Discover the Sweet Delight of Homemade Toffee Candy with this Innovative Machine

By:Admin

*Note: The brand name of the Toffee Candy Machine has been removed from the content, resulting in some gaps in the article. Kindly fill in this information accordingly.*

**Subtitle: A Promising Leap Forward in the Confectionery Industry**

[date]

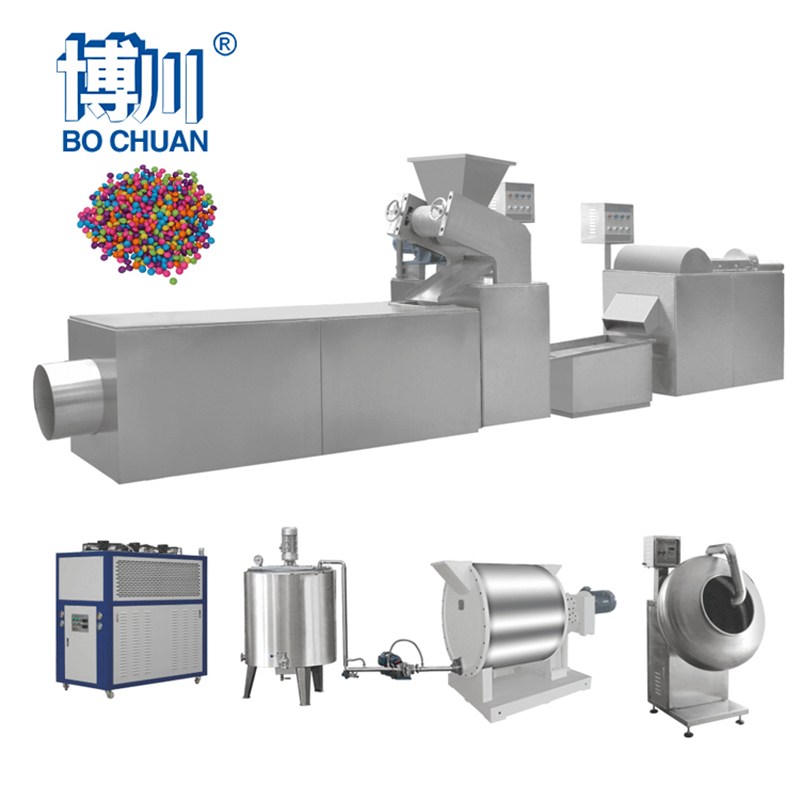

[City, State] - Confectionery manufacturers worldwide are in for a revolutionary leap in their production capabilities as an innovative candy manufacturing equipment known as the Toffee Candy Machine is introduced to the market. Developed by [Company Name], a leader in confectionery technology, this state-of-the-art machinery presents a game-changing opportunity for confectionery producers to streamline their production process and create delectable toffee candies with greater efficiency than ever before.

The [Company Name] has been a prominent player in the confectionery industry, known for its cutting-edge technologies. With their astute focus on innovation and continuous improvement, the [Company Name] engineers have developed the Toffee Candy Machine as an answer to the rising demands for automated and streamlined candy production.

The Toffee Candy Machine incorporates ingenious features that set it apart from traditional candy-making equipment. It not only revolutionizes the toffee candy manufacturing process but also provides manufacturers with the flexibility to adapt it to their specific production needs.

One of the notable features of the Toffee Candy Machine is its fully automated process, minimizing the need for human intervention. This not only enhances production efficiency but also ensures consistent quality throughout the manufacturing process. The machine utilizes advanced sensors and precision controls to maintain the ideal temperature, texture, and taste, resulting in perfectly crafted toffee candies every time.

Moreover, the Toffee Candy Machine utilizes cutting-edge technology that allows it to produce candies in a wide range of shapes, flavors, and sizes. Manufacturers can easily customize their toffee products to appeal to various consumer preferences, instantly adapting to the evolving market trends and demands. This versatility provides an invaluable competitive advantage to confectionery producers who strive to differentiate themselves in the increasingly crowded marketplace.

