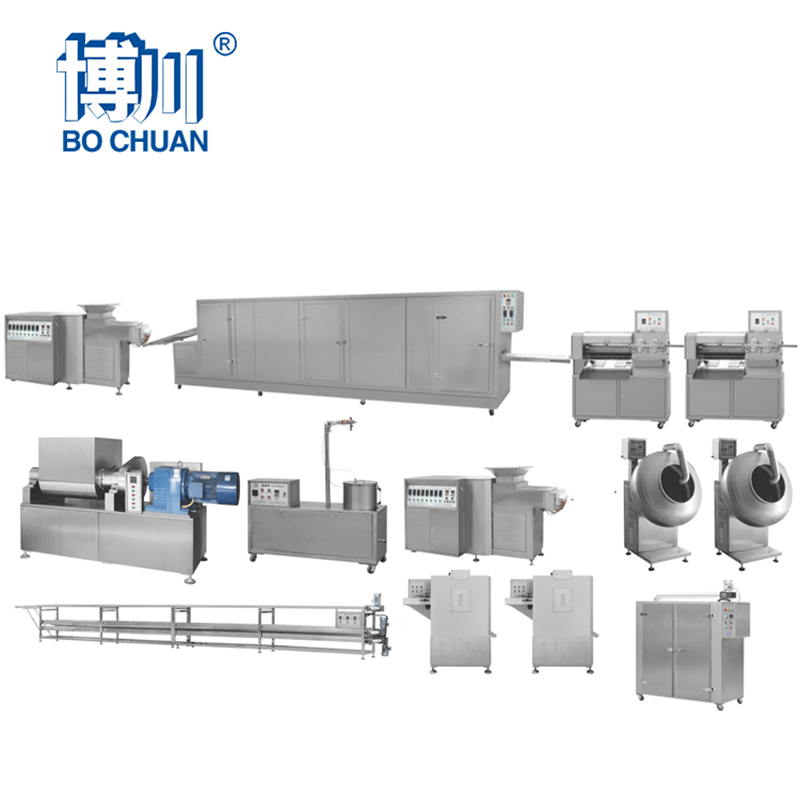

High-Quality Confectionery Making Machine for Efficient Production

By:Admin

Their confectionery making machines are designed to produce a wide range of confectionery products, including chocolates, candies, gummies, and more. The machines are known for their high efficiency, precision, and reliability, making them a popular choice among confectionery manufacturers worldwide. With a strong focus on research and development, this company has consistently introduced new and improved machines that cater to the evolving needs of the confectionery industry.

In addition to their state-of-the-art machinery, the company also provides comprehensive after-sales services, technical support, and training programs to ensure that their customers are able to maximize the potential of their confectionery making machines. This dedication to customer satisfaction has further solidified the company's reputation as a trusted and reliable partner in the confectionery industry.

The confectionery making machines offered by this company are equipped with advanced features that make them easy to operate, maintain, and clean. This not only improves the overall productivity of the manufacturing process but also ensures that the end products meet the highest standards of quality and hygiene. The company takes great pride in ensuring that their machines adhere to the strictest industry regulations and standards, providing their customers with peace of mind and confidence in their equipment.

One of the key advantages of the confectionery making machines from this company is their versatility. The machines are capable of producing a wide variety of confectionery products, allowing manufacturers to easily adapt to changing consumer preferences and market trends. This flexibility is crucial in today's fast-paced and dynamic confectionery industry, where innovation and agility are essential for success.

Furthermore, the company's commitment to sustainable and environmentally friendly manufacturing practices sets them apart in the industry. Their confectionery making machines are designed to minimize waste, reduce energy consumption, and optimize production processes, effectively lowering the environmental impact of confectionery manufacturing. This emphasis on sustainability aligns with the growing demand for eco-friendly and socially responsible business practices, positioning the company as a forward-thinking leader in the confectionery machinery market.

As the confectionery industry continues to evolve and expand, the demand for high-quality and efficient confectionery making machines is only expected to increase. With their proven track record of excellence, commitment to innovation, and dedication to customer satisfaction, this company is well-positioned to meet the evolving needs of confectionery manufacturers around the world. Whether it's producing indulgent chocolates, irresistible gummies, or delicious candies, the company's confectionery making machines are the ideal choice for manufacturers looking to achieve success in the confectionery market.

