manufacturers offer customized machines that can create up to ten different layers, producing candies with multilayered looks.It is interesting to note that most of the hard candy forming machine manufacturers in China also supply to other countries where their products are highly sought after. They have successfully managed to capture a considerable share of world markets and provide unmatched quality to users at competitive pricing.It is no surprise, given the growth potential in the candy market, that China's candy-forming machine manufacturers are experiencing increasing demand from across the globe. Besides, the companies are continually innovating, developing, and improving their products to suit the ever-changing market demands.In conclusion, one can confidently say that the future of hard candy forming machines made in China is bright, and the country is well-positioned to meet diverse requirements and dominate the global candy market.About the company (fill in with company details)We are a leading manufacturer of forming machines for hard candies and other confectionery products in China. Our company has more than ten years of experience in the industry and provides unparalleled quality and service to our customers globally.We specialize in producing rotary hard candy forming machines and flat hard candy forming machines, and custom-made machines according to our customers' specific requirements.Our machines are equipped with advanced controls systems that make them user-friendly and easy for operators to navigate. With an output capacity of 200-400 pieces per minute, our machines deliver high speed and precision for our customers' satisfaction.We are committed to continuous innovation, development, and improvement of our products to meet the ever-changing market demands. With us, you are assured of the highest quality and the best after-sales service.