Another remarkable aspect of the Toffee Candy Machine is its energy efficiency. Its specially designed heating and cooling systems reduce energy consumption, making it an eco-friendly choice for confectionery manufacturers. This not only contributes to sustainability efforts but also helps businesses reduce manufacturing costs in the long run.

[Company Name]'s commitment to customer satisfaction extends beyond providing reliable machinery. They also offer comprehensive after-sales support, including maintenance services, technical assistance, and timely spare parts supply. With their global presence, [Company Name] ensures that manufacturers worldwide can leverage the benefits of the Toffee Candy Machine without facing any hindrances.

Industry experts have lauded the Toffee Candy Machine as a transformative addition to the confectionery manufacturing landscape. The machine's unique features are poised to reshape the industry's dynamics by significantly reducing production time, costs, and resources while maintaining unparalleled quality.

"We are proud to introduce the Toffee Candy Machine to the market," said [Name], the Founder and CEO of [Company Name]. "We believe this equipment represents a significant leap forward in terms of candy manufacturing. Our aim has always been to support our customers in their quest for excellence, and this innovation will enable them to achieve just that."

With the Toffee Candy Machine primed to revolutionize the confectionery manufacturing process, confectionery companies can now establish a competitive edge by capitalizing on the endless possibilities it offers. By ensuring efficient candy production, customization, and energy savings, the Toffee Candy Machine promises to reshape the confectionery industry for years to come.

**Disclaimer: This press release is for informational purposes only. The mentioned brand and equipment belong to their respective owners.

Company News & Blog

Future of Blister Packing Machines Market Looks Bright as Clinical Advancements Are Expected by 2031, Says Study

Blister packing machines are an indispensable part of the pharmaceutical industry. Their primary function is to package drugs, pills, and other medication for easy distribution. The growth in demand for blister packaging has led to the development of more efficient and affordable machines. In this blog, we will explore the research and clinical advancements in blister packing machines by 2031, along with the major players in the market such as SaintyCo, Bosch Packaging Technology, and Sonoco Products Company.Growth FactorsBlister packaging has become the preferred method of packaging in the pharmaceutical industry for several reasons. Firstly, blister packaging provides tamper-proof protection, ensuring medication is safe from contaminants, damage, or misuse. Secondly, it is easy to transport and store. Thirdly, it is cost-effective, as manufacturers can produce large volumes of blister packs with minimal material waste.The blister packaging machine industry has seen tremendous growth in recent years, and it is expected to continue growing at a CAGR of 4.9% from 2021 to 2031. One of the primary drivers of this growth is the increasing demand for blister packaging in emerging markets. The rise in disposable incomes and growing awareness of healthcare have led to a surge in demand for medication across the globe.Clinical AdvancementsOne of the most significant advancements in blister packing machine technology is the move towards automation. Automation has made the packaging process faster and more efficient, leading to higher volumes produced each day. Modern machines can package up to 600 blisters per minute, compared to 400 to 500 blisters per minute previously.Another advancement is the integration of smart technologies into blister packing machines. These technologies include sensors, monitoring systems, and automation controls that can detect errors and correct them immediately. This ensures that the packaging process is accurate and consistent, reducing wastage while further increasing efficiency.Major PlayersSeveral major players dominate the blister packing machine market, including SaintyCo, Bosch Packaging Technology, and Sonoco Products Company. Each of these companies has different areas of expertise, supplying various types of machines to meet the different needs of the market.SaintyCo offers a wide range of blister packing machines that cater to the precise needs of the pharmaceutical and nutraceutical industries. Their range includes both semi-automatic and fully-automatic machines that are designed to package tablets, capsules, and other dosage forms safely.Bosch Packaging Technology is a globally recognized pharmaceutical machinery manufacturer that specializes in blister packaging machines. Their machines integrate smart technology to ensure that they are efficient and reliable.Sonoco Products Company offers specialized packaging solutions that not only cater to the pharmaceutical industry but also the food and beverage industry. They offer a broad range of packaging equipment, including blister packing machines, that meet the highest standards of quality and efficiency.ConclusionIn conclusion, blister packing machines are critical pieces of equipment in the pharmaceutical industry. With the ongoing research and clinical advancements, machines will continue to get better and faster. Companies like SaintyCo, Bosch Packaging Technology, and Sonoco Products Company are continually innovating and improving to meet the growing needs of the market. With these developments, the industry is set to experience even more growth in the years to come.Keywords: Bqs Blister Packing Machine, SaintyCo, Bosch Packaging Technology, Sonoco Products Company, pharmaceutical industry, tamper-proof protection, automation, smart technologies, sensors, monitoring systems, and automation controls.

