How to Make Candy Floss at Home: A Complete Guide to Making Delicious Cotton Candy

By:Admin

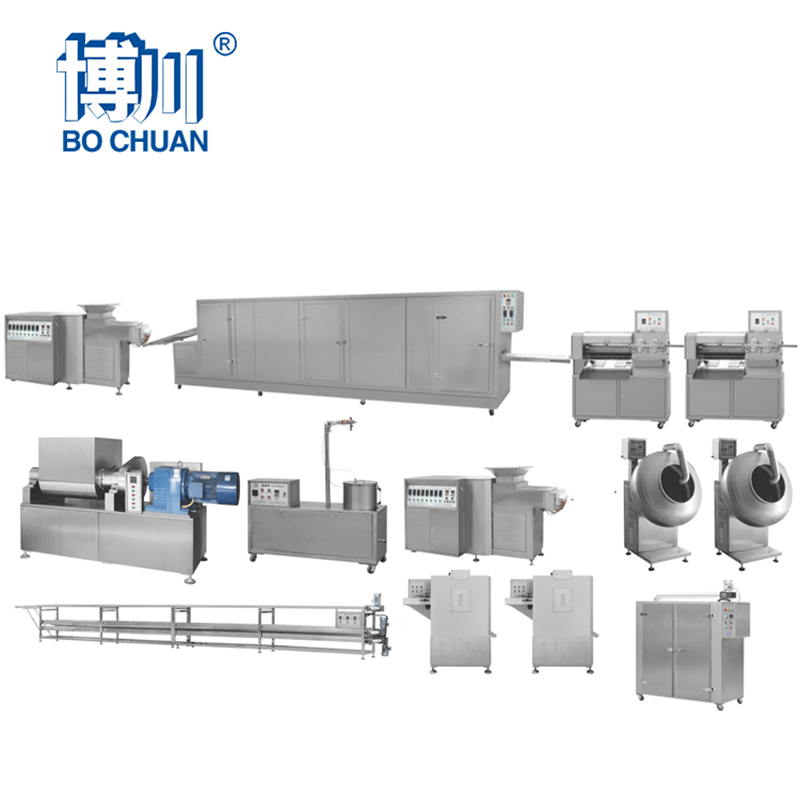

The confectionery industry has been revolutionized with the introduction of the latest Candy Floss Making Machine by a leading manufacturer in the industry. This innovative machine has brought about a significant change in production processes, making it easier and more efficient to create high-quality candy floss in large quantities.

The Candy Floss Making Machine boasts advanced technology and user-friendly features, making it a game-changer for confectionery businesses around the world. This machine has the capability to produce large quantities of candy floss in a short amount of time, saving businesses time and increasing productivity.

The company behind this groundbreaking machine has been a leader in the confectionery industry for over a decade. With a strong commitment to innovation and quality, they have continuously pushed the boundaries of what is possible in the industry. This dedication to excellence has made them a trusted name in the confectionery world, with a reputation for delivering top-quality products and innovative solutions.

The Candy Floss Making Machine is a testament to the company's dedication to innovation and quality. It is designed to be easy to operate, with intuitive controls and a user-friendly interface. This makes it accessible to businesses of all sizes, from small local shops to large-scale production facilities.

The machine is also built to withstand the rigors of continuous use, with durable materials and robust construction. This ensures that businesses can rely on the machine to consistently produce high-quality candy floss, without the need for frequent maintenance or repairs.

One of the key features of the Candy Floss Making Machine is its versatility. It is capable of producing a wide range of flavors and colors, allowing businesses to cater to a diverse range of tastes and preferences. This flexibility is a major advantage for businesses looking to expand their product offerings and attract a broader customer base.

In addition to its advanced technology and user-friendly design, the Candy Floss Making Machine is also highly efficient. It is equipped with energy-saving features and optimized production processes, reducing waste and maximizing output. This not only saves businesses money on operating costs but also makes the machine more environmentally friendly.

The introduction of this innovative machine has had a significant impact on the confectionery industry. Businesses that have adopted the Candy Floss Making Machine have seen a noticeable improvement in their production capabilities, with increased output and higher quality products. This has translated to improved customer satisfaction and increased profitability for these businesses.