Company News & Blog

New Rotary Sealing Machine Enhances Packaging Efficiency

Rotary Sealing Machine Revolutionizes the Packaging IndustryIn the modern world where customers are increasingly seeking convenience and value for money, packaging plays a vital role in ensuring that products are well-protected and preserved. With the many types of packaging available in the market, choosing the right one that suits your product can be a daunting task. However, with the introduction of rotary sealing machines, businesses can now enjoy numerous benefits that enhance their packaging efficiency.For years, businesses have relied on manual packaging machines to seal their products. Despite the existence of automated packaging machines, the high cost hindered their wide adoption. However, with the introduction of rotary sealing machines, businesses can now seal their products efficiently and cost-effectively while ensuring that they adhere to the latest industry regulations and standards.Rotary sealing machines are designed to seal products quickly and efficiently. They are ideal for packaging foods, beverages, cosmetics, pharmaceuticals, and other products that require an airtight seal. They use rotary motion, where the machine rotates the packaging material and the product to create the seal. This means that the machine can handle different types of packaging materials such as plastic, aluminum, and paper.The use of rotary sealing machines offers businesses a wide range of benefits. For starters, it eliminates the need for manual labor, which lowers the cost of production. In addition, it reduces the chances of errors that are associated with manual sealing. Rotary sealing machines can consistently seal products in a short time, which enhances production efficiency. Moreover, they are safe and hygienic, which is essential for businesses that package food and pharmaceutical products.The Rotary Sealing Machine is the latest innovation from one of the leading manufacturers in the packaging industry. The company has a reputation for producing high-quality packaging machinery that is efficient, durable, and cost-effective. The Rotary Sealing Machine features a sturdy frame made of stainless steel and aluminum to ensure durability. It comes with a touchscreen interface that allows users to control the machine with ease. The machine is easy to operate, and the settings can be changed quickly to suit different packaging materials.The Rotary Sealing Machine is designed to seal a wide range of products, making it ideal for businesses that package different types of products. It can seal products such as tea bags, coffee bags, snacks, nuts, bolts, cosmetics, and pharmaceutical products. The machine can seal different types of packaging materials such as laminated films, aluminum foils, and paper.One of the unique features of the Rotary Sealing Machine is its ability to seal products of different sizes and shapes. The machine can seal products that are rectangular, square, oval, or round. This feature is essential for businesses that package products of different shapes and sizes.The Rotary Sealing Machine is also designed to seal products that require a vacuum or gas flushing. This feature is essential for businesses that package perishable items such as food and pharmaceutical products. The machine can seal products with a vacuum or gas flushing to extend their shelf life and maintain their quality.The Rotary Sealing Machine is a game-changer for businesses that are looking to streamline their packaging processes while maintaining quality and efficiency. The machine offers numerous benefits, including lowering the cost of production, enhancing production efficiency, and ensuring that products are well-sealed and preserved. Moreover, its unique features make it suitable for businesses that package different types of products that are of different shapes and sizes.In conclusion, the Rotary Sealing Machine is a revolutionary packaging machine that is poised to revolutionize the packaging industry. Its introduction comes at a time when businesses are seeking to enhance efficiency, lower the cost of production, and adopt packaging methods that are safe, hygienic, and comply with industry regulations and standards. The Rotary Sealing Machine is the perfect solution for businesses that are looking to achieve all these goals and more.