Vegetable Seed Packing Machine - Affordable China Supplier

Shuntian Vegetable Seeds Packing Machine For Sale: A Game-Changer in the Vegetable IndustryShuntian, a renowned name in the world of packaging machinery, has launched its latest offering- the Vegetable Seeds Packing Machine. This advanced packaging machine is aimed at transforming the way vegetables are packed and shipped across the world. As the global demand for vegetables continues to rise, there is a greater need for efficient and effective packaging solutions. The Shuntian Vegetable Seeds Packing Machine is designed to meet this need by providing an innovative packaging solution that offers numerous benefits.One of the main advantages of the Shuntian Vegetable Seeds Packing Machine is its precision and speed. The machine is designed to pack vegetable seeds efficiently and accurately, ensuring that each packet contains the exact amount of seeds required. This eliminates the need for manual packing, which can be time-consuming and prone to error. In addition to its precision, the Shuntian Vegetable Seeds Packing Machine is also built for speed. With its high-speed packaging capabilities, this machine can pack thousands of vegetable seed packets in a short amount of time. This makes it an ideal solution for vegetable seed companies looking to increase their production capacity.Another advantage of the Shuntian Vegetable Seeds Packing Machine is its versatility. The machine can be customized to pack a wide range of vegetable seeds, including tomatoes, peppers, beans, and more. This flexibility allows vegetable seed companies to use the machine for multiple products, making it a cost-effective solution for their packaging needs.Moreover, the machine is also designed with ease of use in mind. It features a user-friendly interface that makes it easy for operators to operate and maintain the machine. This eliminates the need for extensive training, which can be costly and time-consuming.In conclusion, the Shuntian Vegetable Seeds Packing Machine is an innovative and cost-effective solution that is set to revolutionize the way vegetables are packed and shipped across the world. Its precision, speed, versatility, and ease of use make it an ideal solution for vegetable seed companies looking to enhance their packaging capabilities. If you are looking for a reliable and efficient factory and supplier of vegetable packing machines from China, do not hesitate to contact us at [email protected] or call us at 0086 13920077206. We are committed to providing you with superior quality packing machines that will help take your business to the next level.