The company behind the Candy Floss Making Machine has also provided extensive support to businesses looking to implement this technology. From initial setup and training to ongoing maintenance and technical support, they are committed to helping their customers get the most out of this game-changing machine.

Looking ahead, the future of the confectionery industry looks brighter than ever, thanks to the innovative solutions being developed by companies like this one. With the Candy Floss Making Machine leading the way, businesses around the world are poised to take their production capabilities to new heights, satisfying the sweet cravings of customers everywhere.

Company News & Blog

Ultimate Guide to Oil Pouch Packing Machines: Everything You Need to Know

Oil Pouch Packing Machine: A Game Changer in Packaging IndustryThe packaging industry has seen a significant revolution in recent years, and the introduction of the Oil Pouch Packing Machine has been a game-changer for many companies. This innovative machine has been designed to meet the growing demands of the packaging industry, providing efficient and reliable packaging solutions for a wide range of products. {Company Name} is one of the leading manufacturers of the Oil Pouch Packing Machine, with an extensive portfolio of packaging solutions for various industries. The company has established itself as a trusted name in the industry, with a commitment to delivering high-quality, cost-effective, and innovative packaging solutions.The Oil Pouch Packing Machine is designed to meet the specific needs of the oil packaging industry, providing a seamless and efficient packaging process. It is capable of packaging a wide range of oil products, including cooking oil, lubricants, and essential oils, among others. The machine is equipped with advanced technology and features, ensuring precision and accuracy in the packaging process.One of the key features of the Oil Pouch Packing Machine is its ability to ensure product safety and integrity. The machine is designed to maintain the quality and freshness of the oil products, preventing any contamination or spoilage during the packaging process. This is essential for companies looking to maintain the highest standards of quality and safety for their products.In addition to its advanced technology, the Oil Pouch Packing Machine is also known for its high-speed packaging capabilities. This enables companies to increase their production efficiency and output, meeting the growing demands of the market. The machine is capable of handling large volumes of packaging, making it an ideal solution for companies with high production needs.Furthermore, the Oil Pouch Packing Machine offers a user-friendly and intuitive interface, making it easy to operate and maintain. This is essential for companies looking to streamline their packaging processes and reduce the risk of errors and downtime. The machine is also designed for easy cleaning and maintenance, ensuring a long and reliable service life.{Company Name} takes pride in its commitment to customer satisfaction, offering comprehensive support and services for the Oil Pouch Packing Machine. The company provides customized solutions and technical support to help its customers maximize the benefits of the machine. This includes installation, training, and maintenance services, ensuring that the machine operates at peak performance.The introduction of the Oil Pouch Packing Machine has received positive feedback from the industry, with many companies recognizing its potential to transform their packaging processes. The machine has been widely adopted by companies looking to improve their packaging efficiency, reduce costs, and enhance the quality of their products. This has positioned {Company Name} as a key player in the packaging industry, with a reputation for delivering innovative and reliable packaging solutions.In conclusion, the Oil Pouch Packing Machine has emerged as a game-changer in the packaging industry, offering a powerful and reliable solution for companies looking to optimize their packaging processes. With its advanced technology, high-speed capabilities, and user-friendly design, the machine has set a new standard for oil packaging solutions. {Company Name} continues to lead the way in delivering cutting-edge packaging solutions, providing its customers with the tools they need to succeed in a competitive market.