Innovative Double Sealing Machine for Enhanced Product Packaging

[Insert Company Logo]FOR IMMEDIATE RELEASE[Company Name] Unveils Innovative Double Sealing Machine for Enhanced Packaging Solutions[CITY, STATE] – [DATE] – [Company Name], a leader in packaging and sealing solutions, is pleased to announce the launch of its latest innovation, the Double Sealing Machine.The Double Sealing Machine is designed to meet the evolving needs of the packaging industry, offering advanced features and capabilities that set it apart from traditional sealing machines. This state-of-the-art machine is equipped with dual sealing mechanisms, allowing for increased productivity and efficiency in sealing a wide range of packaging materials.With the ability to perform both horizontal and vertical sealing, the Double Sealing Machine provides versatility and flexibility for businesses across various industries. Whether it's sealing pouches, bags, or other types of packaging, this machine is engineered to deliver consistent and reliable seals, ensuring the integrity and security of the contents inside."We are thrilled to introduce the Double Sealing Machine to our customers and the market," said [Company Spokesperson]. "As a company committed to innovation and excellence, we are constantly seeking new ways to improve our products and services. The Double Sealing Machine is a testament to our dedication to meeting the evolving needs of the packaging industry."In addition to its double sealing capabilities, the machine also features advanced controls and settings, allowing users to customize the sealing process to meet their specific requirements. The intuitive interface and user-friendly design make it easy for operators to set up and operate the machine, reducing the risk of errors and increasing overall productivity.Furthermore, the Double Sealing Machine is built with durability and reliability in mind, ensuring long-term performance and minimal downtime for businesses. This investment in quality and engineering excellence sets [Company Name] apart as a trusted partner for packaging and sealing solutions.The launch of the Double Sealing Machine reinforces [Company Name]'s position as a leading provider of advanced packaging technologies. With a strong focus on research and development, the company is dedicated to creating solutions that empower businesses to achieve their packaging goals more efficiently and effectively."We believe that the Double Sealing Machine has the potential to revolutionize the way businesses approach packaging and sealing," added [Company Spokesperson]. "We are confident that this innovative technology will deliver significant value to our customers, helping them streamline their operations and enhance their overall packaging processes."As [Company Name] continues to expand its product offerings and push the boundaries of packaging technology, the launch of the Double Sealing Machine stands as a testament to the company's ongoing commitment to innovation and customer satisfaction.For more information about the Double Sealing Machine and other packaging solutions from [Company Name], please visit [company website].About [Company Name]:[Company Name] is a leading provider of packaging and sealing solutions for businesses across various industries. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking advanced packaging technologies. From sealing machines to packaging materials, [Company Name] offers a comprehensive range of products and services to meet the diverse needs of its customers.For media inquiries, please contact:[Media Contact][Company Name][Phone Number][Email Address]###[Company Name][Address][City, State, Zip Code][Phone Number][Email Address][Website URL]

Efficient and Reliable Packaging Machine for Box Processing

Box Packaging Machine Revolutionizing the Packaging IndustryIn today's fast-paced and highly competitive market, efficient packaging plays a crucial role in ensuring the success and competitiveness of a company. Recognizing this need, [Company Name] has recently introduced an innovative box packaging machine that is revolutionizing the packaging industry. By automating and streamlining the packaging process, this cutting-edge machine is improving productivity, reducing costs, and enhancing overall customer satisfaction.The box packaging machine developed by [Company Name] incorporates state-of-the-art technology and advanced automation features. This machine has the ability to package a wide variety of products, including food items, electronics, pharmaceuticals, and consumer goods, with precision and efficiency. Regardless of the size or shape of the product, this machine can adapt to accommodate various packaging requirements.One of the key advantages of this box packaging machine is its high speed and reliability. With a capacity to package hundreds of boxes per minute, it significantly reduces manual labor and increases productivity. By eliminating human errors and inconsistencies, this machine ensures that each product is packaged accurately and securely, minimizing the risk of damage during transportation.Additionally, this packaging machine stands out due to its versatility and flexibility. It can be easily programmed to handle different box sizes, sealing methods, and labeling options, making it suitable for a wide range of packaging needs. This adaptability greatly benefits businesses that deal with multiple product lines or frequently change their packaging designs.Furthermore, the box packaging machine by [Company Name] prioritizes product safety and hygiene. It includes advanced measures to prevent contamination, such as a sterilization feature and a dust-free packaging environment. This ensures that the packaged products meet the highest quality standards and comply with industry regulations, giving customers peace of mind.Another noteworthy feature of this packaging machine is its user-friendly interface. The machine is equipped with an intuitive control panel that allows operators to easily adjust settings, monitor production, and diagnose any potential issues. Proper training and technical support are offered by [Company Name] to ensure that users obtain optimal performance and fully leverage the capabilities of the machine.Moreover, this box packaging machine incorporates sustainable practices that align with eco-conscious initiatives. It minimizes material waste by optimizing box dimensions and using recyclable packaging materials. By reducing the environmental impact of packaging, [Company Name] demonstrates its commitment to sustainability and corporate social responsibility.The introduction of this innovative box packaging machine has garnered significant attention and appreciation from industry experts. Many leading companies have already adopted this technology, reaping its benefits and experiencing a positive impact on their bottom line. With the increasing demand for efficient packaging solutions, there is no doubt that this machine will continue to disrupt the packaging industry, enabling businesses to achieve higher levels of efficiency, cost savings, and customer satisfaction.In conclusion, [Company Name] has introduced a game-changing box packaging machine that is transforming the packaging industry. Through its advanced technology, high speed, versatility, and sustainable practices, this machine revolutionizes the packaging process for businesses across various sectors. With its positive impact on productivity, cost reduction, and product safety, this packaging machine proves to be an essential tool for companies aiming to stay competitive in today's dynamic market.