Efficient and Versatile Manual Packing Machine for Streamlined Packaging

Title: Advanced Packaging Solution Revolutionizes Manufacturing IndustrySubtitle: A Pioneer in High-speed, Precision Manual Packing Machines Transforms Packaging Operations[City, Date] - The manufacturing industry is set to witness a significant transformation with the introduction of an innovative Manual Packing Machine by a leading packaging solutions company. By integrating cutting-edge technology and a vision for revolutionizing packaging processes, this ground-breaking solution is poised to streamline operations and skyrocket efficiency in the global manufacturing sector.With constant advancements in technology, businesses are increasingly gravitating towards automation to optimize their operations. Resonating with this trend, the Manual Packing Machine, manufactured by [company name], offers a reliable, high-speed, and precision-enabled solution to the packaging industry.The Manual Packing Machine embodies the perfect blend of innovation, functionality, and user-friendly design. It demonstrates an exceptional capacity to manage diverse packaging requirements while ensuring accuracy and efficiency. Thanks to its groundbreaking features, [company name]'s Manual Packing Machine has quickly gained popularity among manufacturers across various industries.A key strength of the Manual Packing Machine is its ability to adapt to the unique needs of manufacturing operations. Its customizability enables it to handle a wide range of products, including but not limited to electronic devices, pharmaceuticals, cosmetics, food items, and industrial parts.Designed with utmost precision, the Manual Packing Machine ensures seamless packaging execution, minimizing the risk of errors and maximizing output. The incorporation of cutting-edge motion control mechanisms allows for unparalleled accuracy, guaranteeing consistent and reliable results batch after batch.Another notable feature of the Manual Packing Machine is its high-speed capabilities. Equipped with efficient sensors and advanced control systems, it boasts an impressive production rate that greatly enhances productivity. This ensures that manufacturers can package their products at an accelerated pace, meeting market demands without compromising on quality.Furthermore, the user-friendly design of the Manual Packing Machine empowers even non-technical operators to efficiently operate the equipment. The machine's intuitive interface and simplified controls make it accessible to individuals with minimal training. This versatility opens possibilities for manufacturers to optimize their workforce, reduce training costs, and improve overall production efficiency.The sustainability aspect of the Manual Packing Machine is yet another noteworthy attribute. Designed with a focus on reducing material waste, it maximizes resource utilization and ensures environmentally conscious packaging practices. This aligns with the growing demand for sustainable manufacturing solutions, making the Manual Packing Machine exceptionally desirable for businesses in pursuit of eco-friendly practices.In addition to its impressive technical capabilities, [company name] has built a reputation for its commitment to customer satisfaction. With an extensive support network spanning across various regions, the company offers prompt and efficient aftersales service. This ensures that any operational issues or maintenance requirements of the Manual Packing Machine are addressed promptly, minimizing downtime and maintaining manufacturing continuity.“Today’s manufacturers face immense pressure to deliver products efficiently, meeting the ever-evolving demands of the global market. Our Manual Packing Machine has been specifically designed to help alleviate this burden and provide revolutionary packaging solutions. By combining advanced technology, precision, and user-friendliness, we aim to empower manufacturers and elevate their packaging operations to new heights,” said [company spokesperson], emphasizing the significance of this groundbreaking solution.With the game-changing Manual Packing Machine on the market, the packaging industry stands poised for a transformative shift. Manufacturers worldwide are now equipped with the means to streamline their packaging processes, significantly enhancing productivity and output. As a result, businesses can remain competitive in an increasingly fast-paced and demanding market while continuing their commitment towards sustainable manufacturing practices.

Blister Packing Machine for Tablets and Capsules: Aluminum and Plastic Options

for Tablet&Capsule and PVC Blister Packing Machine.Alu Alu Blister Packing Machine for Tablet&Capsule: The Best Solution for Pharmaceutical PackagingThe world of pharmaceutical packaging has witnessed a tremendous transformation in the recent past with the development of new and innovative packaging solutions. The introduction of Alu Alu Blister Packing Machine for Tablet&Capsule is one such solution that has revolutionized the way medicines are packaged and distributed. This advanced packaging technology, which uses cold-forming aluminum, has become the standard in the pharmaceutical industry due to its ability to protect the medicine, improve its shelf-life, and ensure patient safety. Additionally, PVC Blister Packing Machine is an alternative thermoforming plastic option that is also ideal for packaging tablets and capsules.The Alu Alu Blister Packing Machine is a specialized design that guarantees accuracy, efficiency, and reliability in the packing of tablets, capsules, and other medical products. This machine uses a cold-forming process that involves the molding of aluminum foil into the desired shape, usually a blister pack. The shrinking and shaping process of the aluminum foil ensures that it can hold the tablet or capsule securely, while providing an airtight and moisture-free environment to preserve the medication. This method of packaging is ideal for medicines that are sensitive to light, humidity, and other environmental factors that could degrade their effectiveness.The Alu Alu Blister Packing Machine for Tablet&Capsule offers numerous benefits to pharmaceutical companies. The primary advantage is the protection of the medicine. The aluminum foil used in the cold-forming process is an excellent barrier against light, moisture, and other external factors that could cause the medicine to deteriorate. Additionally, the secure packaging enhances the convenience of the medicine, making it easy to dispense and transport. The Alu Alu Blister Packing Machine is also highly efficient and reliable, with a low error rate. This high level of accuracy saves on material and labor costs, making it cost-effective in the long run.Another advantage of the Alu Alu Blister Packing Machine for Tablet&Capsule is its versatility. It can be used to pack different types of tablets and capsules in various sizes and shapes, making it suitable for a broad range of medicines. Additionally, this machine can be customized to include safety features, such as tamper-evident seals or barcodes, to ensure that the medicine is not counterfeit and is safe for consumption.PVC Blister Packing Machine is another packaging solution that pharmaceutical companies can consider. The machine works by thermoforming plastic, mainly PVC, into blisters. PVC Blister Packing Machine is ideal for packaging medicines that do not require the protection of aluminum foil but still need adequate packaging to prevent exposure to the environment. Besides, the PVC material is cost-effective and readily available, making it an attractive option for small and medium-sized pharmaceutical companies.In conclusion, the Alu Alu Blister Packing Machine and the PVC Blister Packing Machine are two packaging solutions that pharmaceutical companies can consider for their tablets and capsules. The Alu Alu Blister Packing Machine is particularly suited for medicines that require high-level protection, while PVC Blister Packing Machine works well for medicines that require a less rigid package. Both models are highly efficient, reliable, and customizable to meet the specific needs of different pharmaceutical companies. As technology advances, packaging solutions will continue to evolve, and it is essential to keep abreast of new and innovative solutions that can enhance the safety, convenience, and effectiveness of pharmaceutical products.