What to consider when choosing a wad sealing machine

Wad Sealing Machine Revolutionizing Pharmaceutical PackagingIn the fast-paced world of pharmaceutical packaging, efficiency and precision are paramount. Every step of the packaging process must be precise, from filling the bottles with the correct dosage of medication to ensuring that the packaging is tamper-proof and secure. This is where the Wad Sealing Machine, developed by a leading provider of packaging solutions, comes into play.The Wad Sealing Machine is a cutting-edge piece of equipment that revolutionizes the packaging process for pharmaceutical companies. Its advanced technology ensures that the sealing process is both efficient and reliable, making it an essential tool for companies looking to streamline their operations and improve the safety and security of their products.The Wad Sealing Machine is designed to seal bottles with aluminum foil and other materials, providing a tamper-evident seal that gives consumers peace of mind knowing that their medication has not been tampered with. This is a crucial feature in the pharmaceutical industry, where product safety and integrity are of utmost importance.One of the key features of the Wad Sealing Machine is its high-speed sealing capabilities, significantly reducing the time it takes to seal each bottle. This not only improves productivity but also ensures that the packaging process is efficient and cost-effective. In addition, the machine is equipped with advanced sensors and controls, allowing for precise sealing and accurate application of the sealing material.The versatility of the Wad Sealing Machine is another noteworthy aspect of its design. It is compatible with a wide range of bottle sizes and shapes, making it suitable for various pharmaceutical products. This flexibility is particularly valuable for companies that produce multiple types of medications and need a reliable sealing solution for their diverse product lines.The company behind the development of the Wad Sealing Machine has a long-standing reputation for providing high-quality packaging solutions to the pharmaceutical industry. With a focus on innovation and customer satisfaction, the company has become a trusted partner for pharmaceutical companies worldwide.With a commitment to excellence and a deep understanding of the unique challenges faced by pharmaceutical packaging operations, the company has continually developed groundbreaking solutions like the Wad Sealing Machine to address the evolving needs of the industry. Its dedication to research and development has led to the creation of cutting-edge technologies that have raised the bar for packaging efficiency and product integrity.In addition to the Wad Sealing Machine, the company offers a comprehensive range of packaging equipment and materials, including filling machines, labeling solutions, and packaging materials. This comprehensive approach allows pharmaceutical companies to source all their packaging needs from a single, trusted provider, streamlining their operations and ensuring compatibility between different pieces of equipment.The success of the Wad Sealing Machine can be attributed to the company's unwavering commitment to quality, innovation, and customer satisfaction. By consistently delivering reliable and efficient packaging solutions, the company has established itself as a leader in the pharmaceutical packaging industry, earning the trust and respect of its clients.As the pharmaceutical industry continues to evolve and grow, the demand for advanced packaging solutions like the Wad Sealing Machine will only continue to rise. With its exceptional sealing capabilities, versatility, and compatibility with a wide range of products, the Wad Sealing Machine is poised to become an indispensable tool for pharmaceutical companies seeking to enhance the safety, efficiency, and integrity of their packaging operations.

Enhance Efficiency with an Advanced Fully Automatic Cup Sealing Machine

article.Fully Automatic Cup Sealing Machine Revolutionizes the Food and Beverage IndustryInnovation is at the core of any industry, and the food and beverage industry is no exception. In order to meet the ever-growing demands of consumers for faster and more convenient services, food and beverage companies have been incorporating new technologies into their workflows. One such technology that has made waves in the industry is the Fully Automatic Cup Sealing Machine.This cutting-edge machine is designed to seal cups of various sizes and materials, making it an ideal option for restaurants, cafes, food trucks, and other businesses that serve drinks or desserts. The machine is fully automated, which means it can seal up to 900 cups per hour, all while maintaining an exact seal and reducing the risk of human error or injury.The Fully Automatic Cup Sealing Machine is an ideal solution for businesses that are looking to streamline their operations, reduce labor costs, and increase productivity. It's also a great investment for startups looking to grow their business by offering a wider range of products and services.The technology behind this machine is impressive. Its smart sensors can measure the size of the cup and adjust the sealing process accordingly. The user-friendly interface and simple controls also make it easy for even the least skilled employee to use. The machine is also made of high-quality materials that are durable and long-lasting, reducing the need for frequent repairs or replacements.Aside from its functionality, the Fully Automatic Cup Sealing Machine also boasts an attractive design that fits seamlessly into any modern setting. Its compact size and sleek appearance make it a great choice for businesses with limited space or that want to create a modern and clean aesthetic in their space.X, a leading manufacturer of Fully Automatic Cup Sealing Machines, has been in the business for more than a decade, providing high-quality machines to businesses all over the world. X's machines are known for their durability, functionality, and ease of use, making it a top choice for many businesses.“X's Fully Automatic Cup Sealing Machine is designed to meet the needs of every business, from small startups to large corporations,” said the CEO of X. “Our machines are reliable, efficient, and easy to operate, making them a great investment for any business looking to improve their workflow and save on labor costs.”X's machines also come with a variety of accessories, such as customized cup holders, lid dispensers, and cleaning kits, making it easier for businesses to adapt to their specific needs.Since its introduction to the market, the Fully Automatic Cup Sealing Machine has transformed the food and beverage industry. Businesses have been able to reduce their costs, increase their efficiency, and improve their customer service by providing faster, more reliable service. Moreover, the implementation of this machine has created a safer work environment by reducing the risk of employee injury and human error.In conclusion, the Fully Automatic Cup Sealing Machine is a game-changer in the food and beverage industry. Whether you are a small, medium, or large business, investing in this technology will allow your business to grow, adapt, and thrive in a competitive industry. With its ease of use, durability, and innovative design, X's Fully Automatic Cup Sealing Machine is an investment that is worth considering.