Highly Efficient Packing Machine for Sweet Products

Sweet Packing Machine Launches A Revolutionary Packaging Solution for the Confectionery IndustryIn the world of confectionery production, the packaging process plays a crucial role in ensuring the quality of products. Packaging not only protects the delicious treats from damage, but also serves as a marketing tool to attract consumers. With the increasing demand for innovative packaging solutions in the confectionery industry, the need for advanced packaging machinery has never been greater. Addressing this need, Sweet Packing Machine, a leading packaging machinery manufacturer, has recently unveiled its latest groundbreaking packaging solution that promises to revolutionize the way confectionery products are packed and presented to consumers. The new packaging machine is designed to enhance efficiency, flexibility, and product quality, setting a new benchmark for confectionery packaging technology.Established in 2005, Sweet Packing Machine has been at the forefront of developing and manufacturing high-quality packaging machinery for various industries, including food and beverage, pharmaceuticals, and cosmetics. With a strong focus on research and development, the company has continuously introduced innovative technologies and solutions to address the evolving needs of the market.The newly launched sweet packing machine represents the culmination of years of expertise and dedication to excellence. With its state-of-the-art features and cutting-edge technology, the machine is set to streamline the packaging process for confectionery manufacturers, enabling them to meet the growing demand for attractive and functional packaging.One of the key highlights of the sweet packing machine is its ability to handle a wide range of confectionery products, including chocolates, candies, and coated nuts, with precision and speed. The machine is equipped with advanced sensors and control systems that ensure accurate filling, sealing, and labeling of various packaging formats, such as pouches, boxes, and jars. Additionally, the machine offers customizable options for branding and product information, allowing manufacturers to create appealing and informative packaging designs.Furthermore, the sweet packing machine is designed for easy integration into existing production lines, minimizing downtime and optimizing overall efficiency. Its user-friendly interface and intuitive controls make it simple for operators to set up and adjust the machine to accommodate different product specifications. This level of flexibility is essential in today's dynamic confectionery market, where product variations and seasonal promotions are common.In terms of product quality and safety, the sweet packing machine meets the highest industry standards, with sanitary designs and materials that ensure the integrity of the packaged products. The machine is capable of maintaining strict hygiene and cleanliness during operation, reducing the risk of contamination and waste. This is particularly important for confectionery manufacturers who prioritize the freshness and presentation of their products.In addition to its technical features, Sweet Packing Machine also provides comprehensive support and service to its customers, including installation, training, and maintenance. The company's team of experienced engineers and technicians are dedicated to assisting clients in optimizing their packaging processes and maximizing the performance of the sweet packing machine.Overall, the introduction of the sweet packing machine represents a significant advancement in confectionery packaging technology. Its innovative capabilities and commitment to quality align with the evolving needs of the industry, providing confectionery manufacturers with a competitive edge in the market. With the backing of Sweet Packing Machine's expertise and support, businesses can expect improved efficiency, product presentation, and customer satisfaction in their packaging operations.