and Flexible Packaging.In the world of packaging, there have been many advancements over the years that have revolutionized the industry. One of the most significant changes in recent years has been the shift towards flexible packaging. Flexible packaging is a type of packaging that is made from materials that are more pliable than traditional rigid materials, such as glass or metal. Instead, flexible packaging is made from materials such as plastic, paper, and foil.One of the key benefits of flexible packaging is the decreased carbon footprint. Because flexible packaging is lighter and more compact than rigid packaging, it requires less energy to transport and store. This means that less fuel is needed to transport products, resulting in a lower carbon footprint for the company using flexible packaging.Another benefit of flexible packaging is the savings on shipping and storage. Because flexible packaging is lighter and more compact, it takes up less space in warehouses and on trucks. This means that companies can store more products in a smaller space, reducing the need for additional storage facilities or trucks.Flexible packaging also offers a more prominent shelf-presence. Because it can be easily molded and shaped, it can be designed to stand out on store shelves. This makes it easier for consumers to find the products they are looking for and can increase sales for the company.Finally, flexible packaging offers a larger canvas for automatic packing machine. Because it can be easily printed on, it can be used to showcase the brand’s message or to provide additional information about the product. This can help to differentiate the product from its competitors and can create a stronger brand identity in the minds of consumers.Overall, the benefits of using flexible packaging are clear. Whether you are in the food industry, the cosmetics industry, or any other industry that requires packaging, flexible packaging can help you to reduce your carbon footprint, save money on shipping and storage, increase sales, and create a stronger brand identity. So if you haven’t already, consider making the switch to flexible packaging for your automatic packing machine needs.