How to Choose and Use a Commercial Gummy Making Machine

Commercial Gummy Making Machine Revolutionizes Candy ProductionCandies come in various shapes, sizes, and flavors, but nothing beats the timeless chewy gummy candy. Gummy candy has been a favorite among kids and adults alike, and it is not going away anytime soon. The love for gummy candies is what has led to the development of the Commercial Gummy Making Machine. This innovative candy production machine has revolutionized the manufacturing process of gummy candies while enhancing the overall quality of production.The Commercial Gummy Making Machine is a unique machine that is designed to streamline the production process of gummy candies for manufacturers, confectioners, and retailers. With this machine, candy production has never been more efficient and cost-effective. Furthermore, the Gummy Making Machine allows the candy producer to customize the candies, by incorporating a variety of colors, shapes, and flavors.The Commercial Gummy Making Machine, created by a dedicated team of engineers, has been the result of years of research and investment. The machine is designed to be user-friendly while incorporating cutting-edge technology to deliver high-quality gummy candy. The machine boasts a range of features that make it the go-to solution for manufacturers worldwide.The structure of the Commercial Gummy Making Machine is sturdy, durable, and compact, which makes it perfect for small and medium-sized manufacturing companies. The gummy candy making machine comes in different production capacities, adjustable according to the company’s production needs. The production capacity ranges from a low of 20 kg/hour to a high of 300 kg/hour.Another unique feature of the Commercial Gummy Making Machine is the ability to produce different shapes and sizes of gummy candies. The machine is capable of creating a wide range of shapes, such as cubes, worms, bears, fruit slices, and much more. An impressive feature of this machine is that it can produce gummy candies in different colors while keeping the texture and taste consistent.In the candy manufacturing business, quality is of utmost importance. The Commercial Gummy Making Machine is designed to deliver the highest quality of gummy candies possible. By using advanced technologies such as automated feeding systems, vacuum cooking, and a perfect blending system, the gummy candy machine ensures the consistency of the final product. The result is gummy candies that are visually appealing, and most importantly, meet the strict quality standards of food safety regulatory bodies globally.The Commercial Gummy Making Machine comes with many benefits to its users that go beyond its impressive capabilities. The machine caters to manufacturers of different sizes, ensuring that everyone has a chance to create high-quality gummy candies. The increased efficiency and productivity that comes with the machine help to save time and reduce costs that would otherwise be incurred by hiring more employees to handle the production of gummy candies. Furthermore, the machine is easy to operate, reducing training costs for new staff members on the production line.In conclusion, the Commercial Gummy Making Machine is a game-changer in the candy manufacturing industry. It is not just about the production of high-quality gummy candy, but it offers a plethora of benefits that make it the perfect investment for candy manufacturers worldwide. With its versatility, durability, and cost-effectiveness, the machine has proven to be a worthy addition to any candy manufacturing line. Furthermore, the machine has been tested and approved, meeting the highest safety standards set by regulatory bodies globally. With the Gummy Making Machine, manufacturers and confectioners can produce gummy candies faster, more efficiently, and most importantly, with an exceptional level of quality. The Commercial Gummy Making Machine is a must-have investment for all candy manufacturers looking to take their production to the next level.