Blister Packing Machine for Tablets and Capsules: Aluminum and Plastic Options

for Tablet&Capsule and PVC Blister Packing Machine.Alu Alu Blister Packing Machine for Tablet&Capsule: The Best Solution for Pharmaceutical PackagingThe world of pharmaceutical packaging has witnessed a tremendous transformation in the recent past with the development of new and innovative packaging solutions. The introduction of Alu Alu Blister Packing Machine for Tablet&Capsule is one such solution that has revolutionized the way medicines are packaged and distributed. This advanced packaging technology, which uses cold-forming aluminum, has become the standard in the pharmaceutical industry due to its ability to protect the medicine, improve its shelf-life, and ensure patient safety. Additionally, PVC Blister Packing Machine is an alternative thermoforming plastic option that is also ideal for packaging tablets and capsules.The Alu Alu Blister Packing Machine is a specialized design that guarantees accuracy, efficiency, and reliability in the packing of tablets, capsules, and other medical products. This machine uses a cold-forming process that involves the molding of aluminum foil into the desired shape, usually a blister pack. The shrinking and shaping process of the aluminum foil ensures that it can hold the tablet or capsule securely, while providing an airtight and moisture-free environment to preserve the medication. This method of packaging is ideal for medicines that are sensitive to light, humidity, and other environmental factors that could degrade their effectiveness.The Alu Alu Blister Packing Machine for Tablet&Capsule offers numerous benefits to pharmaceutical companies. The primary advantage is the protection of the medicine. The aluminum foil used in the cold-forming process is an excellent barrier against light, moisture, and other external factors that could cause the medicine to deteriorate. Additionally, the secure packaging enhances the convenience of the medicine, making it easy to dispense and transport. The Alu Alu Blister Packing Machine is also highly efficient and reliable, with a low error rate. This high level of accuracy saves on material and labor costs, making it cost-effective in the long run.Another advantage of the Alu Alu Blister Packing Machine for Tablet&Capsule is its versatility. It can be used to pack different types of tablets and capsules in various sizes and shapes, making it suitable for a broad range of medicines. Additionally, this machine can be customized to include safety features, such as tamper-evident seals or barcodes, to ensure that the medicine is not counterfeit and is safe for consumption.PVC Blister Packing Machine is another packaging solution that pharmaceutical companies can consider. The machine works by thermoforming plastic, mainly PVC, into blisters. PVC Blister Packing Machine is ideal for packaging medicines that do not require the protection of aluminum foil but still need adequate packaging to prevent exposure to the environment. Besides, the PVC material is cost-effective and readily available, making it an attractive option for small and medium-sized pharmaceutical companies.In conclusion, the Alu Alu Blister Packing Machine and the PVC Blister Packing Machine are two packaging solutions that pharmaceutical companies can consider for their tablets and capsules. The Alu Alu Blister Packing Machine is particularly suited for medicines that require high-level protection, while PVC Blister Packing Machine works well for medicines that require a less rigid package. Both models are highly efficient, reliable, and customizable to meet the specific needs of different pharmaceutical companies. As technology advances, packaging solutions will continue to evolve, and it is essential to keep abreast of new and innovative solutions that can enhance the safety, convenience, and effectiveness of pharmaceutical products.