Latest updates on Breaking News in the Food and Drink Industry

Title: The Art of Crafting Delicious Chocolate Drinks: The Evolution of Chocolate Drink Making MachinesIntroduction:Indulging in a scrumptious chocolate drink is a luxury enjoyed by people of all ages. Whether it's a steaming cup of hot cocoa on a chilly winter evening or a refreshing chocolate milkshake to beat the summer heat, these velvety concoctions never fail to delight our taste buds. While the process of making chocolate beverages has evolved over time, the advent of chocolate drink making machines has revolutionized how we savor these delightful treats. In this blog, we will explore the fascinating journey of chocolate drink making machines and how they have simplified the process of creating heavenly chocolate beverages.1. The Evolution of Chocolate Drink Making:The history of chocolate drinks dates back to ancient civilizations who enjoyed consuming cocoa in its purest form. As time progressed, the art of making chocolate drinks evolved, incorporating ingredients like sugar and milk to enhance the taste and texture. Traditionally, the process involved grating chocolate blocks and meticulously stirring them into liquid to create a smooth, velvety drink. However, with the advent of technology, chocolate drink making machines emerged on the market, revolutionizing the way these delightful beverages are prepared.2. The Role of Chocolate Drink Making Machines:Chocolate drink making machines have simplified the process of crafting chocolate beverages, making it accessible for both domestic and commercial purposes. These machines come in various shapes and sizes, from compact home appliances to large-scale devices used in professional establishments. By automating the grinding, heating, and mixing processes, these machines provide consistent results, guaranteeing a flawless chocolate drink every time.3. Key Features and Functionality:a. Grinding and Tempering: Chocolate drink making machines are equipped with powerful grinders that finely process cocoa beans into a smooth paste. This paste is then tempered to enhance the consistency and flavor of the chocolate drink.b. Heating and Blending: The machines have integrated heating mechanisms that efficiently warm the ingredients, ensuring a perfectly heated beverage. Additionally, they possess blending features to mix the ingredients thoroughly, creating a lusciously indulgent chocolate drink.c. Customization Options: To cater to diverse preferences, these machines often offer customization options, allowing users to adjust the sweetness, creaminess, and overall flavor of the chocolate beverage.d. Versatility: Chocolate drink making machines are not restricted to a single type of chocolate drink. They can create a wide range of beverages, including hot cocoa, chocolate milkshakes, mochas, and more, providing a versatile solution for chocolate enthusiasts.4. Benefits of Chocolate Drink Making Machines:a. Time-saving: These machines significantly reduce preparation time, making it effortless to satisfy those chocolate cravings both at home and in commercial establishments.b. Consistency: With precise temperature control and automated processes, chocolate drink making machines ensure consistent results every time, eliminating any room for error.c. Cost-effective: Investing in a chocolate drink making machine can be cost-effective in the long run, especially for cafes, restaurants, and canteens, as it eliminates the need for manual labor and frees up valuable time for staff.d. Quality Assurance: By using high-quality ingredients in combination with the machine's functionalities, one can ensure the creation of delicious chocolate drinks with a rich and indulgent taste.e. User-friendly: Chocolate drink making machines are designed to be user-friendly, with intuitive controls that make the process effortless for both amateurs and professionals.Conclusion:In the world of delicious chocolate drinks, the advent of chocolate drink making machines has truly revolutionized how we create and enjoy these delightful concoctions. From simplifying the process to ensuring consistent results, these machines have become an essential tool for chocolate enthusiasts and professionals alike. Whether it's a comforting cup of hot cocoa or a refreshing chocolate milkshake, with a reliable chocolate drink making machine, the indulgence is just a press of a button away. So, let your taste buds rejoice as you embrace the convenience and luxury of crafting divine chocolate beverages effortlessly.

SEO Title: Industry-Leading Food Packaging Machines & Tools for Efficient Production