Compact Packaging Machine for Efficient and Cost-Effective Packaging

In today's fast-paced and competitive market, the demand for small packaging machines is on the rise. These efficient and compact machines are essential for businesses looking to streamline their packaging processes and improve overall productivity. {Company name}, a leading provider of industrial machinery, is at the forefront of this growing trend with their top-of-the-line small packaging machines.{Company name} has been a key player in the industrial machinery industry for over two decades. With a strong focus on innovation and quality, they have gained a reputation for delivering state-of-the-art equipment that meets the evolving needs of their clients. Their small packaging machines are no exception, offering a range of advanced features and capabilities that set them apart from the competition.These small packaging machines are designed to handle a variety of packaging materials, including plastic, paper, and metal. They are capable of efficiently packaging a wide range of products, from food and beverages to pharmaceuticals and household goods. With their compact size and user-friendly interface, these machines are suitable for businesses of all sizes, from small startups to large-scale manufacturers.One of the key features of {Company name}'s small packaging machines is their high level of automation. These machines are equipped with advanced technology that allows for precise and consistent packaging, reducing the risk of errors and product wastage. This ultimately leads to cost savings and improved overall efficiency for businesses.Additionally, these small packaging machines are designed with versatility in mind. They can be easily reconfigured to accommodate different packaging needs, offering businesses the flexibility to adapt to changing market demands. This adaptability is crucial for businesses looking to stay competitive and agile in today's dynamic market landscape.{Company name} takes pride in their commitment to customer satisfaction. They offer comprehensive training and support to ensure that their clients are able to maximize the potential of their small packaging machines. With a team of experienced technicians and customer service professionals, they are dedicated to providing ongoing assistance and maintenance to keep their clients' operations running smoothly.Furthermore, {Company name} places a strong emphasis on sustainability and environmental responsibility. Their small packaging machines are designed to minimize energy consumption and waste, contributing to a more eco-friendly manufacturing process. By investing in these machines, businesses can reduce their environmental footprint and align with increasingly stringent regulations and consumer preferences.As the demand for small packaging machines continues to grow, {Company name} is poised to meet the needs of businesses across various industries. Their dedication to innovation, quality, and customer service positions them as a trusted partner for businesses looking to invest in efficient and reliable packaging solutions.In conclusion, {Company name}'s small packaging machines are a game-changer for businesses seeking to optimize their packaging processes. With their advanced features, versatility, and commitment to customer satisfaction, these machines are a valuable asset for businesses looking to stay competitive and efficient in today's fast-paced market. As the market for small packaging machines continues to evolve, {Company name} remains a leading provider, delivering cutting-edge solutions that empower businesses to thrive and succeed.

Top Heat Sealers for Food Packaging to Keep Your Products Fresh

Introducing Innovative Heat Sealers for Food PackagingIn the food packaging industry, the need for effective and efficient packaging solutions is always at the forefront. With the increasing demand for convenience and sustainability, companies are continuously seeking new methods to ensure that their products are packaged securely and attractively. This has led to the development of advanced heat sealing technology, which has revolutionized the way food products are packaged and sealed.One company that has been at the forefront of this innovation is {}. With a long history of providing high-quality packaging solutions, the company has recently introduced a new line of heat sealers that are designed to meet the diverse needs of the food packaging industry. These heat sealers are engineered to provide a secure and airtight seal, keeping food products fresh and safe for extended periods of time.The company's heat sealers are equipped with advanced features that make them ideal for a wide range of food packaging applications. Whether it's for packaging fresh produce, frozen foods, or dry goods, these heat sealers are versatile enough to handle the task with precision and reliability. This versatility is crucial for companies looking to streamline their packaging processes and ensure that their products are delivered to consumers in the best possible condition.One of the key advantages of {}'s heat sealers is their user-friendly design. With intuitive controls and easy-to-use settings, operators can quickly and efficiently seal packages without any hassle. This not only saves time and labor costs but also ensures consistent and reliable sealing results. Additionally, the heat sealers are equipped with safety features to protect operators from potential hazards, making them an ideal choice for busy packaging facilities.In addition to their functionality, {}'s heat sealers are also designed with sustainability in mind. The company is committed to reducing the environmental impact of packaging processes, and their heat sealers are engineered to minimize waste and energy consumption. This is achieved through innovative sealing techniques that optimize material usage and reduce the overall carbon footprint of the packaging process.With the growing emphasis on sustainable packaging solutions, {}'s heat sealers are well-positioned to meet the evolving needs of the food packaging industry. By providing a combination of reliability, efficiency, and sustainability, these heat sealers offer a compelling solution for companies looking to improve their packaging processes and reduce their environmental impact.Furthermore, {}'s heat sealers are backed by the company's extensive support network. From installation and training to ongoing maintenance and technical support, customers can rely on {} to provide the assistance they need to maximize the performance of their heat sealers. This level of support is essential for companies looking to invest in new packaging equipment and ensures that they can maintain peak operational efficiency.As the food packaging industry continues to evolve, the demand for innovative and reliable packaging solutions will only continue to grow. With {}'s heat sealers, companies can stay ahead of the curve by implementing cutting-edge technology that delivers superior sealing performance while also addressing sustainability concerns. By investing in {}'s heat sealers, companies can enhance their packaging processes, reduce their environmental impact, and ultimately deliver better products to consumers.