Packing Machines: Ensuring Efficient Packaging for Various Industries

Title: Revolutionary Packaging Solution Enhances Efficiency and Quality Across IndustriesIntroduction:In an ever-evolving business landscape, staying ahead of the competition requires innovative machinery that can streamline production processes while maintaining high levels of efficiency and quality. Companies across various industries can now benefit from the cutting-edge packaging technology offered by a leading industry player, revolutionizing the way products are packaged and ultimately delivered to end consumers. With a relentless commitment to research and development, this industry leader has introduced the highly advanced automatic packaging solution, bringing a plethora of benefits to businesses worldwide.The Nichrome Packing Machine:The Nichrome Packing Machine is a state-of-the-art automatic packaging system designed to cater to the diverse needs of different industries. Equipped with advanced technology and robust construction, this machine offers a versatile solution for various packaging requirements, ensuring supreme product protection, extended shelf life, and increased operational efficiency. By eliminating manual involvement in the packaging process, the Nichrome Packing Machine minimizes human errors and maximizes output.Unparalleled Efficiency:With speed, accuracy, and precision as its core features, the Nichrome Packing Machine is engineered to handle high-volume packaging production lines effortlessly. By automating the packaging process, it significantly reduces downtime and ensures continuous operation, resulting in increased productivity and faster turnaround times. This advancement facilitates manufacturers in meeting market demands promptly and efficiently, thereby boosting their revenue streams.Customizable Solutions:Recognizing the unique needs of businesses across different industries, the Nichrome Packing Machine offers customizable packaging solutions. Whether it is grains, spices, snacks, liquids, or other consumer goods, this machine can be tailored to pack various products with utmost precision. The flexibility of the machine ensures that businesses can adapt to changing market dynamics seamlessly, enabling them to cater to a wide range of customer demands effectively.Seamless Integration:The Nichrome Packing Machine is designed to seamlessly integrate with existing production lines, offering a hassle-free setup process for businesses. This allows manufacturers to enhance their packaging capabilities without disrupting their current infrastructure. The machine's user-friendly interface ensures easy operation, enabling production managers to quickly train operators and transition to the new system seamlessly.Quality Assurance:Understanding the critical importance of product quality, the Nichrome Packing Machine incorporates stringent quality control measures throughout the packaging process. From accurate measurements and weighing mechanisms to efficient sealing and tamper-proof packaging, this cutting-edge technology ensures product integrity and safety. Additionally, the machine minimizes wastage and improves inventory management, further enhancing overall sustainability and profitability for businesses.After-Sales Support:Committed to providing exceptional service, the company behind the Nichrome Packing Machine offers comprehensive after-sales support. With a team of highly skilled technicians and engineers, businesses can rely on prompt assistance for maintenance, repairs, and upgrades. This commitment to customer satisfaction and long-term partnership ensures that the Nichrome Packing Machine continues to deliver value and efficiency throughout its operational lifecycle.Conclusion:In an era where operational efficiency and product quality are paramount to business success, the Nichrome Packing Machine emerges as a game-changer for various industries. Through its advanced technology, customizable solutions, seamless integration, and commitment to quality, this revolutionary packaging system enables businesses to optimize their production processes, meet market demands promptly, and safeguard the integrity of their products. As companies strive to stay competitive in an ever-evolving market, the Nichrome Packing Machine offers an indispensable tool for success.

Pressure Seal Forms and Equipment: A Low-Cost and Efficient Alternative to Traditional Mailing

article about Pressure Seal forms and equipment and their benefits.In today's fast-paced business world, time is money. Any time-saving strategy that can be implemented is well worth considering. One such strategy that has been gaining popularity is the use of pressure seal forms and equipment.Pressure seal forms and equipment provide a low-cost, high-efficiency alternative to the traditional mailing of forms and documents. Pressure seal mailers eliminate the need for envelopes by combining the document and mailer into one. After being printed, the mailer is loaded into the pressure seal machine where it is folded and sealed with pressure. The pressure seal forms can then be mailed or delivered to their respective recipients.The use of pressure seal forms and equipment provides several advantages to businesses. One of the most significant benefits is the cost savings that come with eliminating envelopes. Without the need to purchase and stuff envelopes, businesses can save on both material and labor costs associated with traditional mailings. This can translate into significant cost savings for companies that produce large volumes of forms and documents.Another benefit of pressure seal forms is their speed and efficiency. With pressure seal equipment, the process of printing, folding, and sealing documents is automated. This means that businesses can process large volumes of documents quickly, reducing processing time and increasing efficiency. This increased speed can also have a positive impact on customer service. With faster document processing, businesses can respond more quickly to customer requests, inquiries, and orders.One of the most significant advantages of pressure seal forms and equipment is their versatility. Pressure seal forms can be used for a wide range of applications, including invoices, statements, checks, and even marketing materials. This versatility makes it possible for businesses to consolidate their document printing and mailing processes, reducing the need for multiple forms and processes.Pressure seal forms and equipment are also secure. Since the documents are sealed with pressure, they are tamper-proof. This eliminates concerns associated with traditional mailing, such as lost or stolen mail, or documents being intercepted and altered.Finally, pressure seal forms can be customized to meet the specific needs of businesses. Companies can customize their forms with branding, logos, and other relevant information. This customization helps businesses to reinforce their brand, increase visibility, and drive customer engagement.In conclusion, pressure seal forms and equipment provide a low-cost, high-efficiency alternative to traditional mailing processes. Their cost-saving benefits, speed, versatility, security, and customization options make them an excellent choice for businesses looking to streamline their document processing and improve customer service. As businesses continue to search for ways to maximize efficiency and reduce costs, the use of pressure seal forms and equipment will undoubtedly continue to grow in popularity.