- Making Your Packaging Operations More Efficient with the Right Packing Machine As the global market is expanding rapidly, more businesses are facing growing pressure to increase their packaging efficiency without compromising on product quality. With the right packing machine, the process can be streamlined, making it simpler, faster, and more effective. Here, we will discuss how Zhejiang Dongfeng Packing Machine Co., Ltd. can help you achieve your goals with their extensive range of advanced packing equipment. What is a Packing Machine? A packing machine is a device that automates the process of packaging products. It comes in various models and sizes, with different capabilities, designed to pack different types of products. The machine can handle several packaging processes, including filling, sealing, wrapping, and labeling. It offers a more efficient process, reducing labor costs, increasing production speed, and improving product quality. Types of Packing Machines There are several types of packing machines to meet different packaging needs. Some popular models include: 1. Food Packaging Machine The food packaging machine is designed specifically for food products. It provides the required hygiene standards and ensures the packaging process is safe, fast, and efficient. The machine can handle different packaging formats, such as pouches, cups, trays, and containers. 2. Plastic Packing Machine A plastic packing machine is designed for packaging products in plastic bags. It can handle different bag sizes, types, and materials, including polyethylene, nylon, and laminated films. The machine ensures a tight seal is created for each bag to avoid any contamination or spillage. 3. Plastic Bag Sealer A plastic bag sealer is a compact machine that can seal different types of plastic bags. It applies heat to seal the bags, creating an airtight seal to protect the products inside from moisture, dust, and damage. The machine is ideal for small businesses or home-based operations that need a simple bag sealing solution. 4. Vacuum Sealing Machine A vacuum sealing machine removes air from the packaging bag before sealing it. It ensures the products inside stay fresh and bacteria-free for an extended period. The machine is suitable for the packaging of meat, cheese, fish, and other perishable products. 5. Filling Machine A filling machine is used to pack liquids and semi-liquids, such as juices, oils, and sauces. The machine can handle different filling volumes, ranging from small packets to large containers. It is an ideal solution for businesses that need to pack liquid products accurately and quickly. 6. Shrink Packing Machine A shrink packing machine is used to wrap products in a heat-shrinkable film. The film applies heat to shrink and conform to the product's shape, creating a tight seal. The machine is ideal for packaging products with an unusual shape or size and provides excellent product visibility. Why Choose Zhejiang Dongfeng Packing Machine Co., Ltd.? Zhejiang Dongfeng Packing Machine Co., Ltd. is a leading manufacturer of packing machines worldwide. It offers a wide range of advanced machines that meet various packaging needs for different industries. The company has been in operation for over 20 years, earning recognition for its high-quality products, excellent customer service, and innovative technology. Some key reasons to choose Zhejiang Dongfeng Packing Machine Co., Ltd. include: 1. Quality Assurance The company produces all its machines using high-quality materials and advanced manufacturing methods. Each machine undergoes rigorous quality tests to ensure it meets the industry's highest standards. 2. Diverse Range of Machines Zhejiang Dongfeng Packing Machine Co., Ltd. offers a wide range of machines, including food packaging machines, plastic packing machines, plastic bag sealers, vacuum sealing machines, filling machines, and shrink packing machines. The machines are versatile, durable, and designed to meet various packaging needs. 3. Customizable Machines The company can customize its machines to meet different customer requirements. The machines can be designed to handle specific packaging processes, different product types, or unique packaging formats. 4. Competitive Pricing Zhejiang Dongfeng Packing Machine Co., Ltd. offers its machines at a competitive price without compromising on quality. They also provide flexible payment terms, making it affordable for businesses of all sizes. Conclusion Investing in the right packing machine can dramatically improve your packaging efficiency, speed, and quality. Zhejiang Dongfeng Packing Machine Co., Ltd. offers an extensive range of advanced machines that can help you achieve your packaging goals efficiently. Whether you need a food packaging machine, plastic packing machine, plastic bag sealer, vacuum sealing machine, filling machine, or shrink packing machine, the company has you covered. Contact them today to learn more about their products and how they can help you streamline your packaging process. Keywords: Packing Machine, Food Packaging Machine, Plastic Packing Machine, Plastic Bag Sealer, Vacuum Sealing Machine, Filling Machine, Shrink Packing Machine.

\ According to the news content, a cutting machine has been developed specifically for snack foods such as peanut candy and sesame candy. This automatic cutting machine is suitable for cutting various snack foods including crispy egg cake, crispy corn cake, melon seeds cake, and crispy black rice cake. The machine consists of five parts including a feeding part, cutting part, cooling part, conveying part, and cutting control system. With its high speed and accuracy, this machine is set to revolutionize the snack food industry.

, cutting part, conveying part, cooling part and collecting part.The feeding part of this peanut candy sesame candy cutting machine for snack food is designed with a vibratory feeder to ensure accurate feeding. The cutting part is equipped with high-quality cutting knives to ensure that the candies are evenly cut without deformation. The conveying part is equipped with high-quality stainless steel mesh belts, which can transport the candies to the cooling part. After cooling, candies can be collected efficiently and quickly through the collecting part.The peanut candy sesame candy cutting machine for snack food is highly automated and can be operated by one person. It not only improves production efficiency but also saves labor costs. The cutting size of the peanut candy sesame candy can be adjusted according to the customer's needs. The machine has a wide range of applications, which can be used in food factories, supermarkets, and candy processing plants, etc.Compared with traditional manual cutting methods, the peanut candy sesame candy cutting machine for snack food has many advantages. Firstly, the cutting size is consistent and accurate, which can greatly improve the appearance of the candies and increase their aesthetic value. Secondly, the machine is more hygienic and safe. It is made of stainless steel and food-grade materials, which can ensure the hygiene and safety of the candies. Finally, it can significantly reduce the production cost, improve the production efficiency and increase the profit margin.In conclusion, the peanut candy sesame candy cutting machine for snack food is a must-have machine for candy processing. It can not only help the candy manufacturers to improve the product quality but also significantly reduce the production cost and increase the production efficiency. Therefore, it is highly recommended for those who want to expand their candy business and improve the competitiveness of their products in the market.