Boost Your Packaging Efficiency with a Top-notch Case Sealer Machine

Innovative Case Sealer Machine Revolutionizes Packaging Industry[Company Name], a leading provider of cutting-edge packaging solutions, has recently unveiled its latest innovation, a state-of-the-art Case Sealer Machine. This revolutionary piece of equipment is set to transform the packaging industry with its advanced features and unparalleled efficiency.With globalization and e-commerce on the rise, the demand for effective packaging solutions has never been higher. Companies are constantly searching for ways to streamline their packaging processes, reduce costs, and enhance efficiency. Recognizing this need, [Company Name] took on the challenge of developing a Case Sealer Machine that would revolutionize the way products are packaged.The new Case Sealer Machine is equipped with cutting-edge technology, providing automated sealing capabilities that surpass traditional methods. It features a sleek design, combining aesthetics with functionality, and is capable of sealing cases of various sizes and formats. This versatility enables businesses to package a wide range of products effectively, regardless of their dimensions.One of the standout features of the Case Sealer Machine is its intelligent control system, which ensures precise and consistent sealing of every case. The machine is programmed to detect the dimensions of each case and automatically adjust its settings accordingly, eliminating the need for any manual intervention. This level of automation significantly reduces the risk of errors, saving time and resources for companies.In addition, the Case Sealer Machine boasts a high-speed sealing capability, guaranteeing swift and efficient packaging operations. With its advanced motor technology and optimized mechanisms, the machine is capable of sealing cases at an astounding rate. This ensures that businesses can meet high-volume packaging demands without compromising on quality or speed.Furthermore, the Case Sealer Machine is designed with user-friendliness in mind. Its intuitive interface allows operators to easily control and monitor the packaging process, ensuring smooth operations and quick troubleshooting. The machine is also equipped with safety features, such as emergency stop buttons and sensors, to prioritize the well-being of operators and prevent accidents.[Company Name] takes great pride in its commitment to sustainability. Therefore, the Case Sealer Machine is engineered to minimize environmental impact. It utilizes energy-efficient components, reducing power consumption without compromising on performance. Additionally, the machine is designed to optimize material usage and minimize waste, promoting eco-friendly packaging practices.With the introduction of the Case Sealer Machine, [Company Name] aims to revolutionize the packaging industry by offering a comprehensive and efficient solution for businesses worldwide. The advanced features and cutting-edge technology of this machine ensure that packaging processes are streamlined, saving both time and resources. By automating the sealing process, companies can achieve higher productivity levels and enhance their overall operational efficiency.The Case Sealer Machine is adaptable to various industries, including food and beverages, pharmaceuticals, e-commerce, and manufacturing. Its versatility and precision make it the go-to choice for businesses seeking to optimize their packaging operations without compromising on quality.[Company Name] has always been at the forefront of innovation in the packaging industry. With the introduction of the game-changing Case Sealer Machine, the company continues to drive progress and set new standards. This revolutionary equipment is poised to transform the way products are packaged and positioned [Company Name] as a leader in the market.As the global packaging industry continues to evolve, businesses must adapt to remain competitive. With the innovative Case Sealer Machine from [Company Name], companies can stay ahead of the curve by streamlining their packaging processes, reducing costs, and ultimately delivering products to market faster and more efficiently than ever before.