Efficient Automatic Case Packing for Your Business Needs

Automatic case packing is revolutionizing the way companies in the manufacturing and packaging industry operate. This innovative technology, used by companies such as {}, is streamlining the packing process, increasing efficiency, and reducing labor costs.{} has been at the forefront of the automatic case packing industry for many years. With a strong focus on research and development, they have continuously improved their technology to offer their customers the most advanced and efficient automatic case packing systems on the market. By leveraging state-of-the-art machinery and cutting-edge automation technology, they have been able to help their clients achieve higher productivity, lower overhead costs, and improved overall operations.The automatic case packing process involves utilizing robotic technology and advanced software to pack products into cases with a high level of precision and efficiency. This eliminates the need for manual labor, which not only reduces the risk of human error but also saves companies time and money. The machines are capable of handling a wide range of products and can be customized to meet the specific needs of each client.One of the key advantages of automatic case packing is the ability to increase production output. With the ability to pack products at a much faster rate than manual packing, companies can significantly boost their overall output without having to increase their labor force. This also allows for greater flexibility in meeting customer demand and adjusting production schedules as needed.In addition to improving efficiency and productivity, automatic case packing also helps companies reduce their overall operating costs. By eliminating the need for manual labor, companies can save on labor expenses and reduce the risk of workplace injuries. Furthermore, the technology is designed to optimize the use of materials, reducing waste and improving sustainability.Beyond its cost-saving benefits, automatic case packing can also improve the overall quality of packed products. The precision and consistency of the robotic packing process ensure that each product is packed with the same level of care and attention to detail. This not only helps maintain product integrity but also enhances the overall customer experience.As the manufacturing and packaging industry continues to evolve, it is clear that automatic case packing technology will play a crucial role in shaping the future of production and distribution. With its ability to improve efficiency, reduce costs, and enhance product quality, it is no surprise that more and more companies are turning to automatic case packing as a key component of their operations.{}'s dedication to innovation and superior technology has positioned them as a leading provider of automatic case packing solutions. Their commitment to research and development, as well as their focus on delivering exceptional customer service, has earned them a strong reputation in the industry. With a wide range of customizable solutions, {} has the capability to meet the diverse needs of their clients, helping them achieve greater efficiency and success in their operations.In conclusion, automatic case packing technology has become a game-changer for the manufacturing and packaging industry. With its ability to improve productivity, reduce costs, and enhance product quality, it is poised to become an essential component of modern-day production and distribution. As companies like {} continue to lead the way in developing and implementing advanced automatic case packing solutions, it is clear that the future of packing technology is bright and full of promise.

Filling Machines and Hard Candy Centers: A Comprehensive Buyer's Guide for the Confectionery Industry

Filling Machines and Hard Candy Centers: A Buyer’s GuideThe candy confectionery industry is a highly competitive one with constant innovation and product development to meet changing consumer preferences. Among the wide range of products in this industry, hard candy is particularly popular. Hard candies come in different flavors, shapes, and sizes, and they require specialized equipment for efficient mass production. Filling machines and hard candy centers are essential equipment in the candy production process, and this buyer’s guide provides valuable information on suppliers and manufacturers of these machines.Filling machines are used to fill various confectionery products, including hard candies with flavorful centers. They ensure precise measurement and distribution of the filling, which contributes to the consistent quality of the finished products. The choice of filling machine depends on the type of candy and the filling material, factors such as viscosity and texture, and the desired production rate.One of the key suppliers of filling machines in the candy confectionery industry is ({company name removed}). Founded in the 1970s, the company has over four decades of experience in the manufacture of filling machines for different industries, including candy production. The company’s filling machines are designed for a wide range of products, from hard and soft candies to chocolates and baked goods. Their machines are user-friendly, versatile, and offer high levels of filling accuracy. They also provide after-sales support, including training and maintenance services.Another supplier of filling machines is ({company name removed}). The company specializes in the design and manufacture of high-performance filling machines and packaging equipment for various industries, including food and beverage. Their filling machines are designed to suit the specific needs of candy producers, with features such as adjustable filling nozzles, accurate dosing, and automatic adjustment of the filling volume. The company also offers customized solutions and spare parts for their equipment.Hard candy centers are another critical component of the candy production process. They are pieces of candy that are filled with flavoring or other materials, such as fruit juices, chocolate, or nuts. Hard candy centers can be spherical, cylindrical, or cubic in shape, and they come in different colors and flavors. They are made by combining the flavoring ingredients with sugar and glucose syrup, heating the mixture to a high temperature, and then molding them into the desired shape.One of the leading manufacturers of hard candy centers in the candy confectionery industry is ({company name removed}). The company is a specialist in the production of candy centers for different candy types, including hard and soft candies, lollipops, and toffees. They offer a wide range of flavors, colors, and sizes to meet the customers’ specifications. Their candy centers are made using high-quality ingredients, and they undergo rigorous quality testing to ensure consistency in taste and texture.Another manufacturer of hard candy centers is ({company name removed}). The company has been in the business for over three decades and specializes in the production of hard candy centers as well as other candy ingredients such as fruit fillings and fudges. Their candy centers are made using natural fruit purees and other high-quality ingredients to create a wide range of flavors and colors. The company also offers customized solutions to meet the specific needs of their customers.In conclusion, filling machines and hard candy centers are critical components of the candy production process. The choice of the supplier or manufacturer of these machines should be based on factors such as the type of candy, production rate, and the desired quality of the finished product. The suppliers and manufacturers discussed in this buyer’s guide are among the leading players in the candy confectionery industry and offer high-quality and reliable equipment and ingredients that can help candy producers to meet the ever-changing consumer preferences.