Small Scale Chocolate Making Equipment for Homemade Treats

Are you a chocolate lover? Do you dream of making your own delicious chocolate creations right at home? Well, you're in luck - with the help of a small-scale chocolate making machine, you can turn that dream into a reality!At Ourson-Nature.com, we offer a range of small-scale chocolate making machines to suit every need and budget. Whether you're a home cook looking to experiment with chocolate, or a professional chocolatier in need of a high-quality machine, we have you covered.Our small-scale chocolate making machines are designed with efficiency and ease of use in mind. They are compact and lightweight, making them easy to store and transport, and they are also incredibly user-friendly. With just a few simple steps, you can create your own homemade chocolates that are sure to impress.One of the key features of our machines is their ability to melt and temper chocolate. Tempering is a crucial process in chocolate making that ensures the final product has a smooth, glossy finish and a satisfying snap when you bite into it. Our machines take the guesswork out of tempering, ensuring that your chocolate is perfectly tempered every time.In addition to tempering, our machines are also capable of grinding and refining chocolate to achieve the desired texture and consistency. This allows you to customize your chocolate according to your own preferences, whether you prefer a smooth and creamy texture or a slightly grainy texture with a bit of crunch.Of course, no small-scale chocolate making machine would be complete without the ability to mold and shape your creations. Our machines come with a variety of molds and accessories, allowing you to make chocolates in a range of shapes and sizes. You can even add your own unique flavors and fillings to your chocolate - the possibilities are endless!At Ourson-Nature.com, we are committed to providing high-quality products and excellent customer service. All of our machines are made from durable, food-grade materials and come with a warranty for your peace of mind. We also offer free support and guidance to help you get started with your chocolate making journey.So why not indulge your love of chocolate and try your hand at making your own delicious creations with a small-scale chocolate making machine? With the right tools and a little bit of practice, you can become a master chocolatier in no time.Keywords: Small Scale Chocolate Making Machine, Ourson-Nature.com, chocolate making, homemade chocolate, tempering, grinding, molding, chocolate accessories, chocolatier.

Rewritten SEO title: High-Quality Industrial Vitamin Gummy Bear Making Machine for Commercial Use

Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine: The Perfect Solution for Your Candy Manufacturing NeedsAre you looking for a reliable and efficient machine to produce jelly candy, specifically gummy bear jelly candy? Look no further than the Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine!Working closely with our manufacturing partners, we have designed and developed a machine that ensures optimal productivity and quality while being cost-effective. Whether you're a small-business operator or a large commercial candy manufacturer, our Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine will be the perfect solution for your production needs.One of the main features of our machine is its ability to deposit different types of jelly candy. This includes gummy bears, fruit jelly candies, marshmallows, and so much more. All you need to do is adjust the recipe of your desired candy, and our machine will do the rest.With the help of our Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine, you can be sure that your final product will have consistent size, shape, and texture. This is because our machine uses an automatic depositing system that's designed to produce candies of uniform weight and appearance. Plus, our machine also ensures that each candy has a smooth and glossy surface, making them not just tasty but visually appealing too.Aside from its impressive production capabilities, our machine is also designed for easy operation and maintenance. It's equipped with a user-friendly interface that allows you to set different parameters to achieve different candy styles and flavors. Plus, our machine is made of high-quality materials that are durable and easy to clean, ensuring longevity and low maintenance costs.Overall, our Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine is a must-have for all candy manufacturers who wish to keep up with the ever-growing demand for delicious and nutritious gummy bear jelly candies. Plus, our machine is versatile, efficient, and cost-effective, making it a worthwhile investment for any candy-making business.So, contact us today to get started on your journey to producing high-quality and tasty gummy bear jelly candies with our Industrial Vitamin Gummy Bear Jelly Candy Depositing Making Machine. And don't forget to include the keyword "Jelly Fruit Making Machine" in your search for greater visibility and search engine optimization!