How to Make Lollipop Candy with a Candy Making Machine

Lollipop Candy Making Machine Revolutionizing the Confectionery IndustryIn recent years, the confectionery industry has seen a significant shift towards automation and technological advancements. One company that has been at the forefront of this change is {Company X}, a leading manufacturer of confectionery production equipment. With their innovative approach and cutting-edge technology, {Company X} has been revolutionizing the way lollipop candies are made with their state-of-the-art Lollipop Candy Making Machine.The Lollipop Candy Making Machine is a marvel of engineering and design, capable of producing high-quality lollipop candies with unparalleled efficiency and precision. This advanced machine is equipped with a range of features that make it stand out from traditional candy making equipment. From precision temperature control to automated molding and wrapping, the Lollipop Candy Making Machine streamlines the entire production process, allowing confectionery manufacturers to significantly increase their productivity and output.One of the key features of the Lollipop Candy Making Machine is its versatility. Unlike traditional candy making equipment, which is limited in its capabilities, this innovative machine can produce a wide variety of lollipop shapes, sizes, and flavors, allowing confectionery manufacturers to cater to diverse consumer preferences and market demands. With its adaptable design and customizable settings, the Lollipop Candy Making Machine offers unmatched flexibility and production capabilities.In addition to its technical capabilities, the Lollipop Candy Making Machine is also designed with sustainability in mind. {Company X} is committed to minimizing the environmental impact of their equipment, and the Lollipop Candy Making Machine is no exception. With energy-efficient operation and minimal waste generation, this advanced machine helps confectionery manufacturers reduce their carbon footprint and contribute to a more sustainable future.Furthermore, {Company X} provides comprehensive support and training for the Lollipop Candy Making Machine, ensuring that their clients can maximize the potential of this innovative equipment. From installation and setup to ongoing maintenance and technical assistance, {Company X} is dedicated to helping confectionery manufacturers integrate the Lollipop Candy Making Machine seamlessly into their production processes and achieve the highest levels of efficiency and quality.The impact of the Lollipop Candy Making Machine extends beyond just the confectionery industry. By enabling manufacturers to automate and optimize their production processes, this advanced machine has the potential to create new opportunities for business growth and innovation. With increased production capacity and the ability to deliver a wider range of lollipop candies to the market, confectionery manufacturers can expand their product offerings and reach new consumer segments, driving economic growth and industry advancement.In conclusion, the Lollipop Candy Making Machine from {Company X} represents a significant advancement in confectionery production technology. With its cutting-edge features, versatility, and sustainability, this innovative machine is reshaping the way lollipop candies are made and setting new standards for efficiency and quality in the industry. As {Company X} continues to push the boundaries of confectionery equipment technology, the future looks bright for the confectionery industry, with the prospect of further innovation and growth on the horizon.

Top-of-the-line Candy Making Equipment: A Must-Have for Professional Confectioners

Title: Innovative Candy Making Equipment Revolutionizes the Confectionery IndustryIntroduction:In today's fast-paced confectionery industry, the demand for innovative candy making equipment continues to grow. One company, recognized for its cutting-edge technology and exceptional quality, is revolutionizing candy production. By leveraging state-of-the-art machinery and expertise, this company is paving the way for a new era in confectionery manufacturing. Here, we delve into the details of this revolutionary candy making equipment and explore how it is transforming the industry.I. The Evolution of Candy Making Equipment:Over the years, candy making equipment has undergone significant advancements. Traditional methods of production relied heavily on manual labor, limiting both the efficiency and scope of candy production. However, with the advent of automated machinery, candy manufacturers can now produce confections on a much larger scale, meeting the ever-increasing consumer demand.II. Introducing Professional Candy Making Equipment:Addressing the need for sophisticated candy making equipment, a company (name withheld) has emerged as a leader in the field. By combining cutting-edge technology with extensive industry knowledge, they have succeeded in revolutionizing candy production. The company's dedication to quality, innovation, and customer satisfaction has earned them a reputation as a sought-after provider of comprehensive candy making solutions.III. Key Features and Advantages of Professional Candy Making Equipment:1. Automated and Efficient: This candy making equipment is fully automated, eliminating the need for extensive manual labor. Moreover, its advanced technology enables high-speed production, significantly increasing output while reducing production time.2. Versatile and Customizable: The equipment boasts a wide range of capabilities, making it adaptable to various candy types, shapes, sizes, and flavors. Whether it's hard candies, gummies, lollipops, or chocolate-based confections, this equipment can efficiently handle diverse candy making requirements. Additionally, it allows for easy customization, accommodating specific customer preferences.3. Precision and Consistency: The equipment incorporates precise temperature controls, ensuring the precise heating and cooling required for each candy type. This precision guarantees consistent quality and taste, key factors in maintaining customer satisfaction.4. Hygienic and Safe: The candy making equipment is designed with food-grade materials and follows strict quality control measures. This ensures that the candies produced meet the highest standards of hygiene and safety, conforming to regulatory requirements.5. User-Friendly Interface: The equipment features an intuitive interface, making it accessible to both experienced and novice operators. Additionally, it offers remote monitoring and control capabilities, enabling manufacturers to oversee production processes in real-time.6. Cost-Effective and Economical: By automating the production process, the candy making equipment reduces labor costs and optimizes resource utilization. This leads to enhanced operational efficiency and increased profitability for candy manufacturers.IV. Industry Impact and Customer Testimonials:Having gained significant traction in the confectionery industry, this professional candy making equipment has garnered praise from customers globally. Candy manufacturers who have incorporated this technology into their operations have witnessed an exponential increase in productivity, greater consistency in product quality, and improved customer satisfaction. The equipment's ability to streamline production processes, reduce manual labor, and ensure the highest standards of quality control has solidified its position as an indispensable tool for confectioners worldwide.Conclusion:The introduction of professional candy making equipment has transformed conventional candy production, offering unmatched efficiency, precision, and versatility. With its state-of-the-art features, the equipment empowers candy manufacturers to produce confections on a larger scale, customize their offerings, and optimize operational efficiencies. As the confectionery industry continues to evolve, this innovative candy making equipment promises to shape the future of candy manufacturing, offering unlimited possibilities for confectioners worldwide.