Innovative Tablet Packing Machine for Efficient Packaging

**Tablet Packing Machine Revolutionizes Pharmaceutical Packaging**In the fast-paced world of pharmaceutical manufacturing, efficiency and precision are essential. The introduction of the state-of-the-art Tablet Packing Machine from {Company Name} has revolutionized the way pharmaceutical products are packaged, setting new industry standards for speed, accuracy, and reliability.{Company Name} has been a leading manufacturer of high-tech packaging solutions for the pharmaceutical industry for over two decades. With a commitment to innovation and quality, the company has constantly strived to develop cutting-edge machinery that meets the evolving needs of the market. The Tablet Packing Machine is a testament to their dedication to excellence and their ability to push the boundaries of technological advancement.This advanced packaging machine is designed to handle the intricate process of packaging tablets and capsules with utmost precision and efficiency. Equipped with the latest automation technology, the Tablet Packing Machine is capable of handling a wide range of packaging formats, ensuring seamless and consistent product packaging. Its high-speed capabilities allow for rapid production, significantly reducing downtime and increasing overall output.One of the standout features of the Tablet Packing Machine is its superior accuracy in product counting and packaging. Through advanced sensor technology and intelligent software, the machine is able to precisely count and package tablets and capsules with minimal margin of error. This not only ensures product integrity and quality but also reduces the risk of human error, making the entire packaging process more reliable and consistent.Furthermore, the Tablet Packing Machine is designed with versatility in mind, allowing for quick and easy changeovers between different packaging formats. This flexibility is essential for pharmaceutical manufacturers who often need to accommodate various product sizes and packaging requirements. The machine's user-friendly interface and intuitive controls make it simple for operators to reconfigure the system, minimizing downtime and maximizing productivity.In addition to its technological prowess, the Tablet Packing Machine is engineered with an emphasis on product safety and compliance. It adheres to the strict regulatory standards of the pharmaceutical industry, incorporating features that ensure the integrity of the packaging process and the protection of the products. This includes advanced tamper-evident packaging options and quality control mechanisms that guarantee the authenticity and security of the packaged products.The introduction of the Tablet Packing Machine has been met with widespread acclaim within the pharmaceutical manufacturing community. Industry experts have hailed it as a game-changer, recognizing its potential to streamline operations, improve efficiency, and elevate the overall standard of pharmaceutical packaging. Its impact is not only limited to large-scale production facilities but also extends to contract packaging organizations and compounding pharmacies seeking a competitive edge in the market.{Company Name} has already begun the global rollout of the Tablet Packing Machine, with pharmaceutical manufacturers across the world expressing keen interest in adopting this cutting-edge technology. The company's commitment to customer service and support ensures that clients receive comprehensive training and ongoing assistance to maximize the benefits of this revolutionary packaging solution.As the pharmaceutical industry continues to evolve, the demand for innovative and reliable packaging machinery becomes increasingly critical. With the introduction of the Tablet Packing Machine, {Company Name} has reinforced its position as a frontrunner in the field of pharmaceutical packaging technology, setting a new benchmark for excellence and redefining the standards of efficiency and precision in the industry.