Highly Efficient Hot Air Sealing Machine for Industrial Use

Hot Air Sealing Machine Revolutionizes Packaging IndustryIn a rapidly evolving world, the packaging industry is always looking for new and innovative ways to improve efficiency and quality. One company at the forefront of this evolution is {Company Name}, a leading manufacturer of hot air sealing machines. These machines have revolutionized the packaging industry by providing a faster, more efficient, and cost-effective sealing solution for a wide range of products.With a commitment to providing cutting-edge technology and outstanding customer service, {Company Name} has become a trusted partner for businesses across the globe. Their hot air sealing machines are designed to meet the diverse needs of the packaging industry, from small-scale operations to large-scale production facilities.The key to the success of {Company Name}'s hot air sealing machines is their advanced technology and precision engineering. These machines are equipped with state-of-the-art heating elements and temperature control systems, ensuring a consistent and reliable sealing process. Furthermore, their user-friendly interface and customizable settings make them easy to operate and adjust according to specific sealing requirements.One of the key advantages of {Company Name}'s hot air sealing machines is their versatility. These machines can be used to seal a wide variety of materials, including plastic, paper, and fabric. Whether it's sealing bags, pouches, or other types of packaging, {Company Name} has a solution for every application.In addition to their technical capabilities, {Company Name}'s hot air sealing machines are also designed with efficiency in mind. By utilizing hot air technology, these machines can achieve faster sealing speeds and higher throughput compared to traditional sealing methods. This not only saves time but also reduces operating costs, making them a cost-effective choice for businesses.Furthermore, {Company Name} takes pride in providing exceptional customer support. Their team of experts is dedicated to understanding the specific needs of each client and providing personalized solutions to meet those needs. From installation and training to ongoing technical support, {Company Name} is committed to ensuring the success of their customers.The impact of {Company Name}'s hot air sealing machines on the packaging industry has been significant. Businesses that have adopted these machines have seen improvements in productivity, product quality, and overall cost savings. With the ability to seal a wider range of materials at faster speeds, these machines have helped companies stay competitive in a fast-paced market.Looking ahead, {Company Name} continues to push the boundaries of innovation in the packaging industry. They are constantly researching and developing new technologies to further enhance their hot air sealing machines and meet the evolving needs of their customers. With a focus on quality, efficiency, and customer satisfaction, {Company Name} is poised to remain a leader in the packaging industry for years to come.In conclusion, the hot air sealing machines offered by {Company Name} have set a new standard for the packaging industry. With their advanced technology, versatility, and commitment to customer satisfaction, these machines have revolutionized the way products are sealed and packaged. As the industry continues to evolve, {Company Name} is well-positioned to lead the way with their innovative solutions.